Stemming for inhibiting splashing of iron notch

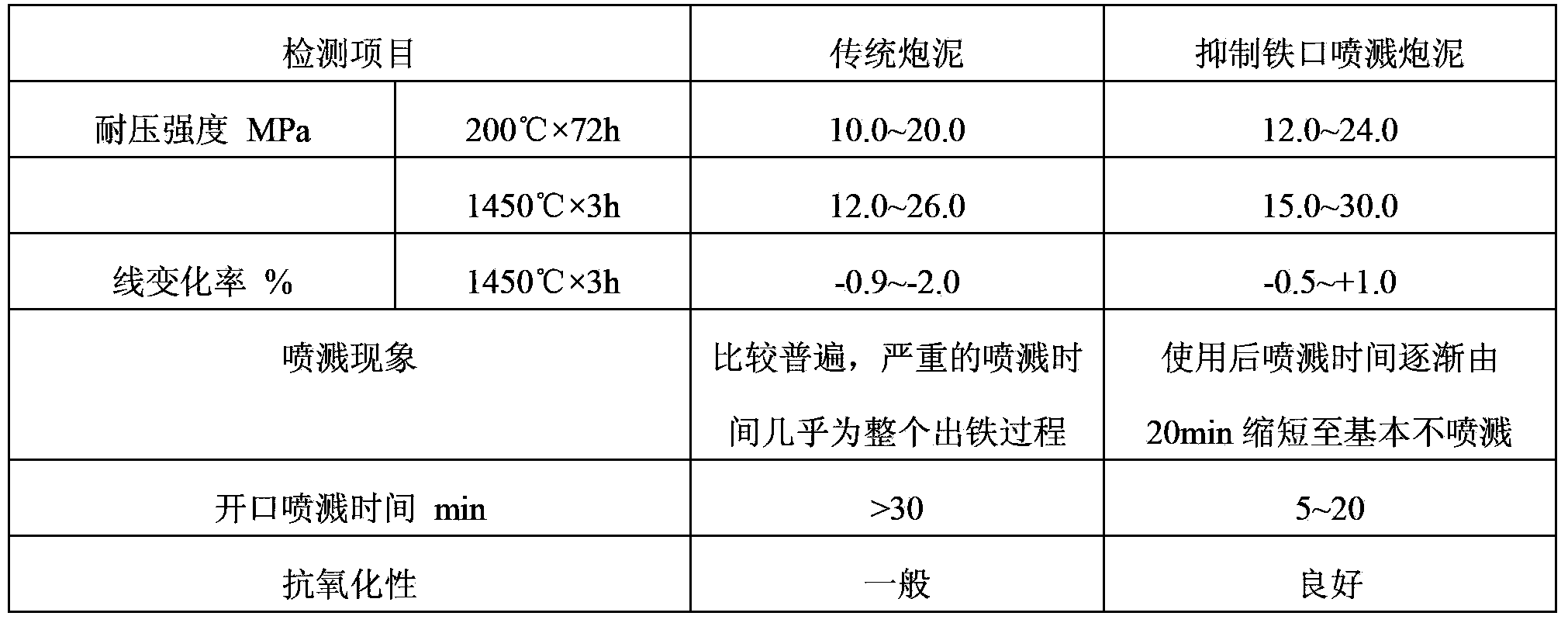

A technology of tap hole splashing and blast mud, which is applied in the field of metallurgical refractory materials, can solve the problems that affect the life of the tap hole and the state of tapping, the blast furnace can not normally tap iron, and the blast mud is prone to cracks, etc., to achieve appropriate micro-expansion performance, The effect of avoiding volume shrinkage and reducing joint gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 4

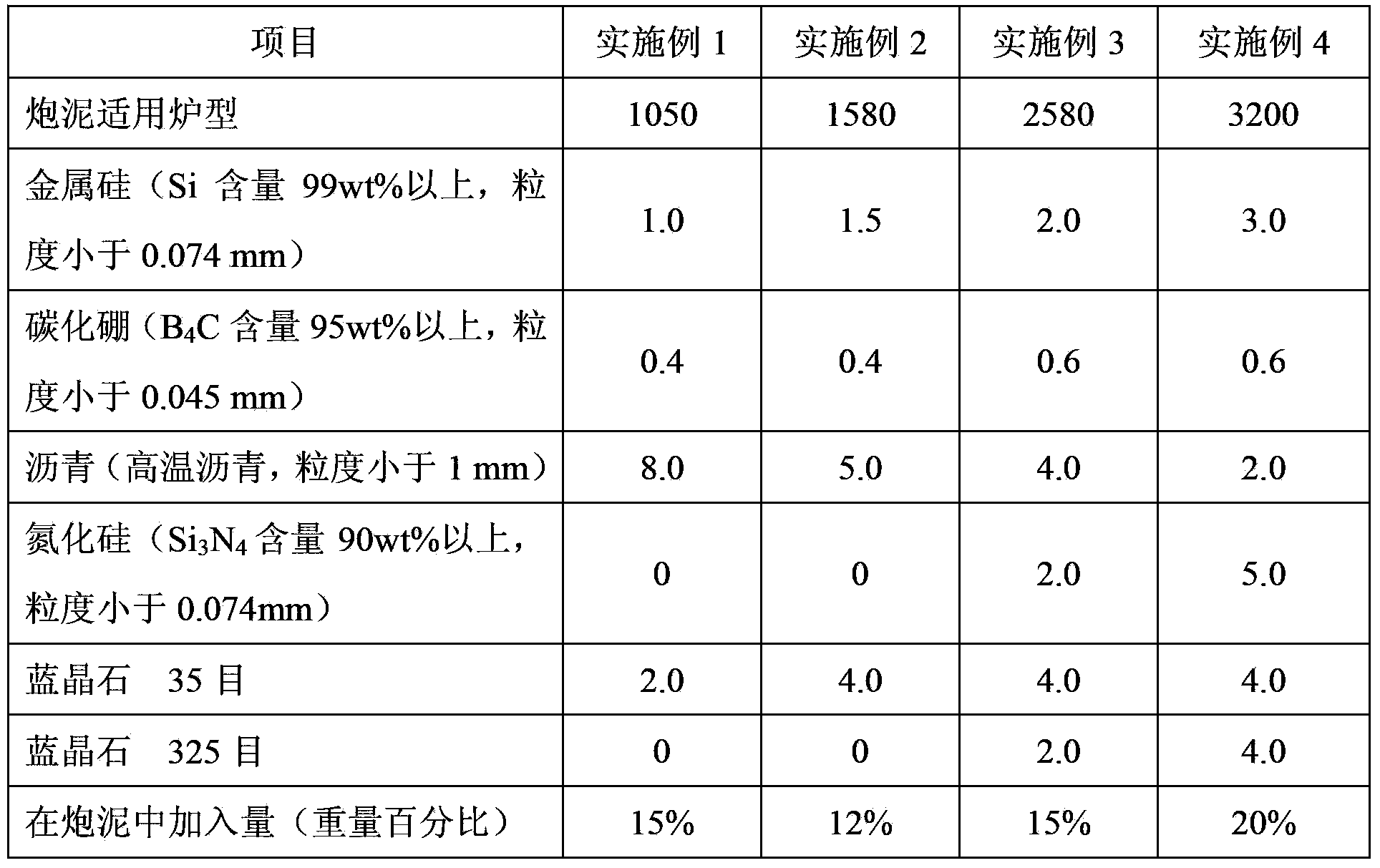

[0035] In Examples 1-4, each component of the additive for gun clay was accurately weighed according to the parts by weight shown in Table 2, stirred in a mixer for 3-10 minutes, and then packaged. Normally it is 25kg per bag. Pay attention to moisture and rain during storage and transportation. When applied to the corresponding gun clay products, it is operated in the form of adding powder.

[0036] Table 2

[0037]

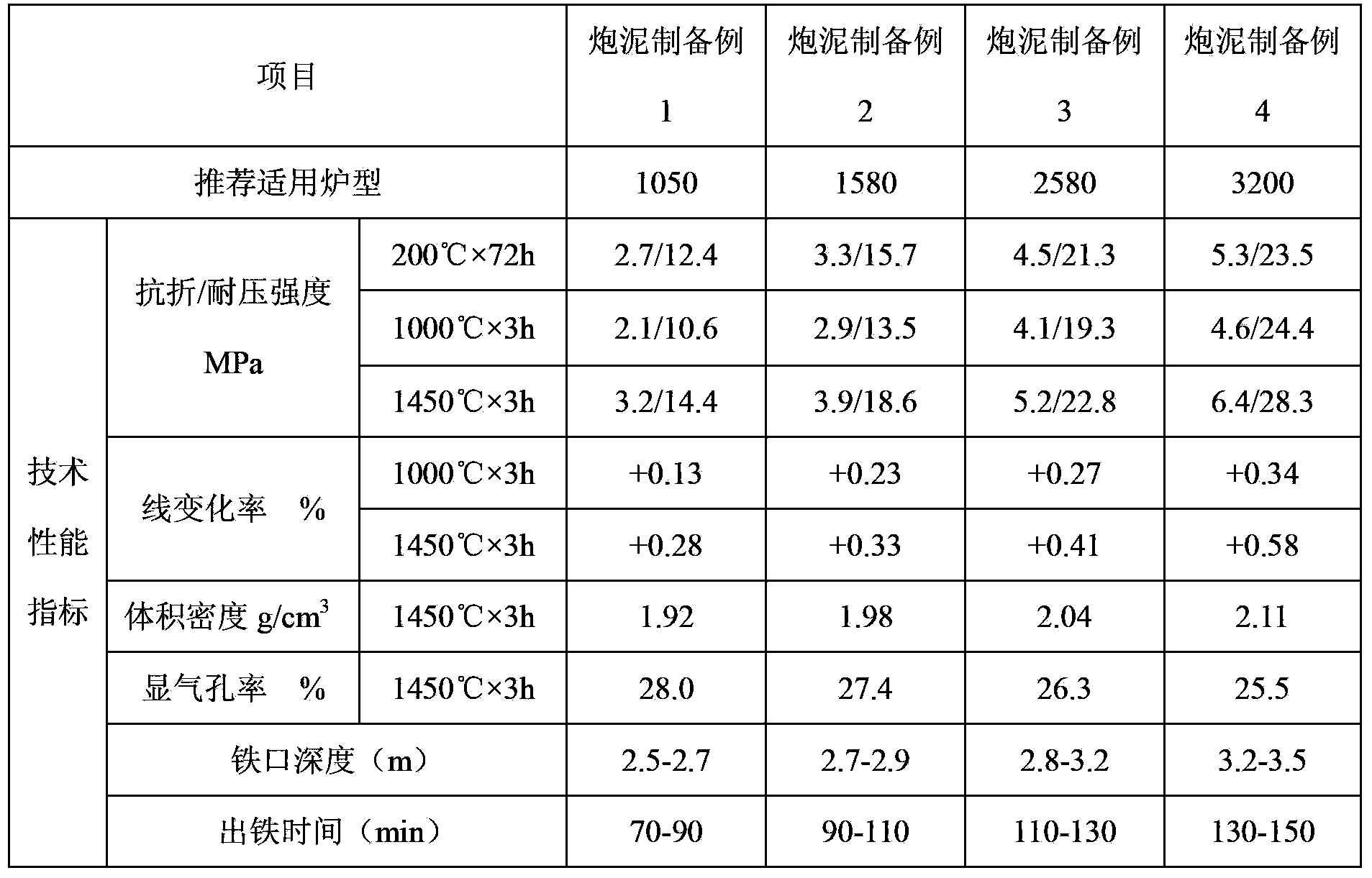

[0038] two. Preparation of taphole clay with additives for suppressing sputtering of iron holes

preparation example 1

[0040] Its components and parts by weight are: 20 parts of bauxite particles; 10 parts of alumina powder; 10 parts of silicon carbide; 20 parts of coke; 7 parts of 120 mesh quartz sand; 18 parts of clay; 15 parts of additives for splashed gunpowder; and

[0041] The binder is 14 parts of tar, and 2 parts of phenolic resin with a curing temperature of 150°C to 200°C.

[0042] Accurately weigh the above-mentioned components by weight, first stir the granular material in the mixer for 2-3 minutes, and then add tar with a tar content of 30wt%, and then stir for 5 minutes, then add the fine powder and stir for 10 minutes. Minutes, then add phenolic resin and the remaining tar binder and stir for 30 minutes to make the binder fully wet the dry material, measure the Masha value with a Masha instrument, and when it has suitable plasticity, it will be extruded and packaged through a mud extruder.

preparation example 2

[0044] Its components and parts by weight are: 25 parts of bauxite particles; 13 parts of alumina powder; 12 parts of silicon carbide; 18 parts of coke; 5 parts of 120 mesh quartz sand; 15 parts of clay; 12 parts of additives for splashed gunpowder; and

[0045] The binder is 10 parts of tar, 4 parts of phenolic resin with a curing temperature of 150°C to 200°C.

[0046] Accurately weigh the above-mentioned components by weight, firstly stir the granules in the mixer for 2-3 minutes evenly, then add tar with a tar content of 40wt%, and stir for another 5 minutes, then add the fine powder and stir for 10 minutes Minutes, then add the resin and the remaining tar binder and stir for 30 minutes to make the binder fully wet the dry material, measure the Masha value with a Masha instrument, and when it has suitable plasticity, it will be extruded and packaged through a mud extruder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com