Installation method of spliced building curtain wall

An installation method and curtain wall technology, which are applied in the directions of buildings, building components, building structures, etc., can solve the problems affecting the production efficiency of unitized curtain walls, waste the physical strength of operators, etc., and achieve the effect of improving cleaning, safe and convenient use and convenience. cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

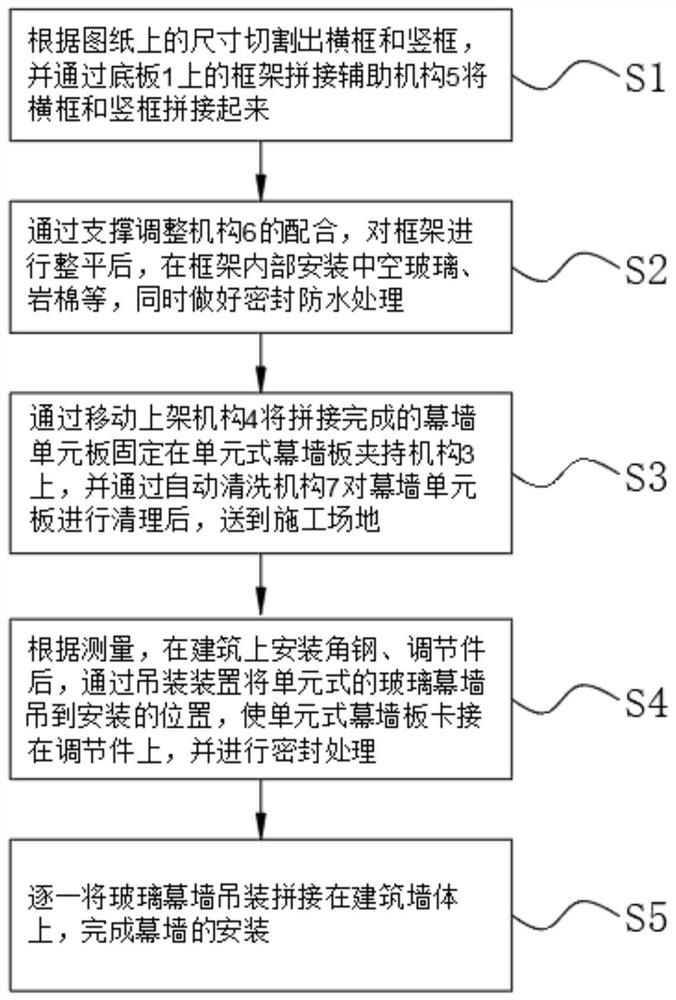

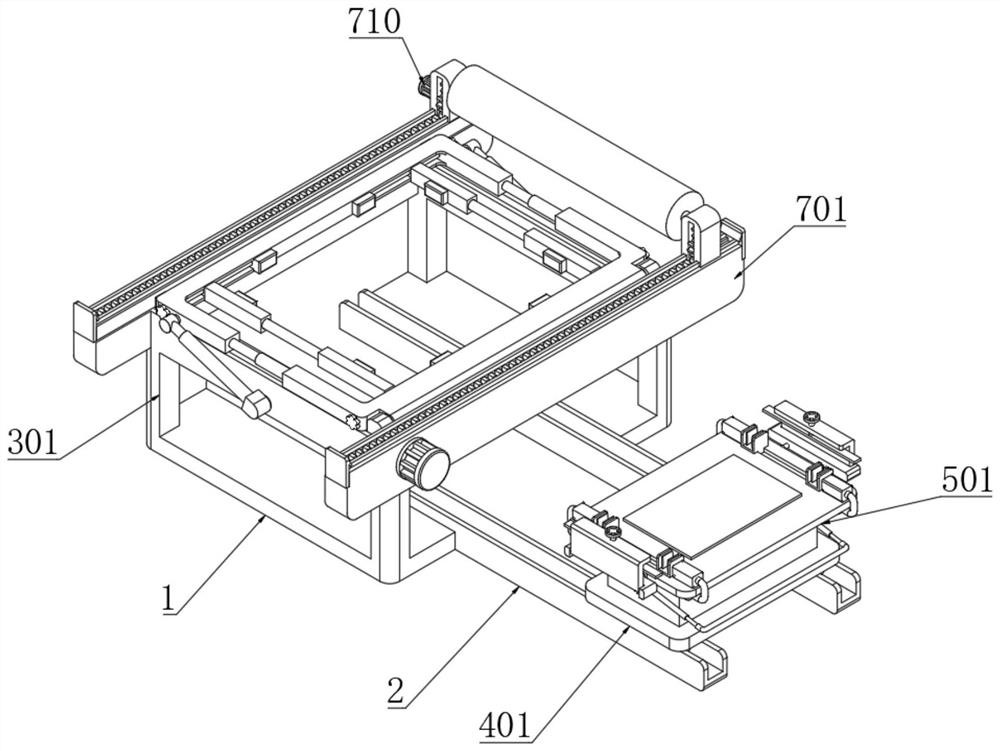

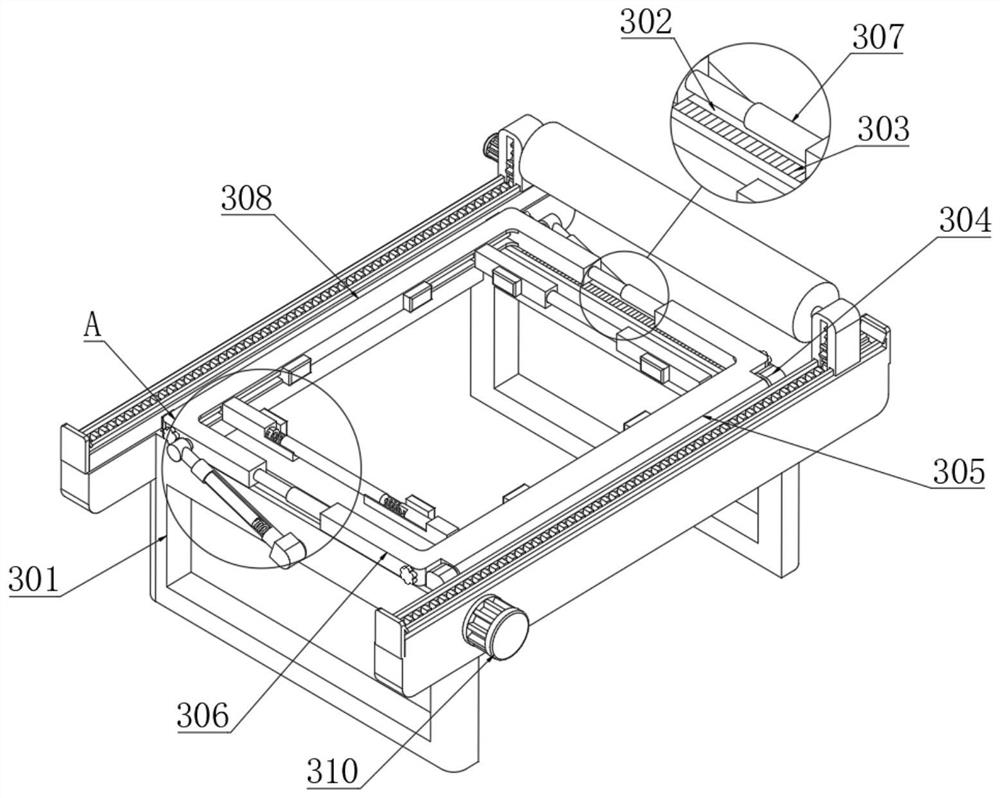

[0039] Example: such asfigure 1 As shown, the present invention provides a technical solution, a method for installing a spliced building curtain wall, comprising the following steps:

[0040] S1. Cut out the horizontal frame and the vertical frame according to the size on the drawing, and splice the horizontal frame and the vertical frame through the frame splicing auxiliary mechanism 5 on the bottom plate 1;

[0041] S2, through the cooperation of the support adjustment mechanism 6, after leveling the frame, install hollow glass, rock wool, etc. inside the frame, and do a good job of sealing and waterproofing;

[0042] S3. Fix the spliced curtain wall unit panels on the curtain wall unit panel clamping mechanism 3 by moving the racking mechanism 4, and send the curtain wall unit panels to the construction site after cleaning the curtain wall unit panels by the automatic cleaning mechanism 7;

[0043] S4. According to the measurement, after installing the angle steel and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com