Lathe with coolant recovery device

A technology of recycling device and coolant, applied in the field of lathes, can solve the problems of high temperature rise, high temperature deformation of knife edge and component surface, affecting the cooling effect of coolant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

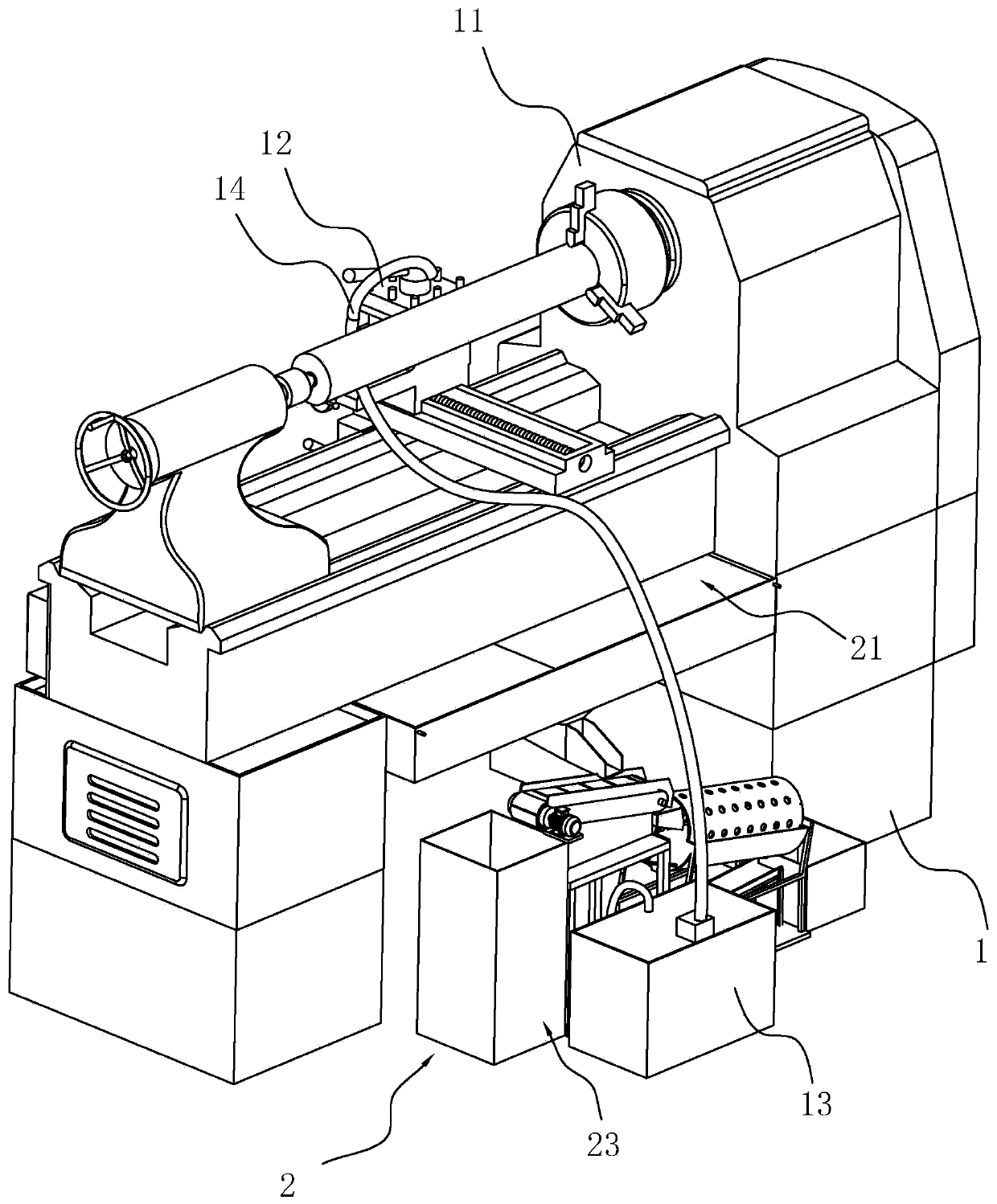

[0037] A lathe with a coolant recovery device, see figure 1 , comprising a frame 1, one end of the frame 1 is fixed with a headstock 11, the top of the frame 1 is slidably connected with a cutter head frame 12, the cutter head frame 12 is fixed with a cutter head, and one side of the frame 1 is fixed A storage box 13 is provided, on which a guide tube 14 extending to the top of the cutter head frame 12 is fixed, the storage box 13 is used to store cooling liquid, and the cooling liquid flows to the cutter head frame 12 through the feed tube 14 To cool the cutter head and the workpiece, one side of the frame 1 is provided with a recovery device 2 for recovering and reusing the coolant.

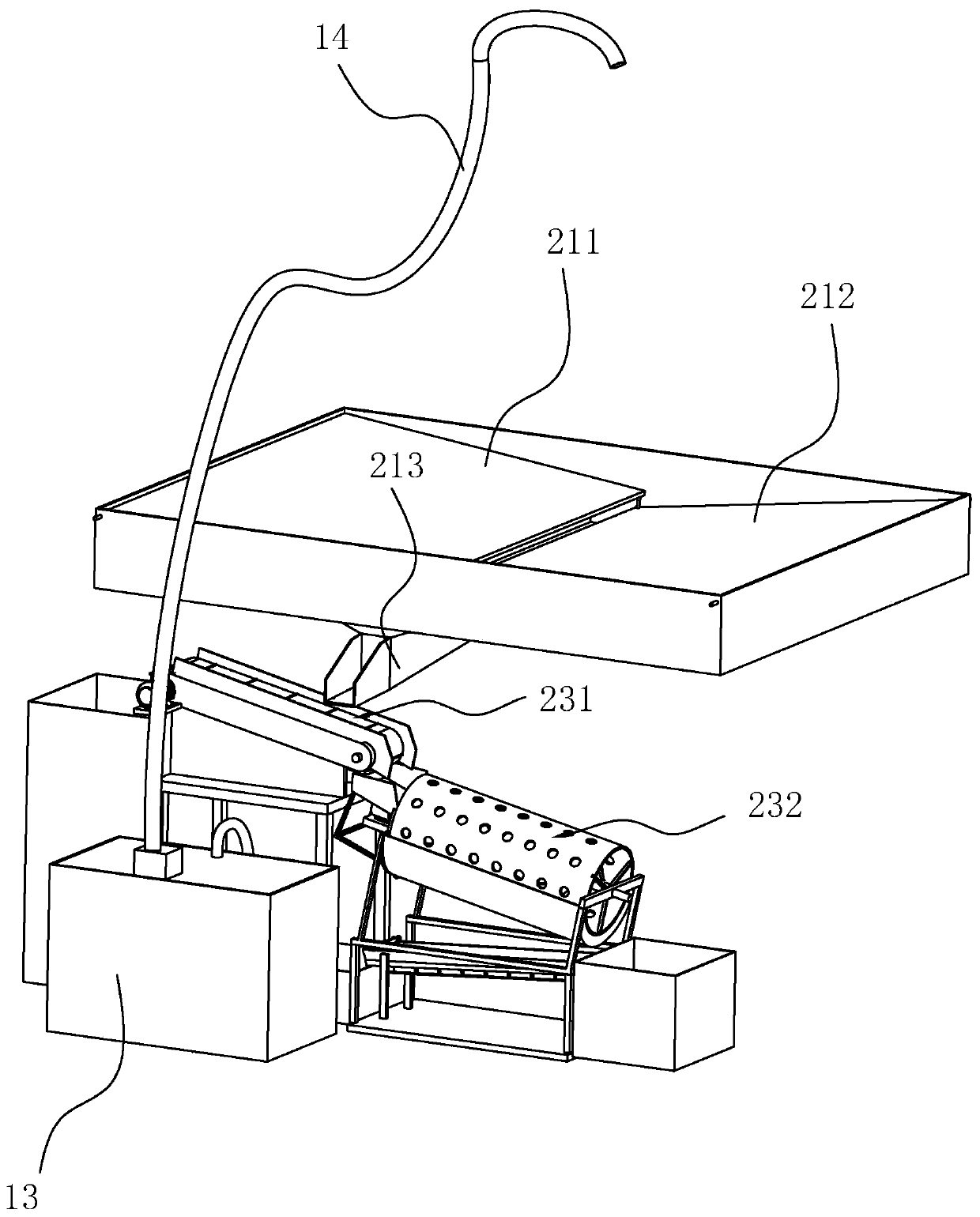

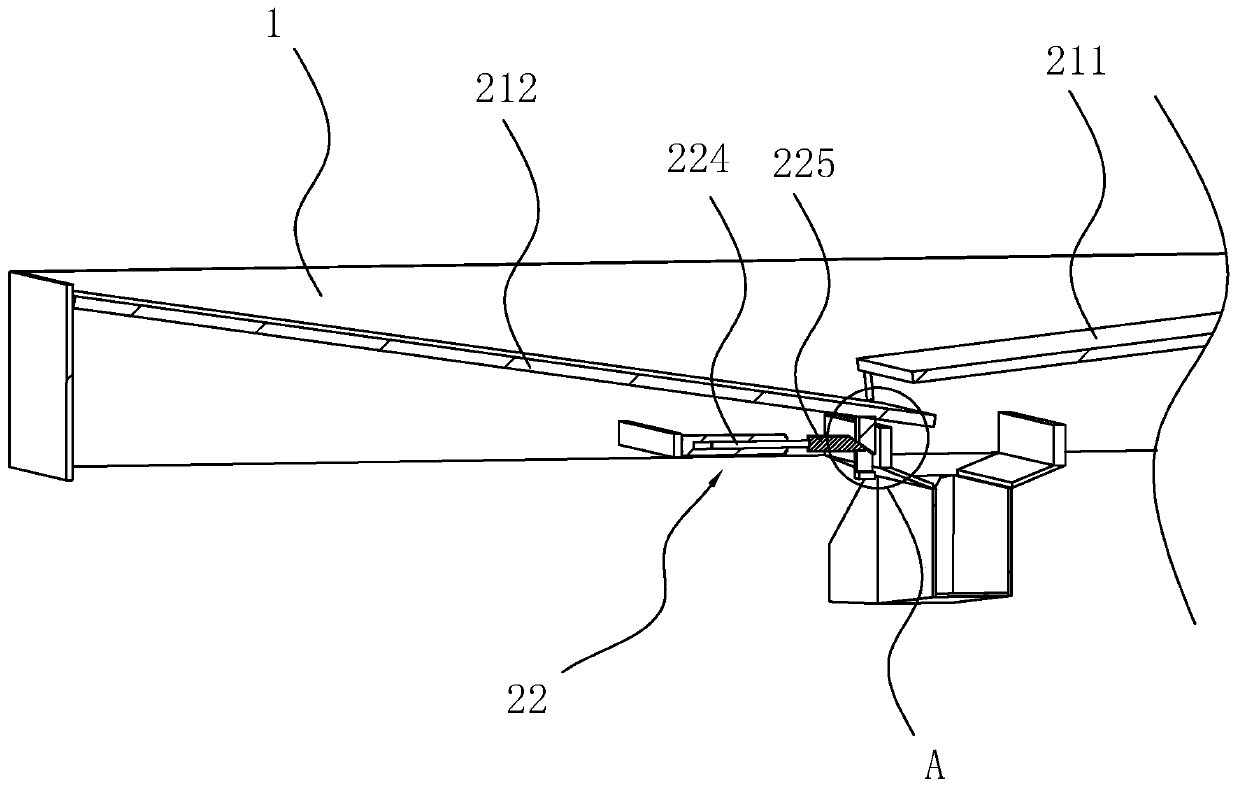

[0038] see figure 2 and image 3 The recovery device 2 includes a collecting mechanism 21 arranged at the bottom of the frame 1 and a filtering mechanism 23 located at one side of the frame 1 and filtering the coolant collected by the collecting mechanism 21 . The collection mechanism 21 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com