Automatic feeding machine

A technology of automatic feeding and transmission mechanism, applied in the field of feeding machines, can solve the problems of high cost, fire, short circuit of wires, etc., and achieve the effects of low cost, fire prevention and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

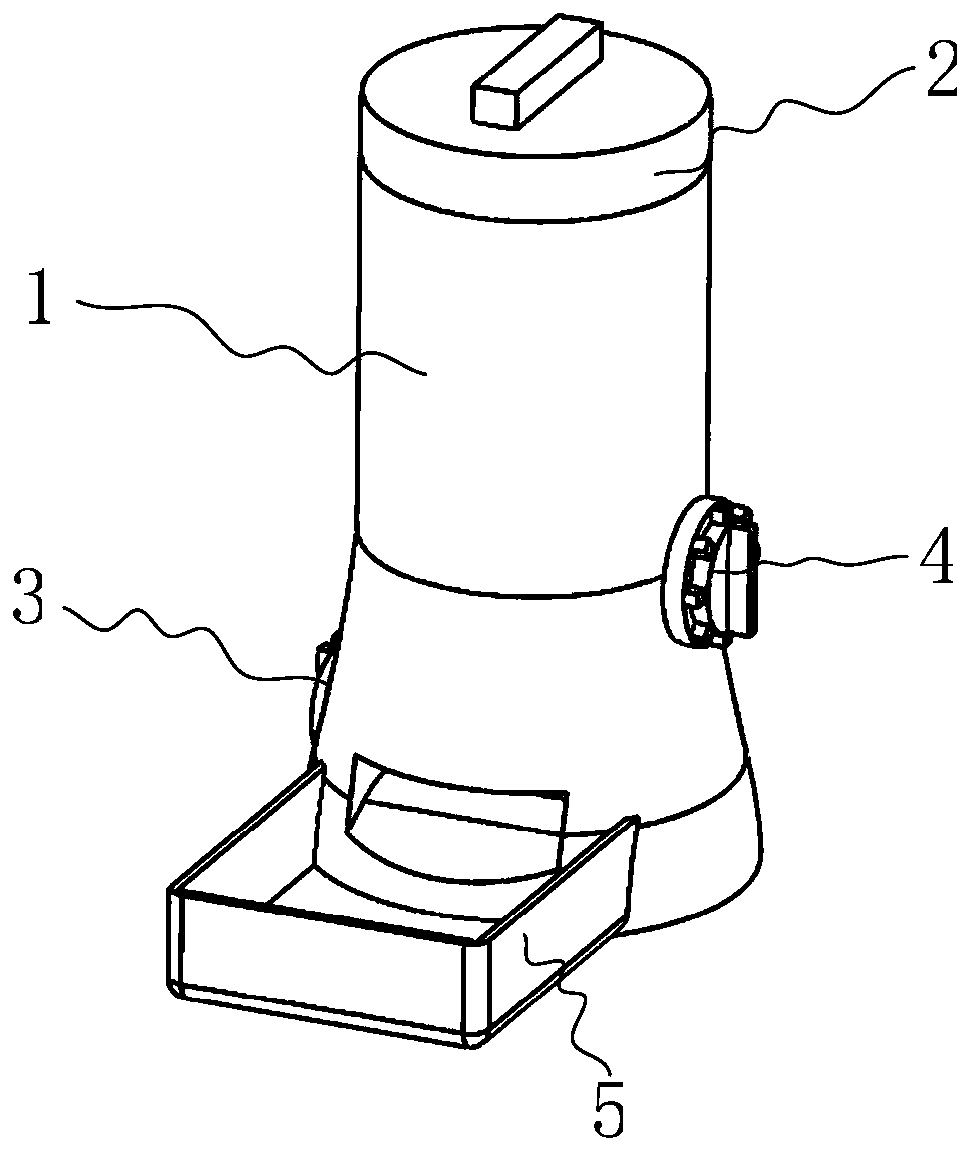

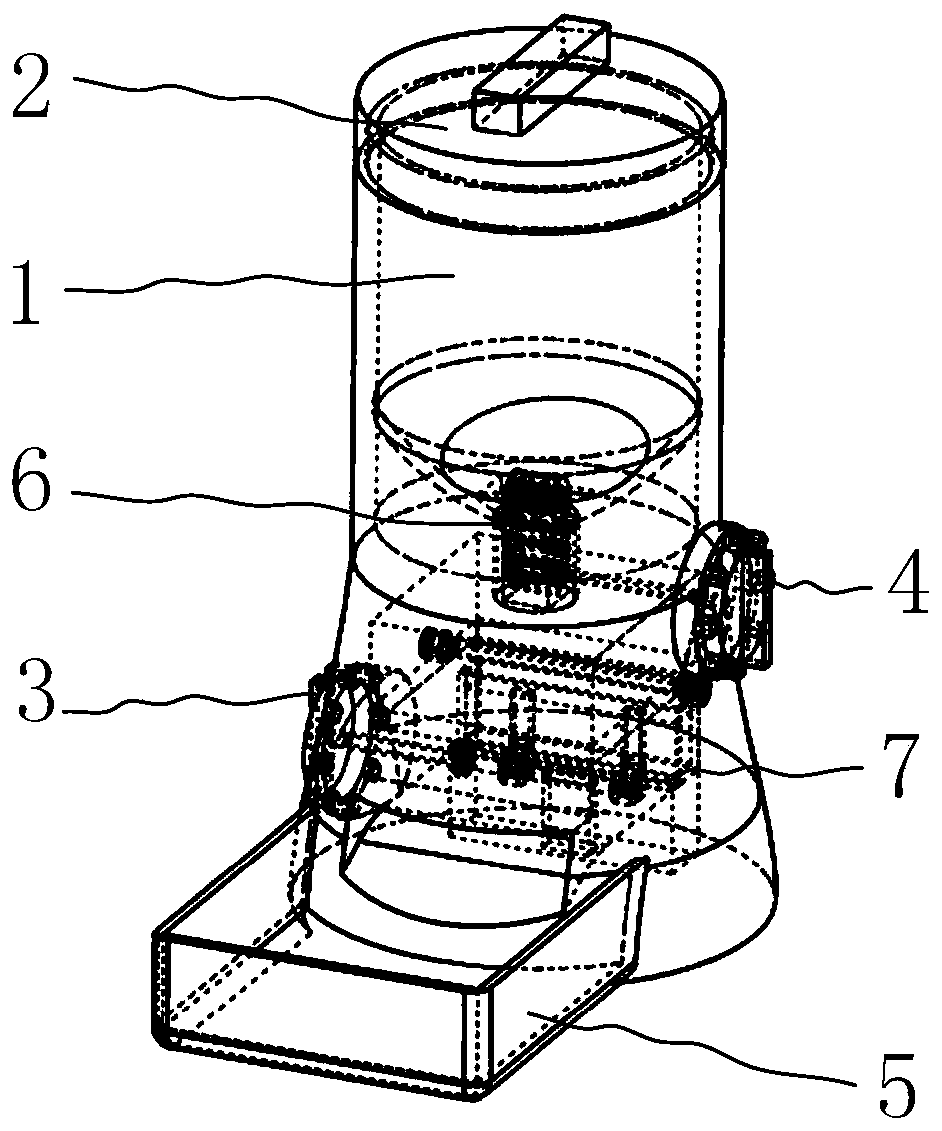

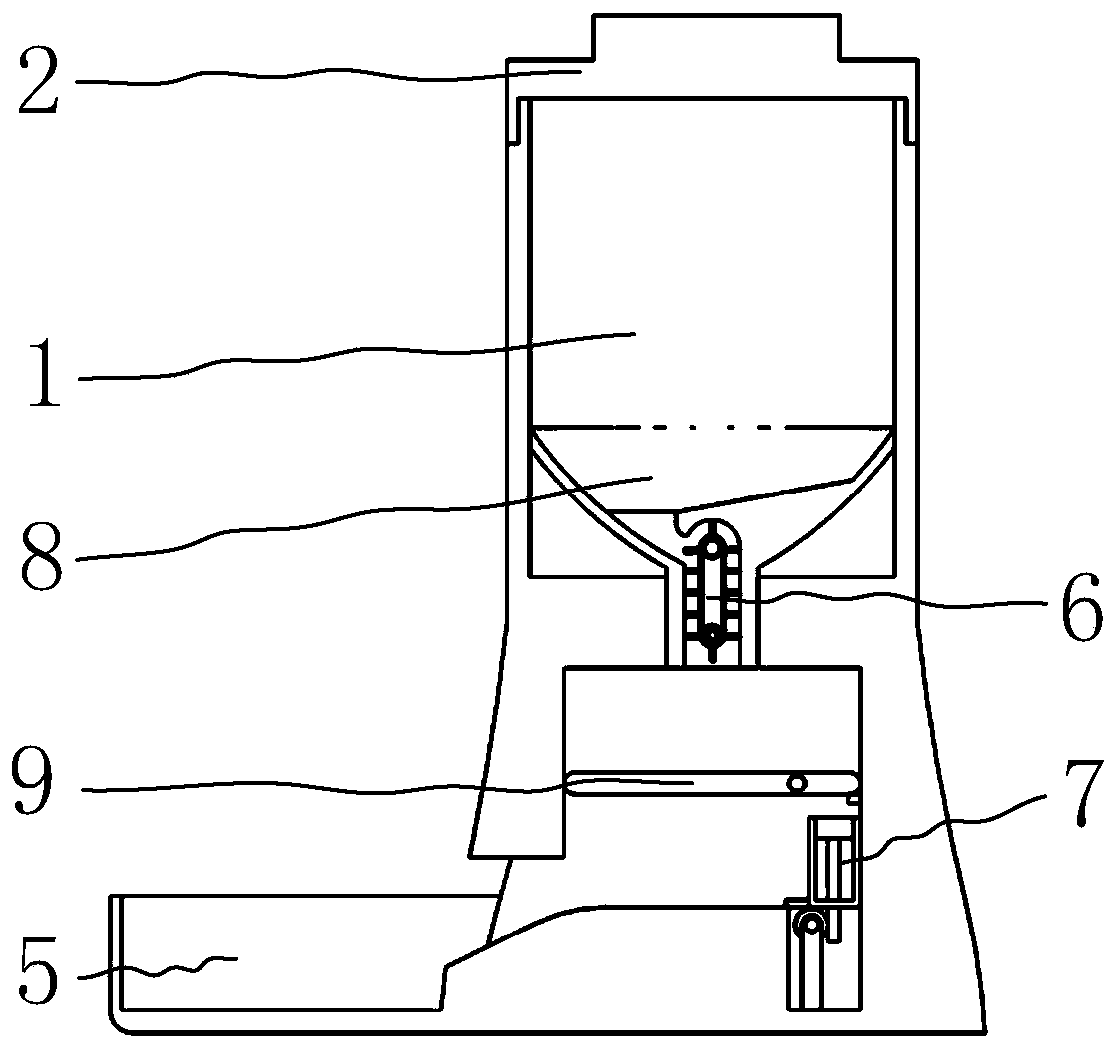

[0058] Such as figure 1 , 2 As shown, it includes a housing 1, a transmission mechanism 6, an adjustment mechanism 7, a diversion bucket 8, and a swing plate 9, among which Figure 7 , 8 As shown, a first marking plate 62 and a second marking plate 63 are installed on the outside of the housing 1, the end surface of the first marking plate 62 has a plurality of second marking blocks 21 evenly in the circumferential direction, and the end surface of the second marking plate 63 There are a plurality of first marking blocks 20 evenly in the upper direction. The function of the first marking disc 62 is to measure the angle at which the second rotation knob drives the first a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com