Gear machining device

A technology for processing devices and gears, which is applied in grinding drive devices, metal processing equipment, grinding/polishing safety devices, etc., can solve the problems of complex structure, affecting the quality and efficiency of gear processing, and difficult to collect metal scraps. The effect of improving efficiency and quality, improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

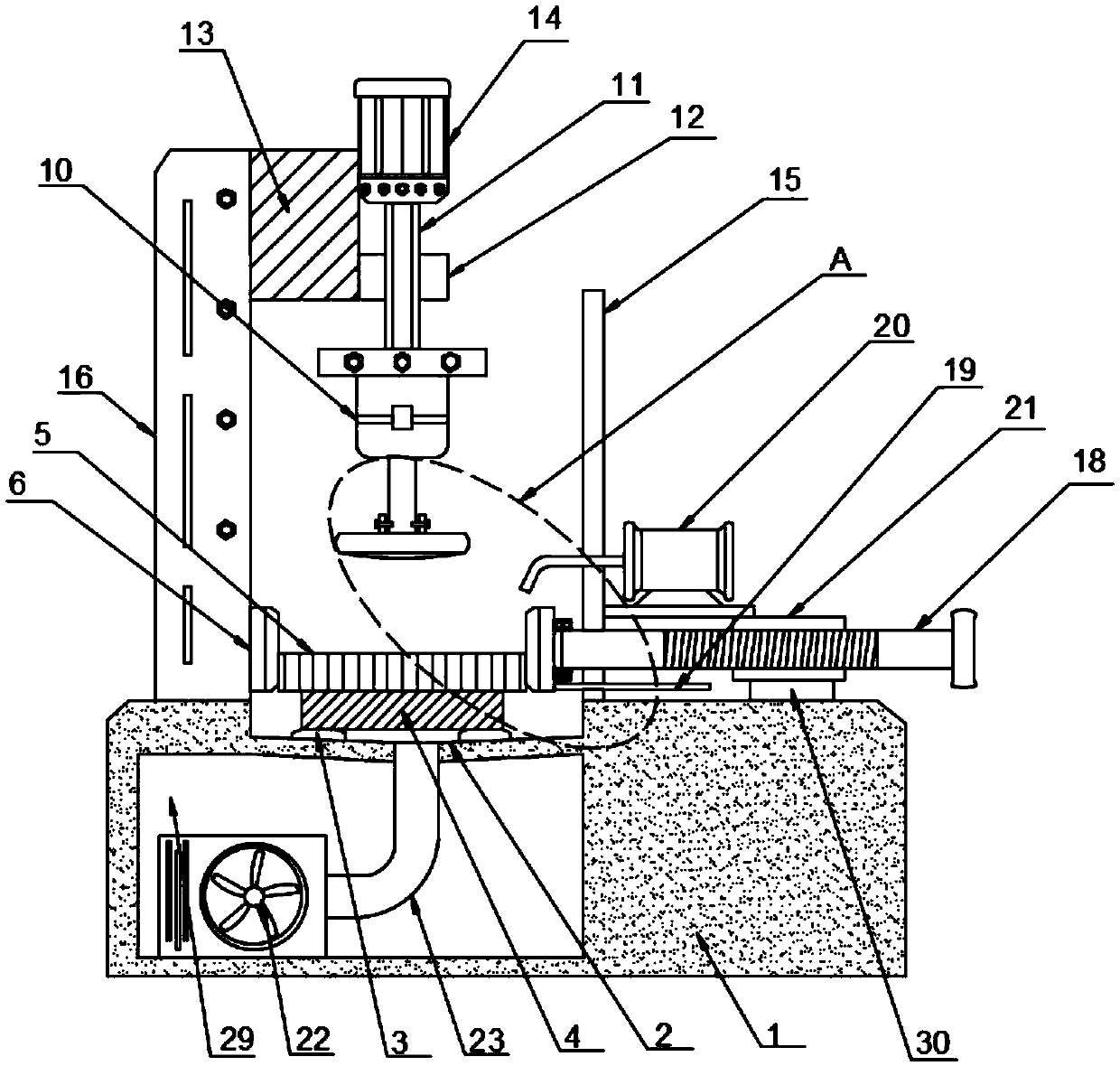

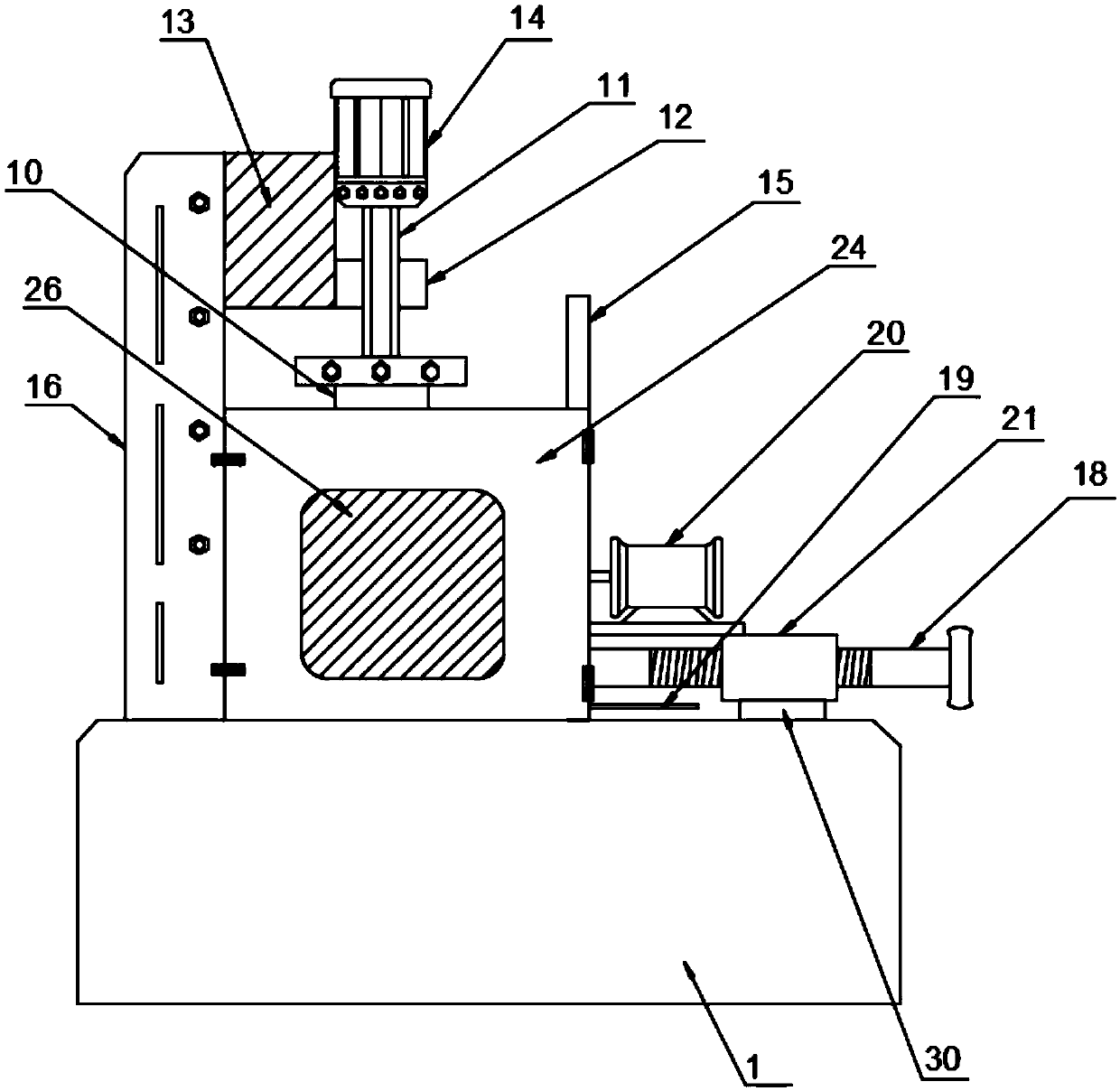

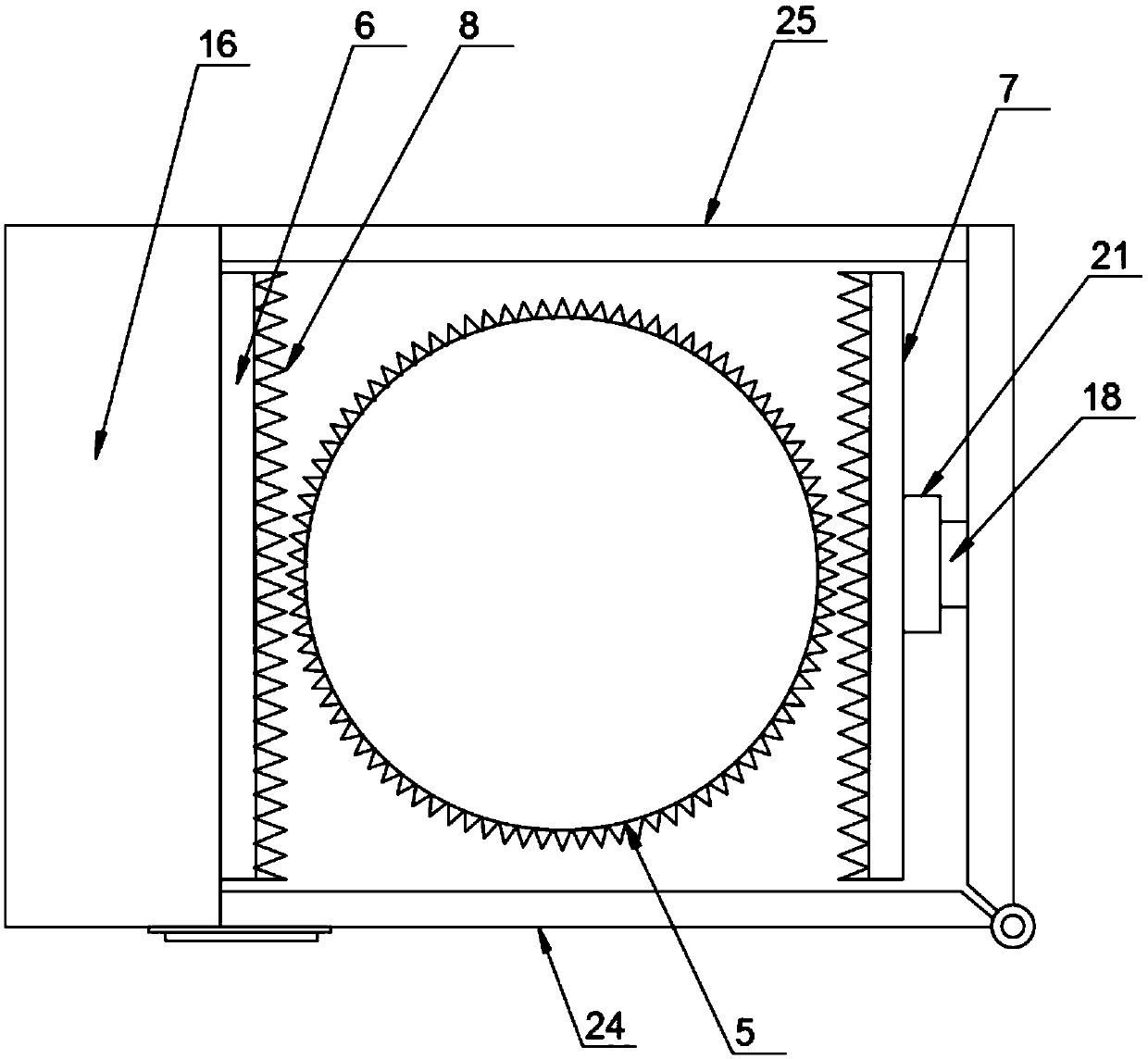

[0023] Such as Figure 1-4 The shown gear processing device includes a machine body 1, a processing tank 2 is embedded on the top of the machine body 1, a pad 3 is provided at the bottom of the inner cavity of the processing tank 2, and a backing plate 4 is provided on the top of the pad 3 , the top of the backing plate 4 is provided with a gear 5, one side of the gear 5 is provided with a fixed clamping plate 6 and the other side is provided with a movable clamping plate 7, the inner side of the fixed clamping plate 6 and the movable clamping plate 7 insides are provided with matching teeth 8, and the top of the gear 5 is provided with a grinding disc 9, and the top of the grinding disc 9 is provided with a high-torque motor 10, and the top of the high-torque motor 10 is provided with a telescopic rod 11, and the telescopic rod 11 The outer wall is covered with a sleeve 12, one side of the sleeve 12 is provided with a fixed platform 13, the top of the telescopic rod 11 is pro...

Embodiment 2

[0027] Such as Figure 1-4 A kind of gear 1 processing device shown, the front side wall of the partition plate 15 is provided with a fan door 24 and the rear side wall is provided with a baffle plate 25, and the described fan door 24 is embedded with a glass window 26, and the glass window 26 is made of double-layer tempered glass material. One side of the door 24 is provided with a hinge shaft and the other side is provided with a latch lock. One side of the door 24 is movably connected with the partition 15 through a hinge shaft and the other It is detachably connected to the support rod 16 through a latch lock;

[0028] Further, in the above technical solution, the number of the pads 3 is multiple, the pads 3 are fixed on the bottom wall of the processing tank 2, and the support rods 16 and the partitions 15 are fixed on the machine body 1, the side wall of the fixed clamping plate 6 is fixedly connected to the side wall of the support rod 16, and the bottom height of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com