Large-diameter corn milling cutter grinding device

A corn milling cutter, large diameter technology, applied in grinding/polishing safety devices, milling cutters, milling machine equipment, etc., can solve the problems of low efficiency of grinding wheel, low tool finish, short equipment life, etc. The effect of reducing pollution and reducing machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

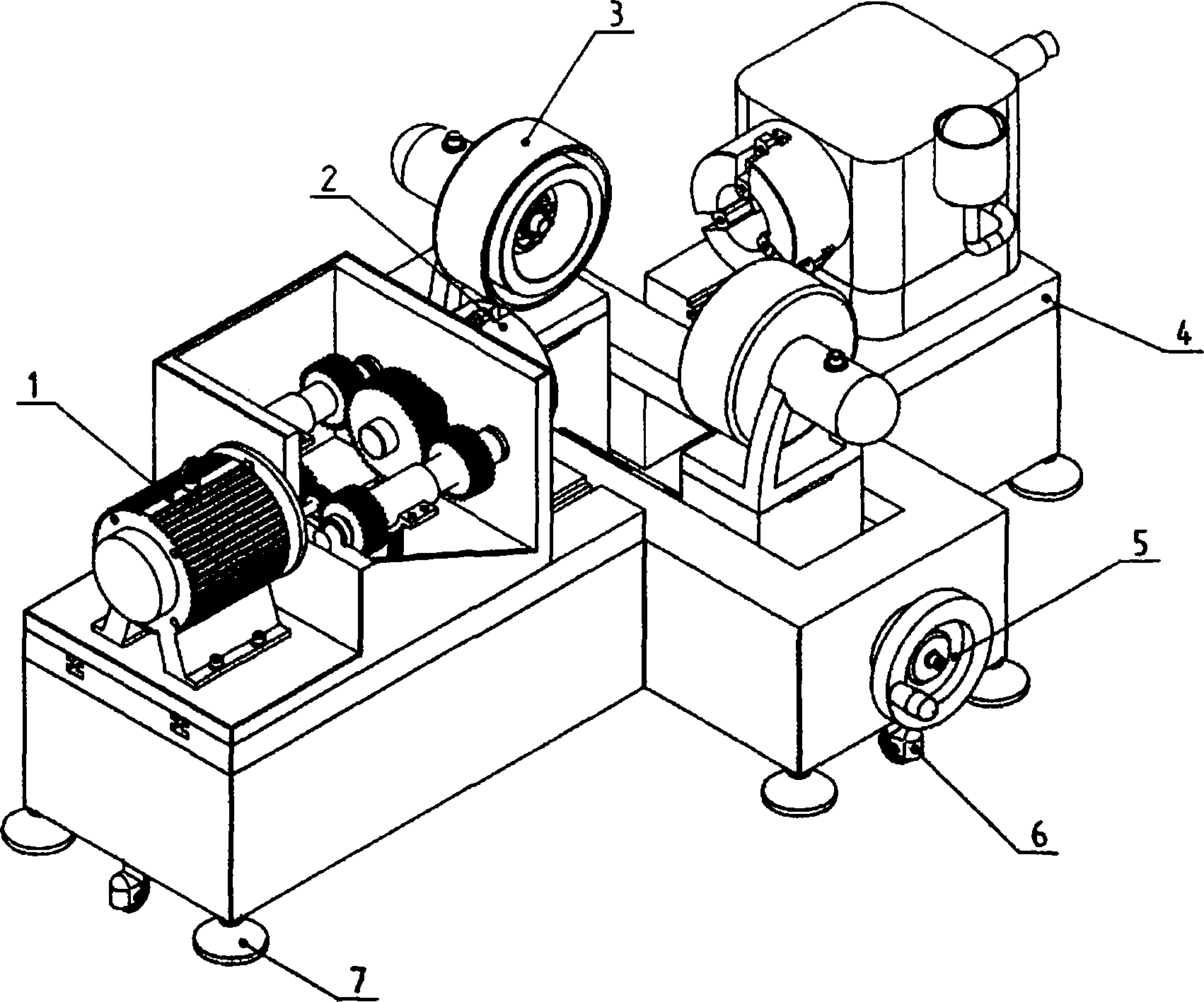

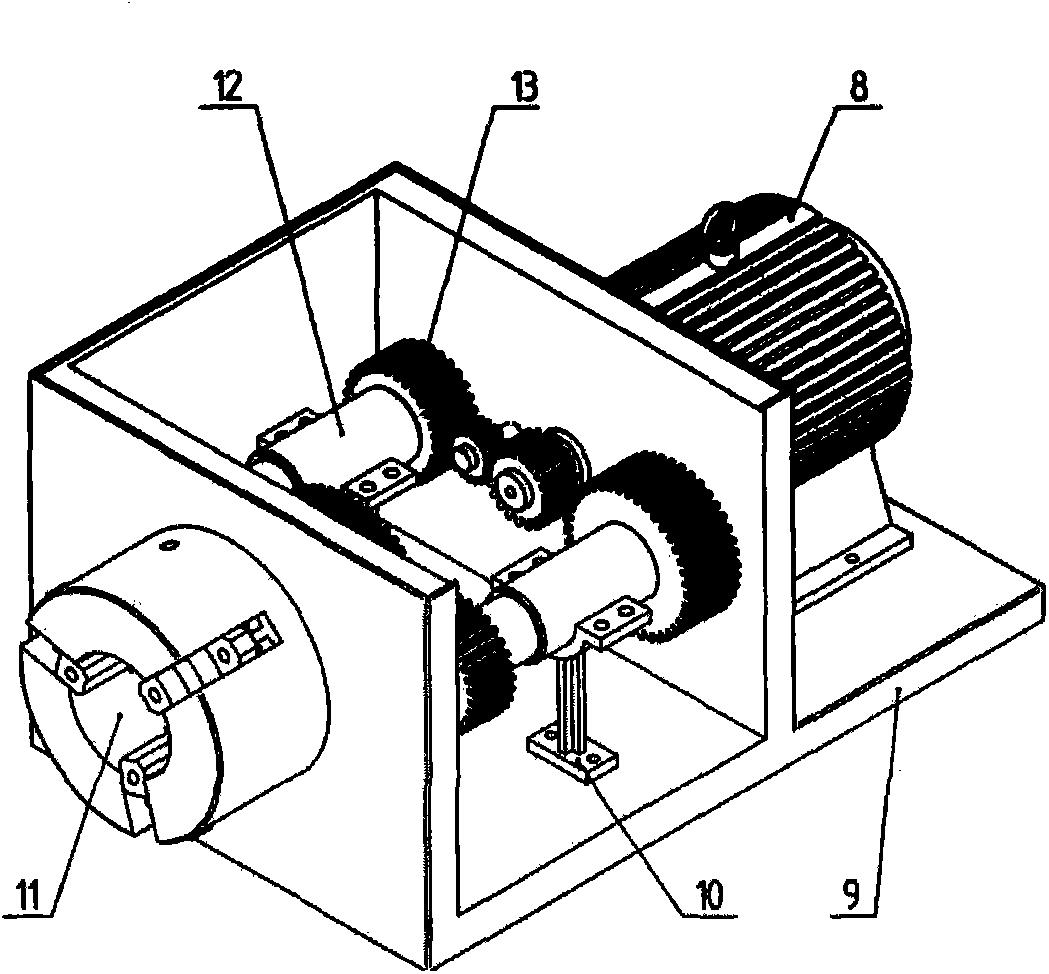

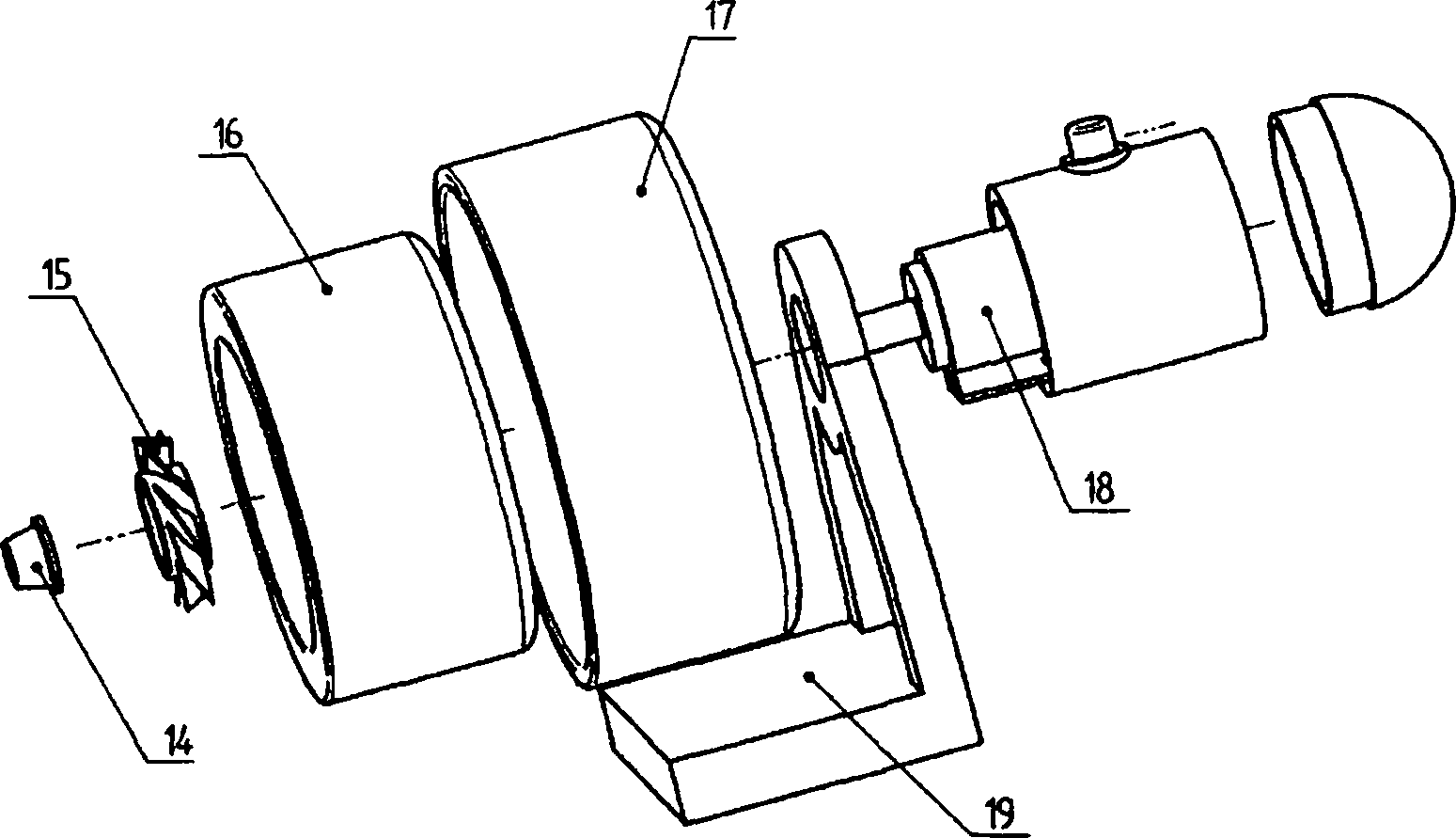

[0032] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0033] as attached figure 1 As shown, a sharpening device suitable for large-diameter corn milling cutters, the sharpening device includes: a power mechanism 1, a clamping mechanism 2, a sharpening mechanism 3, an auxiliary guiding mechanism 4, a distance adjustment mechanism 5, and a universal wheel 6 and fixed support mechanism 7. The clamping mechanism 2 includes an auxiliary ejector column 20, a three-jaw chuck and an auxiliary three-jaw chuck 24, realizing single-end clamping and double-end clamping of different types of milling cutters. In the case of one-way clamping, sometimes in order to achieve two-way fixing, the present invention designs an auxiliary plug to withstand the other side. In order to avoid scratching the milling cutter to be ground, a cylinder-head plug is used instead of a pointed thimble, that is Auxiliary ejector 20, the auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com