Novel thread-sealed multi-cylinder hydraulic circular cone machine

A thread sealing and cone machine technology, applied in the field of multi-cylinder hydraulic cone machines, can solve the problems of lubricating oil splashing, trial production progress deadlock, unable to prevent splashing, etc., and achieve the ideal effect of oil pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

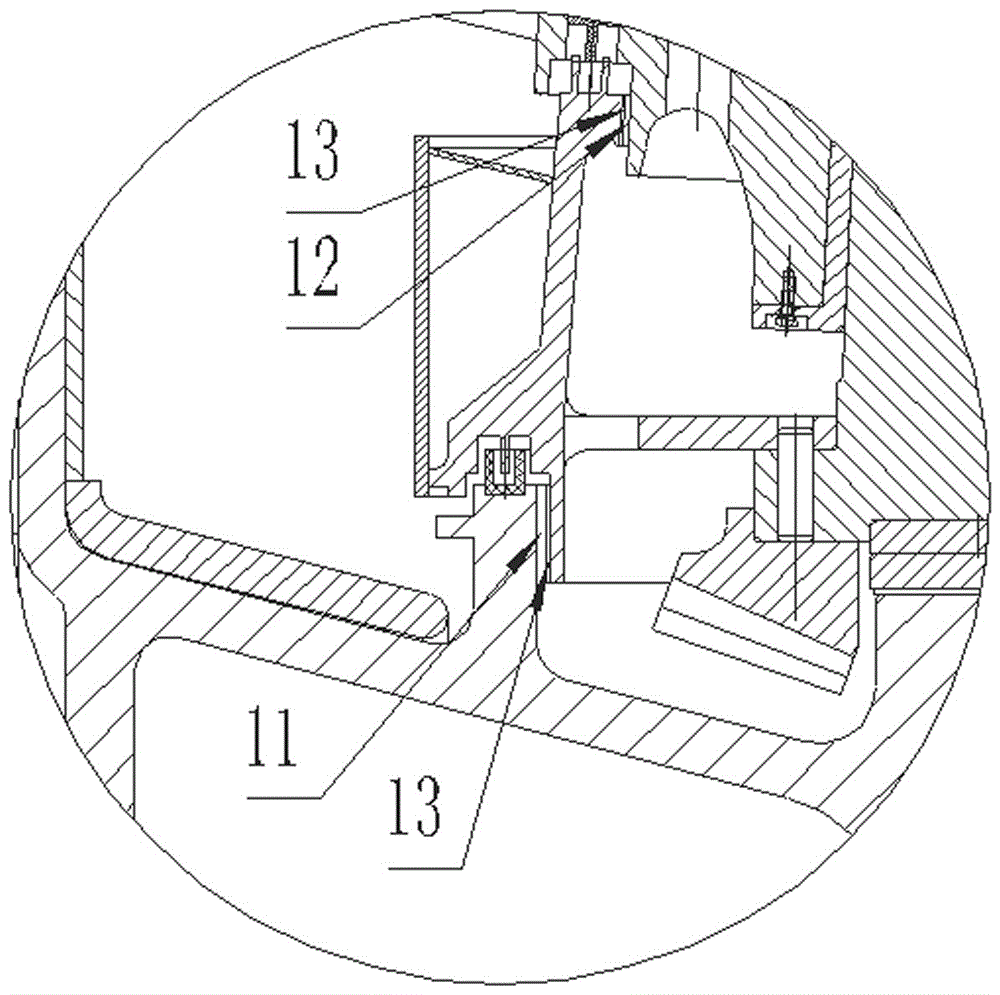

[0024] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

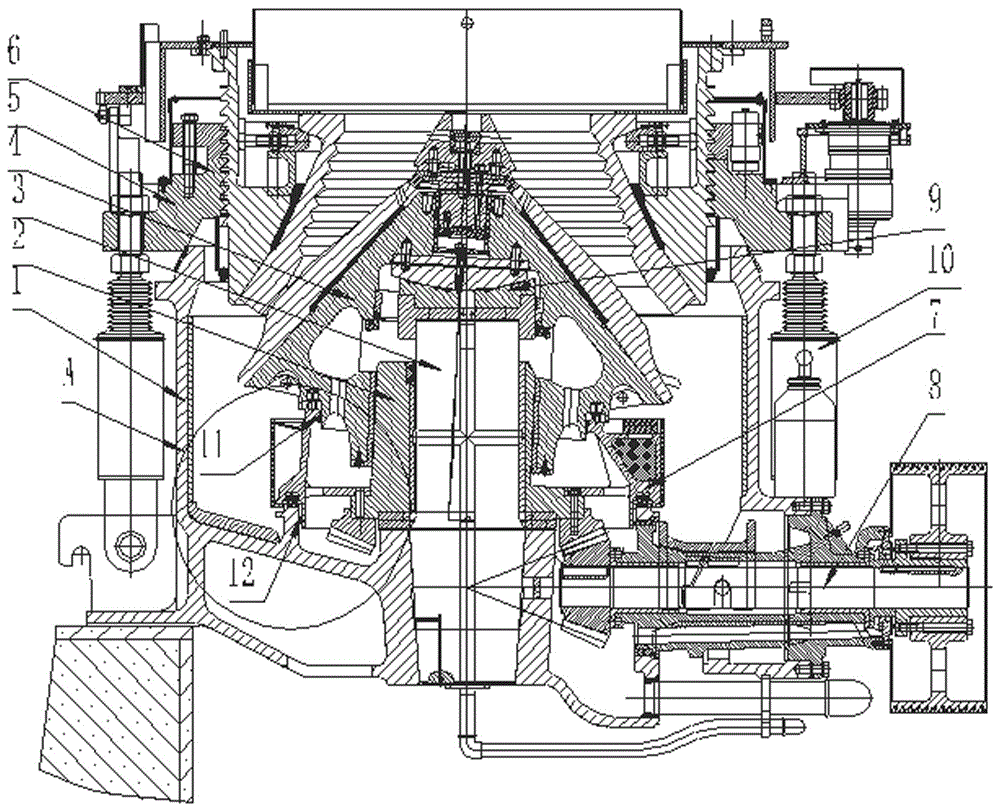

[0025] Such as figure 1 As shown, the new thread-sealed multi-cylinder hydraulic cone machine, including

[0026] Rack 1 is used to provide an installation base;

[0027] The main shaft 3 is fixed in the middle of the frame 1;

[0028] The eccentric sleeve 2, the eccentric sleeve 2 is sleeved on the main shaft, the main shaft 3 is used for positioning the rotation of the eccentric sleeve 2, the outer axis of the eccentric sleeve 2 is eccentric and has an intersection angle with the axis of the main shaft 3;

[0029] Body 4, the body 4 is supported on the bowl-shaped bearing 9, and the lower part is sleeved on the periphery of the eccentric sleeve 2;

[0030] The support sleeve 5, the support sleeve 5 is installed on the frame, and is tightened by the safety hydraulic cylinder;

[0031] An adjustment sleeve 6, the adjustment sleeve 6 is threadedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com