Patents

Literature

138results about How to "Stop splash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

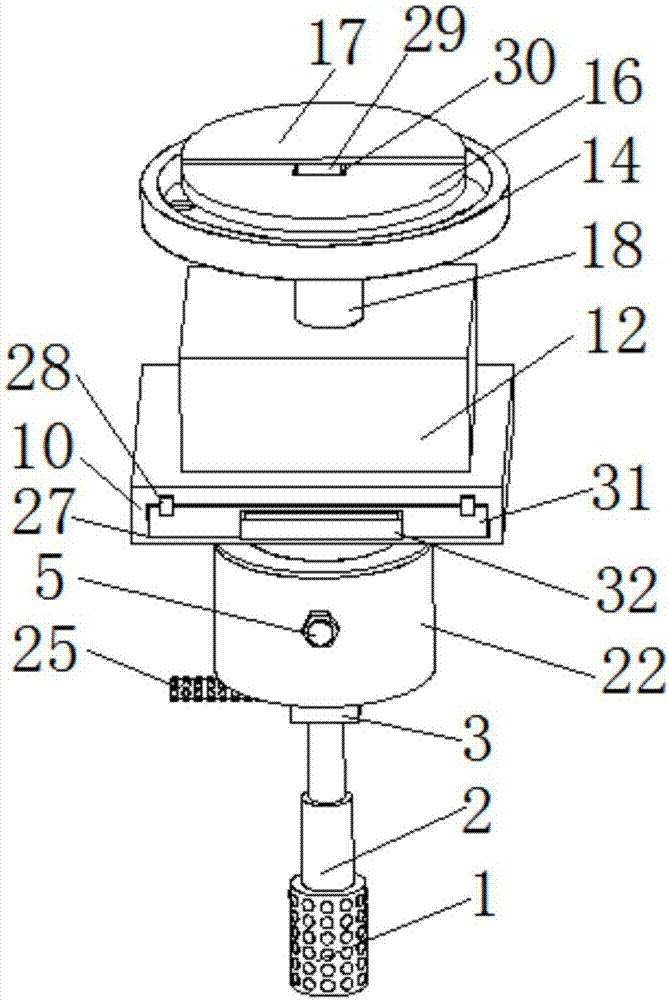

Perforating device

InactiveCN105945330AStop splashProtection securityPositioning apparatusBoring/drilling componentsControl switchPetroleum engineering

The invention discloses a perforating device. The perforating device comprises a workbench, a drilling mechanism, a supporting rod, a drill bit storage platform, telescopic rods, drill bits, lifting rods and a protection cover. The supporting rod is vertically arranged on the upper surface of the workbench. The drilling mechanism is arranged on the supporting rod. The upper end of the drill bit storage platform is connected with the drilling mechanism, and the lower end of the drill bit storage platform is partially concaved inwards to form containing grooves matched with the drill bits. One end of each telescopic rod is fixed in the corresponding containing groove, and the other end of each telescopic rod is connected with the corresponding drill bit. The drilling mechanism is provided with a control switch which can separately control expansion, contraction and rotation of the multiple telescopic rods. The protection cover is arranged below the drill bit storage platform. One end of each lifting rod is connected with the drill bit storage platform, and the other end of each lifting rod is connected with the protection cover. The protection cover is provided with through holes matched with the drill bits in the vertical direction. According to the perforating device, the problems that drill bit replacement of a perforating device in the prior art is inconvenient, and a certain threat is posed to the safety of a user due to the fact that a corresponding chip processing mechanism is not arranged, and produced chips splash everywhere are solved.

Owner:YINFENG CASTING WUHU CO LTD

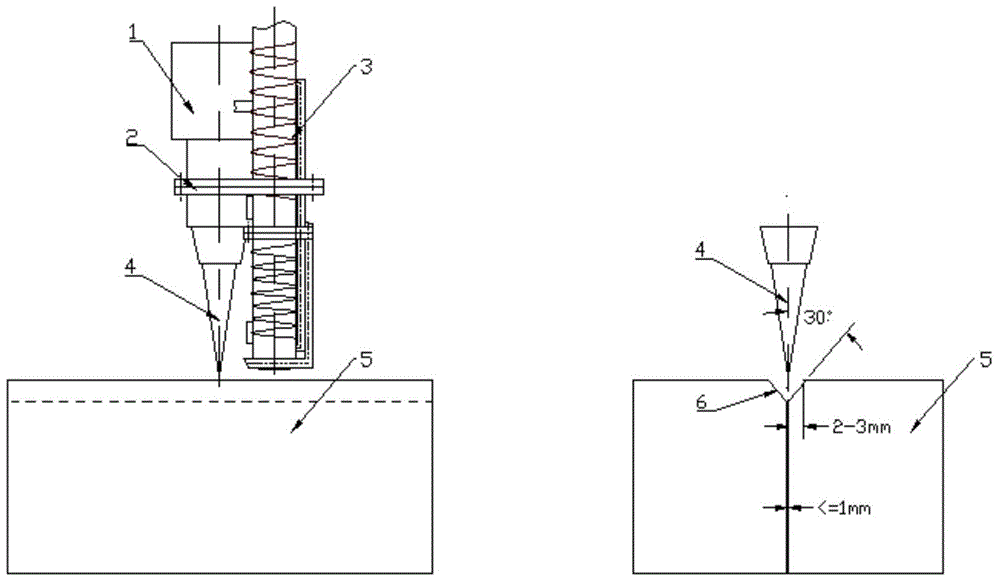

Method for restraining myriawatt-class laser welding thick plate upper surface defects

InactiveCN104625403AImprove liquidityReduce the chance of defectsMetal working apparatusWorkpiece edge portionsWeld beadInertia

The invention provides a method for restraining myriawatt-class laser welding thick plate upper surface defects. The method comprises the specific steps that 1, a welding plate (5) is machined, a metal particle conveying head (3) is installed on a laser welding head (1), and the conveying position of metal particles (16) is on the rear edge of a welding pool (27) lack of fusion; 2, the metal particles (16) are loaded into the metal particle conveying head (3), and a metal particle heating device is turned on to heat the metal particles (16) to the temperature from 900 DEG C to 1100 DEG C below the melting point; 3, the power of a laser is controlled, a laser beam (4) irradiates the welding plate (5) to form the welding pool lack of fusion, a metal particle conveying system controlled by compressed air is turned on, and the heated metal particles are pushed to the welding pool lack of fusion; 4, an inertia shielding gas annular air blow pipe (10) is turned on, and a laser welding head (1) and the metal particle conveying head (3) synchronously move to complete the welding process. According to the method, material losses generated by some splashes can be complemented, and welding bead subsidence is reduced.

Owner:HUNAN UNIV

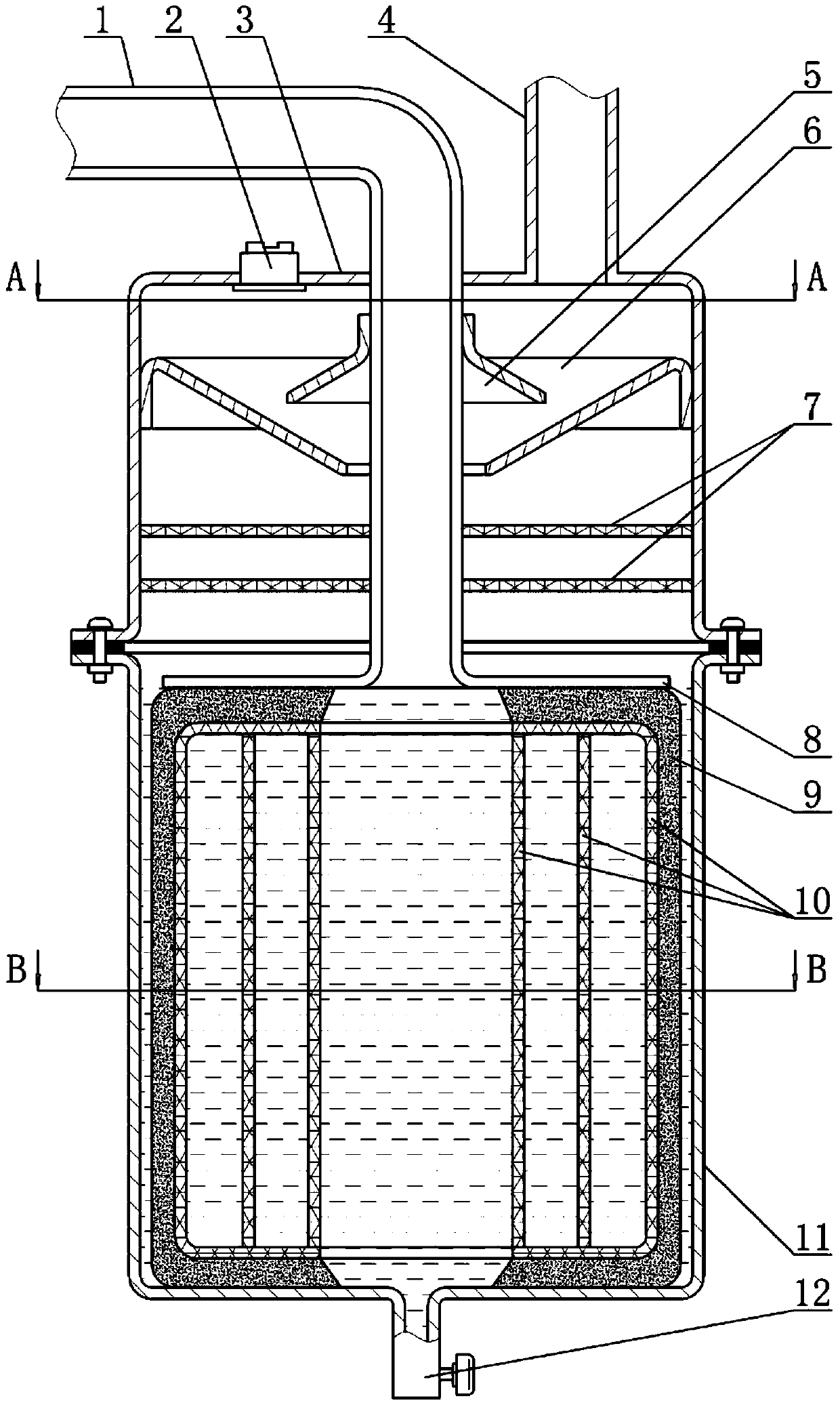

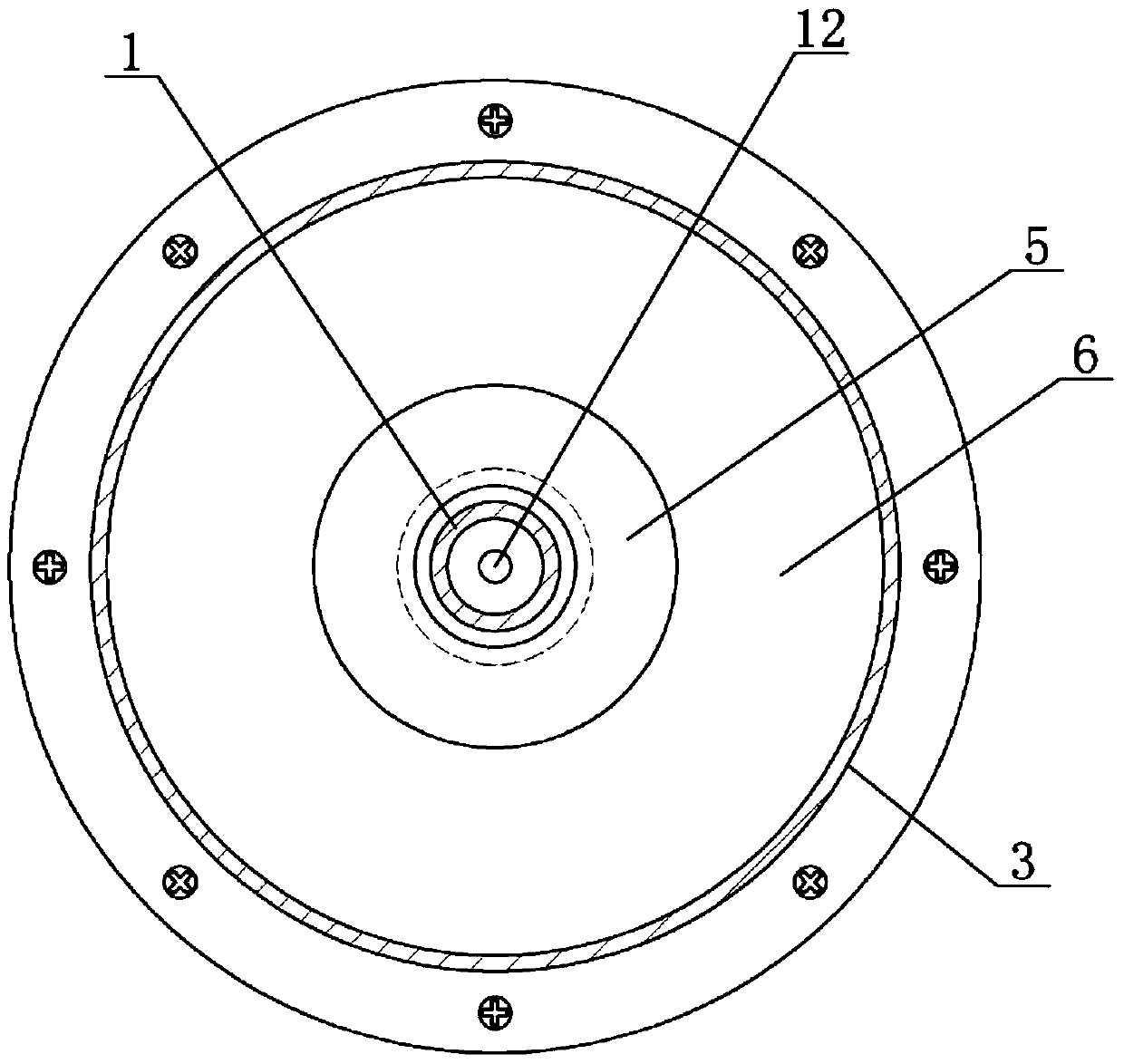

Gas scrubber

InactiveCN104196659AFlow unimpededGuaranteed throughputMachines/enginesAir cleaners for fuelWater useAnti freezing

Disclosed is a gas scrubber. According to the gas scrubber, an air inlet pipe and an anti-overflow hopper are arranged in a tank, the space, above the anti-overflow hopper, inside the tank serves as an air collecting chamber, the space, below the anti-overflow hopper, inside the tank serves as a water containing scrubbing chamber, a pressure plate is arranged on the outer edge of an air outlet of the air inlet pipe, a cylindrical filter element is arranged in the scrubbing chamber and is composed of multiple metal or plastic hoops sleeved together, a brush layer is arranged on the outer surface of the filter element, the portions, located on the upper surface and lower surface of the filter element, of the brush layer are in pressure connection with the bottom surface of the pressure plate and the inner bottom surface of the tank movably respectively, and the air collecting chamber is communicated with an exhaust pipe. Gas is squeezed and separated into numerous tiny bubbles after passing through the multiple hoops in the filter element and the brush layer. In this way, water can adsorb dust and impurities in gas effectively, the gas filtering effect is good, dust adsorbed by water can deposit to the bottom the tank, dirty liquid can be discharged simply by opening a drainage valve port on the bottom of the tank when maintenance is conducted each time, then pure water or anti-freezing solution is replenished, and therefore maintenance is easy. Compared with a dry type filter screen, the gas scrubber has the advantage that water using cost is lower.

Owner:高清春

Dosing device and dosing method for liquids

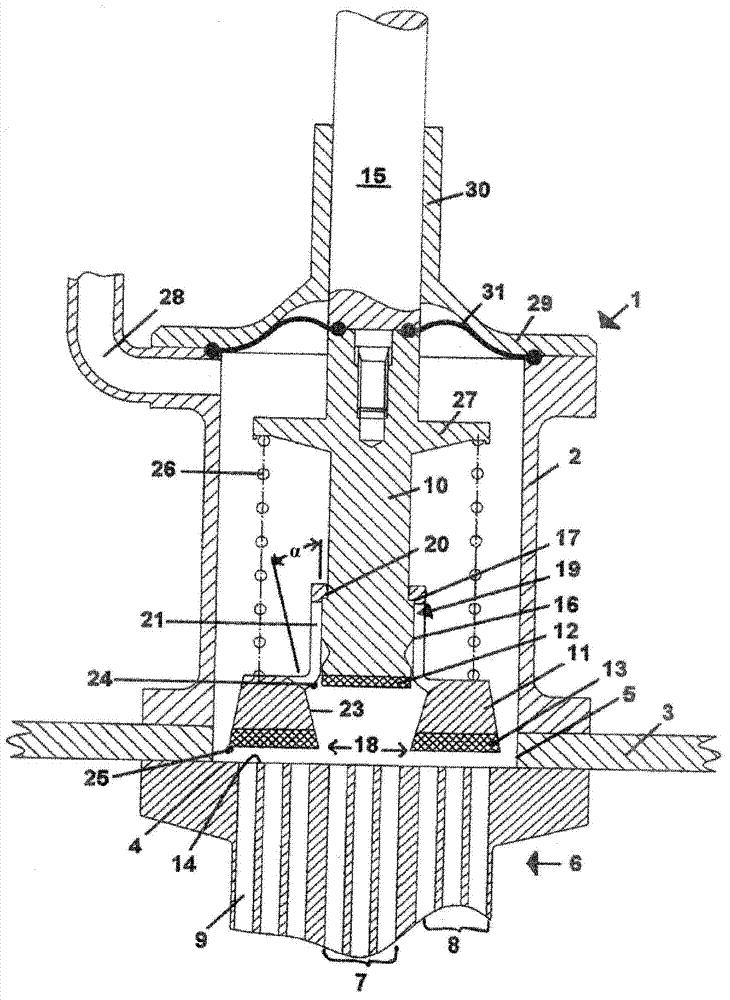

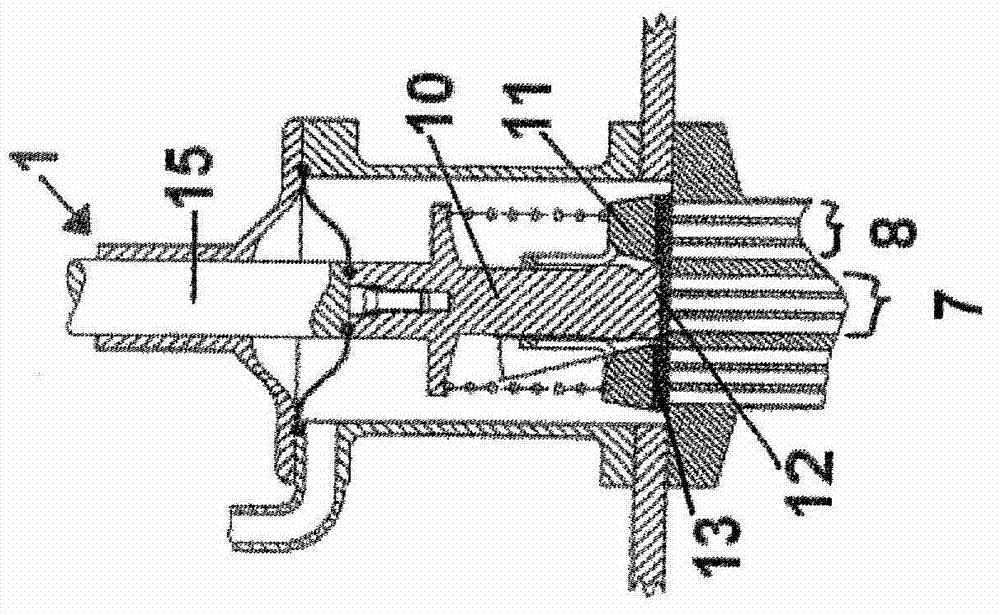

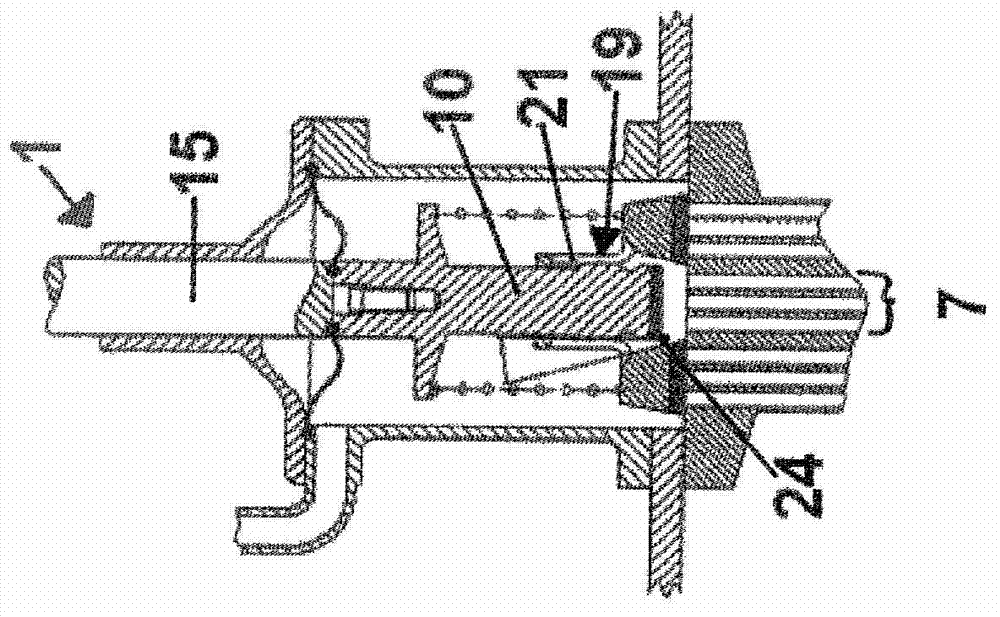

ActiveCN102791612AReduced spatter formationAvoid drainingLiquid materialLiquid bottlingEngineeringValve seat

The invention relates to a dosing device having an inlet (28) for a liquid to be delivered to a container as a dose, in particular a beverage. The device comprises a valve seat (14), a sealing element (10, 11) interacting with the valve seat and an outlet (4) for the dose of the liquid. In order to reduce foam build-up upon delivering the liquid into the container, according to the invention the sealing element can be moved to a first and a second opening position, wherein, in the second opening position, the flow cross-section area between the valve seat and the sealing element is larger than in the first opening position. In addition, the invention relates to a dosing method comprising the supplying of a liquid to a valve which is moved to a first and second opening position.

Owner:ELOPAK SYST

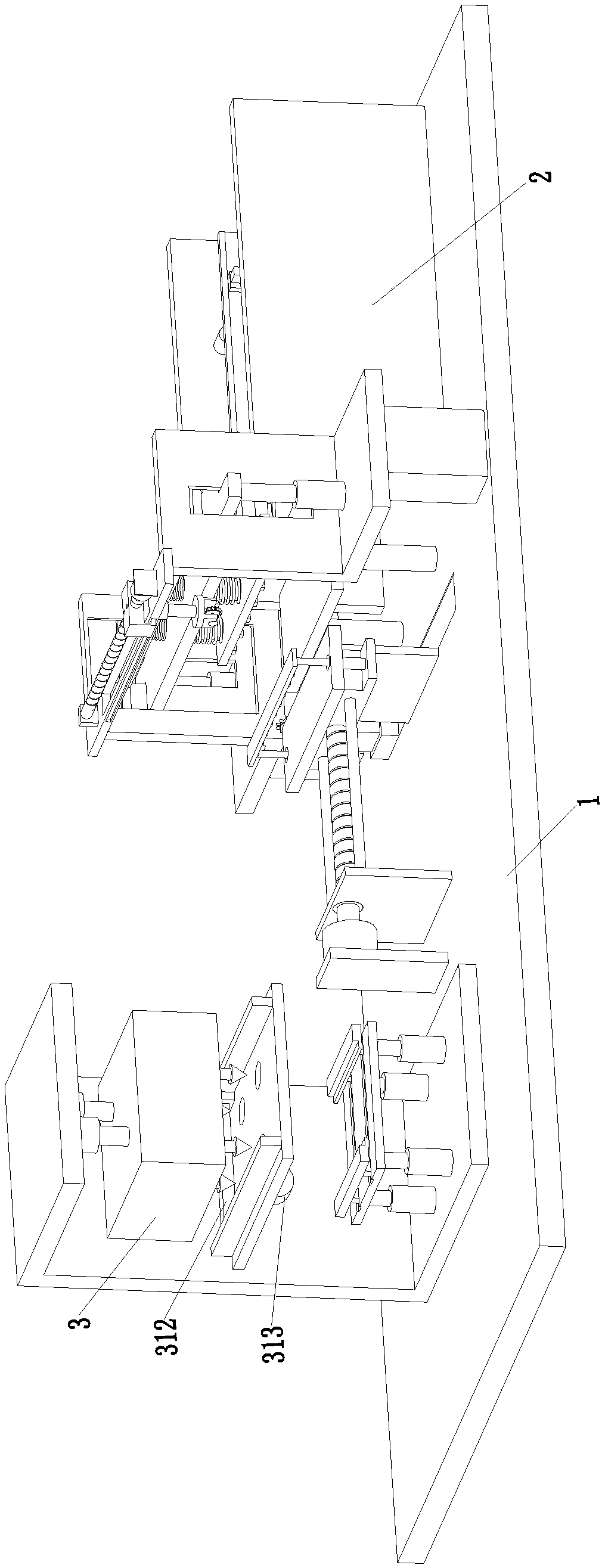

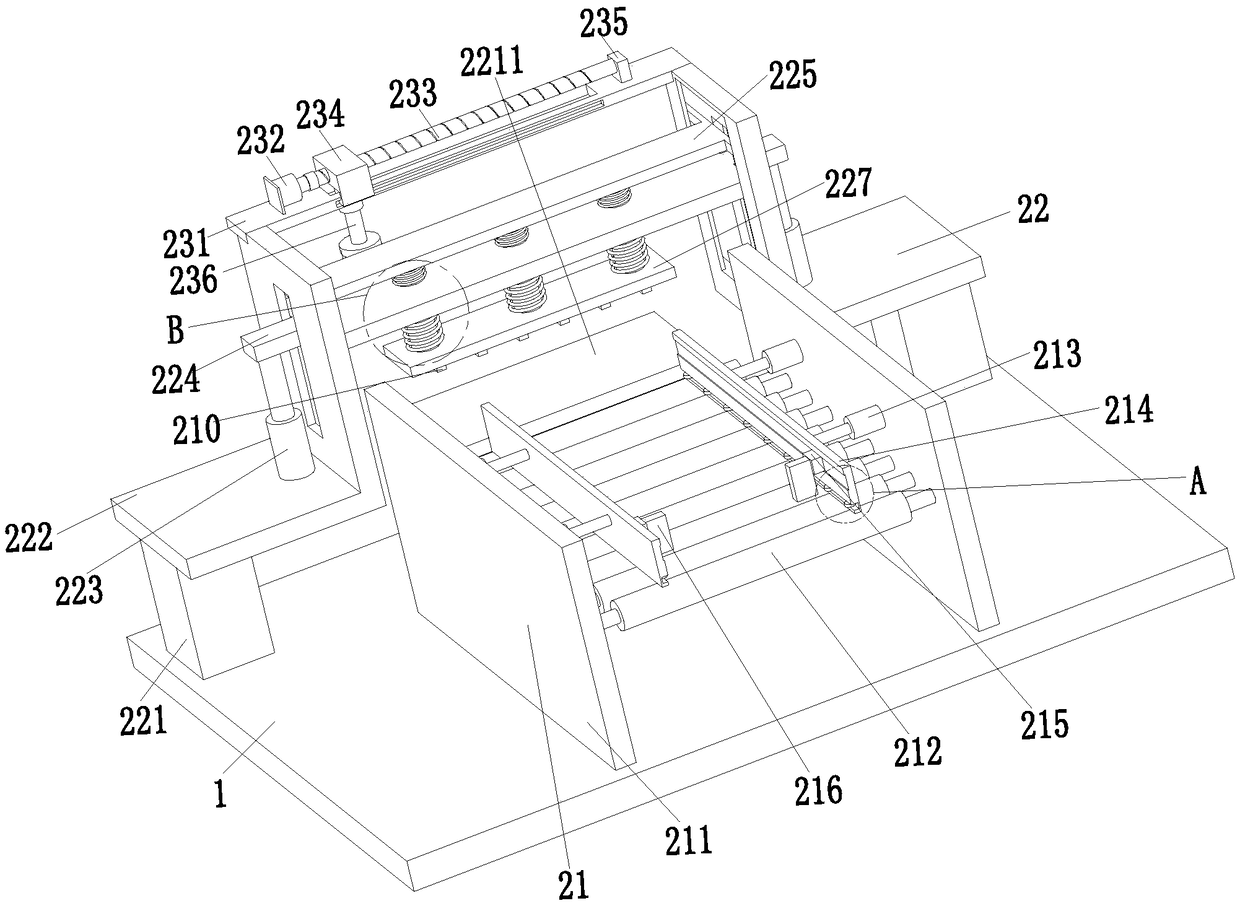

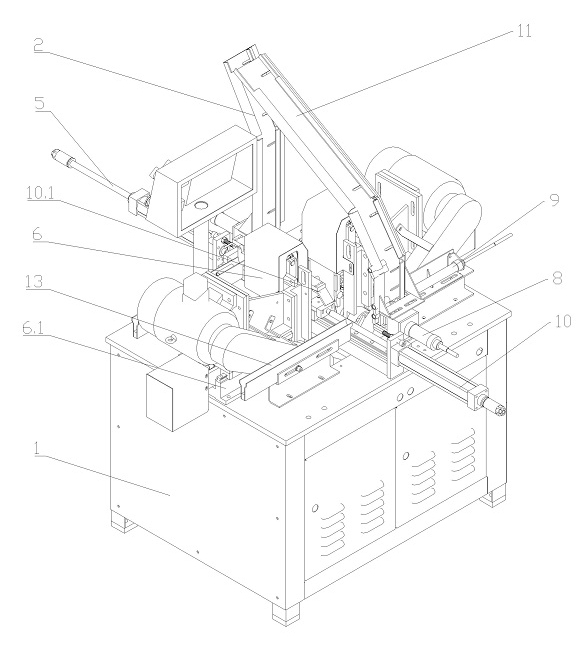

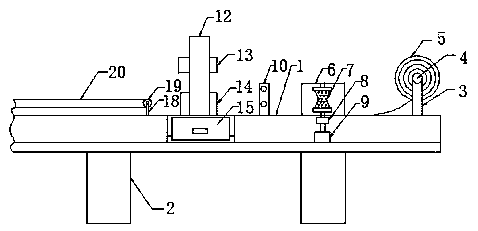

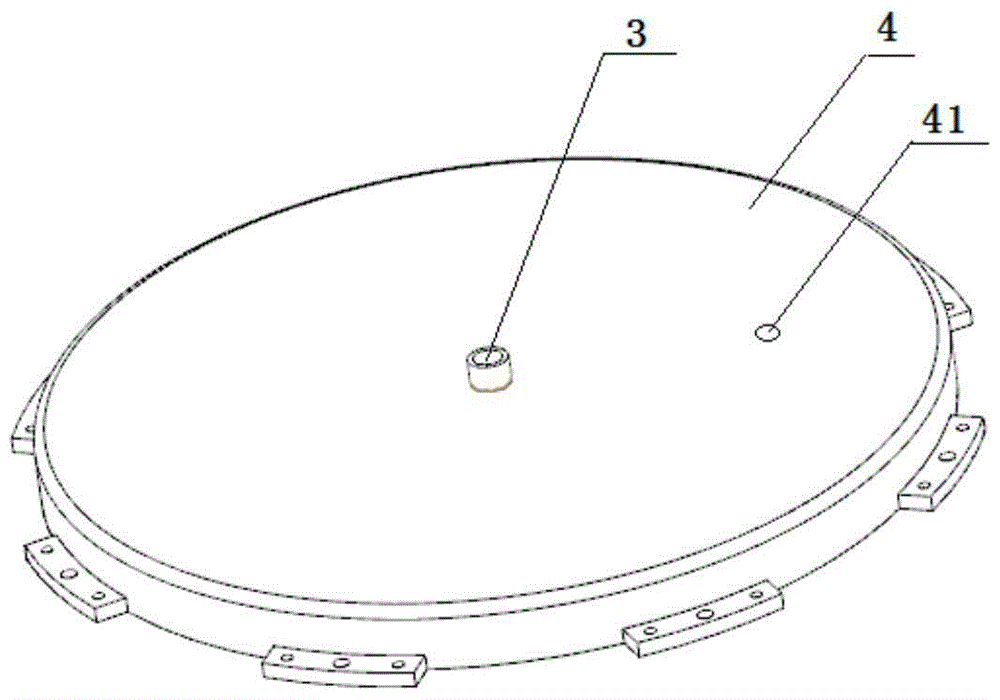

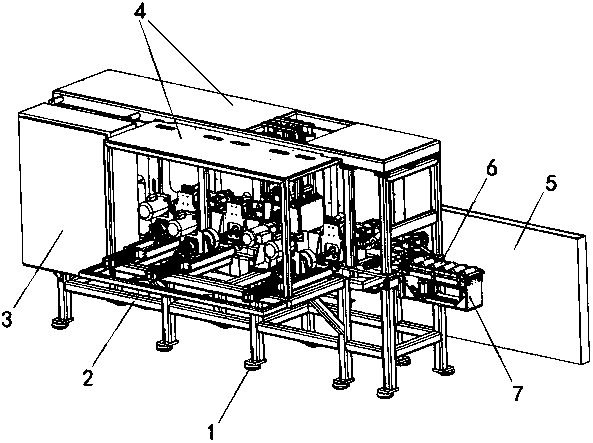

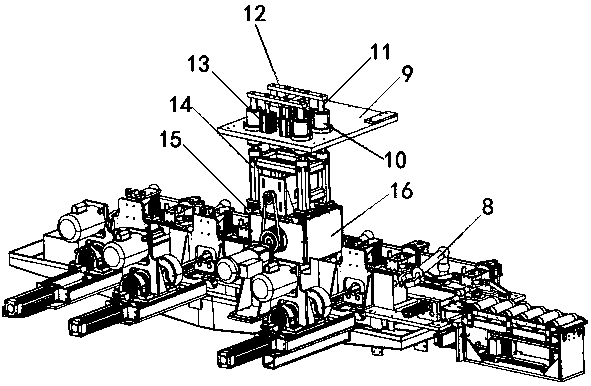

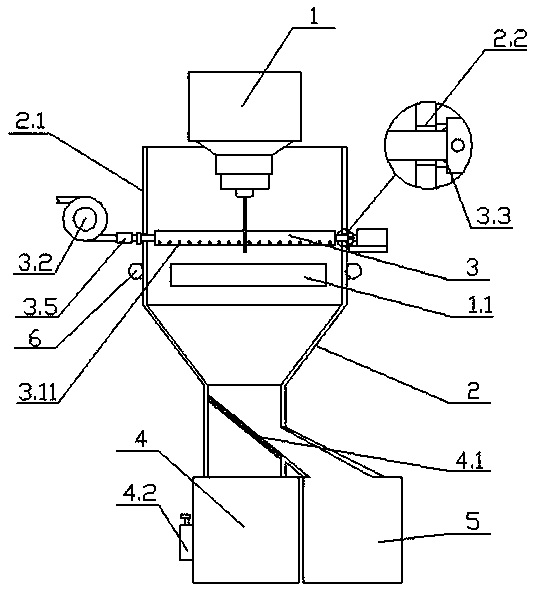

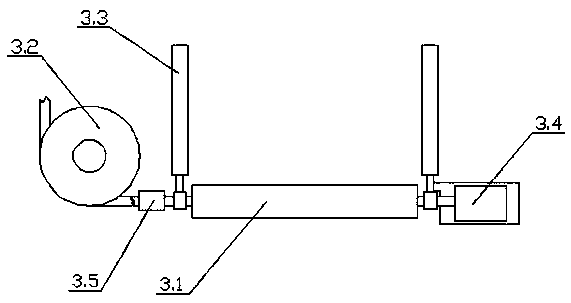

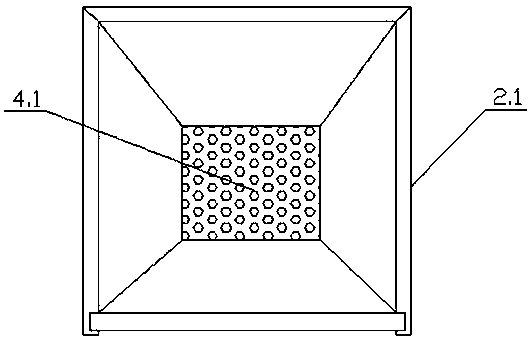

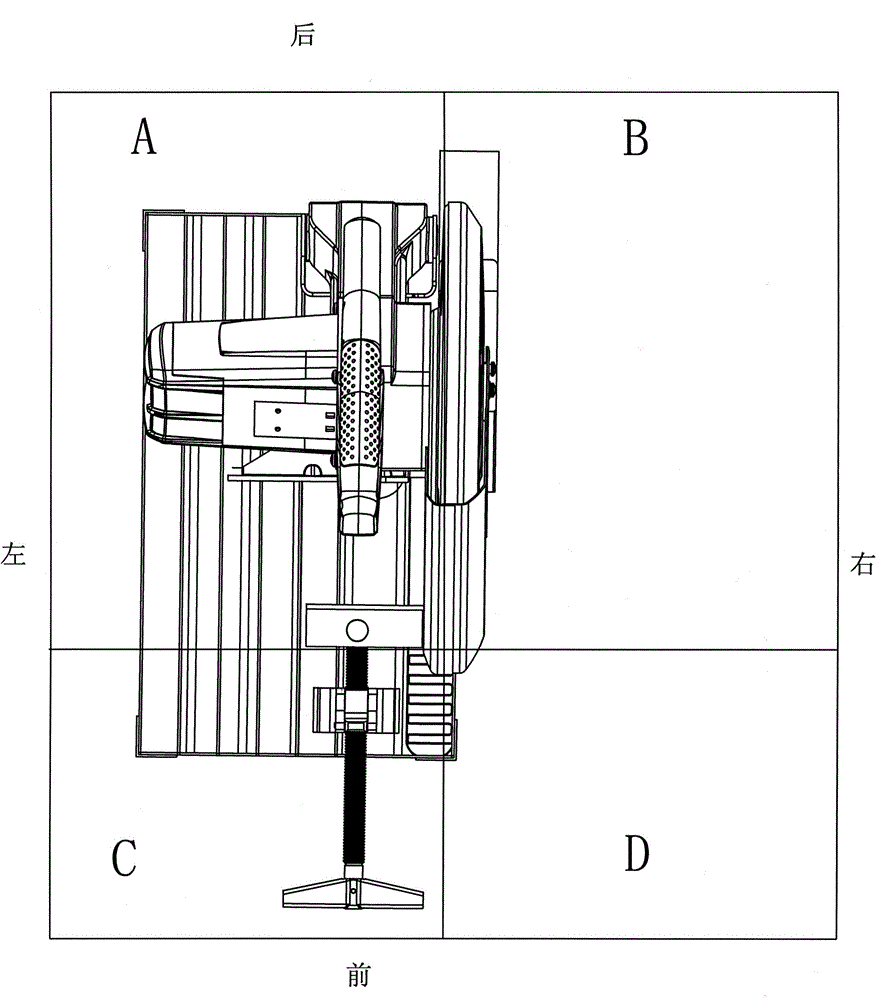

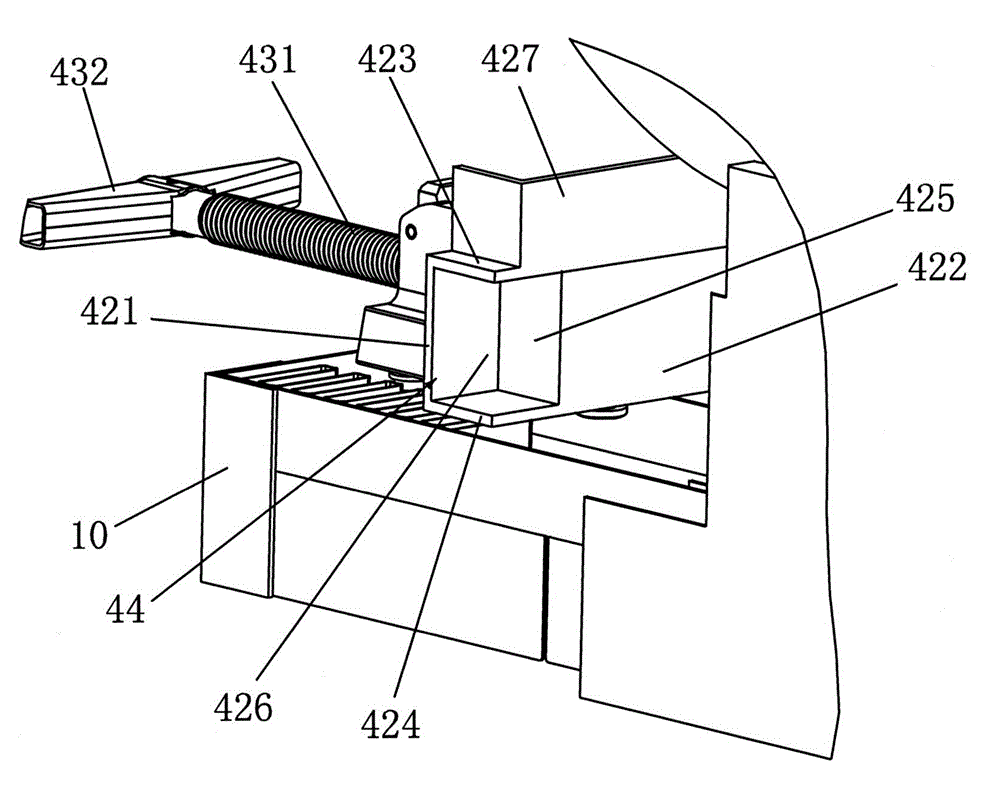

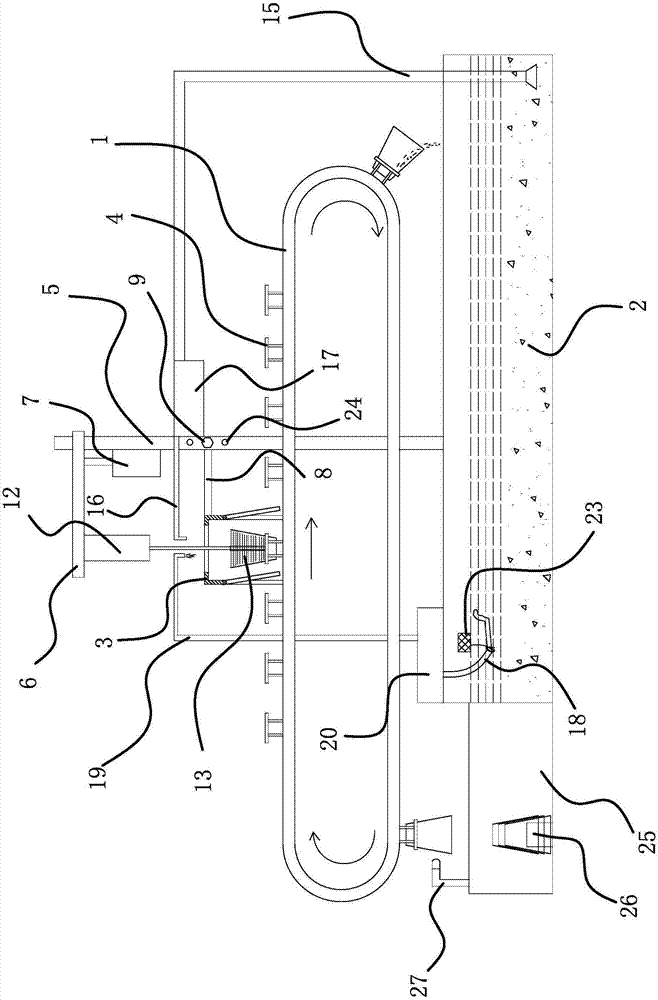

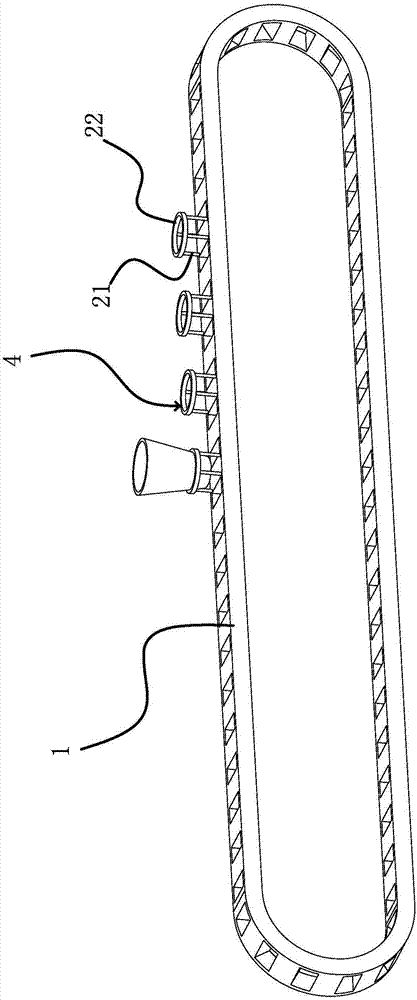

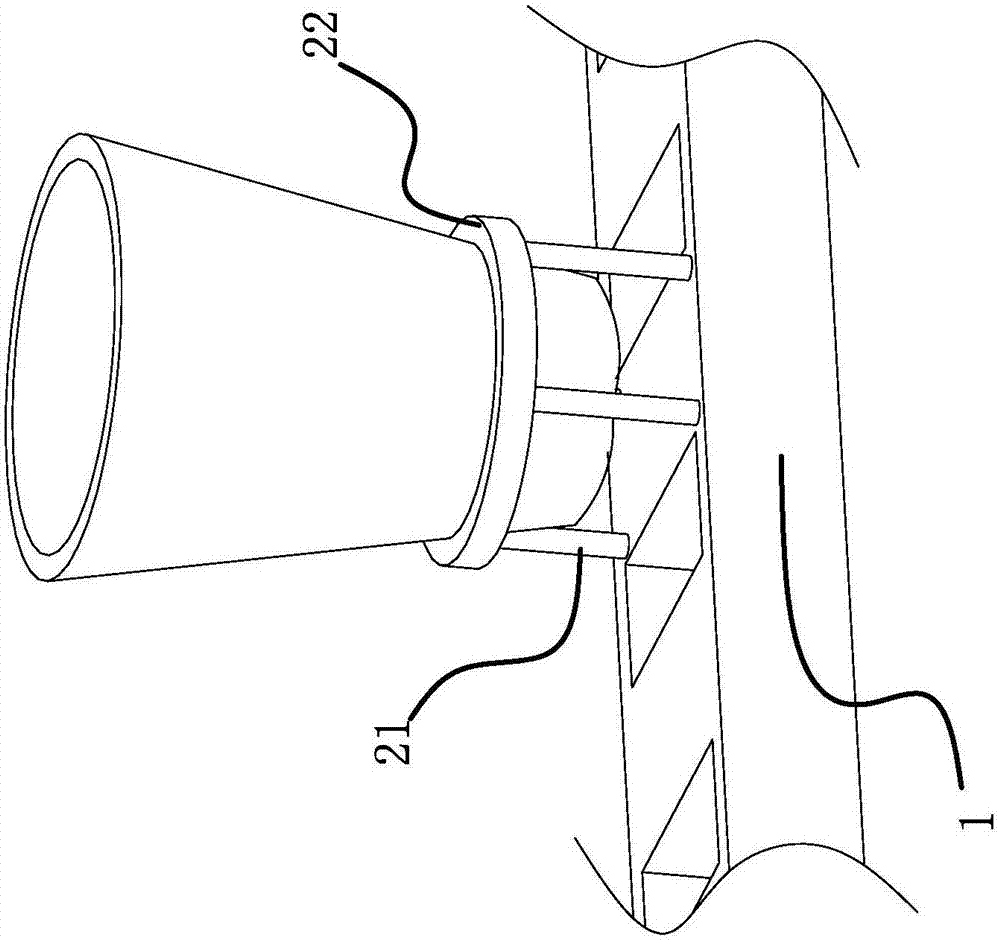

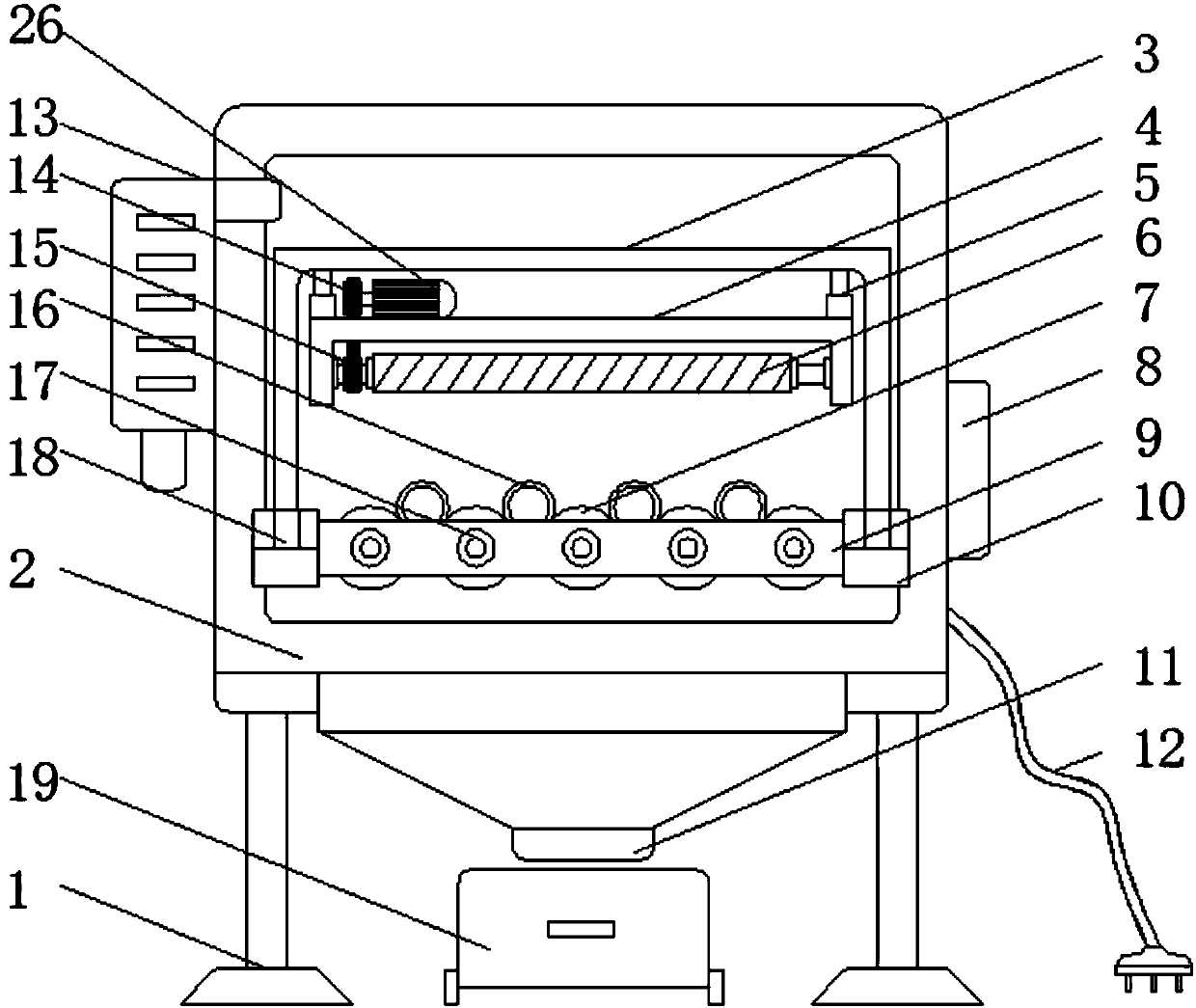

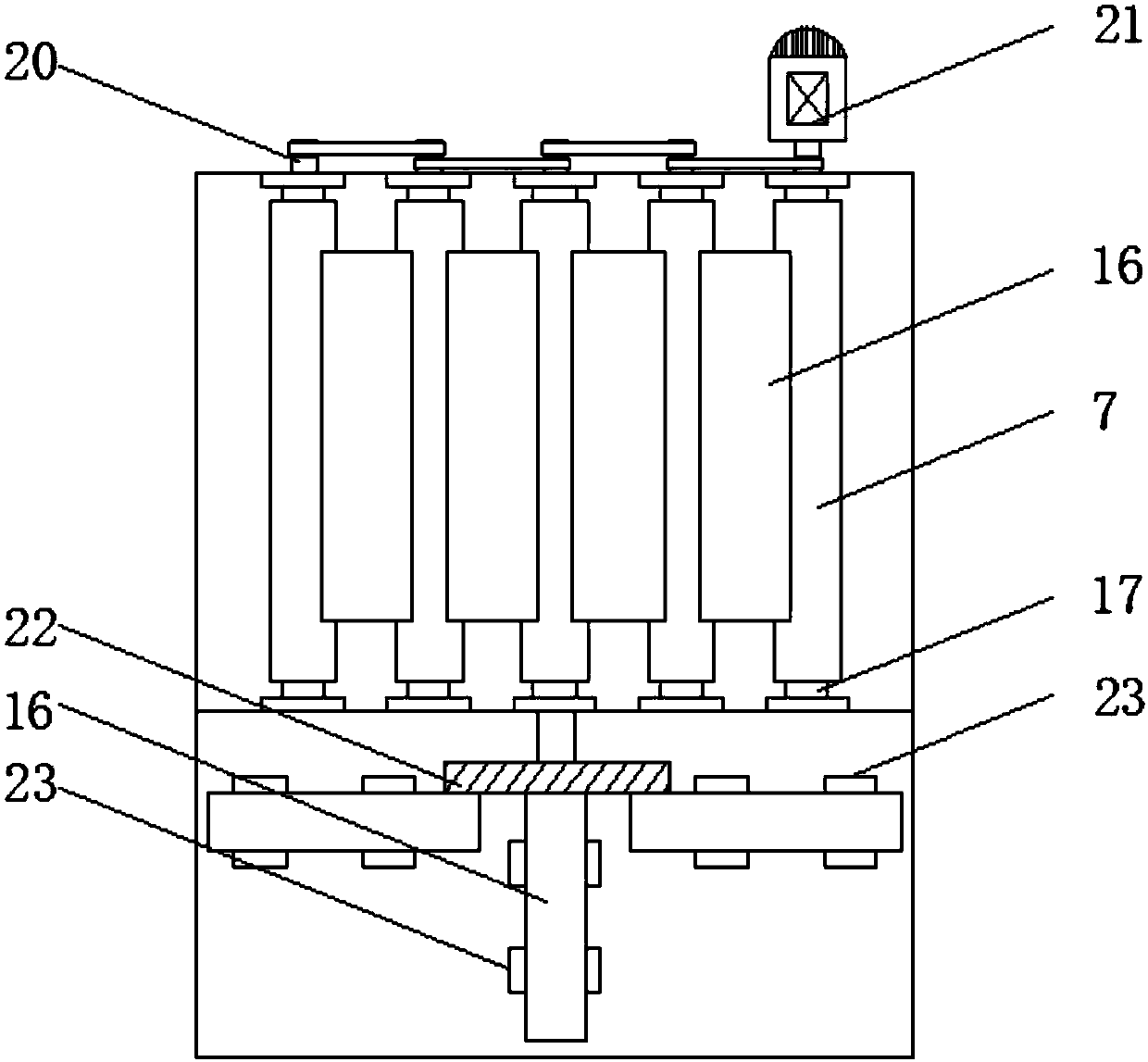

Automatic aluminum base plate cutting and drilling equipment and automatic aluminum base plate machining method

ActiveCN108994618ARealize automatic cleaningRealize automatic cutting of aluminum substrateOther manufacturing equipments/toolsMetal working apparatusInstabilityMechanical equipment

The invention relates to automatic aluminum base plate cutting and drilling equipment and an automatic aluminum base plate machining method. The automatic aluminum base plate cutting and drilling equipment comprises a bottom plate, a plate shearing device and a drilling device. The upper end of the bottom plate is sequentially provided with the plate shearing device and the drilling device from left to right. The automatic aluminum base plate cutting and drilling equipment and the automatic aluminum base plate machining method can solve the problems that according to existing equipment, an aluminum base plate is likely to twist and deform due to too large single-side stress during aluminum base plate cutting, and meanwhile, in the cutting process, the aluminum base plate is prone to cutting damage due to instability of the equipment; in the conveying process, mechanical equipment often damages the surface of the aluminum base plate, the phenomenon of surface scratching is caused; in the drilling process, the situation of waste scattering in the ordinary equipment drilling process is caused, and meanwhile manual cleaning is troublesome; and ordinary drilling equipment is single in work condition and cannot only drill one hole at a time, and the hearing of workers is often damaged due to too large noise in the drilling process. The functions of automatic aluminum base plate cutting and simultaneous multi-hole drilling can be achieved.

Owner:江门市利诺达电路科技有限公司

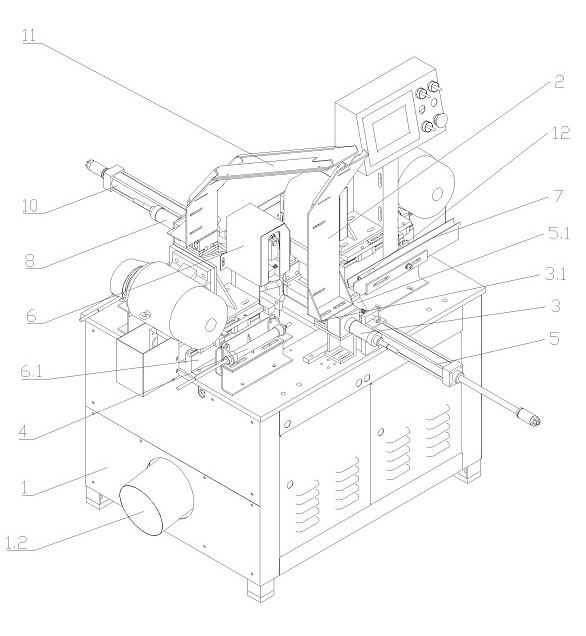

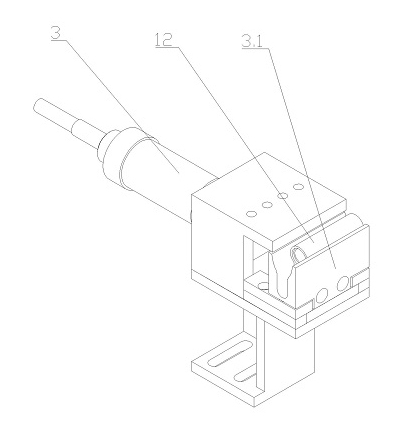

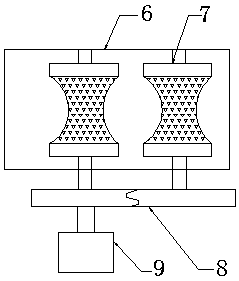

Lock polisher

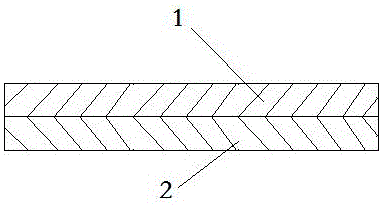

InactiveCN102528595AReduce labor intensityImprove parallelismPlane surface grinding machinesControl systemPolishing

The invention discloses a lock polisher, which comprises a bed (1), a first dropping groove (2), a first linear driving mechanism (3), a second linear driving mechanism (4), a third linear driving mechanism (5), a grinding mechanism (6), a first discharge groove (7) and a control system. The grinding mechanism (6) is arranged on the bed (1), the first linear driving mechanism (3) is provided with a first material taking device (3.1) positioned below an opening of the lower end of the first dropping groove (2), the third linear driving mechanism (5) is provided with a first clamping positioning mechanism (5.1), the second linear driving mechanism (4) is provided with a push rod, and the first discharge groove (7) is arranged on the bed. By the aid of the polisher, a lock is polished faster, labor intensity of workers is reduced, simultaneously, parallelism of two end surfaces of the lock to be machined is good due to automatic polishing, dimension of the lock is controlled well, and patterns of the polished end surfaces are clear.

Owner:NINGBO SHUTAI INFORMATION TECH

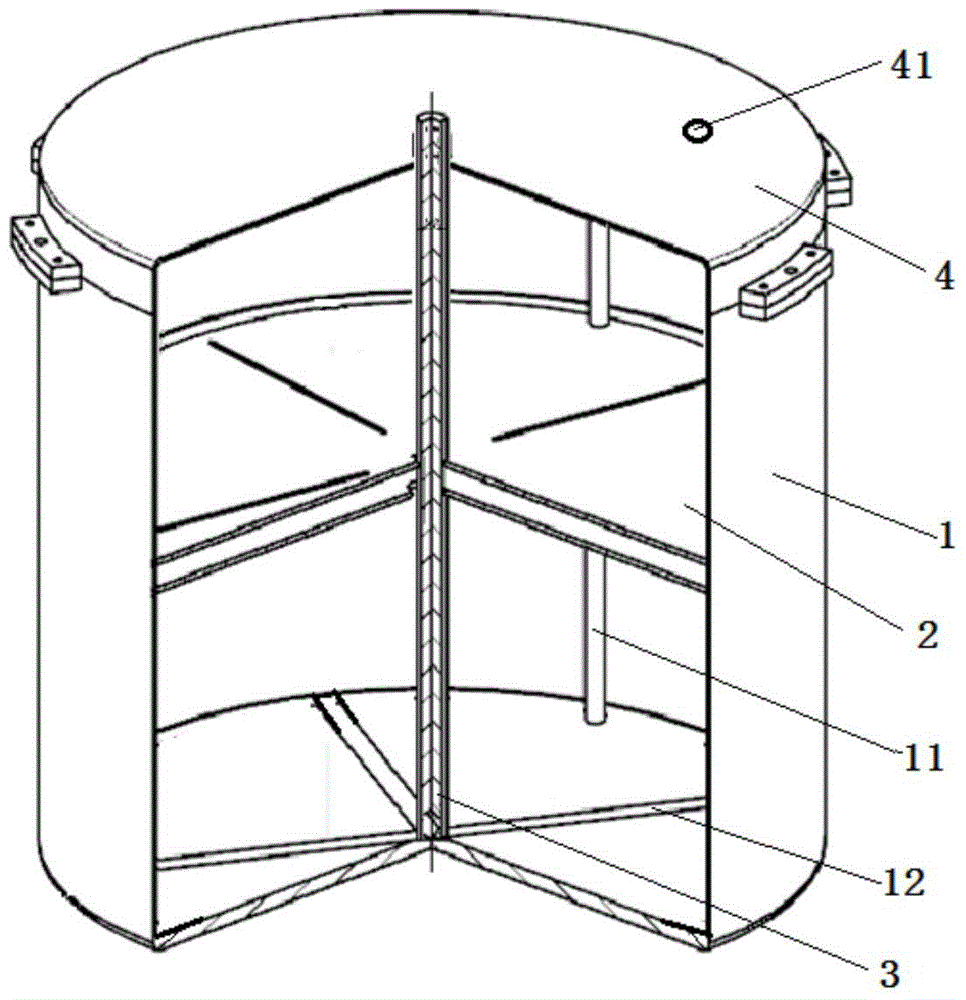

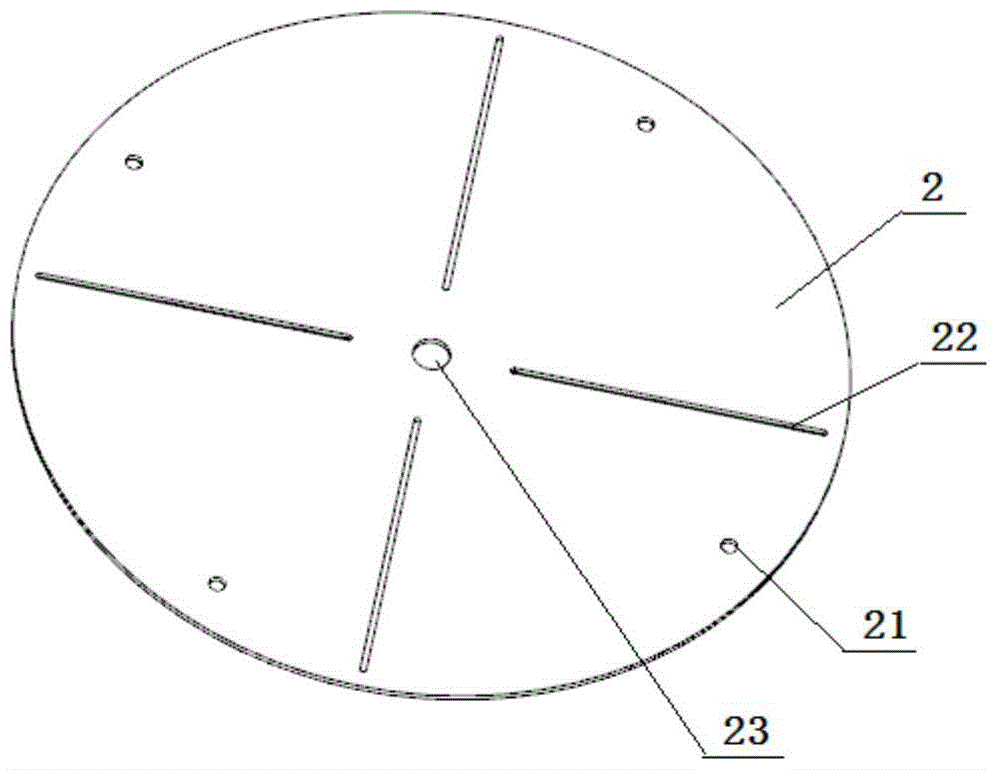

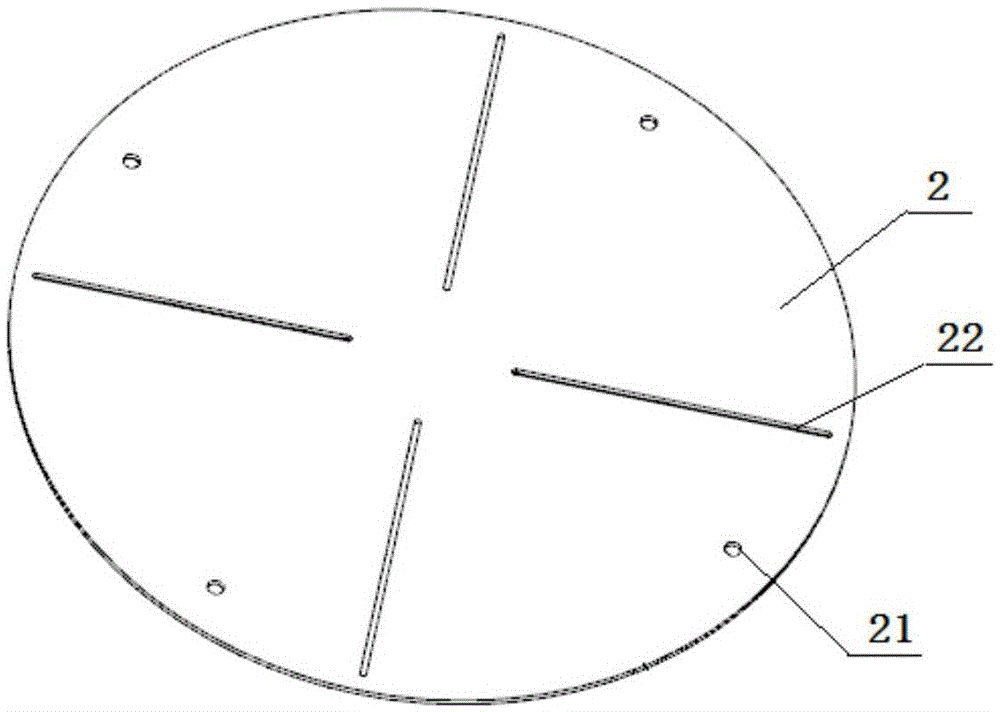

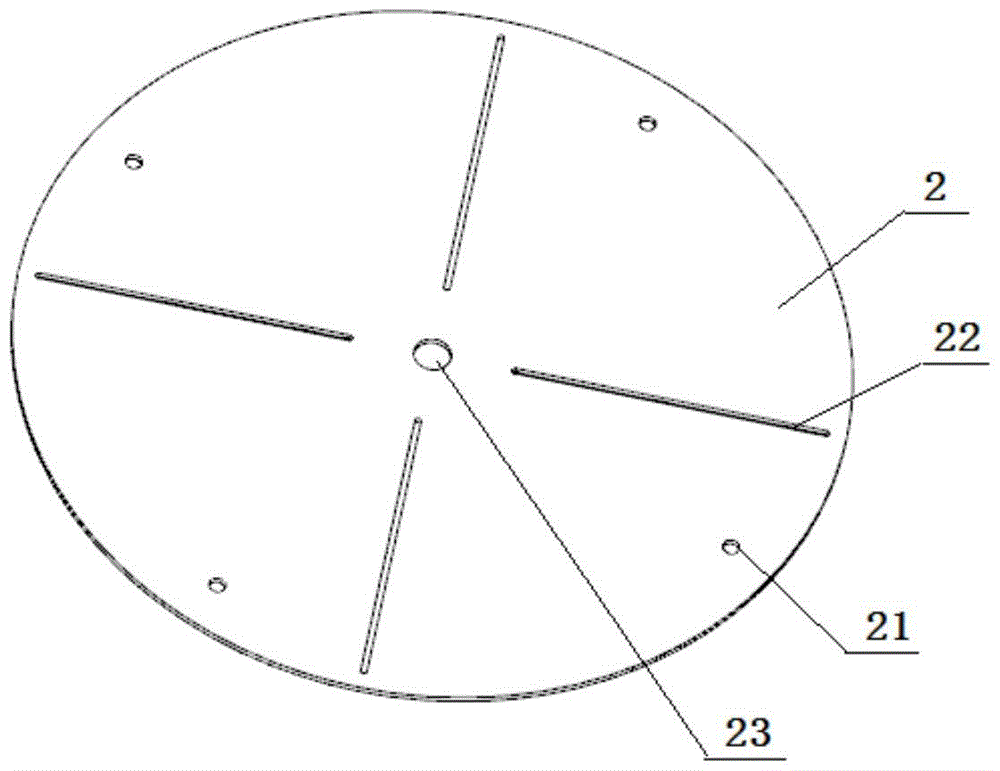

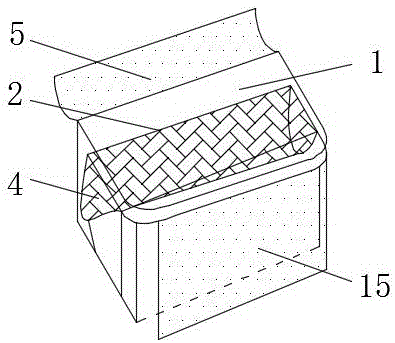

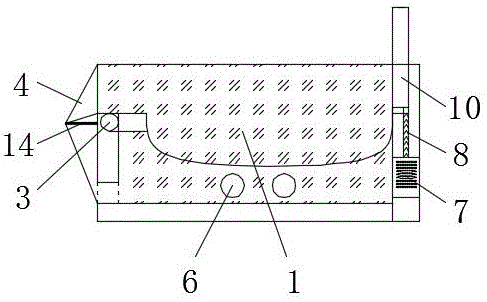

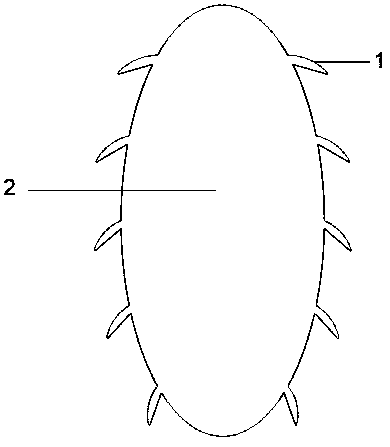

Double-layer anti-oscillation pesticide box for aerial spraying for plant protection

The invention provides a double-layer anti-vibration medicine box for aerial spray plant protection, which includes a box body, a box cover, and at least two anti-vibration plates connected together. Several guide columns are arranged on the bottom surface of the box body. On the body; there are several through-holes and several radial slits on the anti-vibration plate, and the through-holes and radial slits are not on the same diameter; the anti-vibration plate is installed on the guide column through the through-hole, and two adjacent anti-vibration plates The radial gaps do not overlap, and there is a gap between two adjacent anti-vibration plates; there is a gap between the anti-vibration plate and the inner wall of the box, the through hole and the guide column are sliding-guided gaps, and the uppermost anti-vibration plate floats on the liquid surface superior. When the liquid medicine oscillates or tilts, the anti-oscillation plate can weaken the oscillation of the liquid medicine, keep the center of gravity of the medicine box stable, reduce the influence of liquid medicine tilt or oscillation on the balance of the aircraft, and prevent the liquid medicine from splashing and secondary dumping , to ensure the smooth and normal operation of aviation spraying, improve the spray quality and the utilization efficiency of liquid medicine, reduce the waste of liquid medicine, and protect the environment.

Owner:JIANGSU UNIV

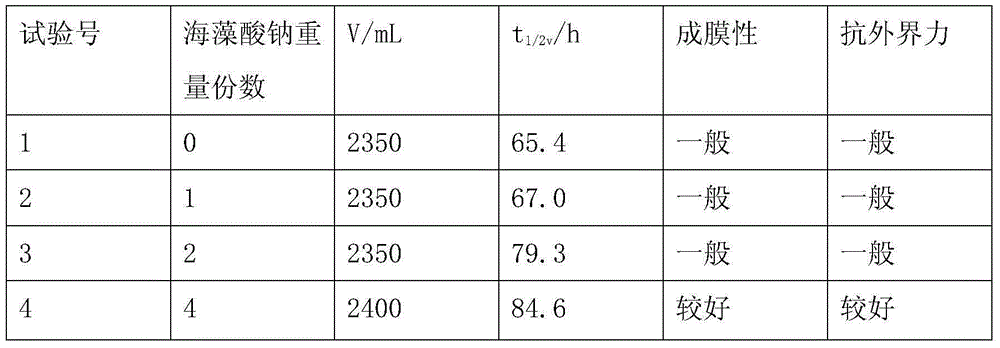

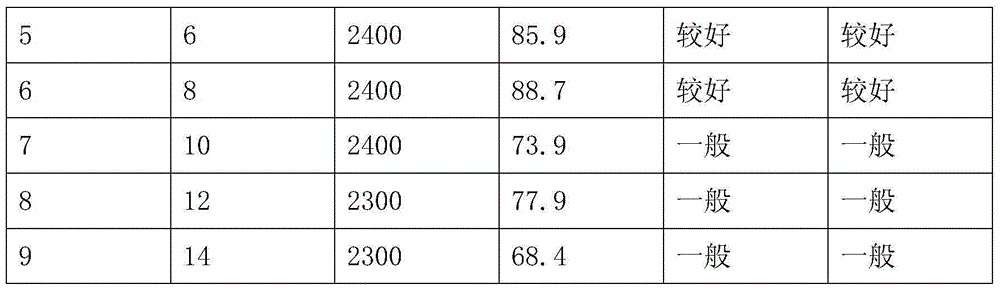

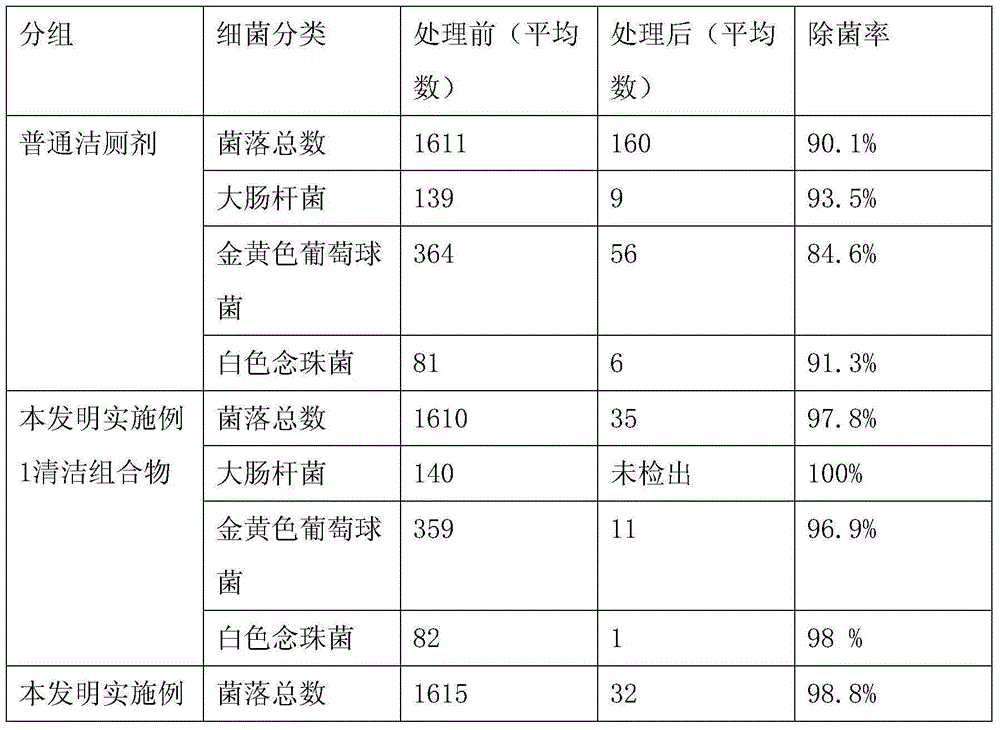

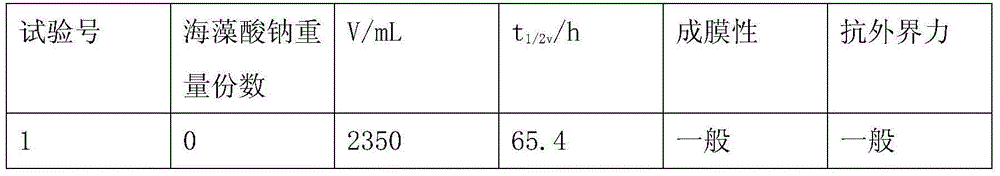

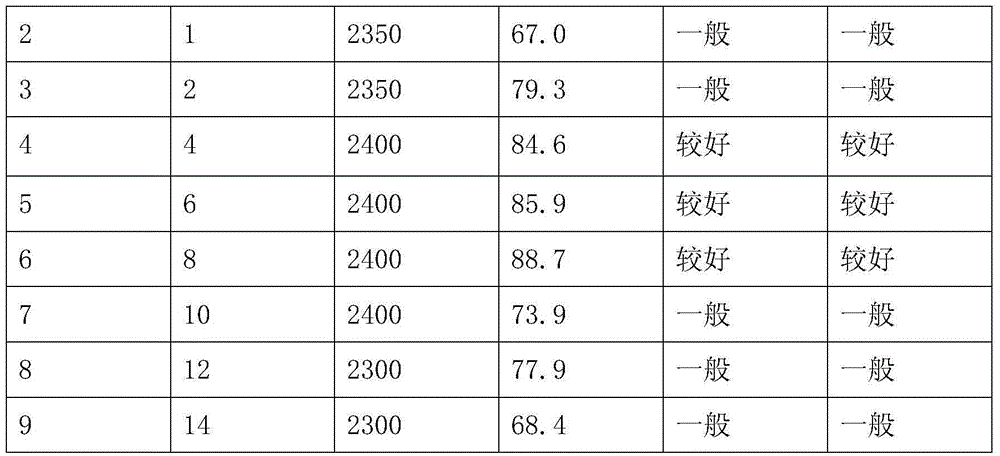

Foam cleaning composition

InactiveCN105154251AStop splashPrevent spillageAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsBedpanDeodorant

The invention provides a foam cleaning composition which comprises an anionic surfactant, a nonionic surfactant, tea saponin, sodium alginate, sodium citrate, sodium chloride, a bioenzyme, betaine and the like. The foam cleaning composition can also comprise a bactericidal deodorant, an essence and a colorant. The foam cleaning composition is suitable for cleaning bedpans, and has the characteristics of high foaming speed, fine and abundant foam, long duration time and the like. The bactericidal deodorant is a pure natural antibacterial deodorant, can remove peculiar smell, has favorable bactericidal action, and is harmless to the human body and environment.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

Special cable cutting equipment

The invention discloses special cable cutting equipment. The special cable cutting equipment comprises an operation platform; a support column is fixedly connected to the bottom end of the operation platform; one end of the operation platform is fixedly connected with a first bracket; a collecting roller shaft is mounted at the top end of the first bracket; a cable is wound at the external of thecollecting roller shaft; a mounting base fixedly connected with the operation platform is arranged on one side of the first bracket; two opposite rollers are mounted in the mounting base; one ends ofthe two rollers are embedded in the top of the mounting base through bearings in insertion connection; the other ends of the two rollers penetrate through the bearings, embedded in the bottom of the mounting base, to fixedly connect with gears; one of the gears is in transmission connection with an output shaft of a driving motor; and the driving motor is mounted in a groove in the operation platform. The special cable cutting equipment is simple in structure, guarantees excellent straightness of the cable for cutting to achieve high cutting efficiency, and collects chips generated in cuttingin a centralized mode for unified treatment.

Owner:TAIZHOU LUOKE ELECTRONICS

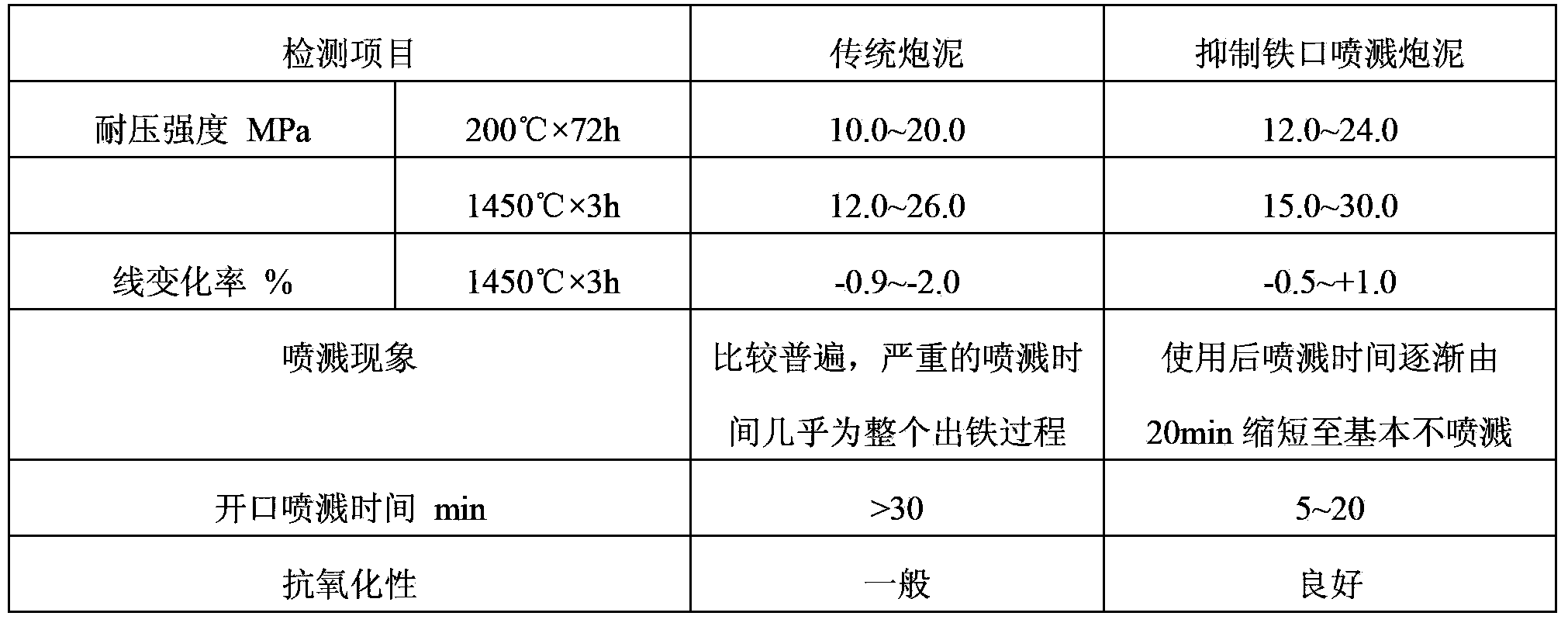

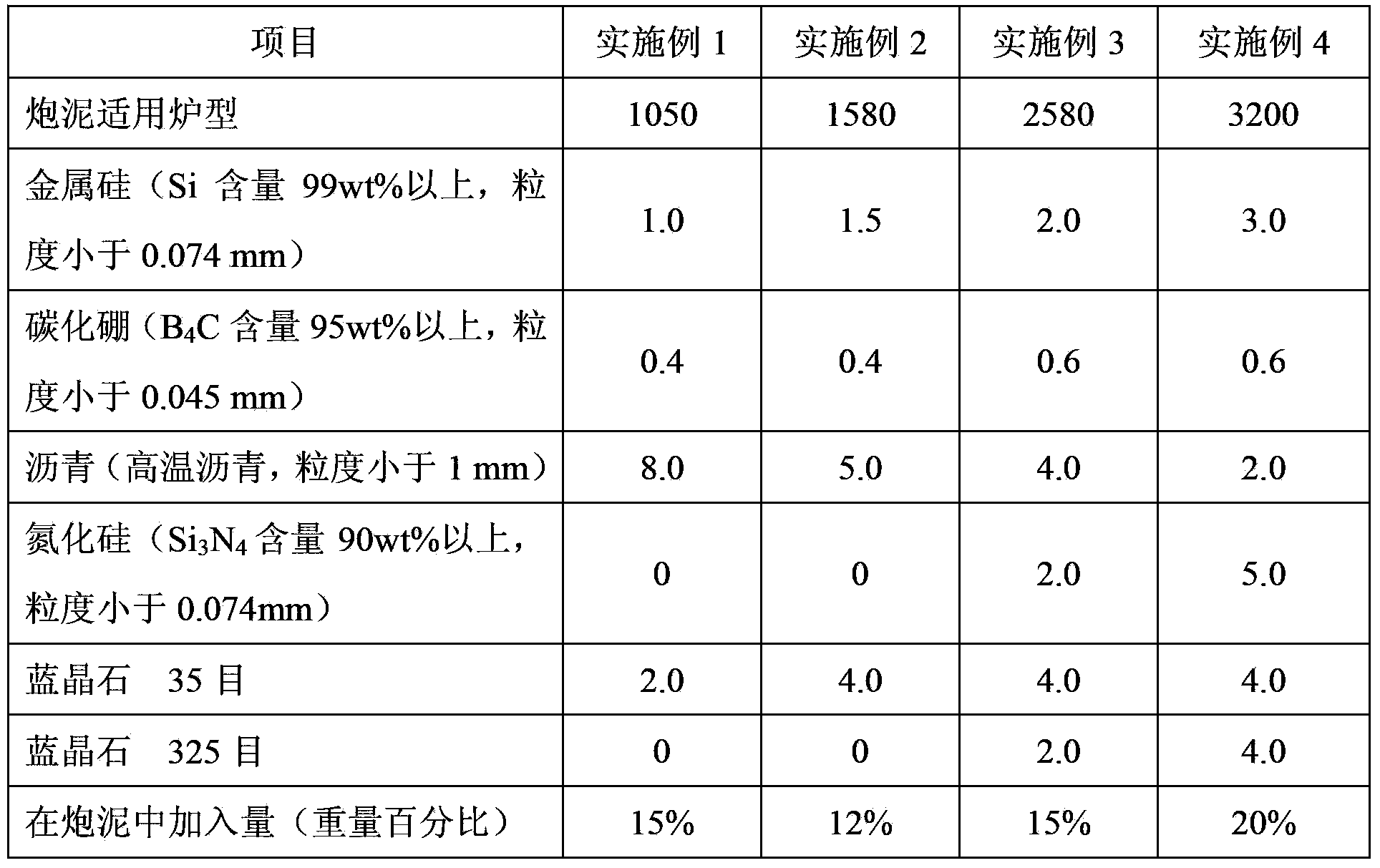

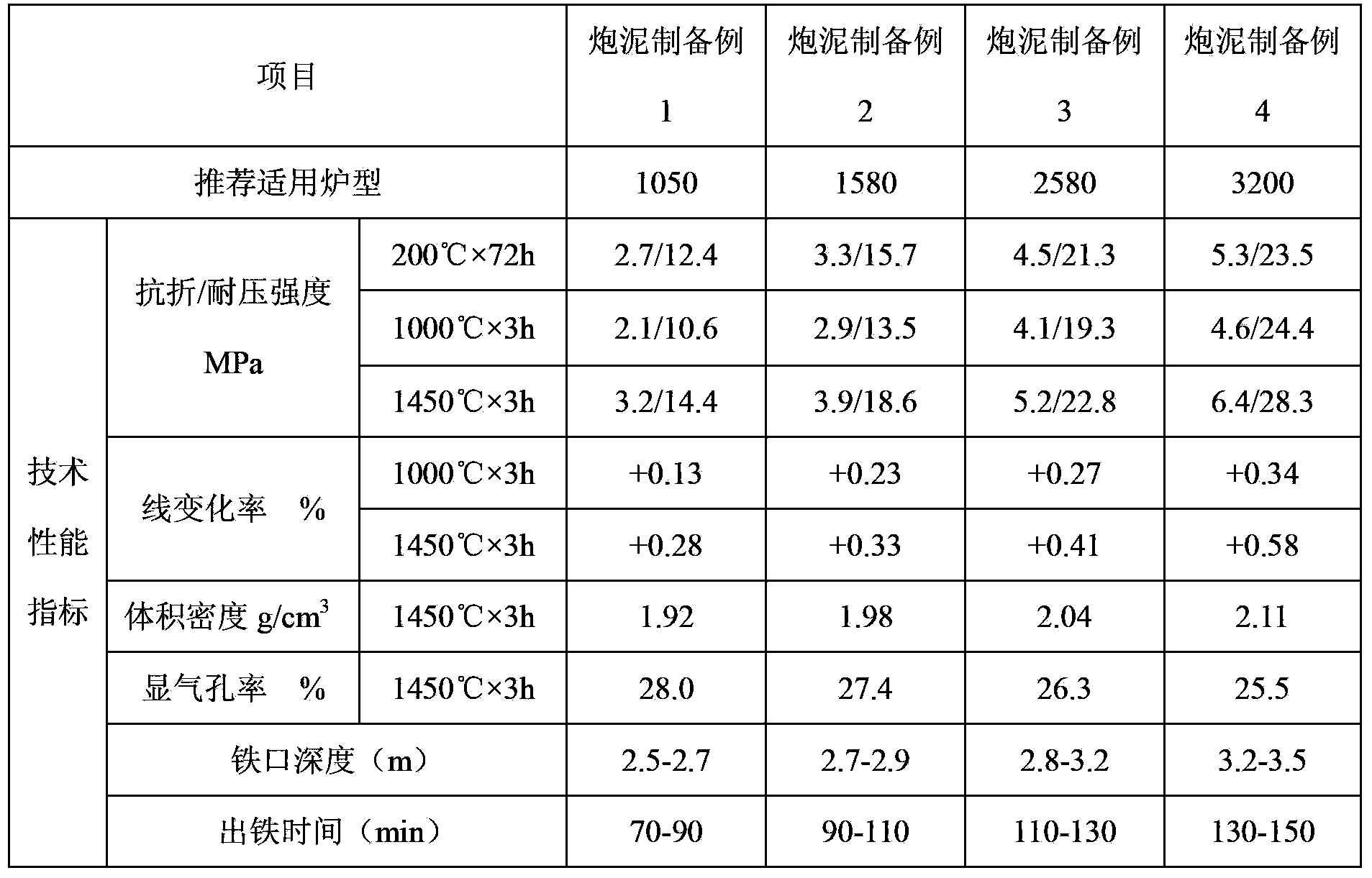

Stemming for inhibiting splashing of iron notch

The invention relates to stemming for inhibiting the splashing of an iron notch. The stemming comprises the following components in parts by weight: 15-25 parts of high-aluminum granules, 10-15 parts of alumina powder, 10-25 parts of silicon carbide, 13-20 parts of coke, 2-7 parts of quartz sand, 10-18 parts of clay, 12-20 parts of additives, 7-14 parts of tar and 2-7 parts of phenolic resin, wherein the additives comprise the following components in parts by weight: 1-3 parts of metallic silicon, 0.4-0.6 part of boron carbide, 2-8 parts of asphalt, 0-5 parts of silicon nitride and 2-8 parts of kyanite. The stemming disclosed by the invention is capable of generating a proper quantity of glass phase components at a high temperature; under the precondition that high temperature property is not influenced, the layer of glass phase in contact with molten iron can effectively plug various crackles of an iron notch channel and thus can prevent the splashing caused by gas moving; in addition, the stemming has the advantages of proper microdilatancy effect and medium-high temperature intensity.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Press-in treatment process method for iron notch sputtering of blast furnace

InactiveCN103114160AImprove the operating environmentImprove smelting safety performanceDischarge devicesBrickControl system

The invention relates to a press-in treatment process method for the iron notch sputtering of a blast furnace, which is characterized in that a special refractory material for an iron notch is pressed into the cold surface and the heat surface of a cooling wall, iron notch combined bricks, and the cracks and the defects of iron notch channel brick ladles via a press-in equipment unit and by adopting the process steps of iron notch cleaning, iron notch sealing plate welding, furnace shell pore opening, and pressure and feed quantity control. The highest pressure of construction equipment is controlled to be not greater than 30 MPa, the pressure of furnace shell press-in holes is controlled to be 1-5 MPa, the press-in quantity of the refractory material is adjusted and controlled via a press-in equipment control system, the press-in speed is controlled to be in a range from 10 to 75 kg per minute, and is steplessly adjusted. The invention discloses a press-in treatment process method which is low in cost and short in furnace blowout time, for the iron notch sputtering of a blast furnace, wherein via the press-in treatment process method, coal gas blowby channels are blocked and sealed, so as to achieve prevention for coal gas blowby in an iron notch area, eliminate the phenomenon of iron notch sputtering, ensure the smooth iron tapping of the iron notch, and improve the operating environment and the smelting safety performance of the blast furnace.

Owner:BEIJING RUIPU TONGCHUANG TECH DEV

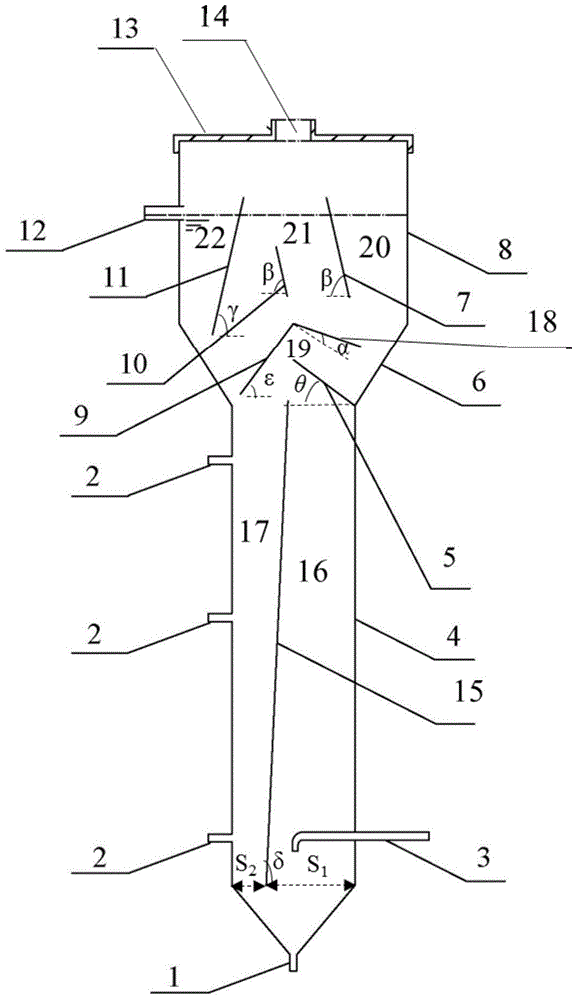

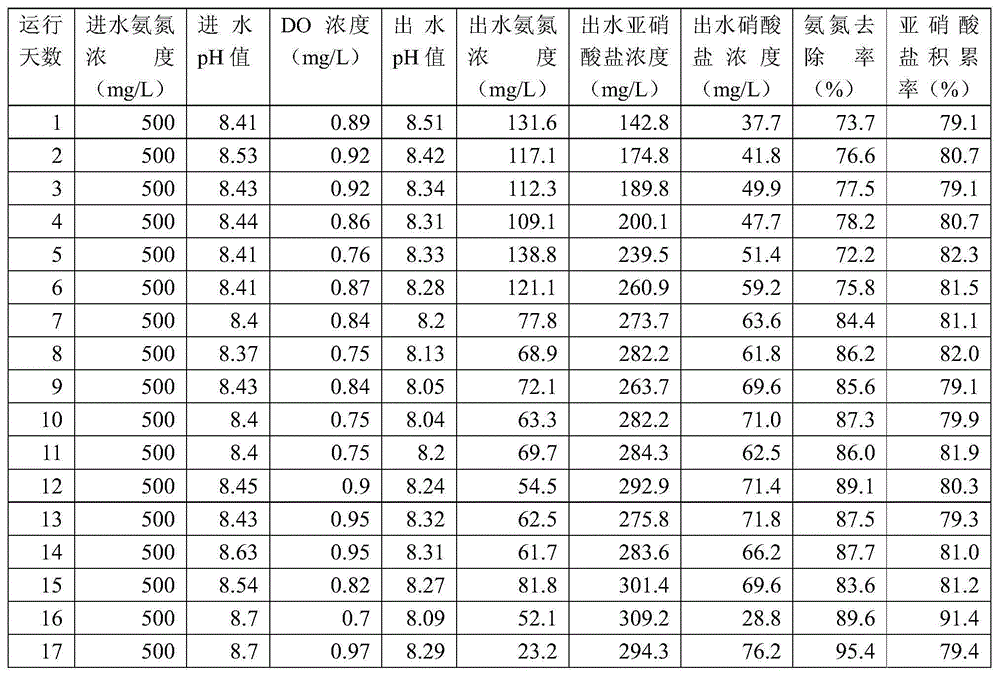

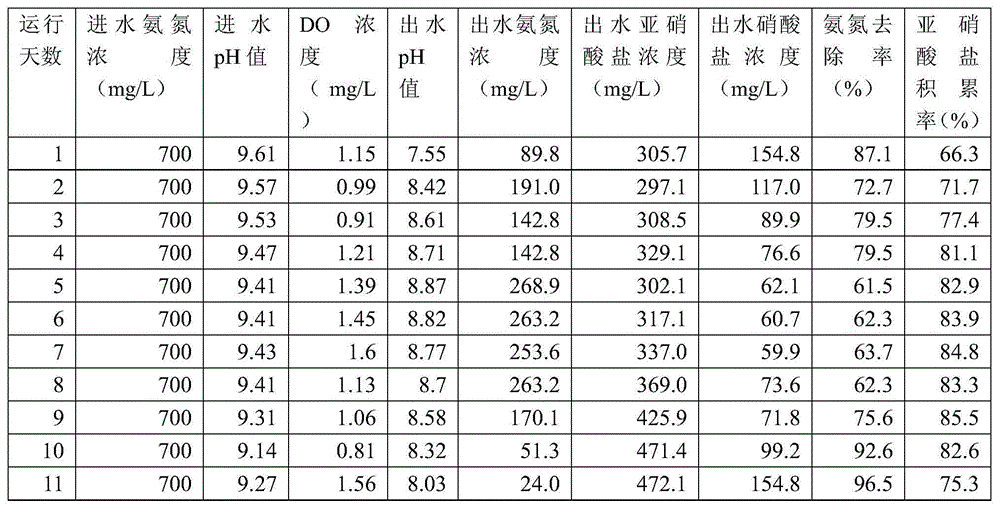

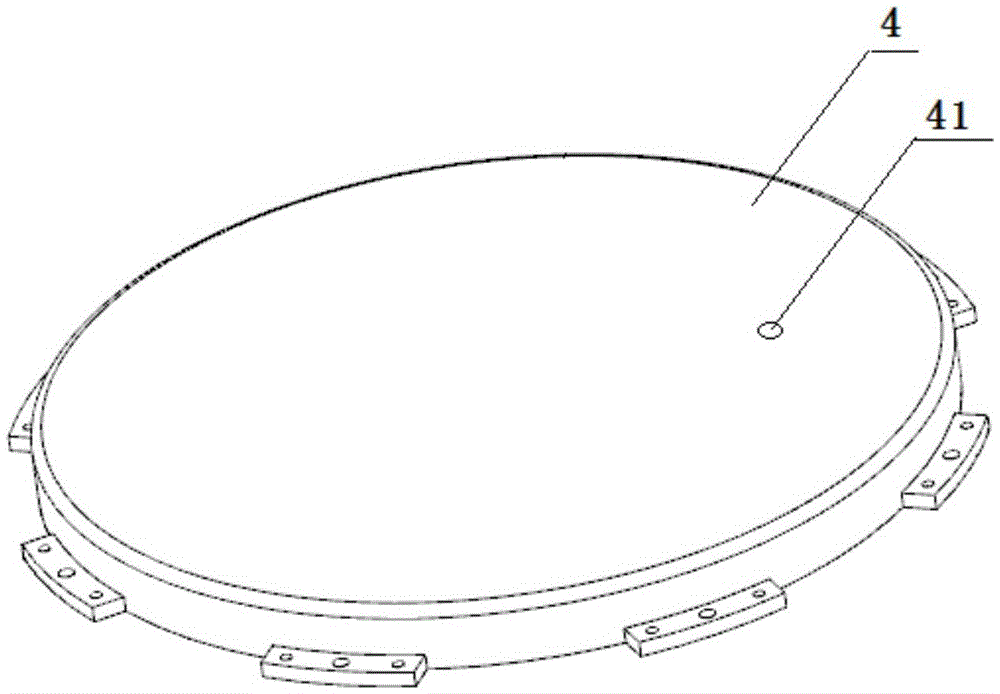

Air lift type bio-nitrification reactor with baffle plate reinforcing internal circulation

ActiveCN104478079AEasy to separateStrong resistance to shock loadsTreatment using aerobic processesSustainable biological treatmentLoad resistanceSludge

The invention discloses an air lift type bio-nitrification reactor with a baffle plate reinforcing internal circulation. The air lift type bio-nitrification reactor with the baffle plate reinforcing internal circulation comprises a reaction chamber and a sedimentation chamber which are arranged from bottom to top, wherein the reaction chamber is connected with the sedimentation chamber by virtue of a funnel-shaped diffusion tube, a water inlet pipe is arranged at the bottom of the reaction chamber, a gas guiding pipe and a sampling pipe which are inserted into the center of the reaction chamber are arranged on the side wall of the reaction chamber, the interior of the reaction chamber is divided into an upflow region and a flow falling region by virtue of a separating baffle, a baffling region formed by the baffle plate is arranged in the diffusion tube, a gas releasing baffling sloping plate, a flow reducing baffling sloping plate and a water yielding baffling sloping plate are arranged in the sedimentation chamber, the sedimentation chamber is divided into a gas releasing region, a slow flow region and a water discharging region, the water discharging region is connected with a water discharging pipe, and an air hole is formed in the top of the sedimentation tank. The air lift type bio-nitrification reactor with the baffle plate reinforcing internal circulation has the advantages that mud, water and gas three-phase circulation in the reaction chamber can be reinforced, and oxygen utilization efficiency is improved; elution of sludge can be effectively avoided, and high biological sludge content in the reactor is maintained; and good impact load resistance and high nitrification performance can be realized.

Owner:CENT SOUTH UNIV

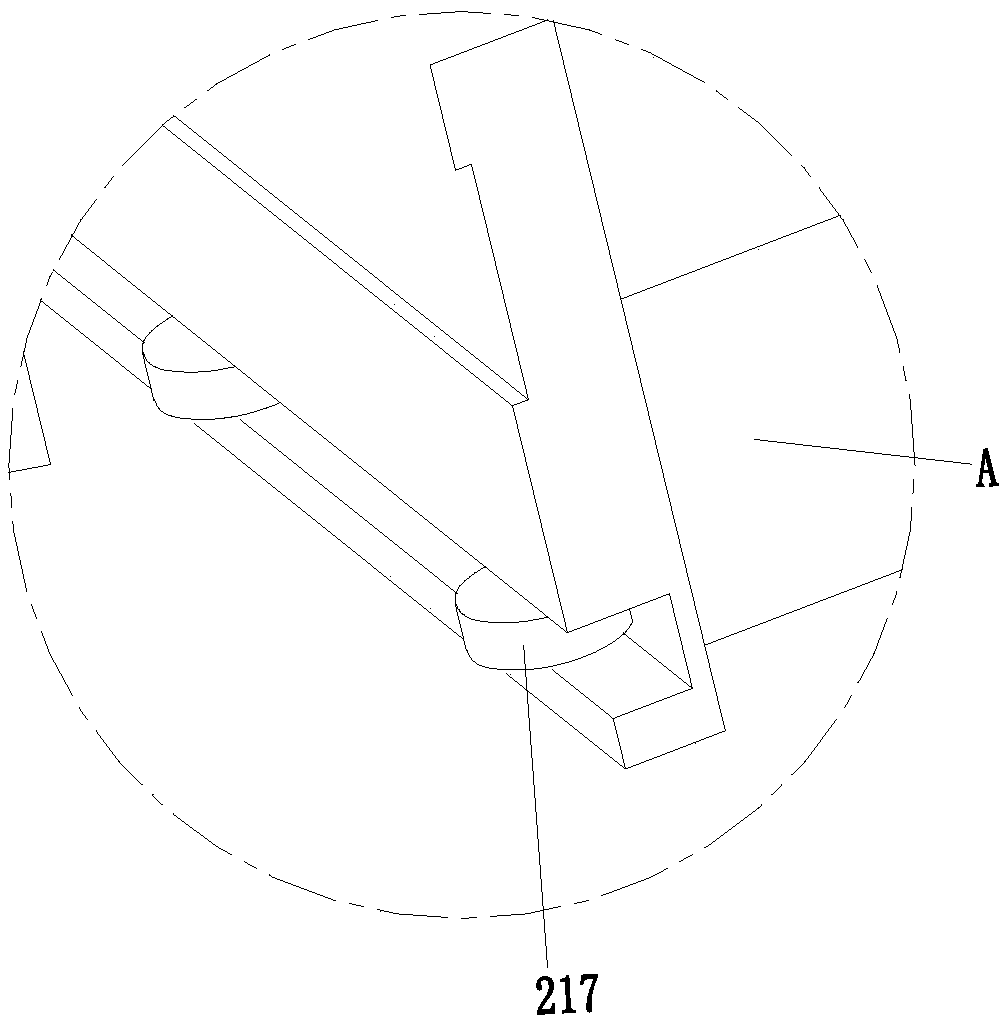

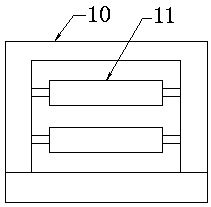

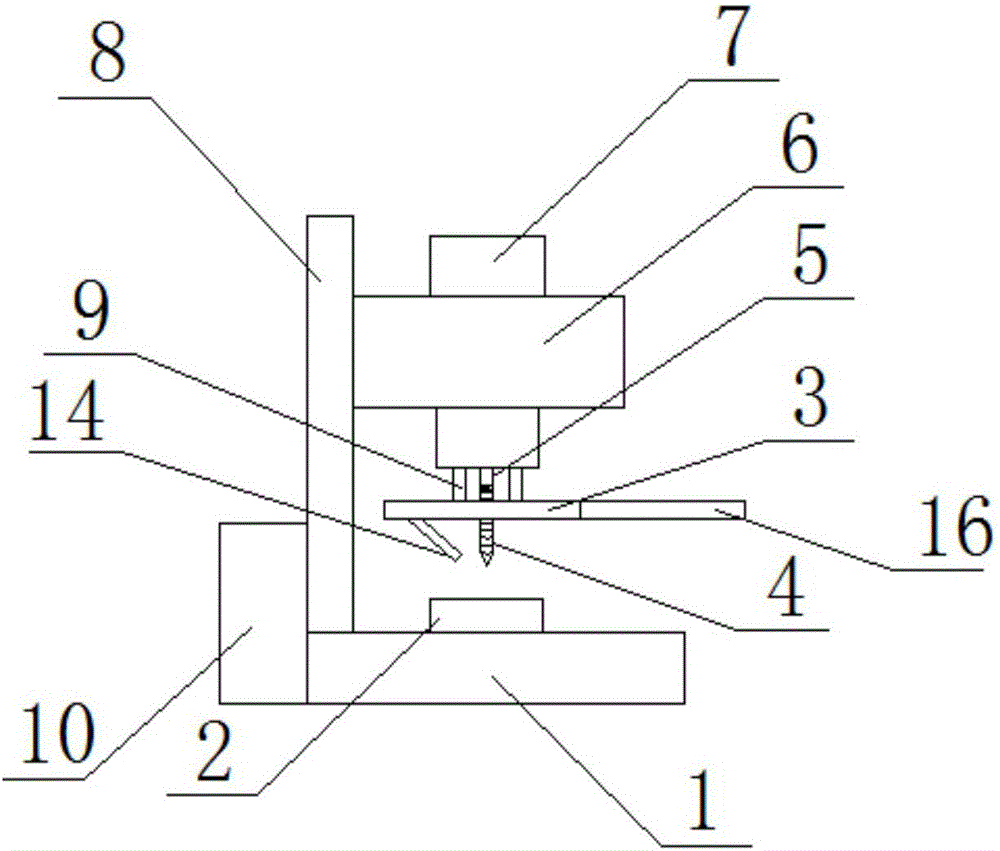

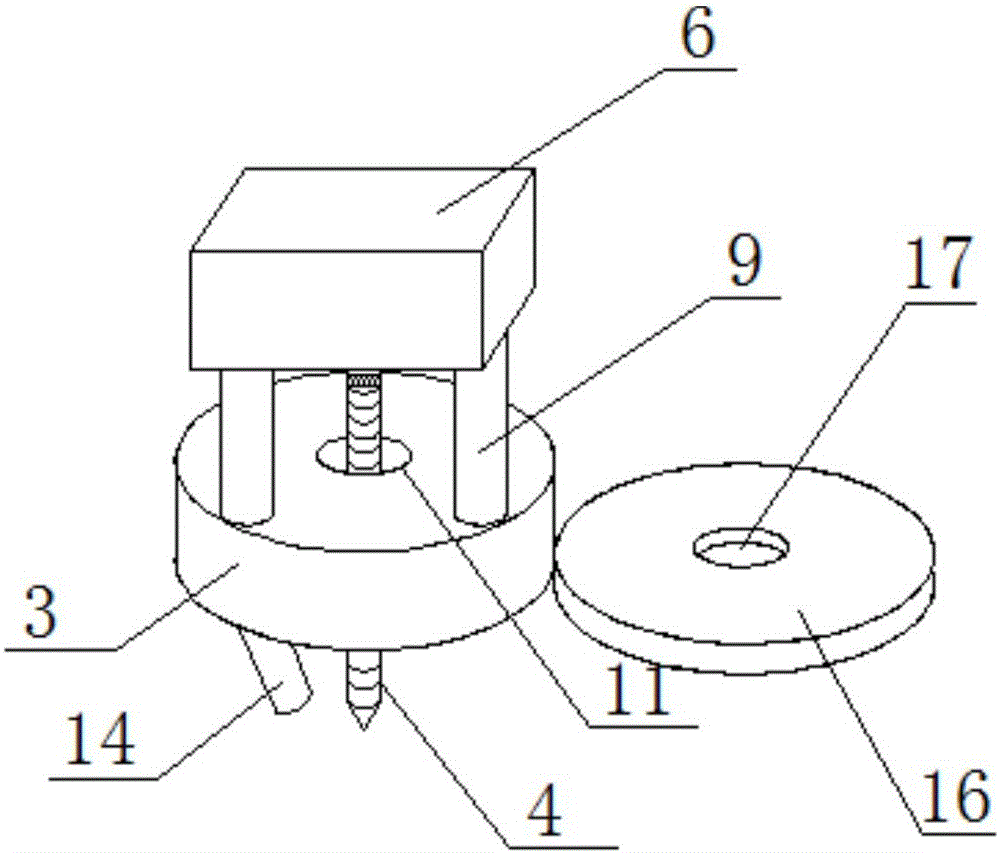

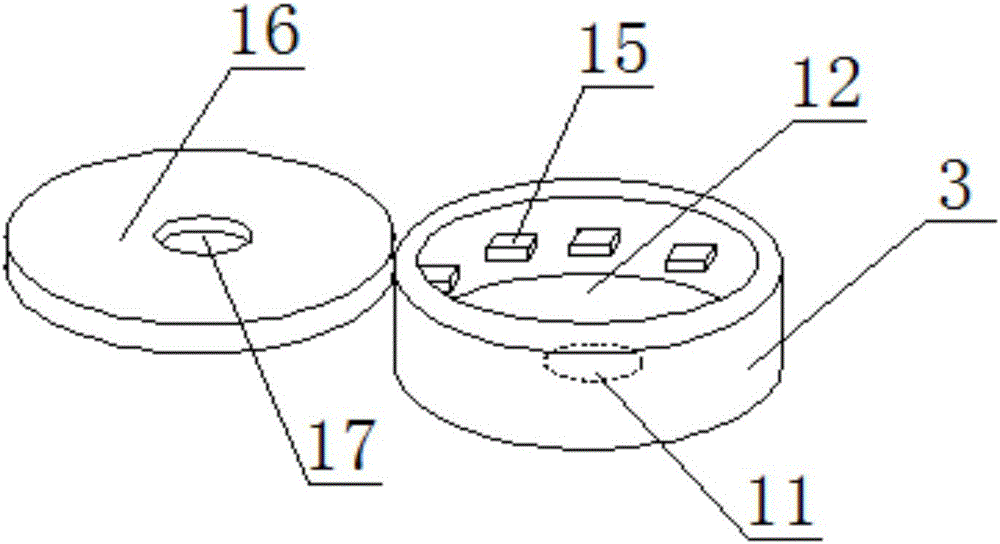

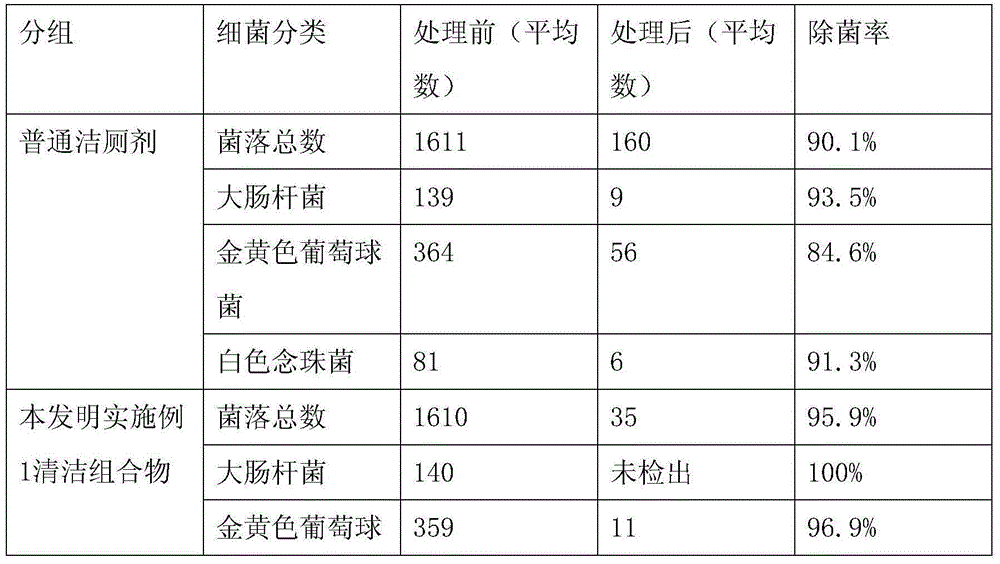

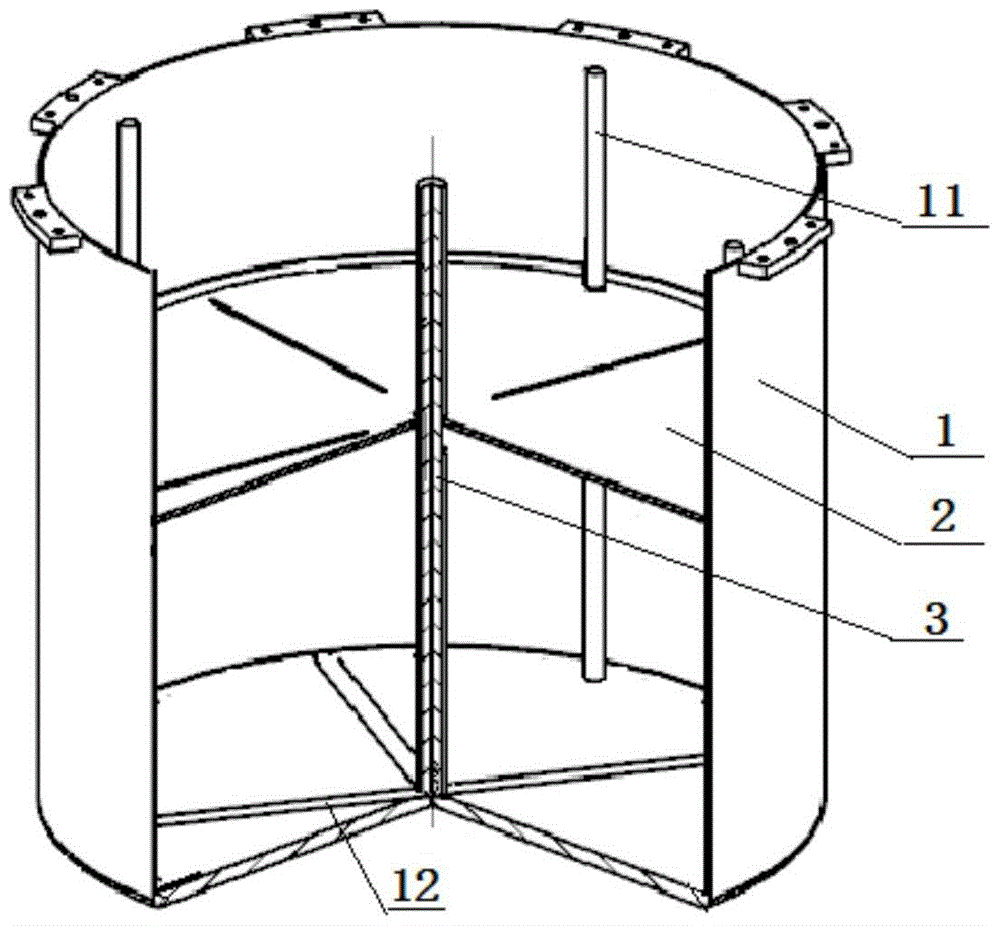

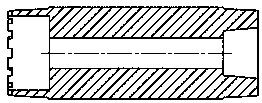

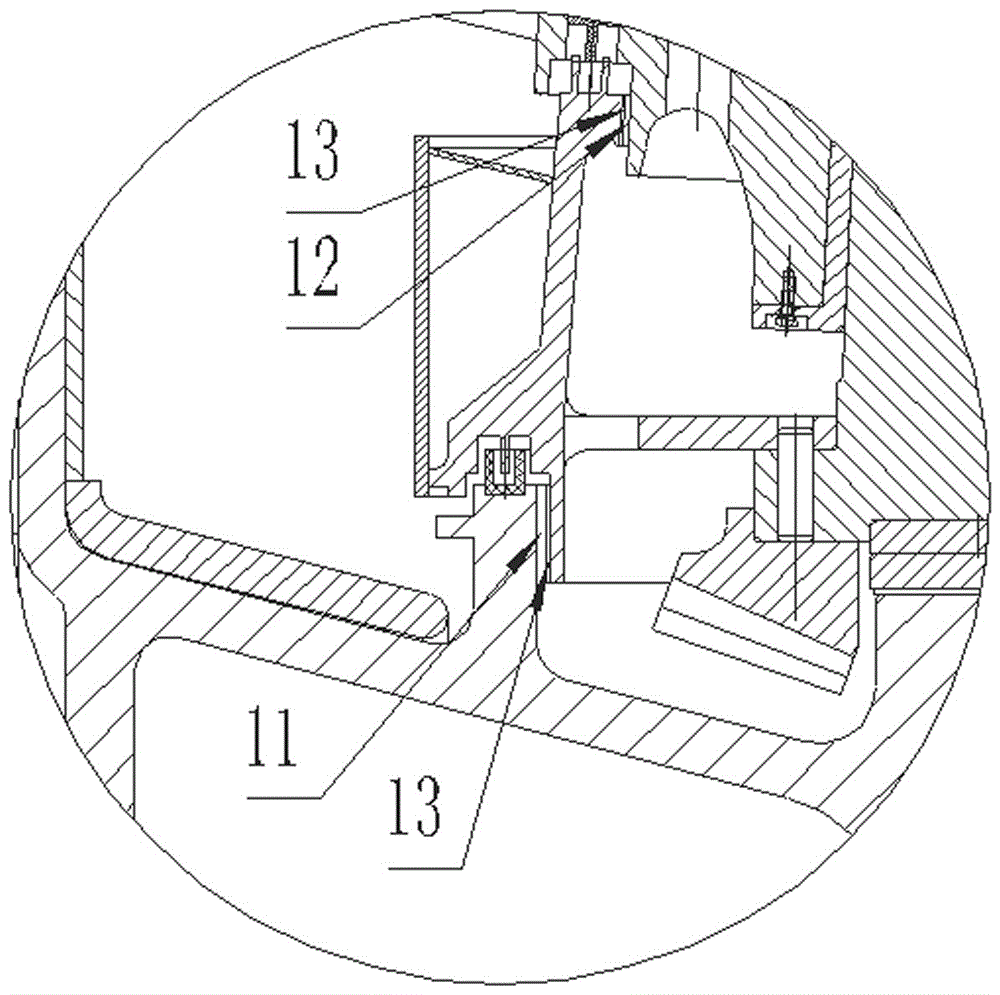

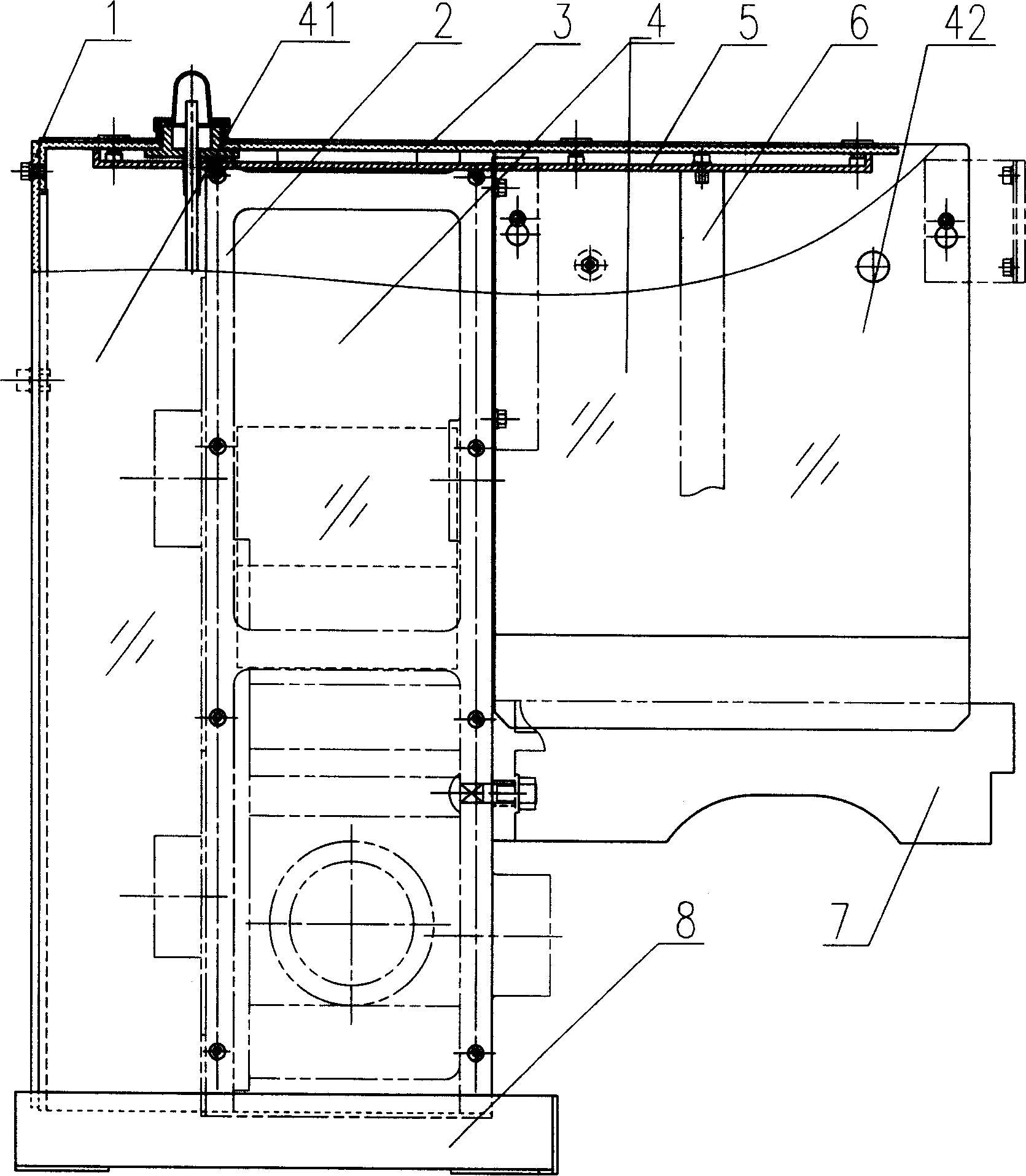

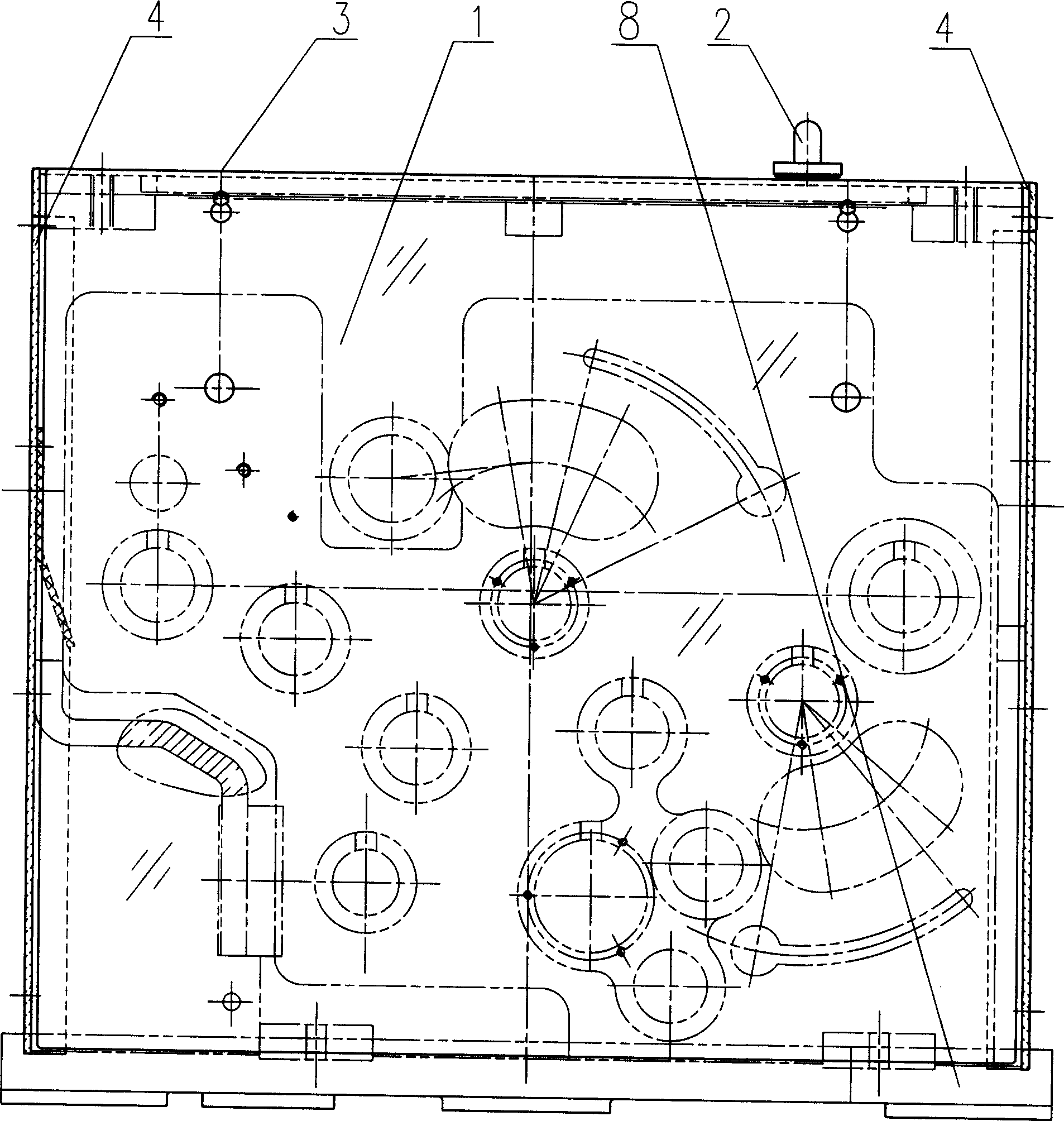

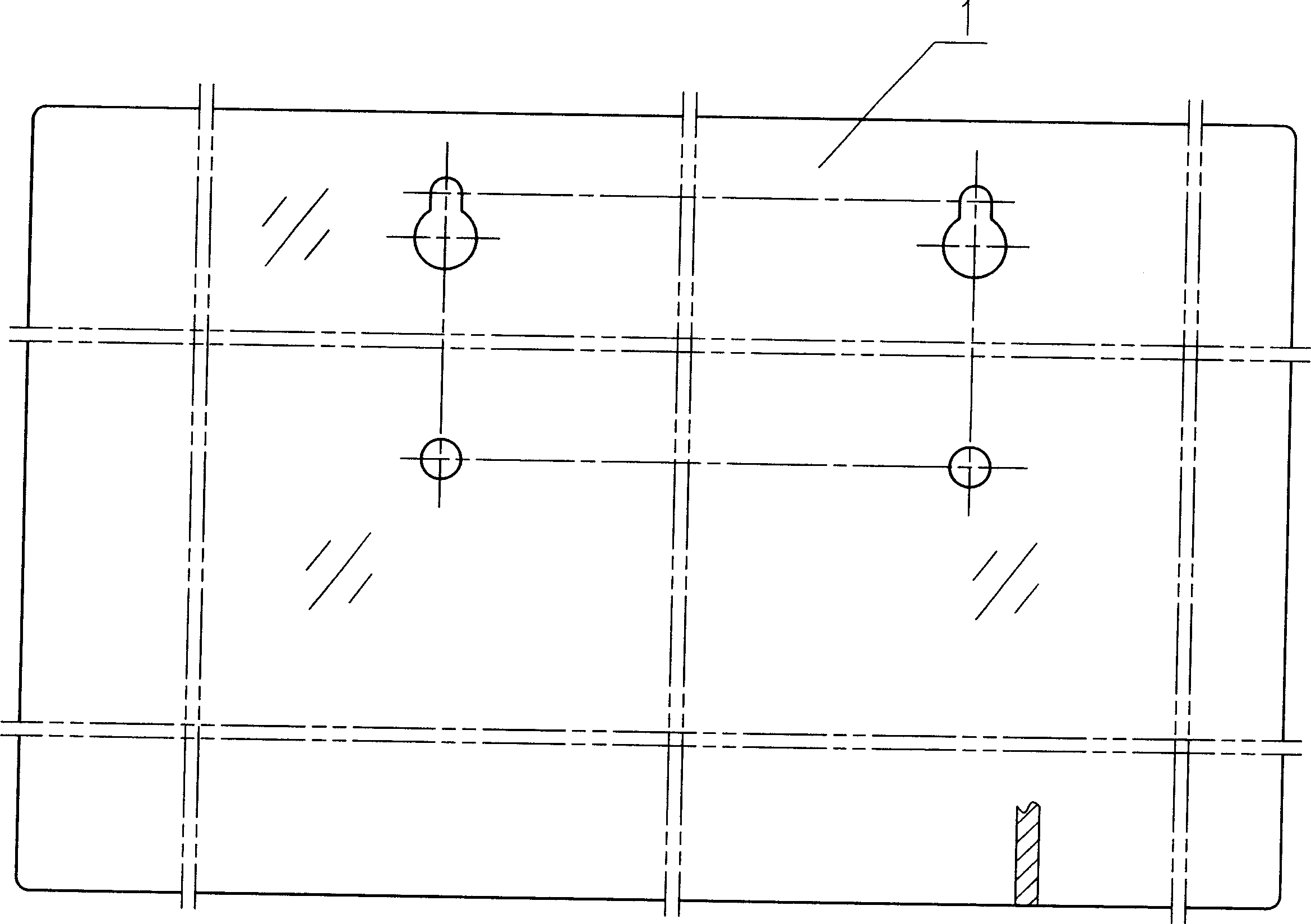

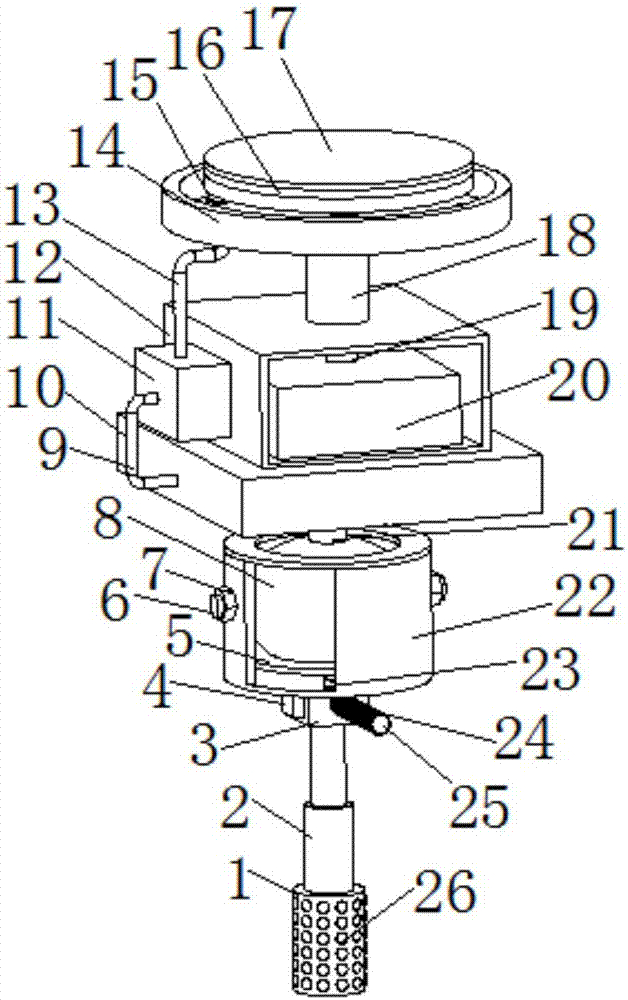

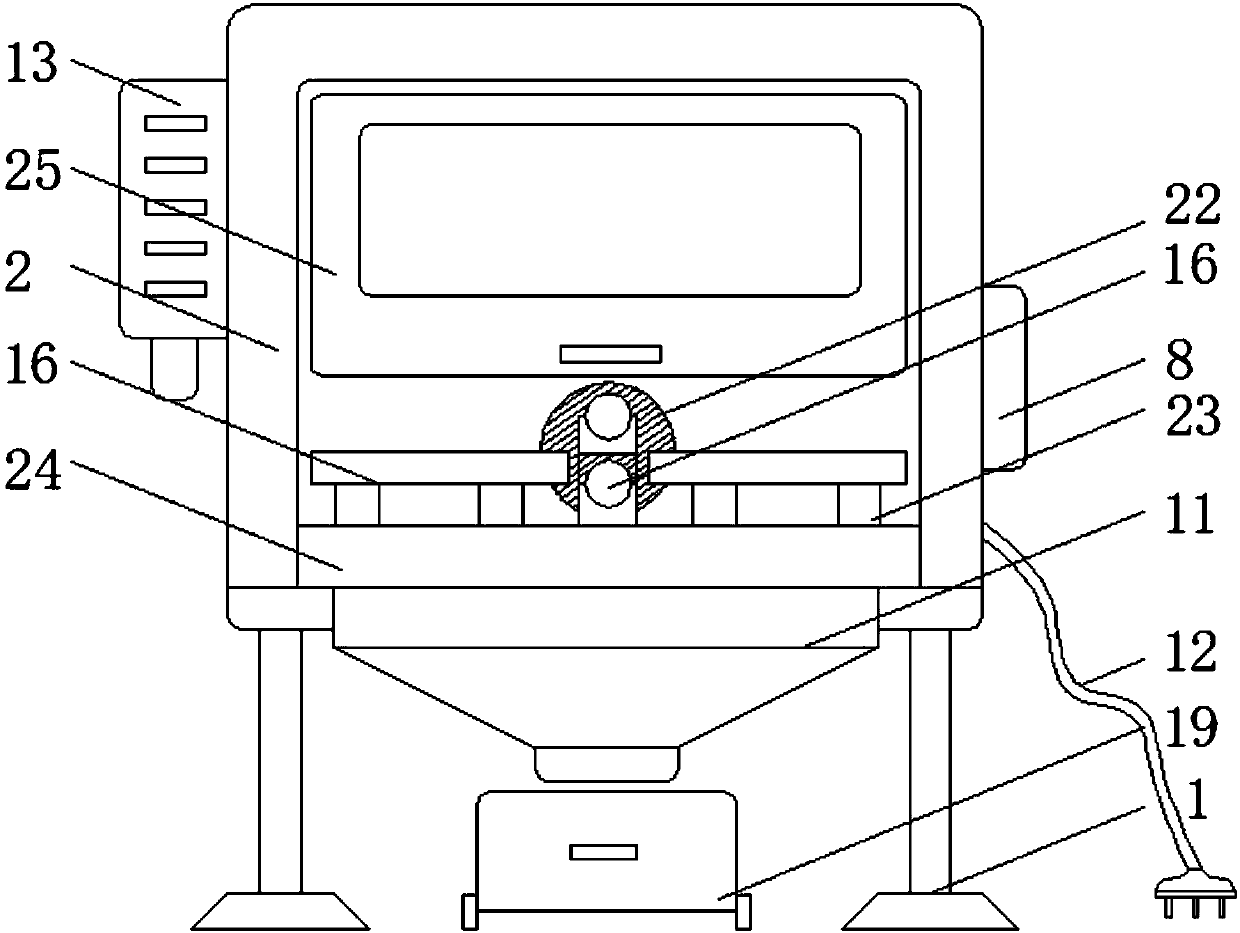

Drilling machine

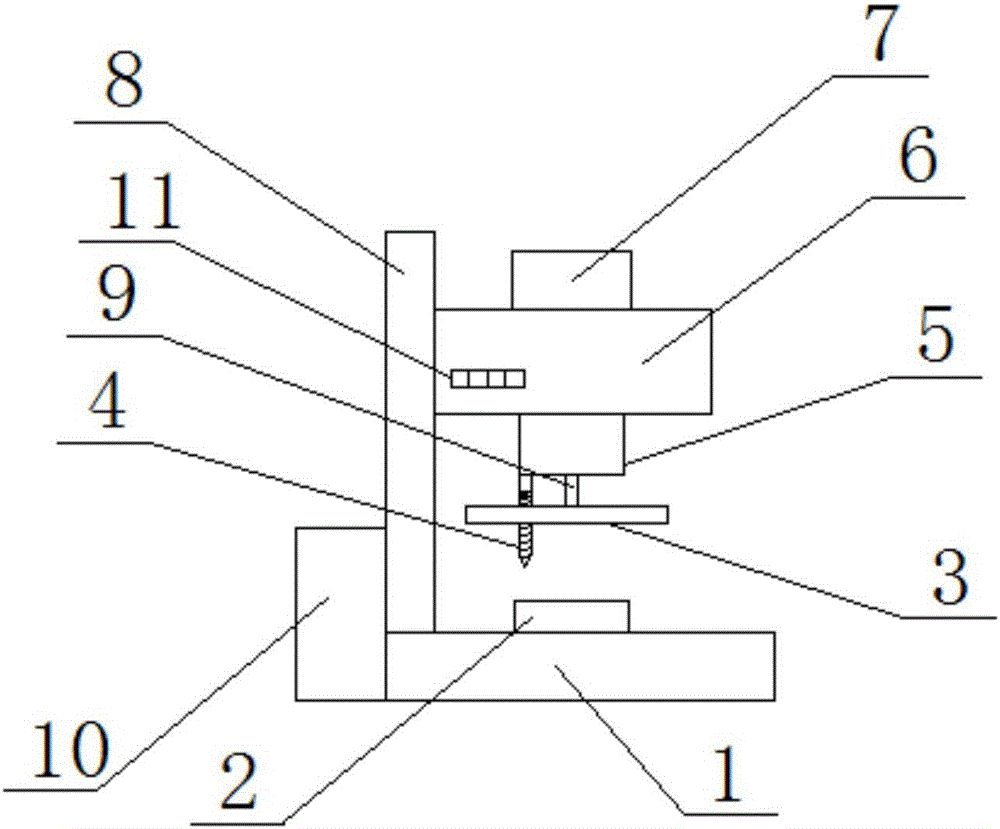

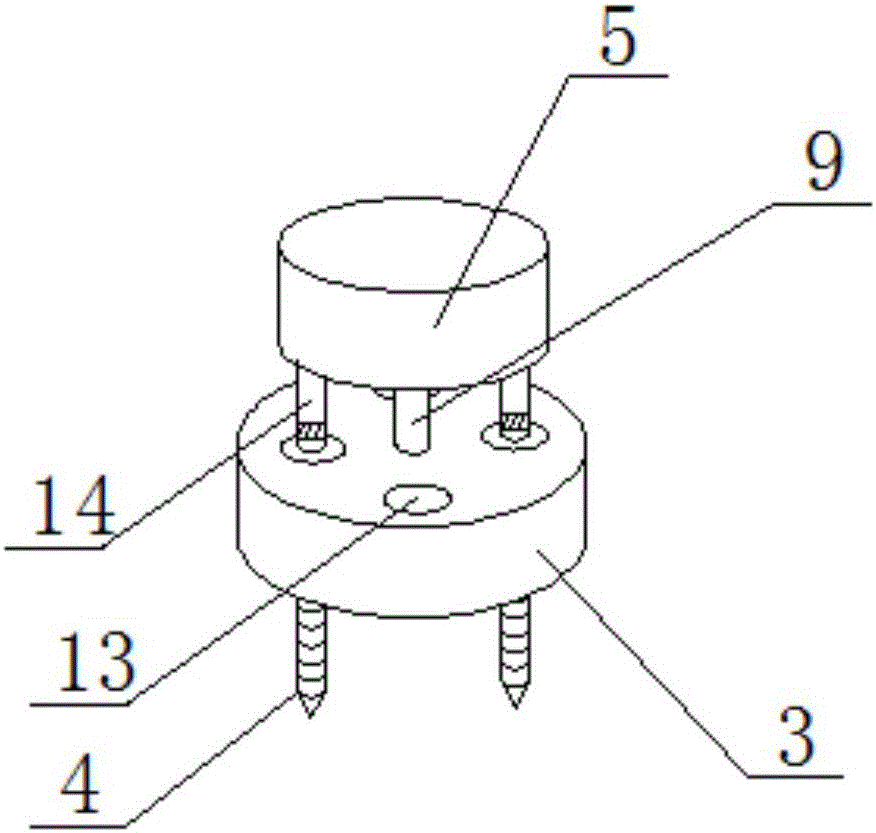

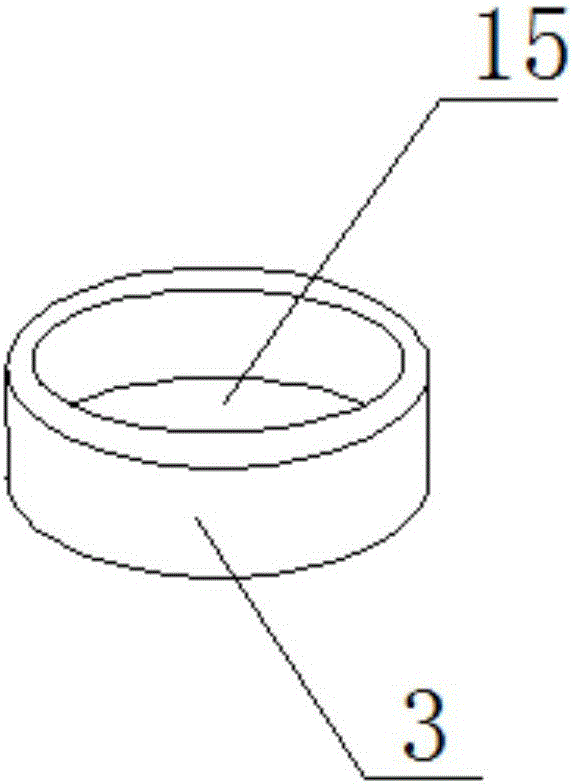

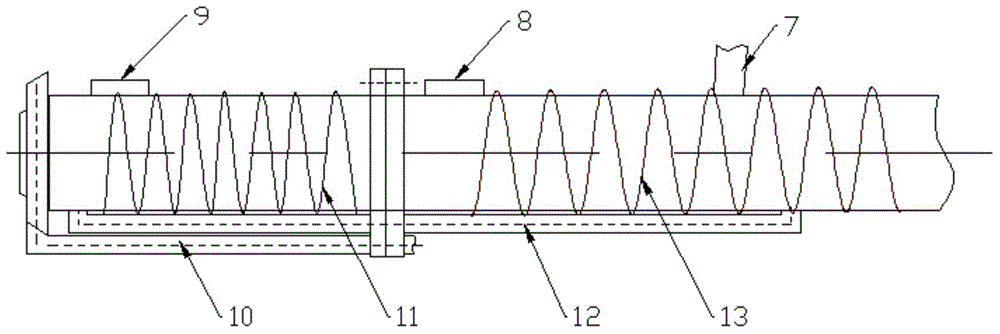

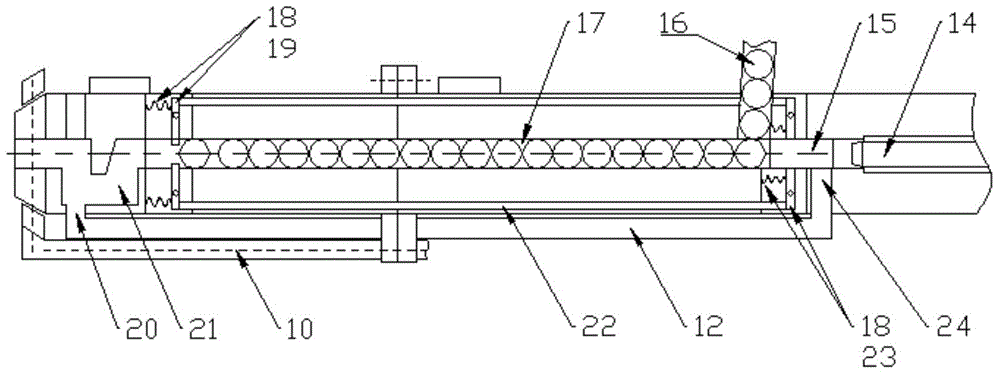

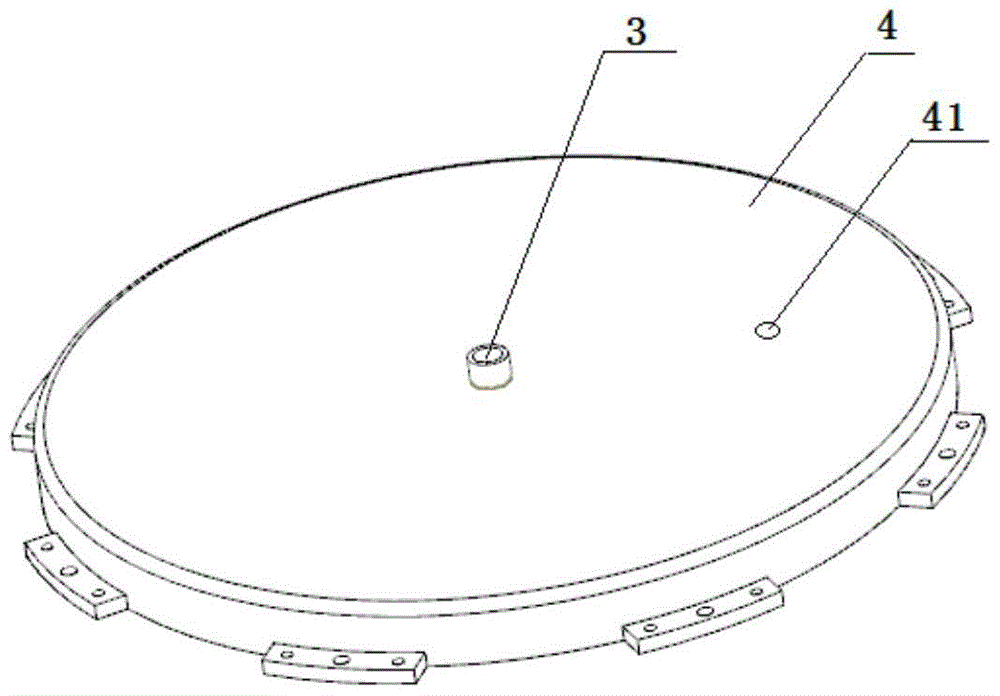

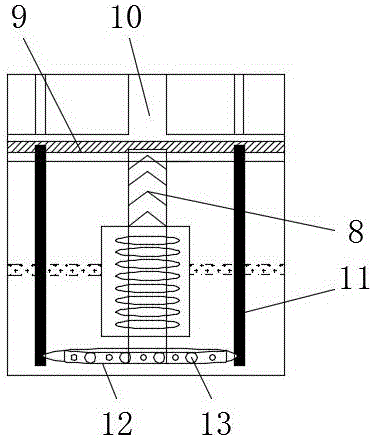

InactiveCN105855985AStop splashProtection securityMetal working apparatusMaintainance and safety accessoriesWorkbenchDrilling machines

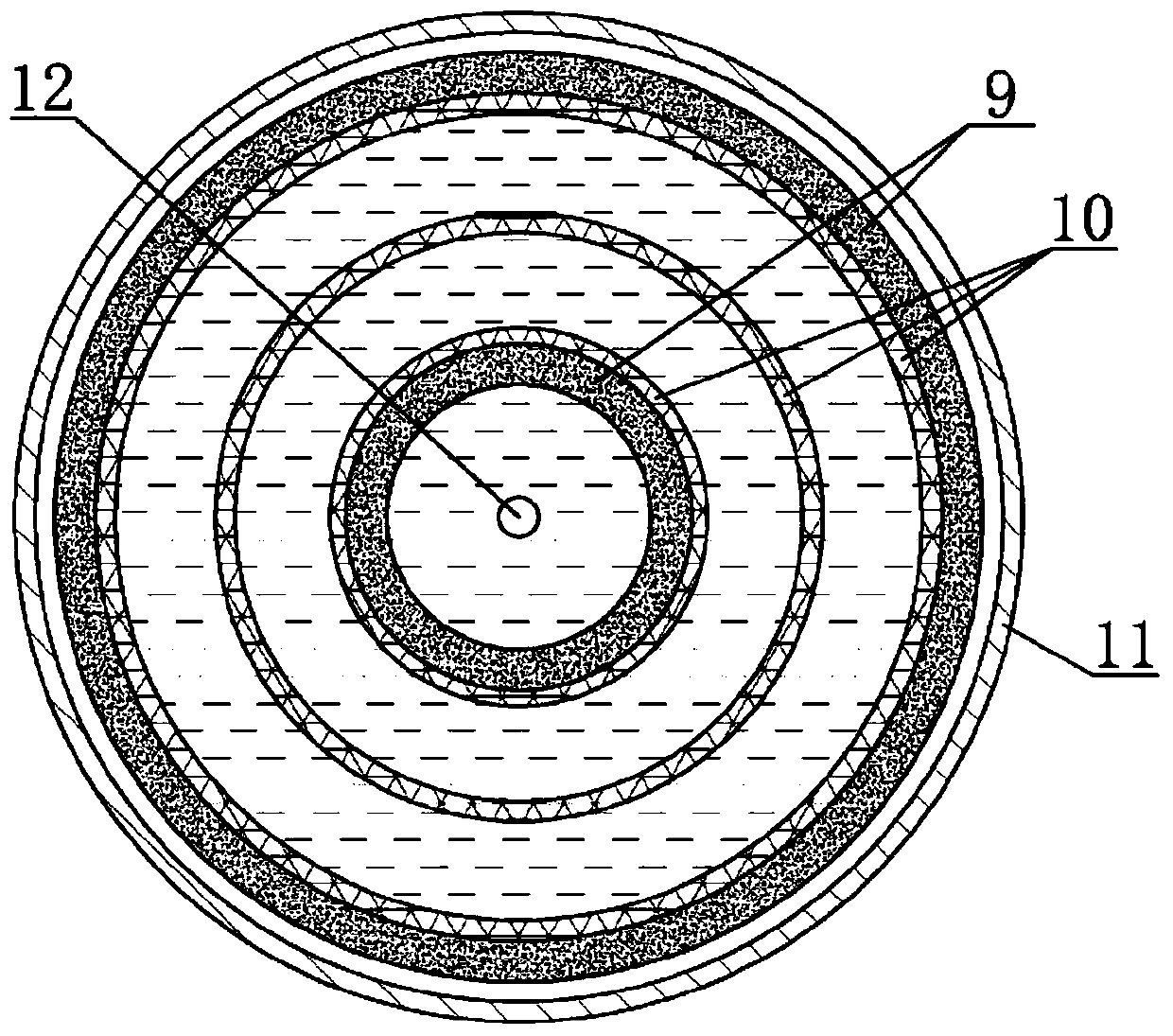

The invention discloses a drilling machine, comprising: a workbench (1), a drilling mechanism, a support rod (8), a telescopic rod (9) and a protective cover (3), and the support rod (8) is vertically arranged on the workbench ( 1) on the upper surface, the drilling mechanism is arranged on the support rod (8), and the drilling mechanism can slide along the length direction of the support rod (8), the telescopic rod (9) is vertically arranged, and the telescopic rod (9) One end is fixed on the lower surface of the drilling mechanism, the other end is connected with the upper surface of the protective cover (3), the lower surface of the protective cover (3) is recessed inwardly to form a cavity (12), and the upper surface of the protective cover (3) is vertically A first through hole (11) matched with the drilling mechanism is provided. The drilling machine overcomes the prior art. The drilling machine does not have a corresponding debris handling vertical structure, and the debris generated splashes around, which not only increases the cleaning workload of the user, but also has poor safety, which poses a threat to the safety of the user. Certainly threatening issues.

Owner:YINFENG CASTING WUHU CO LTD

Foam cleaning composition

InactiveCN105132201AStop splashPrevent spillageOrganic detergent compounding agentsSurface-active detergent compositionsCitrate sodiumFlavor

The invention provides a foam cleaning composition. The foam cleaning composition comprises anionic surfactant, nonionic surfactant, tea saponin, sodium alginate, sodium citrate, antibacterial preservative, perfume, sodium chloride and the like; the foam cleaning composition can further comprise one or more types of colorant. The foam cleaning composition is suitable for bedpan cleaning and has the advantages of being rapid in foaming, fine, smooth and rich in foam, long in duration and the like; meanwhile, the antibacterial deodorant is pure natural, and on one hand, the off-flavor can be removed; on the other hand, a good sterilization function is achieved, and the foam cleaning composition is harmless to human bodies and the environment.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

Double-deck anti-oscillation pesticide box for aerial spraying

InactiveCN105599902AStop shakingReduce reaction forceAircraft componentsInsect catchers and killersAviationThermal spraying

The invention provides a double-deck anti-oscillation pesticide box for aerial spraying. The double-deck anti-oscillation pesticide box comprises a box body, a box cover and at least two anti-oscillation plates, multiple guide posts are arranged on the bottom face of the box body, and the box cover is detachably sealed on the box body; each anti-oscillation plate is provided with multiple through holes and multiple radial gaps, and the through holes and the radial gaps are not in the same diameter direction; the anti-oscillation plates are installed on the guide posts through the through holes, the radial gaps of every two adjacent anti-oscillation plates are not overlapped in an up-and-down mode, and a gap exists between every two adjacent anti-oscillation plates; gaps exist between the anti-oscillation plates and the inner wall of the box body, the through holes are in clearance fit with the guide posts, and the anti-oscillation plate on the uppermost among the multiple anti-oscillation plates can float on the liquid level of pesticide liquid. When the pesticide box oscillates or inclines, it is guaranteed that the pesticide liquid does not oscillate or incline; duet to the fact that the center of gravity of the pesticide box containing the pesticide liquid is stable, the pesticide liquid is prevented from splashing and secondary inclining and oscillation, and influence of pesticide liquid inclining or oscillation on the balance of a plane is reduced; stable aerial spraying operation is guaranteed, the spraying quality and the utilization efficiency of the pesticide liquid are improved, pesticide liquid waste is reduced, and the environment is protected.

Owner:JIANGSU UNIV

Anti-tilting and anti-swaying medicine box for aerial spraying plant protection

InactiveCN105966799ASlump stopStop tiltLarge containersClosures with discharging deviceGravity centerEngineering

The invention provides an anti-tilting and anti-swaying medicine box for aerial spraying plant protection. The box comprises a box body, a box cover and an anti-tilting and anti-swaying plate, wherein multiple guide pillars are disposed on the bottom face of the box body; the density of the anti-tilting and anti-swaying plate is lower than the density of a medicine liquid; multiple through holes and radial gaps are formed in the anti-tilting and anti-swaying plate; the anti-titling and anti-swaying plate is installed on the guide pillars by the through holes; clearance exists between the anti-titling and anti-swaying plate and the inner wall of the box body; slide-guided clearance fitting is formed between the through holes and the guide pillars; and liquid outlets and air holes are formed in the box cover, and the box cover seals the box body in a dismountable manner. The anti-titling and anti-swaying plate floats on the surface of the medicine liquid, and the anti-tilting and anti-swaying plate can prevent the medicine liquid from swaying or tilting by reacting force of the guide pillars when the medicine liquid sways or tilts. In this way, the gravity center of the medicine liquid box can be kept steady; swaying of the medicine liquid can be weakened; splashing of the medicine liquid can be prevented; influences brought by tilting or swaying of the medicine liquid in the medicine box to aircraft balance can be reduced during aerial spraying operations; and quality and efficiency of the aerial spraying operations can be increased.

Owner:JIANGSU UNIV

Motor bearing polishing machine

PendingCN108436624AImprove polishing efficiencyHigh precisionGrinding carriagesPolishing machinesAutomatic controlCircular cone

The invention discloses a motor bearing polishing machine. The motor bearing polishing machine comprises seven stations of a material inlet mechanism, a circular conical surface polishing mechanism, along inner circular surface rough polishing mechanism, an outer circular surface polishing mechanism, a long inner circular surface fine polishing mechanism, a short inner circular surface polishingmechanism and a finished product collecting box which are arranged on a rack, industrial mechanical arms are arranged at positions between the seven stations correspondingly, wherein the right rears of the circular conical surface polishing mechanism, the long inner circular surface rough polishing mechanism, the long inner circular surface fine polishing mechanism and the short inner circular surface polishing mechanism are provided with clamping mechanisms correspondingly, and upper compressing mechanisms are arranged above the long inner circular surface rough polishing mechanism, the longinner circular surface fine polishing mechanism and the short inner circular surface polishing mechanism correspondingly. By means of the motor bearing polishing machine, full-automatic control is realized, seven working procedures of material inlet, circular conical surface polishing, long inner circular surface rough polishing, outer circular surface polishing, long inner circular surface fine polishing, short inner circular surface polishing and finished product collecting of motor bearings to be polished can be finished at a time, the polishing efficiency and precision are high, the quality is good, furthermore, the cost is low, and the labour strength is greatly lowered.

Owner:SUZHOU INST OF INDAL TECH

Drilling machine waste residue collecting device

PendingCN109396940AStop splashPrevent splashMaintainance and safety accessoriesCutting oilDrilling machines

The invention discloses a drilling machine waste residue collecting device which comprises a drilling machine, a material stopping cover, an oil liquid box and a drilling cutting box. The material stopping cover and a baffle prevent drilling cuttings from being splashed outwards, meanwhile, after the material stopping cover and the baffle are magnetized by an electromagnet, the drilling cuttings can be adsorbed, and the drilling cuttings are prevented from being splashed out due to rebounding; a cleaning mechanism is arranged, cleaning of a drilling machine work table and the drilling machineis facilitated, and residues of the drilling cuttings on the work table are reduced; and a vibration motor is arranged, so that the drilling cuttings and cutting oil are quickly separated, and recovery of the cutting oil is facilitated.

Owner:常德市艾锐科机电有限公司

Copper-based electric contact composite material for low-voltage electrical apparatus and warm compaction technology thereof

InactiveCN104103434ASimple manufacturing processImprove welding resistanceContactsLow voltageRare earth

The invention relates to a copper-based electric contact composite material and particularly relates to a method of manufacturing the copper-based electric contact composite material by adopting the warm compaction technology. the copper-based electric contact composite material of the invention is composed of the following materials proportioned by weight: 0.5 to 4% of bismuth, 0.5 to 4% of tungsten carbide, 0.05 to 0.8% of lanthanum-enriched mixed rare earth, 0.02 to 1% of zinc stearate, and the rest of copper and other unavoidable impurities. The material of the invention is manufactured in the method of mixing, powder warm compaction, presintering under the protection of inert gas and sintering under protection of vacuum or nitrogen. The copper serves as the base, resources of the main raw materials are rich, electricity conductivity performance and heat conductivity performance, fusion welding resistance, arc ablation resistance and friction resistance of the material can be comparable with a silver base, basic requirements of en elastic contact and other parts on the material can be met, and outstanding arc ablation resistance performance, good oxidation resistance performance, excellent self-lubrication performance and wear resistance performance are provided.

Owner:UNIV OF JINAN

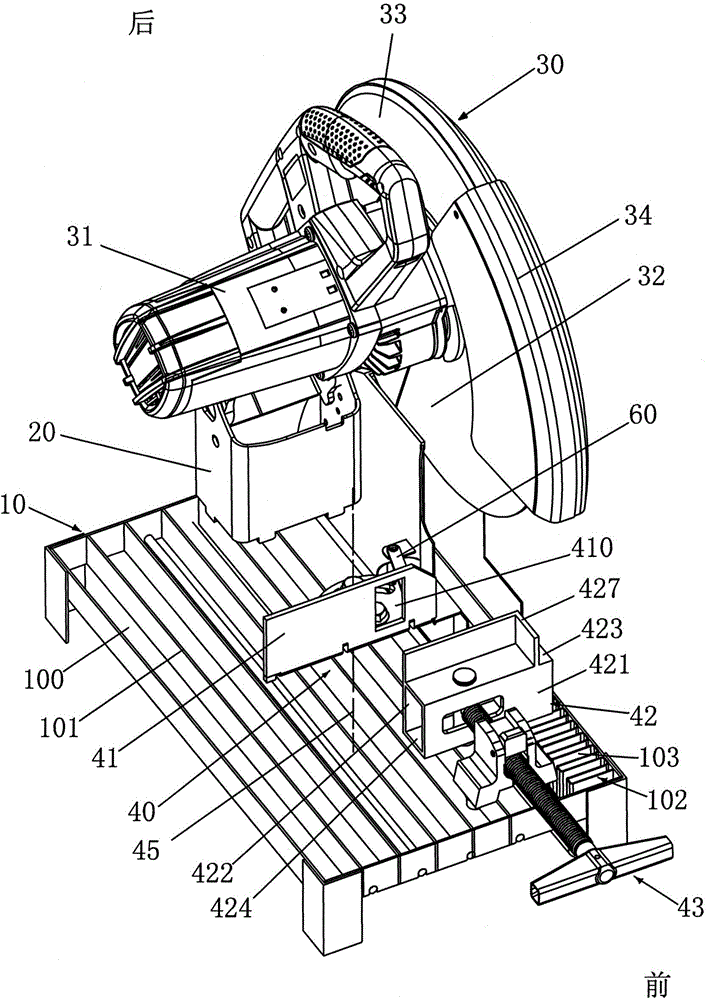

Metal cutting machine

ActiveCN104416224AReduce harmImprove comfort and safetyMetal sawing devicesMetal sawing accessoriesEngineeringKnife blades

The invention relates to a metal cutting machine. The metal cutting machine comprises a base, a support arm, a cutting head, a clamping device and a spark catcher component, wherein the support arm is fixedly mounted on the base, the cutting head is pivotally connected with the support arm, the clamping device is mounted on the base and comprises a first clamping part close to the support arm and a second clamping part distant from the support arm, and the spark catcher component comprises a first side wall. The first side wall extends backwards from the first clamping part along the direction basically parallel to the plane where a blade is located, the second side wall is opposite to the first side wall, and a gap is formed between the first and second side walls. During cutting, at least a part of blade enters the gap, and the third side wall is connected with the rear end of at least one of the first side wall and the second side wall, so that the rear of the spark catcher component is closed, and the front and the upper of the spark catcher component are at least partially opened. By the spark catcher component of the metal cutting machine, sparks generated during cutting are effectively controlled and splashing of the sparks is avoided.

Owner:NANJING CHERVON IND

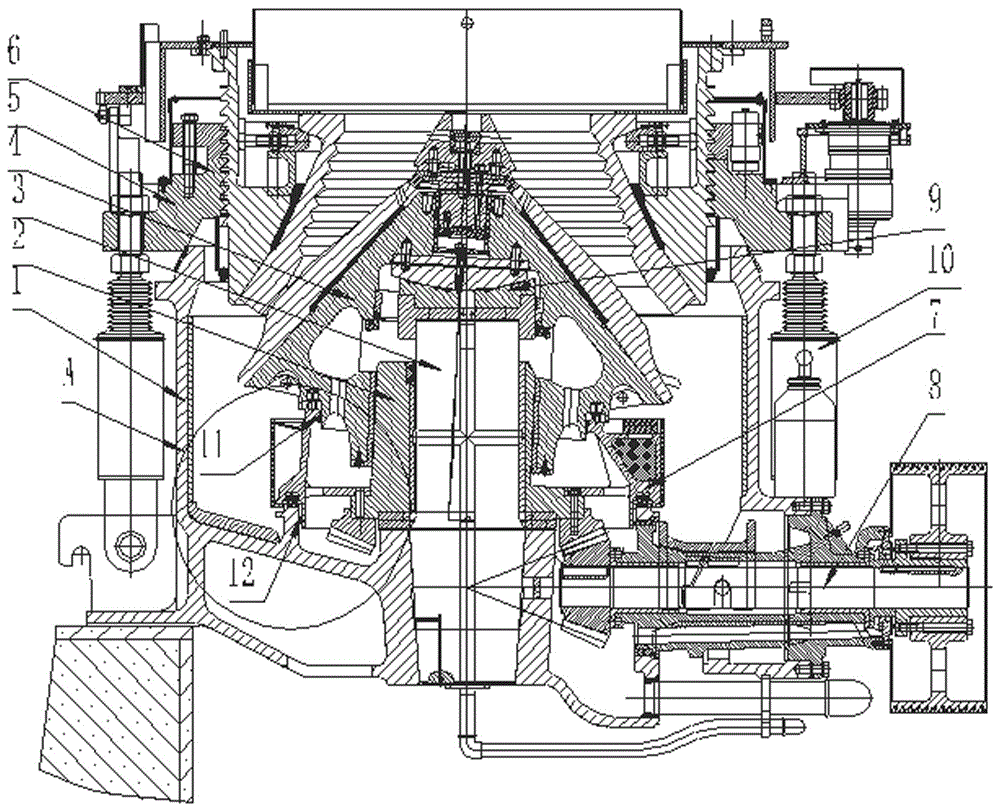

Novel thread-sealed multi-cylinder hydraulic circular cone machine

ActiveCN106140372AStop splashThe effect of pressing oil is idealGrain treatmentsHydraulic cylinderCircular cone

A novel thread-sealed multi-cylinder hydraulic circular cone machine comprises a machine frame used for providing an installation foundation, an eccentric bushing connected to a main shaft in a sleeving manner, a body, a bearing sleeve, an adjustment sleeve and a balance ring. The main shaft is used for positioning rotation of the eccentric bushing. The outer circle axis of the eccentric bushing and the axis of the main shaft are staggered to achieve eccentricity and form an intersection angle. The body is borne on a bowl-shaped bearing. The lower portion of the body is connected to the periphery of the eccentric bushing in a sleeving manner. The bearing sleeve is borne on the machine frame. The adjustment sleeve is connected with the bearing sleeve through a thread. The bowl-shaped bearing is installed in a bowl-shaped bearing frame fixed to the main shaft. The lower portion of a safety hydraulic cylinder is hinged to the machine frame. A piston rod is fixed to the bearing sleeve. The balance ring is installed on the eccentric bushing and provides the balance weight for the eccentric bushing, and vibration is reduced. A first seam is formed between the balance ring and the machine frame. A second seam is formed between the balance ring and the body. A thread is arranged at the position, corresponding to the first seam, on the balance ring, and a thread is arranged at the position, corresponding to the second seam, on the balance ring.

Owner:广东磊蒙重型机械制造有限公司

Mill base barrel cleaning device

InactiveCN107470302AIncrease frictionEasy to cleanHollow article cleaningArchitectural engineeringEngineering

The invention provides a mill base barrel cleaning device. The mill base barrel cleaning device comprises a conveyer belt, a recycling tank, a protective cover, a cleaning assembly, a sand supplying assembly and a cleaning agent supplying assembly. A plurality of locating frames fixing the mill base barrels are fixedly arranged on the conveyer belt. The recycling tank is located under the conveyer belt. A stand column is vertically and fixedly arranged in the middle of the recycling tank. The upper end of the stand column is sleeved with an installation plate vertically sliding along the stand column. The installation plate is driven by a lifting air cylinder fixed to the stand column. The cleaning assembly is fixed to the installation plate and comprises a motor fixed to the installation plate and a brush head connected to the lower end of a motor output shaft. The side portion of the protective cover is connected with a protective rod. The protective rod is fixed to the stand column through a bolt. The side wall of the protective cover is provided with a locating frame and a window which a mill base barrel can pass through. A closing door capable of swinging is hinged to the window. The upper end face of the protective cover is provided with a scuttle allowing the motor output shaft and the brush head to extend out. The brush head drives sand and a cleaning agent, dirt attached to the inner wall of the mill base barrel can be scrapped off, and the cleaning effect is good.

Owner:临海市天马装璜材料厂

Visible cover on spinning frame heed

The invention discloses a visible cover on spinning frame head of ring throstle, arranging a transparent side cover plates on each of the two sides of an engine frame, arranging a transparent end cover plate on the end surface of the engine frame, arranging a transparent top cover plate over the engine frame, where the outer edges of the transparent top cover plate are joined with the transparent side cover plates and end cover plate. The mentioned cover plates are all made of transparent materials. Thus, the intruding of flying cotton and floating dust and the splashing and overflowing of lubricant are prevented effectively and it is able to extremely observe the running and lubricating situation of engine driving equipment, effectively ensuring the smooth running and good lubricating of engine driving system of a spinner.

Owner:DONGFEI MAZUOLI TEXTILE MACHINERY

Anti-splashing concrete pump screening device

InactiveCN106368433AImprove liquidityImprove work efficiencySievingScreeningColloidal particleWaste material

The invention discloses an anti-splashing concrete pump screening device which comprises a stirring bin, a U-shaped guardrail, a guardrail left joining rod, protruded colloidal particles, a screen cloth and a cover plate. The U-shaped guardrail is installed in the stirring bin, the guardrail left joining rod is installed at the left end of the U-shaped guardrail, a waste material outlet is installed on the left of the guardrail left joining rod, the upper portion of the stirring bin is provided with a baffle, a feeding port is disposed in the stirring bin, a motor is installed on the right side of the stirring bin, a movable telescopic rod penetrates into the motor, the upper end of the movable telescopic rod is connected with a guardrail right joining rod, fixed collision plates are installed on the left side and the right side of the guardrail right joining rod, the lower end of the movable telescopic rod is connected with a rotating disc, the protruded colloidal particles are installed on the outer surface of the rotating disc, and the cover plate is installed on the outer surface of the front end of the stirring bin. According to the anti-splashing concrete pump screening device, the U-shaped guardrail recessed in a hopper is adopted to screen concrete, and the splashing of materials can be avoided during feeding.

Owner:陈素红

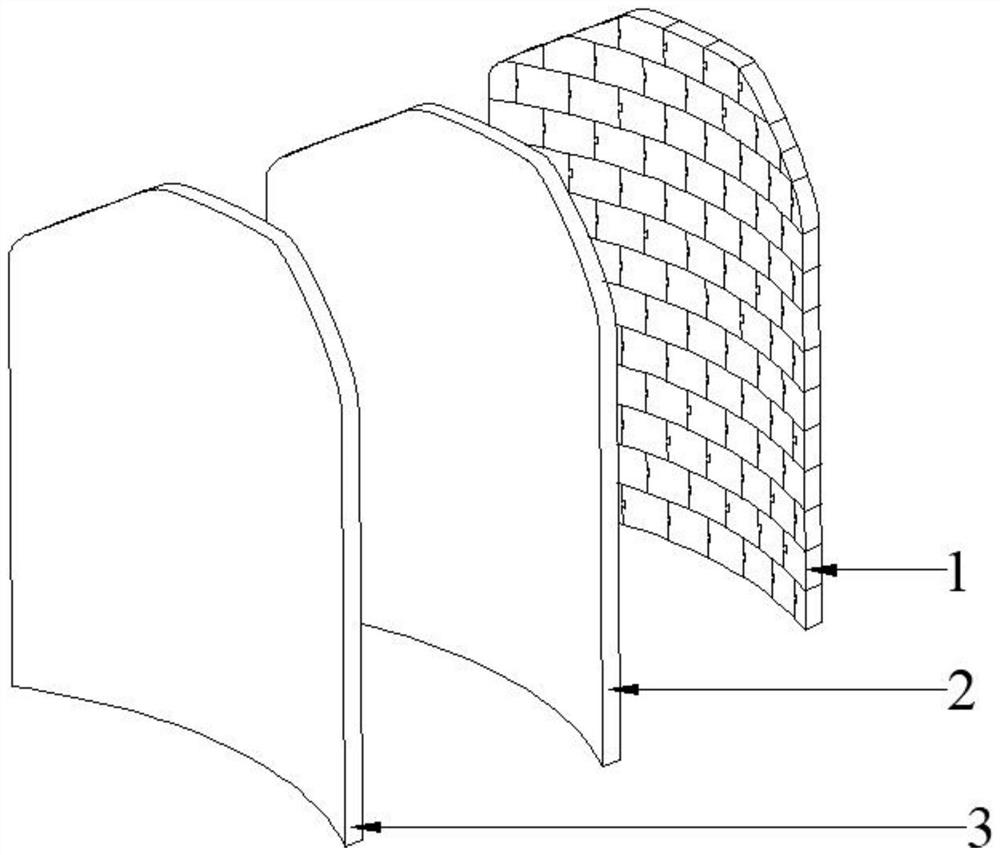

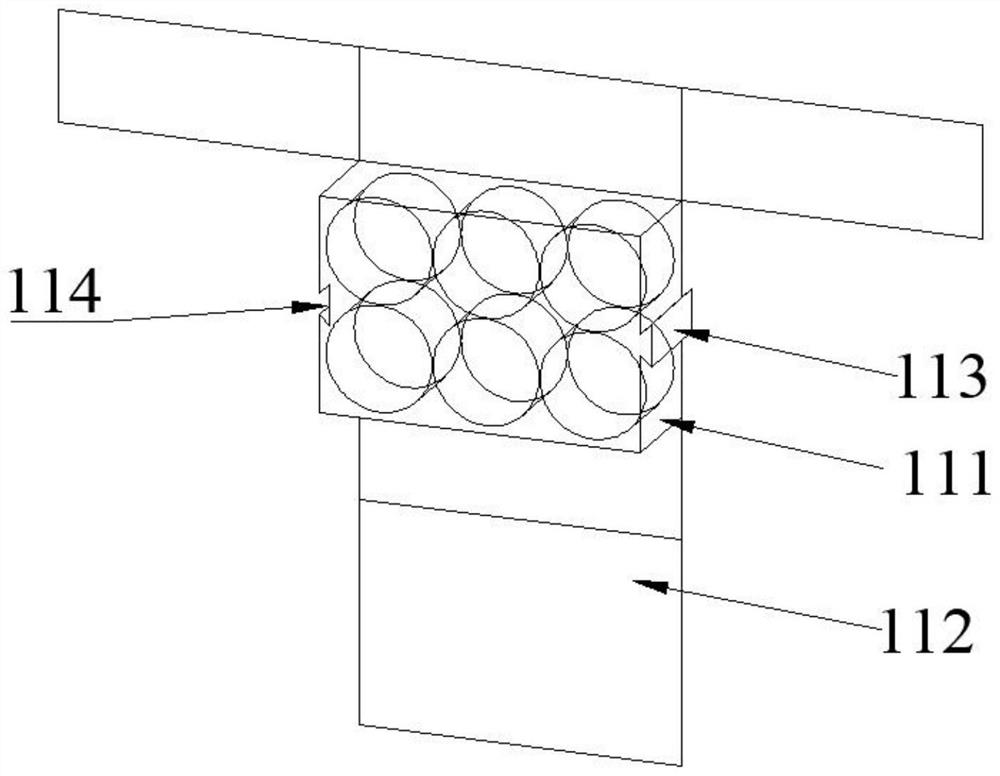

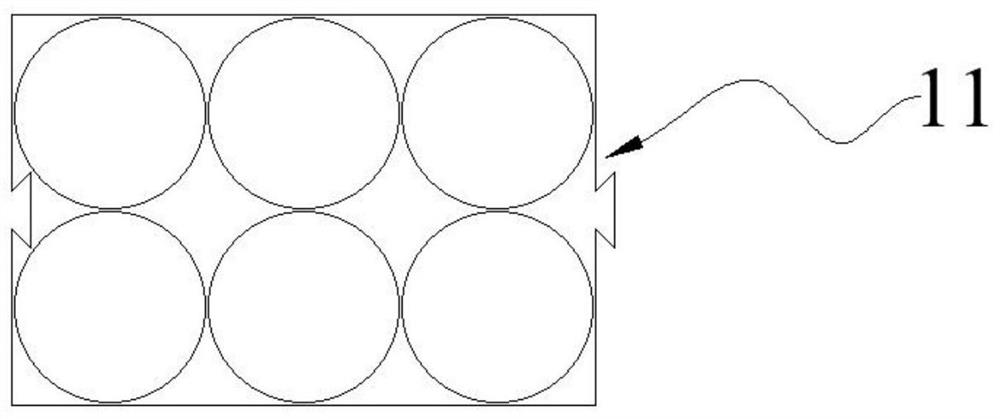

Multi-bullet-resistant light-weight bionic bulletproof flashboard and manufacturing method thereof

InactiveCN114087924AImprove the impact resistance of multiple bulletsReduce impactLayered productsReactive armourEnergy absorptionPlugboard

The invention relates to a multi-bullet-resistant light-weight bionic bulletproof flashboard and a manufacturing method thereof. The light-weight bionic bulletproof flashboard comprises a bionic main bulletproof layer, a buffer energy absorption layer and an inner layer. The bionic main bulletproof layer comprises a hard ceramic panel, the hard ceramic panel comprises a plurality of packaging ceramic units which are closely arranged in a determinant mode, and each packaging ceramic unit comprises a blocky rubber ceramic column structure and wrapping cloth wrapping the rubber ceramic column structure. The rubber ceramic column structure comprises a plurality of ceramic columns which are closely arranged in rows and columns and rubber bodies filled among the ceramic columns. The buffer energy absorption layer is stacked between the bionic main bulletproof layer and the inner layer. By referring to a biological structure, the bulletproof plugboard is designed into a rigid-flex three-layer structure, and the bionic main bulletproof layer is designed into an orderly-arranged hierarchical structure, so that the problem that an existing bulletproof plugboard is insufficient in capacity of resisting multiple bullets is effectively solved, and the bulletproof plugboard is convenient to repair and beneficial to secondary utilization.

Owner:JILIN UNIV

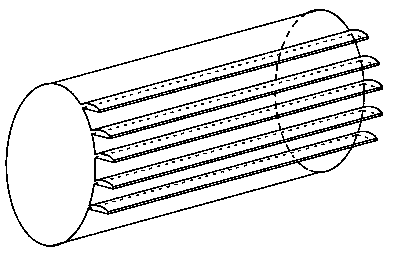

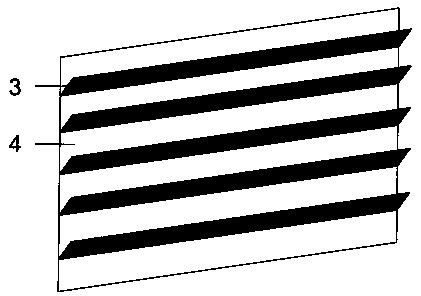

Blade type overflowed oil recovery oil containment boom

PendingCN109322292AReduce oil thicknessOvercome floatingWater cleaningGeneral water supply conservationSurface structurePetroleum engineering

The invention relates to the field of marine overflowed oil recovering, and particularly discloses a blade type overflowed oil recovery oil containment boom. The oil containment boom is an inflatabletype oil containment boom and comprises three parts including a floating body, a skirt body and a weight body. The two sides of the floating body are each provided with a downward curved surface structure; the two faces of the skirt body are each provided with a plurality of rows of upward flat blades; and the weight body has a certain weight and is connected with the lower portion of the skirt body. The blade type overflowed oil recovery oil containment boom is convenient to fold and store, easy to put, simple in structure and high in overflowed oil recovery efficiency, and can effectively prevent or reduce oil from overflowing out from the position below the oil containment boom.

Owner:SOUTHWEST PETROLEUM UNIV

Multi-angle polishing machine

InactiveCN107309755ASimple structureEasy to operateGrinding machine componentsPortable grinding machinesPulp and paper industryControl switch

The invention discloses a multi-angle polishing machine comprising a handle. The top end of the handle is provided with a telescopic rod. A supporting block is arranged at the telescopic end of the telescopic rod. The left side face of the supporting block is provided with a control switch. A hand shank is arranged on the front side face of the supporting block. The upper surface of the supporting block is provided with a steering box. A steering ball is arranged in the steering box. The surface, protruding out of the steering box, of the steering ball is provided with a supporting column. A storage box is arranged at the top end of the supporting column. The upper surface of the storage box is provided with a motor box. The upper surface of the motor box is provided with a fixing cylinder. The multi-angle polishing machine is simple in structure and convenient to operate. Waste chips can be effectively prevented from splashing during polishing through a suction storage groove. Powder and the waste chips generated during polishing are collected through a dust collection machine. Workers can be effectively protected. The angle of the polishing machine can be easily adjusted through the steering box. Through cooperation between the handle and the hand shank, the polishing machine is convenient to carry, and use is easier. Through a replaceable polishing head, cost is reduced, and therefore the work efficiency is further improved.

Owner:SUZHOU BIAOGAN INTPROP OPERATION CO LTD

Cylindrical metal tube polishing device for mechanical equipment

InactiveCN107891352AEasy to placeEasy to unloadPolishing machinesGrinding work supportsArchitectural engineeringMechanical equipment

The invention discloses a metal circular tube polishing device for mechanical equipment, which comprises a casing, a polishing roller and a pillar, a casing is installed above the pillar, a fixing seat is installed inside the casing, and the surface of the fixing seat is An electric guide rail is provided, and the surface of the mounting base is uniformly equipped with a bearing rod through a bearing. A second mounting frame is installed below the telescopic rod, a second motor is installed above the second mounting frame through bolts, a polishing roller is installed below the second mounting frame through bearings, and one side of the housing is installed There is a purifier, and a workbench is installed at one end of the housing, and a polishing disk is installed on the surface of the housing above the workbench. The invention has scientific and reasonable design, simple structure, low cost, economical and practical, easy operation and maintenance, and broad market prospect.

Owner:安吉金麟机械股份有限公司

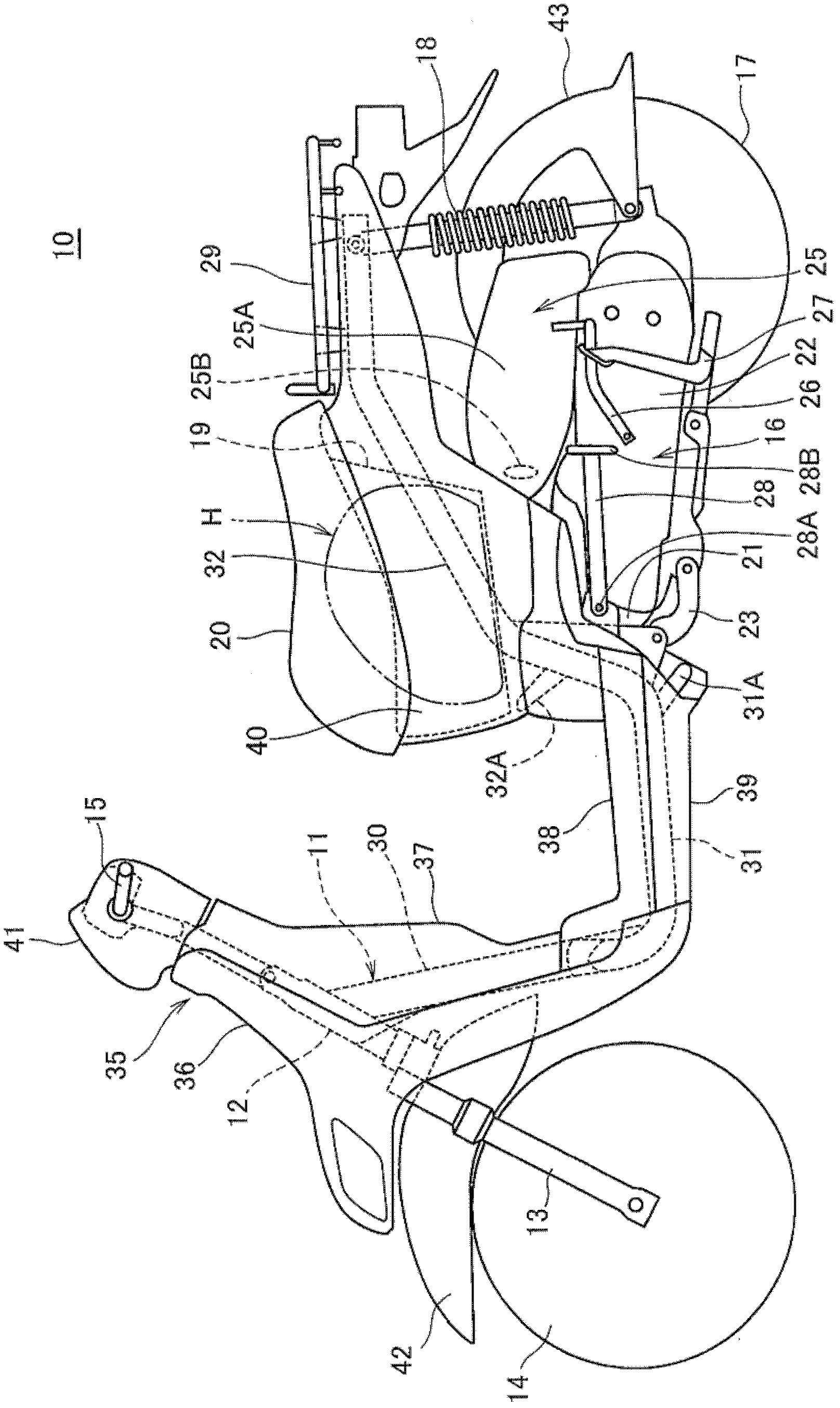

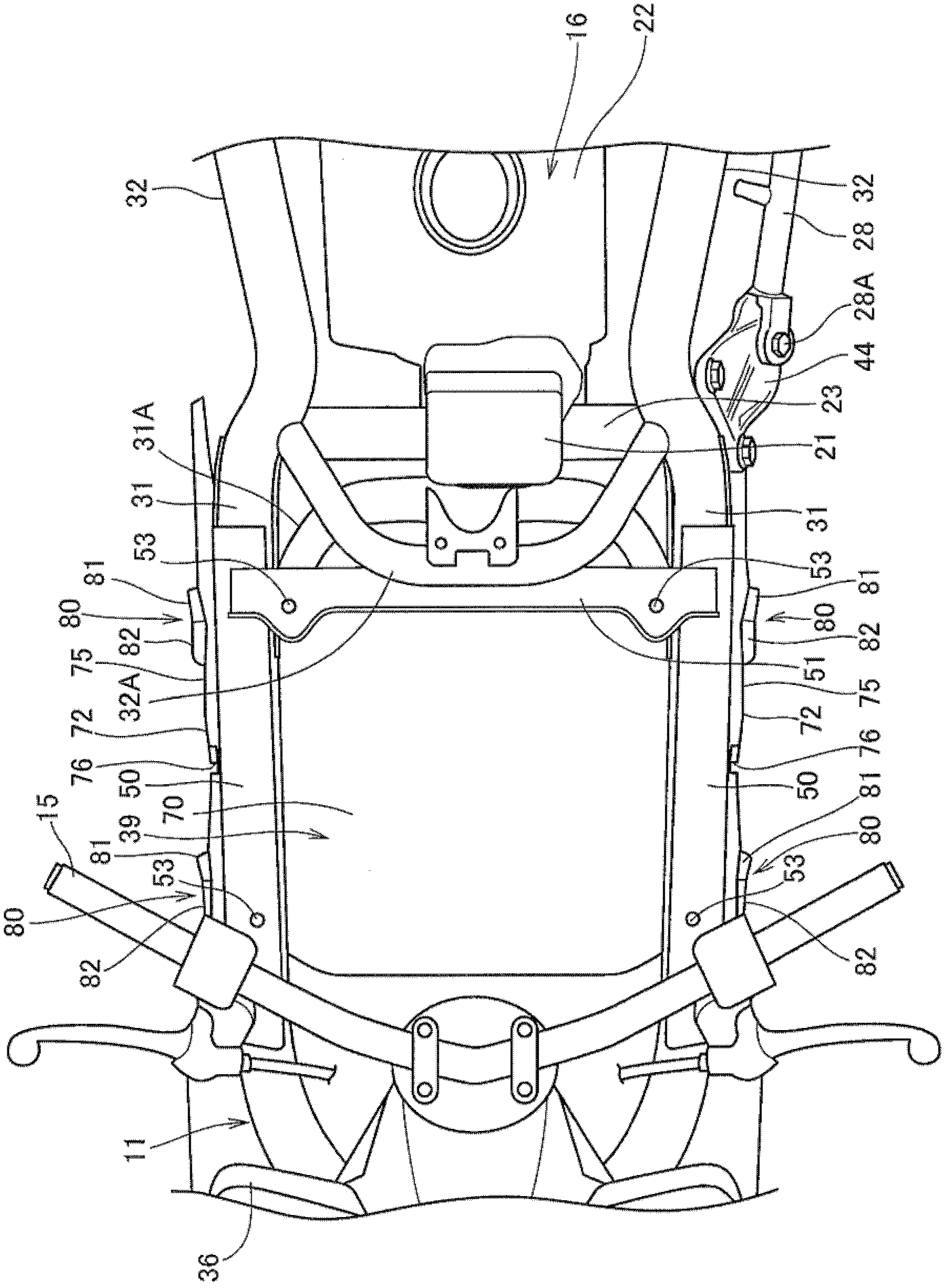

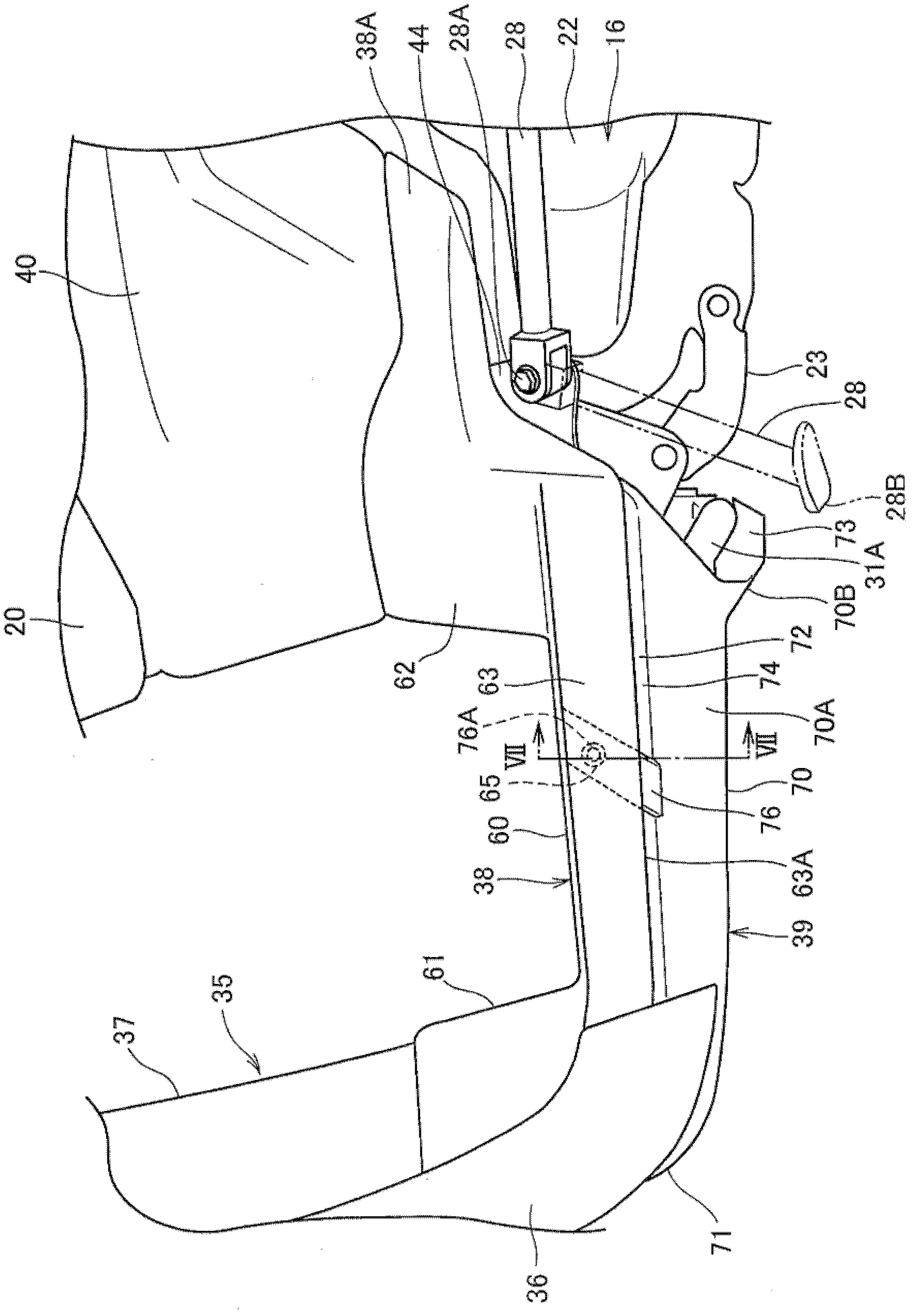

Straddle type vehicle

ActiveCN102530142AReduce maintenance frequencyStop the flowMotorcyclesOther supporting devicesAutomotive engineeringStraddle

The present invention provides a straddle type vehicle capable of preventing polluting vehicle bottom side cover and position nearby the vehicle bottom side cover. The straddle type vehicle comprises: a vehicle seat which is arranged in back of a front wheel and ridden by a driver; a foot plate (38) arranged in back of the front wheel and in front of the vehicle seat, wherein a foot of the driver is placed on the foot plate; a vehicle bottom side cover part (63) extending downwards from a left edge part and a right edge part of the foot plate (38); and a vehicle bottom lower cover (39) covering a lower side of the foot plate (38), wherein the vehicle bottom side cover part (63) is arranged at the foot plate (38), and a gap is provided between a lower side edge part (63A) thereof and an appearance surface (74) of the vehicle bottom lower cover (39) in the width direction of the vehicle.

Owner:HONDA MOTOR CO LTD

Composite contact with high fusion welding resistance for residual current protective breaker

InactiveCN106783240AStop splashImprove electrical lifeContact materialsCircuit-breaking switch contactsContact layerGraphite

The invention discloses a composite contact with high fusion welding resistance for a residual current protective breaker. The composite contact is characterized by comprising a silver alloy contact layer and a copper alloy contact layer, wherein the silver alloy contact layer comprises the following components in proportions by weight: 1-20% of yttrium oxide, 1-10% of diamond and the rest of silver; and the copper alloy contact layer comprises the following components in proportions by weight: 1-50% of molybdenum, 1-20% of graphite and the rest of copper. The thickness of the silver alloy contact layer is 5-50% of the thickness of the whole composite contact. The composite contact has the advantages of excellent performance, low silver content and low price.

Owner:沈阳新同正复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com