A preparation method of a composite phase-change film material that can be used to heat the filter of a non-burning cigarette to reduce the temperature of the smoke

A heat-not-burn, composite phase change technology, applied in heat exchange materials, e-liquid filters, chemical instruments and methods, etc., can solve the problems of phase transition temperature and cooling effect limitation, wide range of suction resistance, and increase of suction resistance. , to achieve the effect of simple and convenient equipment and operation process, reducing flue gas temperature, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

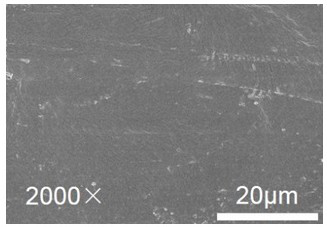

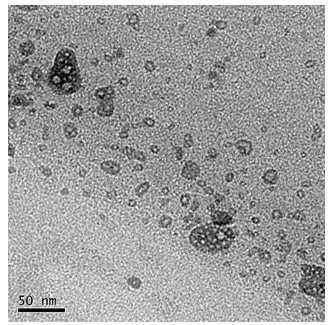

[0021] A method for preparing a composite phase-change film material that can be used to heat the filter tip of a non-burning cigarette to reduce the temperature of smoke, comprising the following steps, the structure and preparation process of the material are as follows: figure 1 Shown:

[0022] (1) Preparation of composite phase change thin film material precursor: under the protection of inert gas, 20g polylactic acid (PLA, molecular weight 137000g / mol), 2g polyethylene glycol diacrylate (PEGDA, molecular weight 400g / mol) were fully mixed and dissolved in 100mL acetonitrile to obtain solution A; then 0.5g vinyl-modified polyhedral polysilsesquioxane (V-POSS) and 0.225g photoinitiator 2-hydroxy-2-methyl-1-phenyl Acetone (HMPF) solution was added to the above solution A, fully stirred evenly to obtain solution B.

[0023] (2) Preparation of composite phase change film material: Take 10mL of solution B obtained in step (1), pour it into a 5cm×5cm polytetrafluoroethylene petr...

Embodiment 2

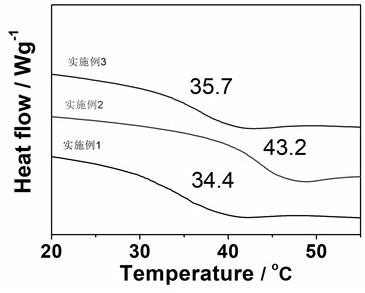

[0026] The experimental procedure is the same as in Example 1, except that the amount of PEGDA used in step (1) is 20 g, the amount of V-POSS is 2.0 g, and the phase transition temperature of the prepared composite phase change thin film material is 43.2 °C (See Figure 4 ), the latent heat of phase change is 81.03J / g.

Embodiment 3

[0028] The experimental procedure is the same as that of Example 1, except that the casting drying temperature in step (2) is 75°C, the UV radiation crosslinking time is 30min, and the phase transition temperature of the prepared composite phase change film material is 35.7°C (See Figure 4 ), the latent heat of phase change is 76.25J / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com