Composite contact with high fusion welding resistance for residual current protective breaker

A compound contact and residual current technology, which is applied in the direction of circuit breaker contacts, circuit breaker components, circuits, etc., can solve the problems of low material utilization, complex production process, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

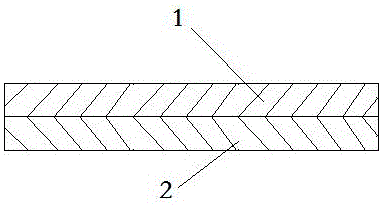

[0015] See figure 1 , the composite contact is composed of a silver alloy contact layer 1 and a copper alloy contact layer 2; the silver alloy contact layer 1 accounts for 20% of the thickness of the composite contact.

[0016] The specific composition and weight ratio of the silver alloy contact layer 1: 10% of yttrium oxide, 1% of diamond, and the balance of silver.

[0017] The specific composition and weight ratio of the copper alloy contact layer 2: molybdenum 3%, graphite 4%, copper balance.

[0018] The composite contact is assembled on a miniature circuit breaker for performance testing and the results are: running short-circuit breaking 6,000 amperes, electrical life of 4,000 times, and temperature rise after electrical life test <60K.

Embodiment 2

[0020] The composite contact is composed of a silver alloy contact layer 1 and a copper alloy contact layer 2; the silver alloy contact layer 1 accounts for 40% of the thickness of the composite contact.

[0021] The specific composition and weight ratio of the silver alloy contact layer 1: 15% of yttrium oxide, 10% of diamond, and the balance of silver.

[0022] The specific composition and weight ratio of the copper alloy contact layer 2: molybdenum 20%, graphite 10%, copper balance.

[0023] The composite contact is assembled on a miniature circuit breaker for performance testing and the results are: running short-circuit breaking 10,000 amperes, electrical life 10,000 times, and temperature rise after the test <60K.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com