Visible cover on spinning frame heed

A technology of locomotives and locomotives, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc. It can solve problems such as inconvenient observation at any time, unfavorable gear rotation stability and transmission life, and easy splashing of lubricating oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

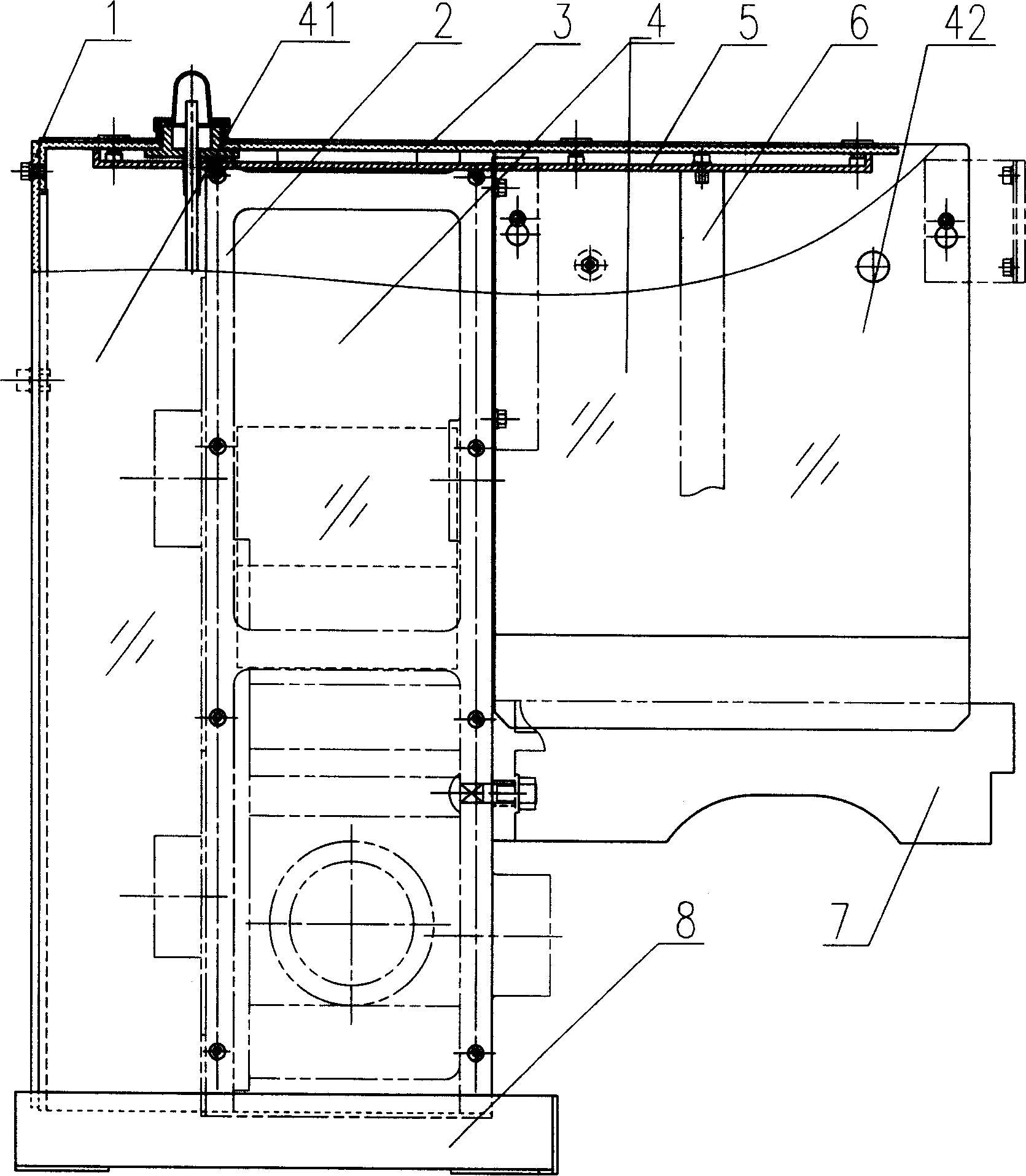

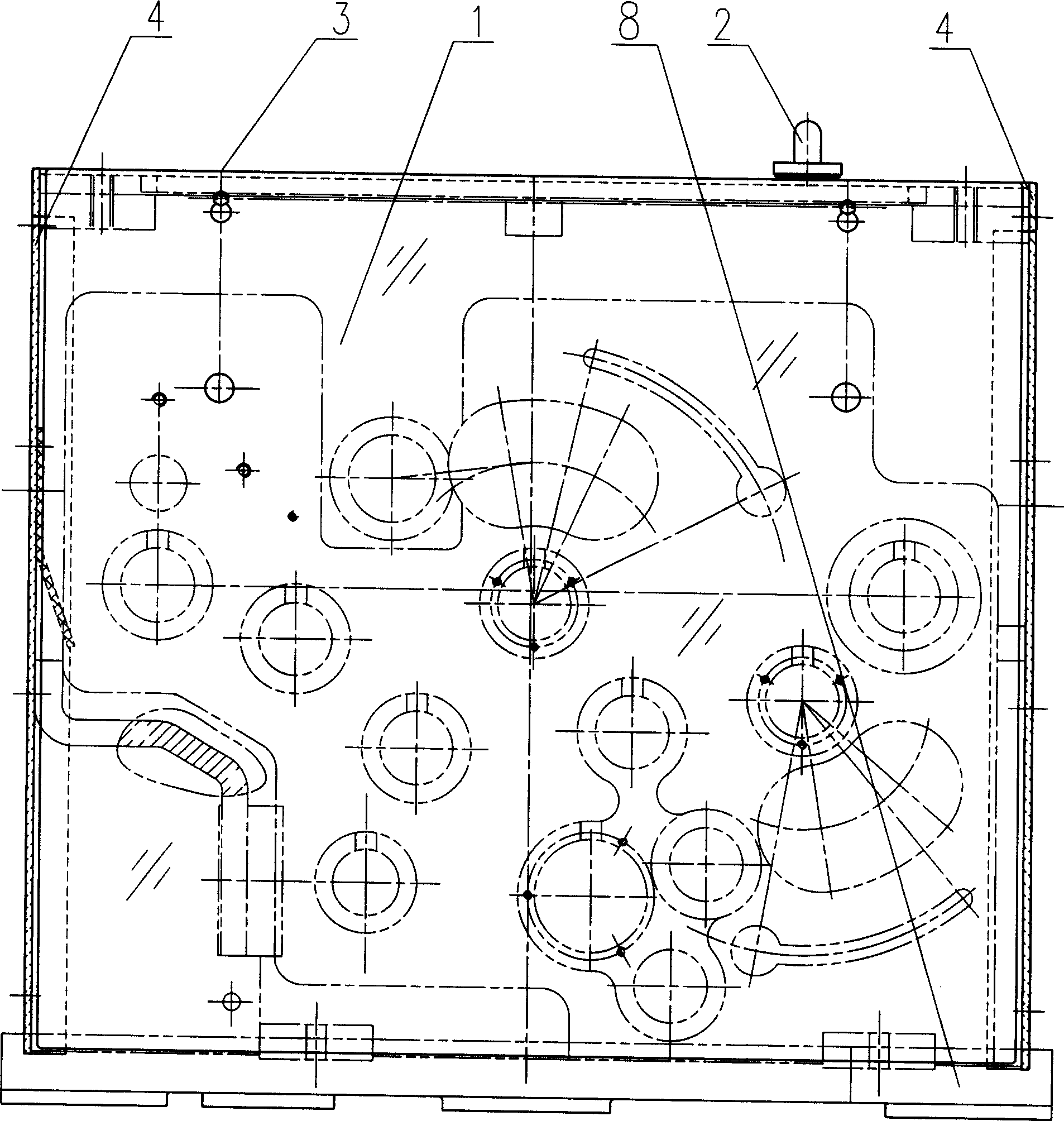

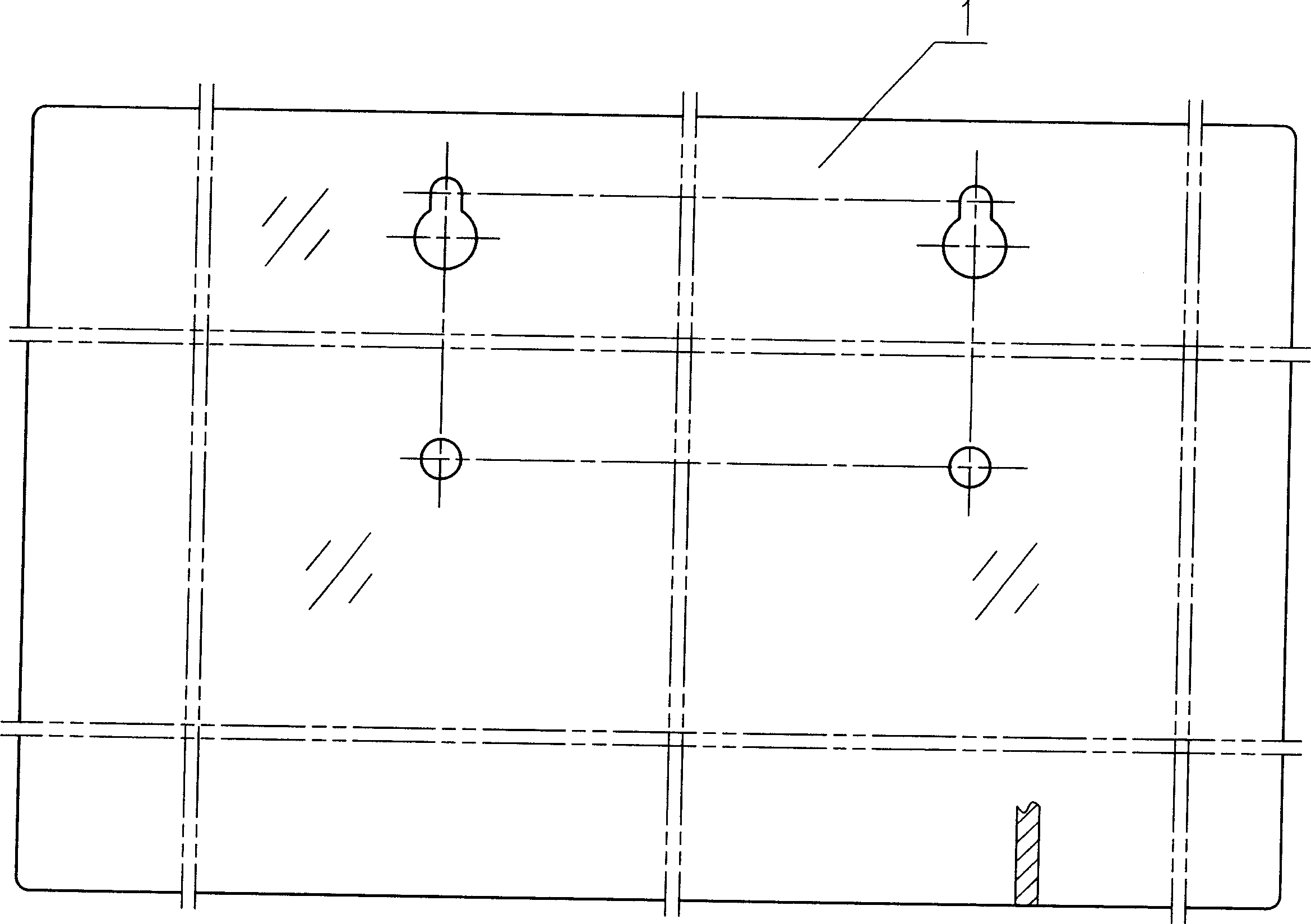

[0015] exist figure 1 , figure 2 In the visible cover of the headstock of the spinning machine shown, the frame of the headstock includes a headstock gear transmission case 2, a short machine beam 7 and a drafting wallboard 6 fixedly connected to each other. A transparent top cover plate 3 is fixedly installed on the top of the headstock frame through an oil pouring tray 5; a transparent end cover plate 1 is installed at the end of the headstock frame, and the transparent end cover plate 1 is articulated on the transparent top cover plate 3 on the end flange. The transparent side cover plate 4 fixedly installed on both sides of the head frame adopts a split structure, which includes a transparent box side plate 41 and a transparent drafting side plate 42, and the transparent box side plate 41 is fixedly connected to the gear transmission box of the headstock by bolts The upper and lower ends of the body 2 are inserted into the oil return pan 8; At the both sides of the dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com