Patents

Literature

81results about How to "Increase grain boundary area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel plate and method thereof used for producing water heater linear enamel by flexible thin slab rolling line

ActiveCN102181805AStable recoveryExcellent anti-scale explosion performanceRoll mill control devicesMetal rolling arrangementsThin slabManganese

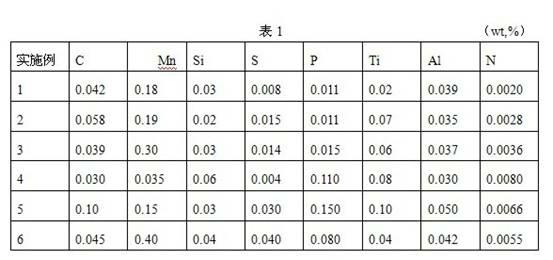

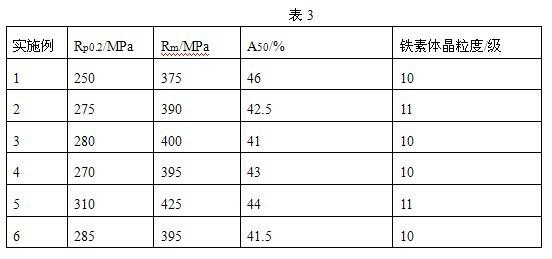

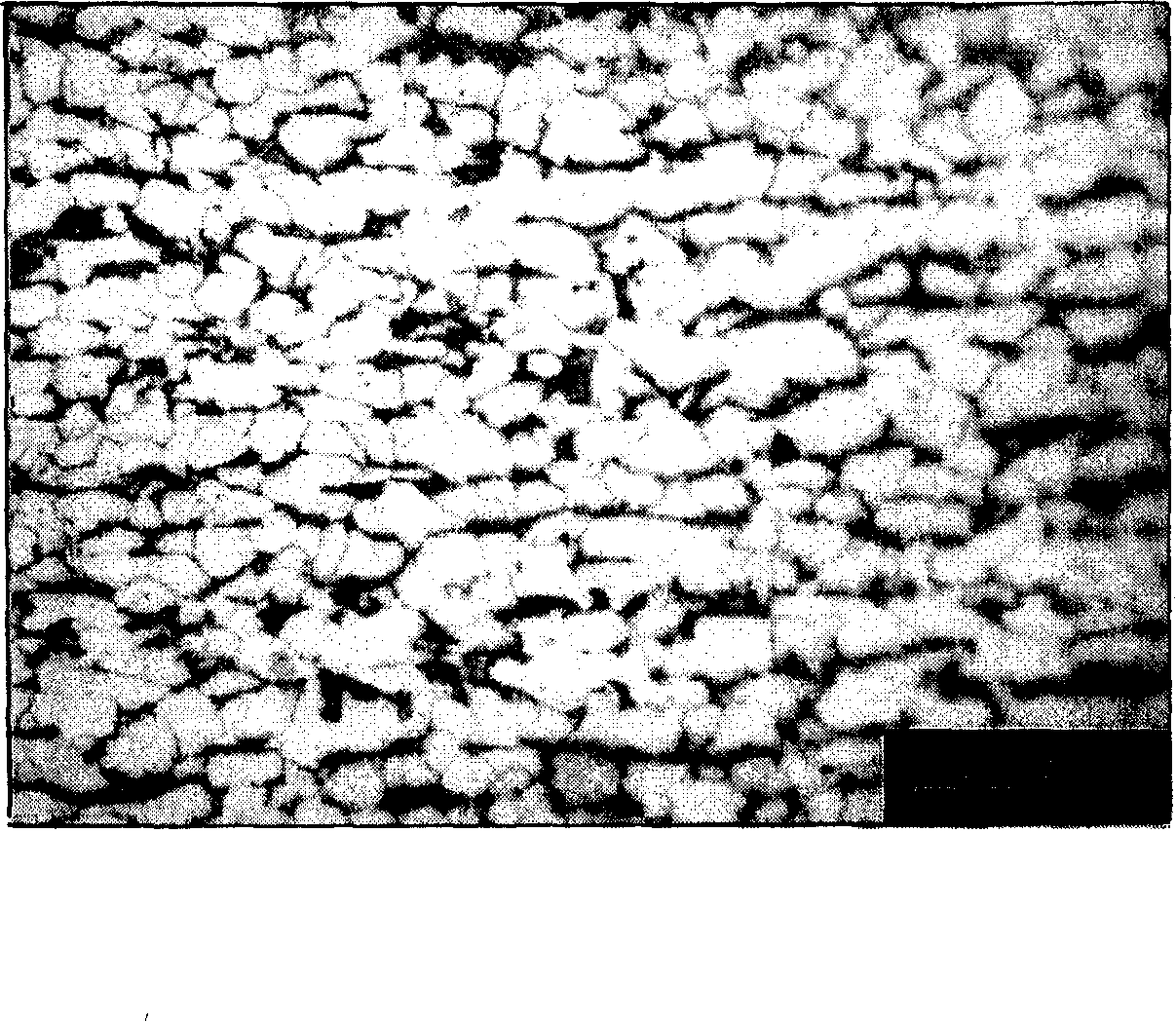

The invention relates to a steel plate and a process method thereof used for producing water heater linear enamel by a flexible thin slab rolling line (FTSR), belonging to the production field of enamel steel plates. The steel plate comprises the following chemical components in percentage by weight: 0.03-0.10wt% of carbon, 0.15-0.40wt% of manganese, less than or equal to 0.06wt% of silicon, 0.004-0.040wt% of sulphur, less than or equal to 0.15wt% of phosphorus, 0.03-0.05wt% of aluminum, 0.002-0.008wt% of nitrogen, 0.02-0.10wt% of titanium and the balance of ferrum and inevitable impurities. The tissue of the water heater linear enamel contains fine grain ferrite and a small quantity of pearlite tissues, and the granularity level of the water heater linear enamel is more than or equal to 10 levels. According to reasonable ingredient design and the FTSR process, steel for manufacturing water-storage water heater linear enamel for home appliances is produced; the steel plate has good enamel adhesion and scaling resistance, and also has the characteristics of few added alloy elements, few production working procedures, low production cost and the like; and a hot rolling scouring plate is used for replacing a cold rolling annealing plate.

Owner:HEBEI IRON AND STEEL

Fine crystal strengthen carbon constructional steel and manufacture process for hot-rolling thin slab thereof

InactiveCN101153367AHigh strengthHigh elongationShaping toolsHeat treatment process controlChemical compositionThin slab

The invention relates to a manufacture process of carbon steel and carbon steel hot rolling plate, in particular to a manufacture process of fine grain reinforcement carbon structural steel and hot rolling sheet plate of the steel. The invention mainly solves the technical problem that hot rolling plate of higher strength can not be produced on common completely continuous hot continuous rolling mill by use of common carbon structural steel at present. The fine grain reinforcement carbon structural steel adopts the following chemical composition (weight percent): 0.14 percent to 0.20 percent of C, 0.10 percent to 0.40 percent of Si, 0.65 percent to 0.90 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S and the rest, Fe. The manufacture process of the hot rolling sheet plate is as follows: a continuous casting slab which meets the requirements of compositions is heated to 1,210 DEG C to 1,250 DEG C; a rough rolling stage comprises five-pass tandem rolling and the end temperature of the rough rolling stage is between 1,050 DEG C and 1,060 DEG C; in addition, the thickness of an intermediate slab ranges from 35 mm to 45 mm. When rough rolling is finished, the intermediate slab is curled through a hot coil box and then is unfolded for finish rolling; a finish rolling stage comprises six-pass tandem rolling with the start rolling temperature ranging between 920 DEG C and 940 DEG C and the end temperature ranging between 820 DEG C and 860 DEG C; after finish rolling, the thickness of a steel plate is between 2 mm to 8 mm; in addition, a laminar flow cooling stage adopts forepart intensive cooling with the coiling temperature ranging from 520 DEG C to 620 DEG C.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Iron-based alloy powder material for plasma cladding quick forming

InactiveCN101709469AImprove toughnessModerate hardnessMetallic material coating processesHardnessWear resistance

The invention discloses an iron-based alloy powder material for plasma cladding quick forming, which comprises the following alloy components in percentage by weight: 0.05-0.15 percent of C, 4-8 percent of Ni,10-15 percent of Cr, 0.1-1 percent of B, 0.8-1.2 percent of Si, 0.8-1.2 percent of Mo, 0.25-0.70 percent of Nb, 0.25-3.5 percent of mixed RE(containing 47 percent of Ce, 26 percent of La,18 percent of Nd and 5 percent of Pr in percentage by mass) and the balance of Fe. The iron-based alloy powder with the components is especially suitable for plasma cladding quick forming, and a cladding layer has medium hardness and wear-resistance. The iron-based alloy powder has little tendency to crack and other cladding defects under the condition of multi-layer cladding, and the cladding process is excellent with low powder cost. The powder can be also used for restoring work-piece size or used as a bottom layer before a functional cladding layer is formed during plasma single-layer cladding repair, and can be applied to wider application needs.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

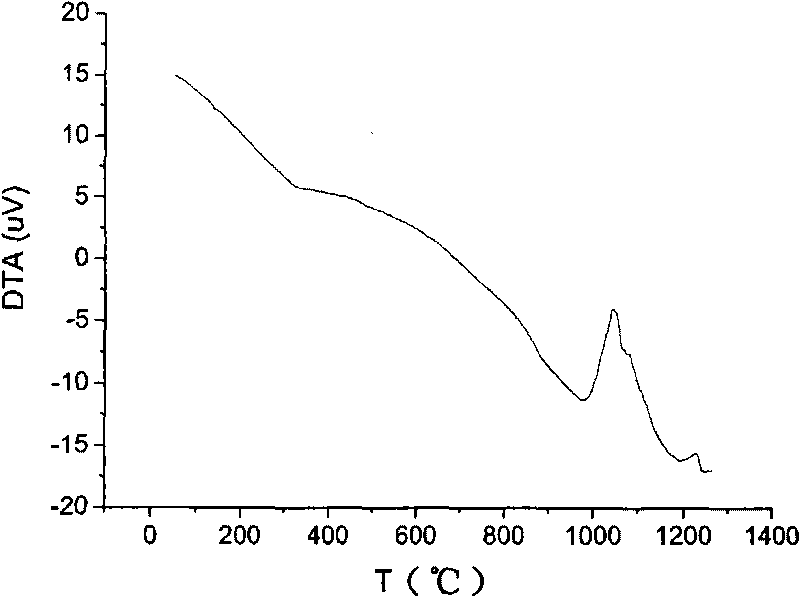

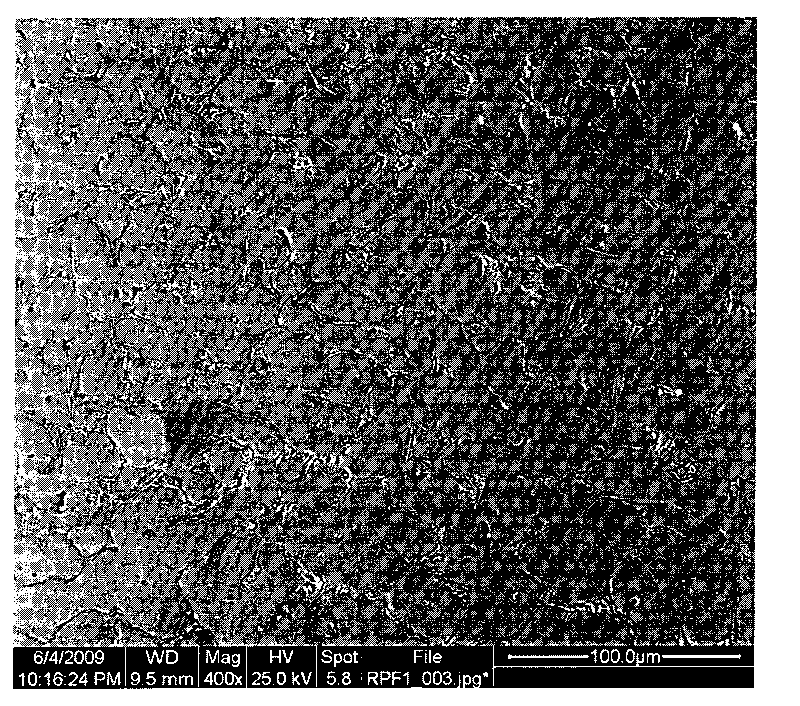

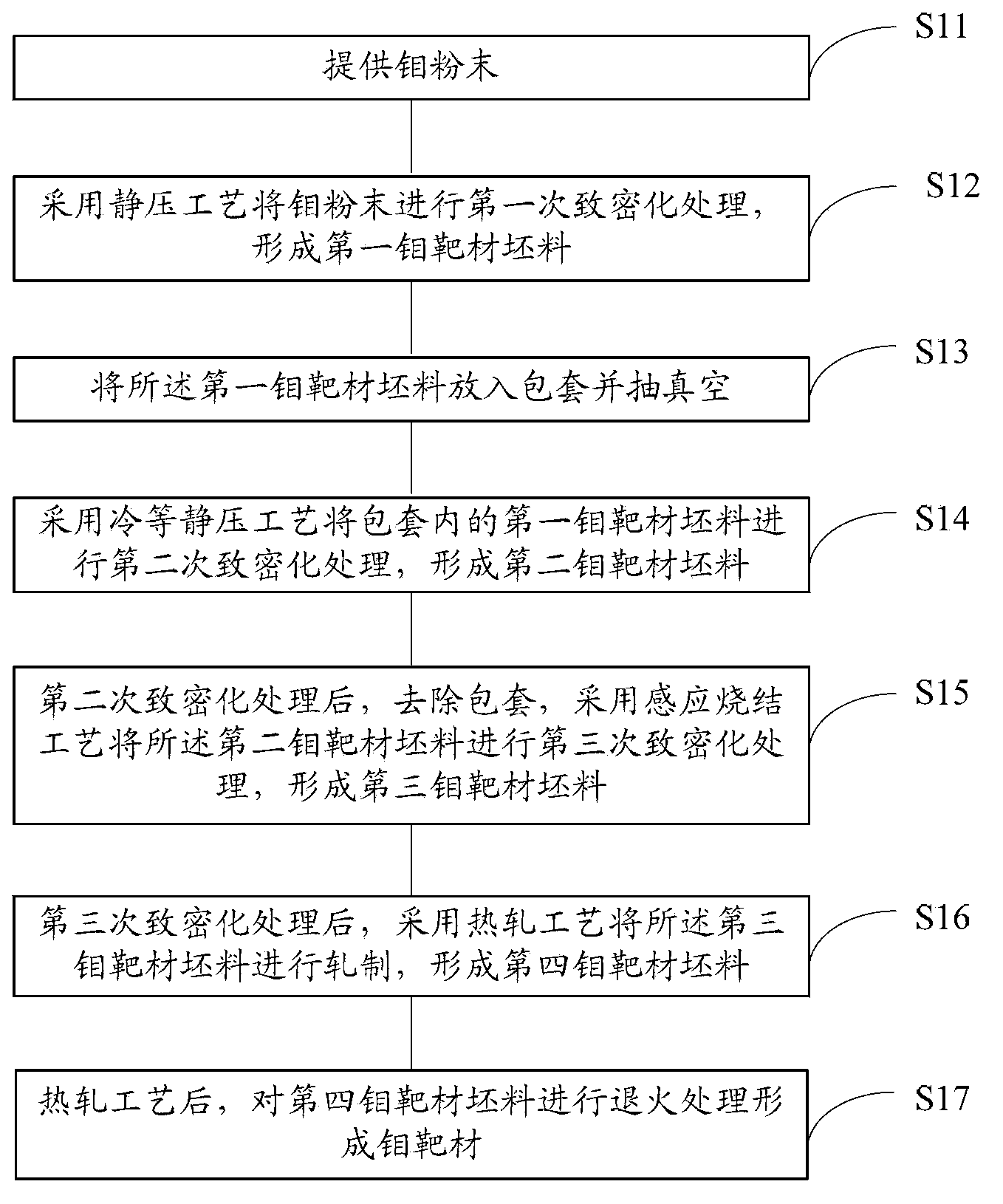

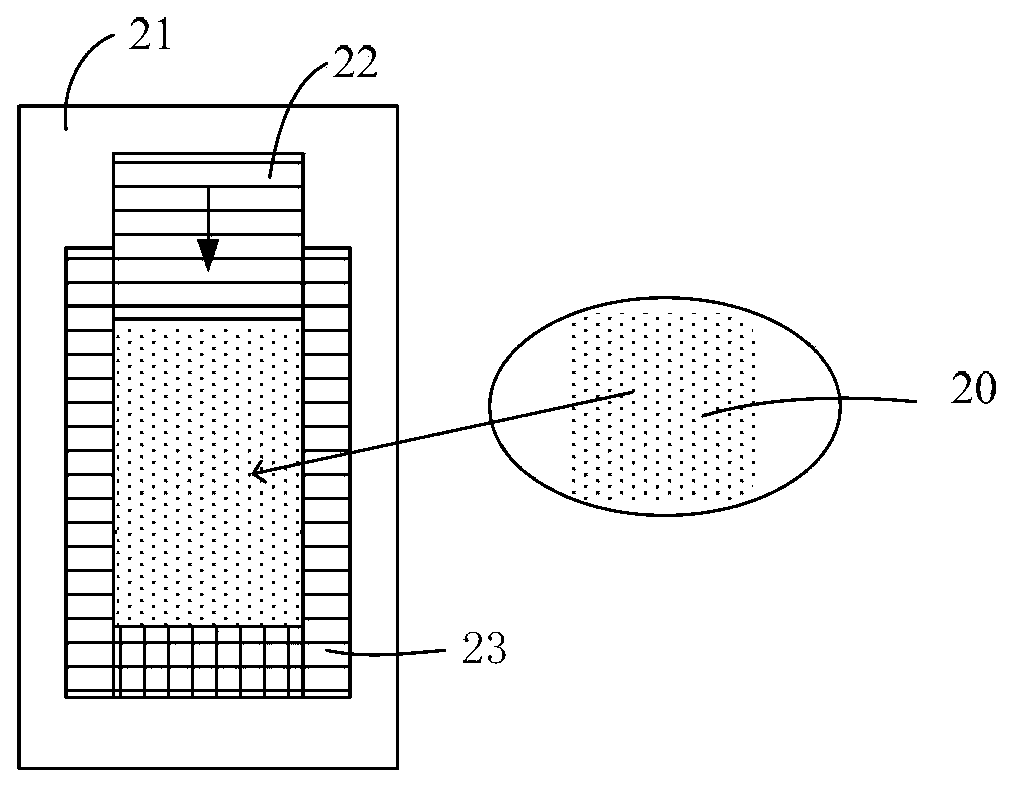

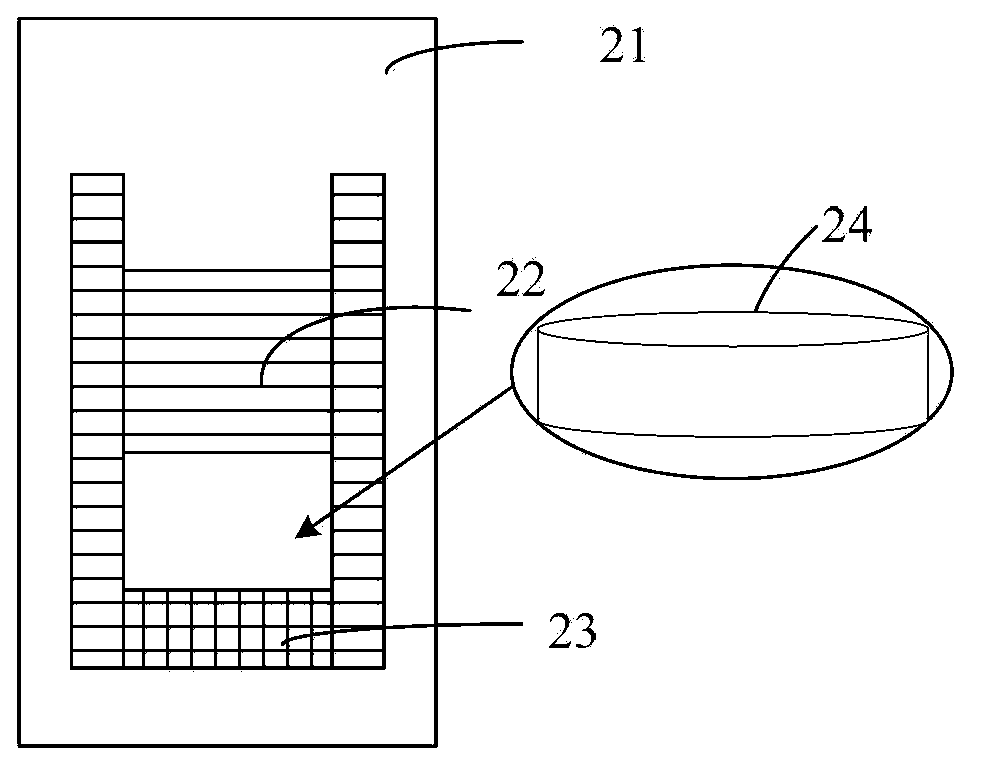

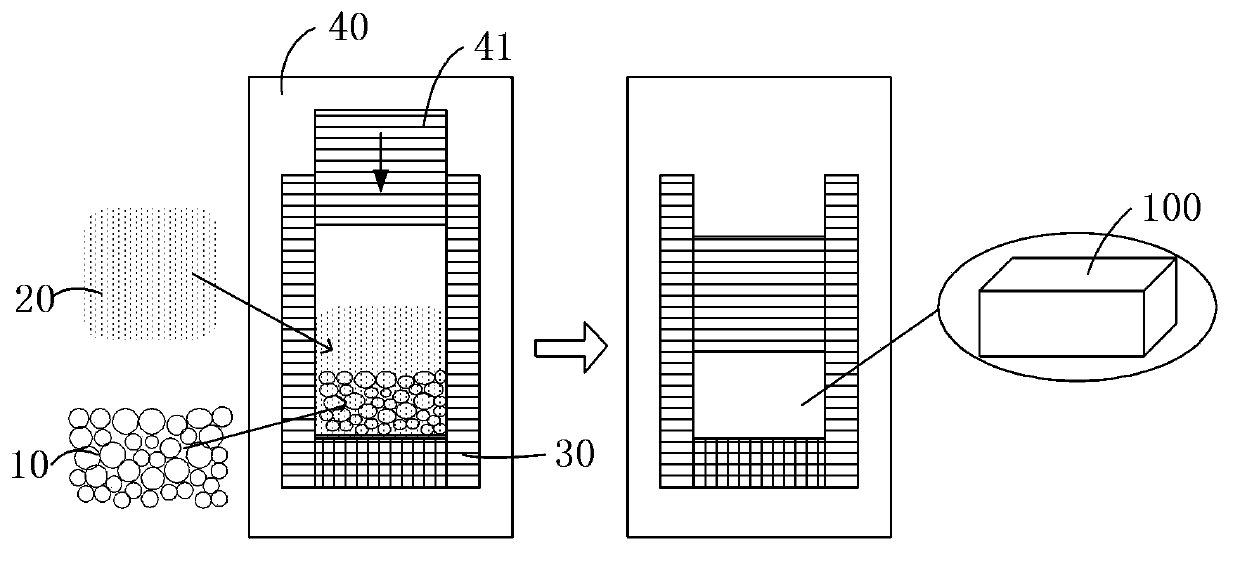

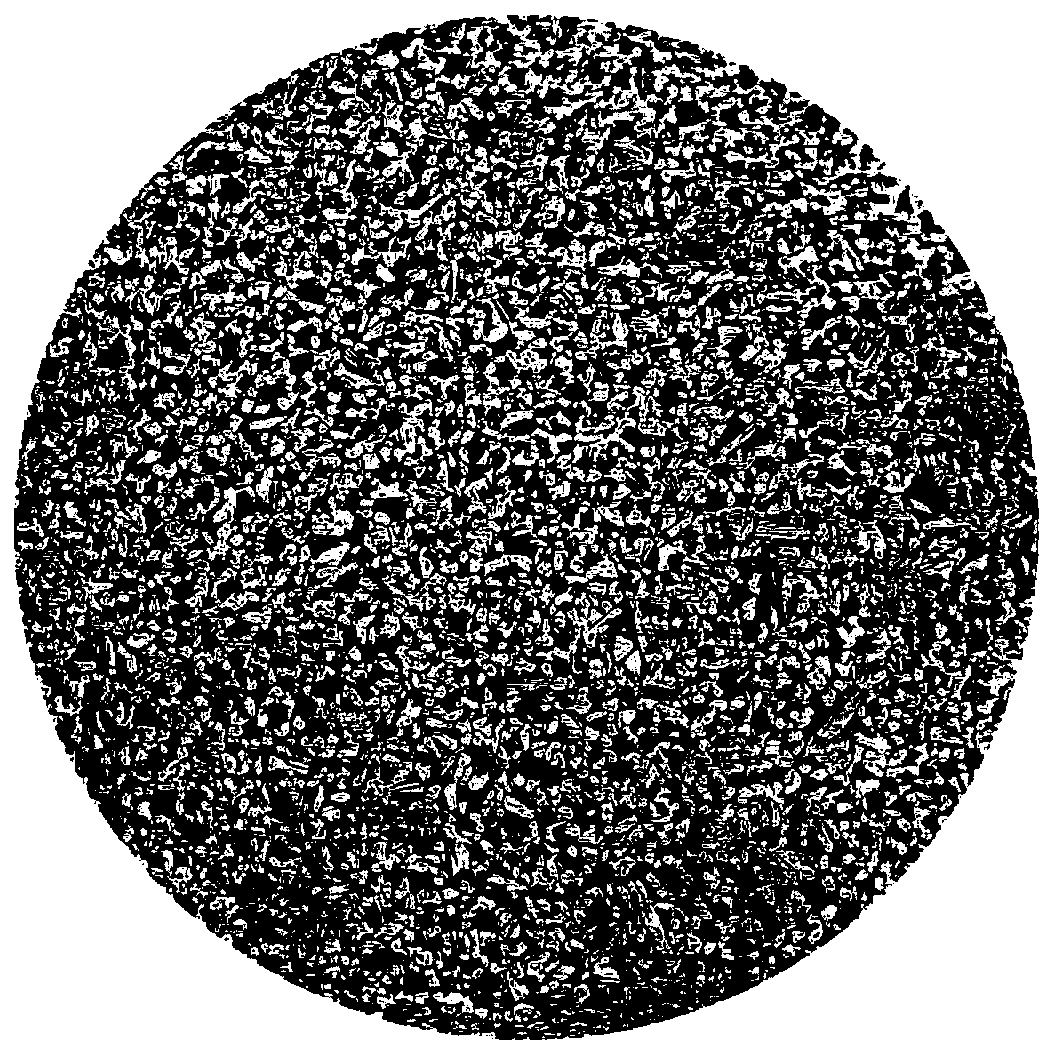

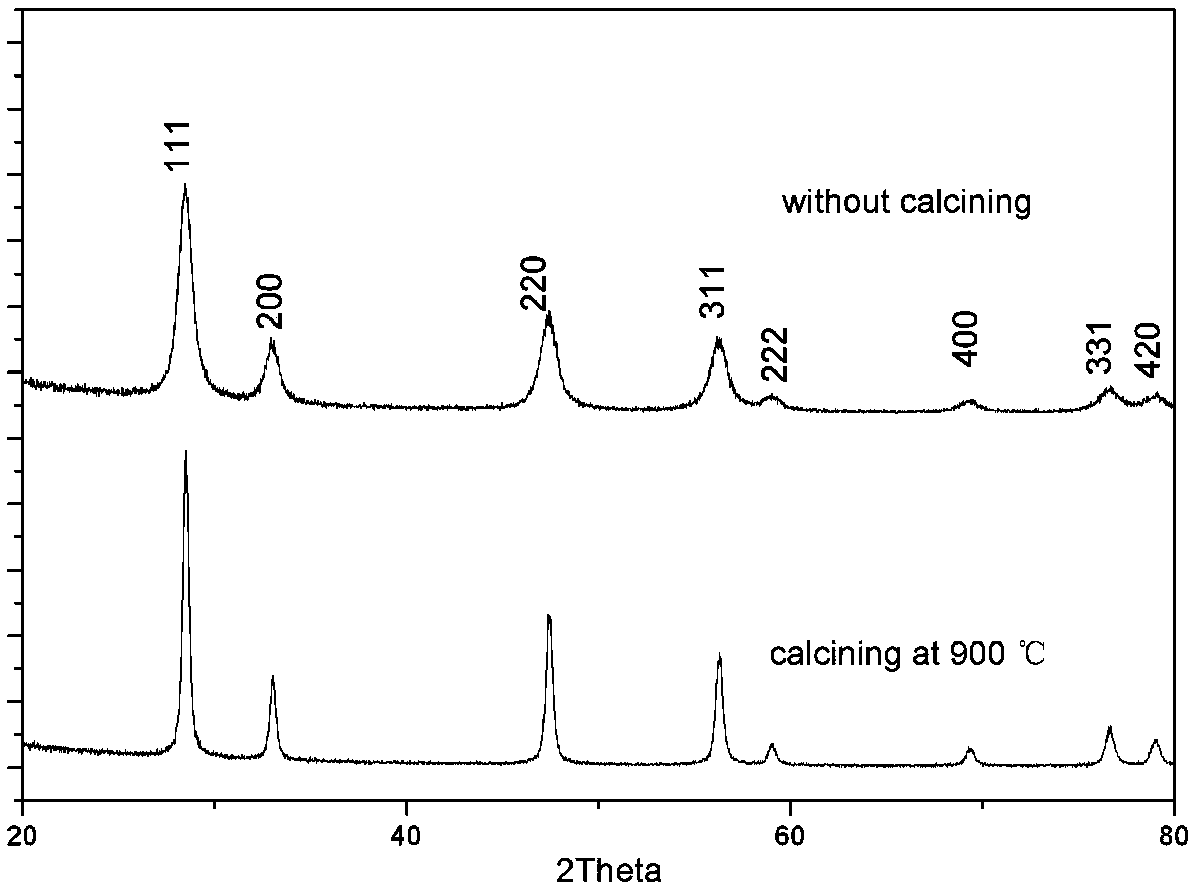

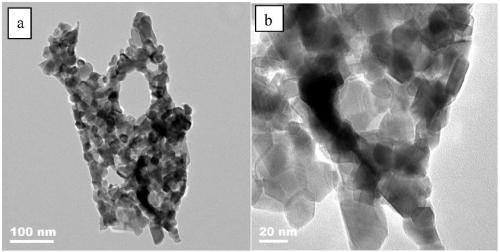

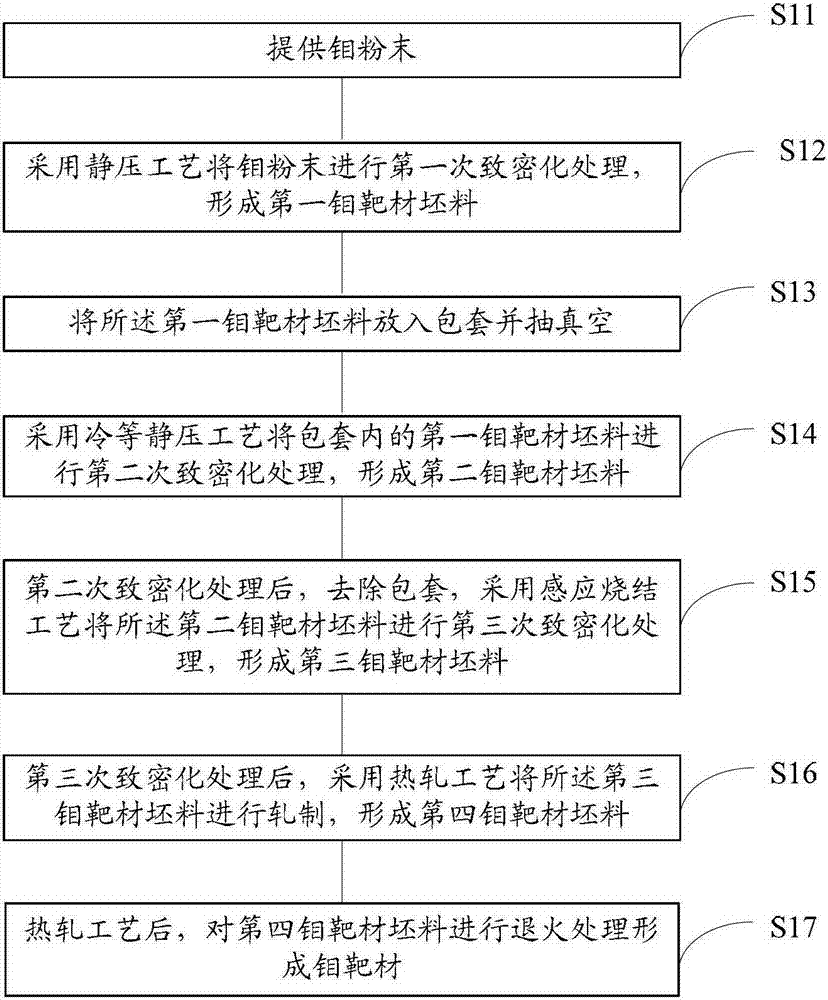

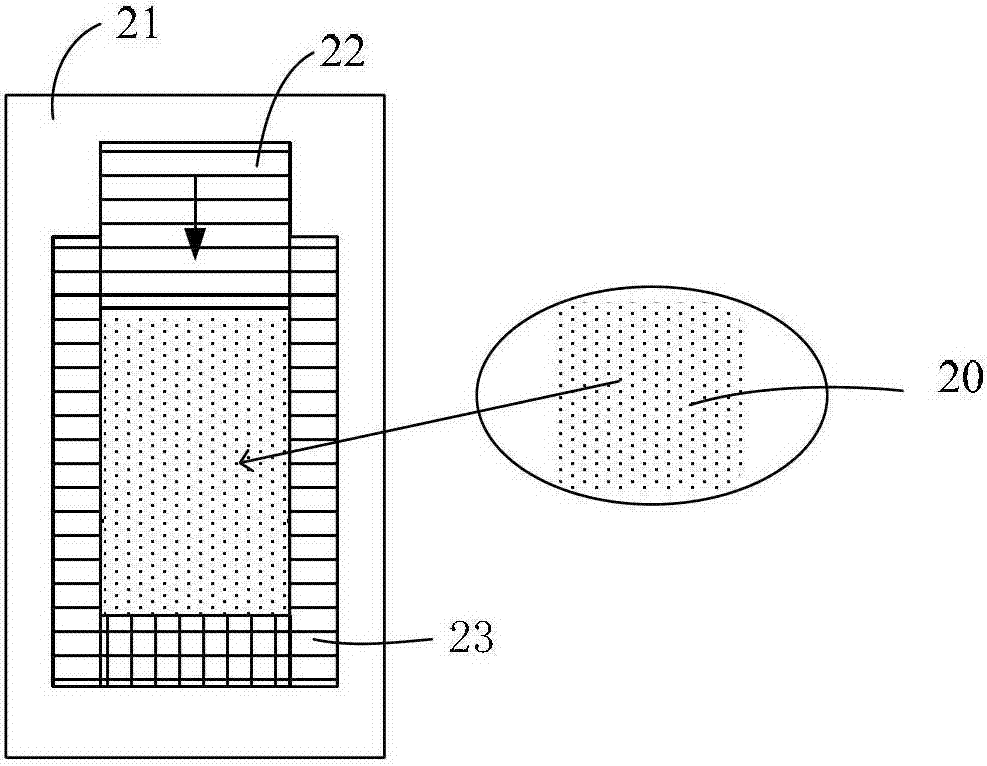

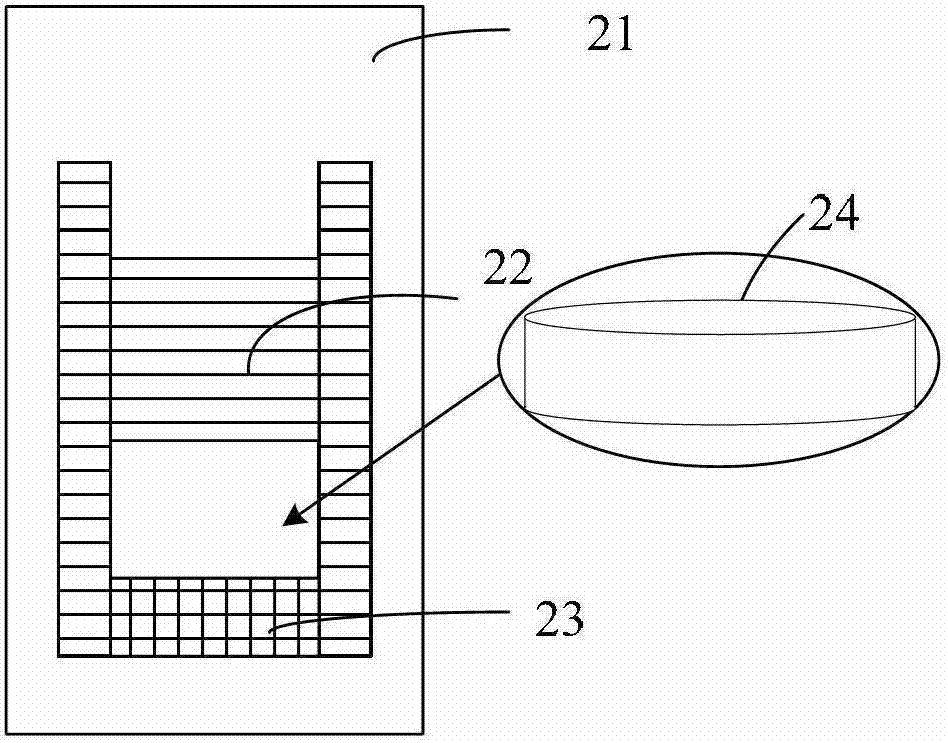

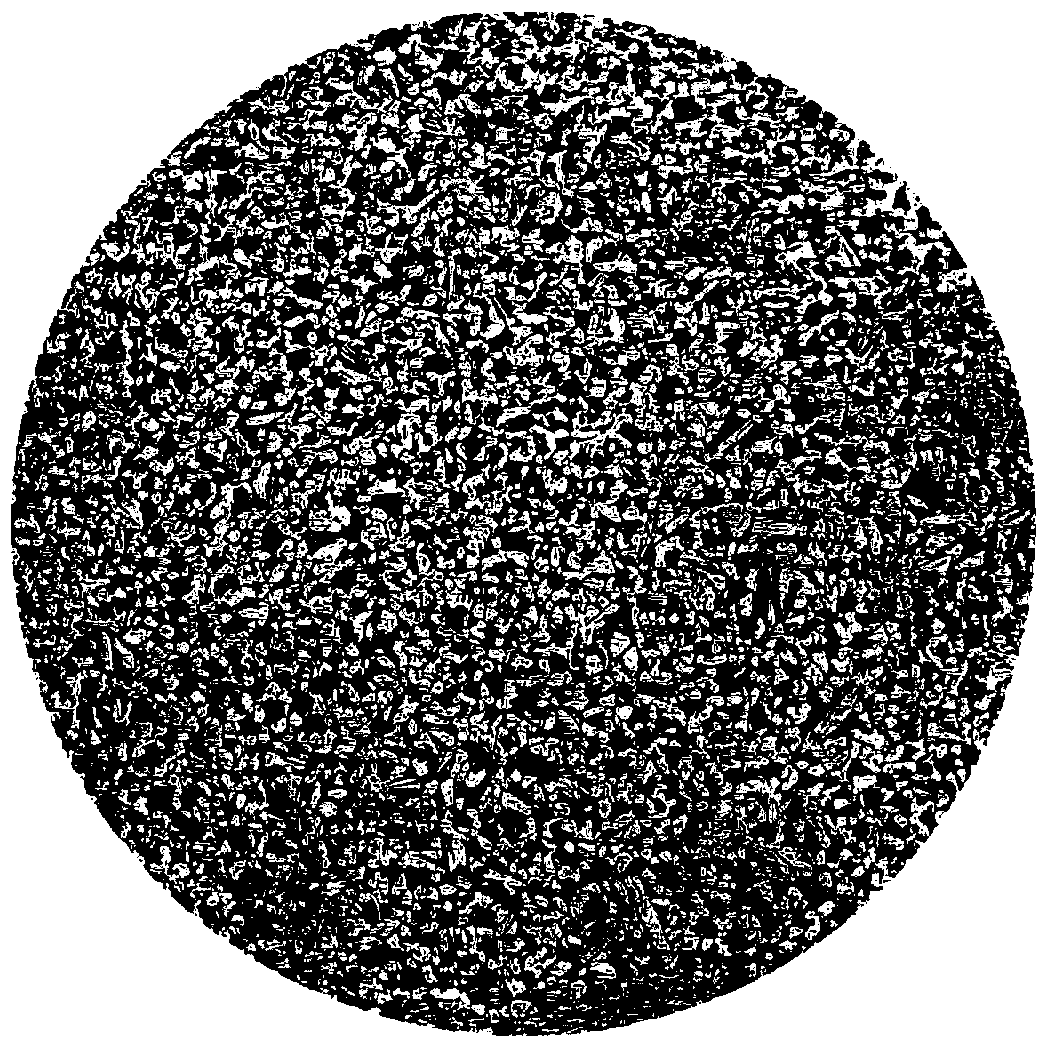

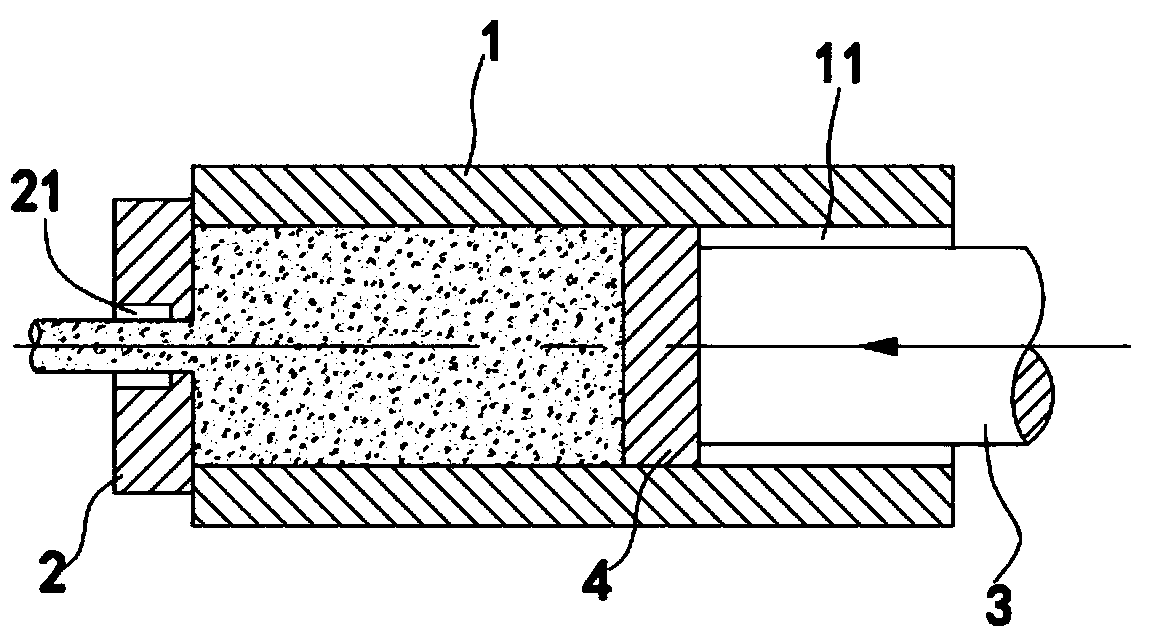

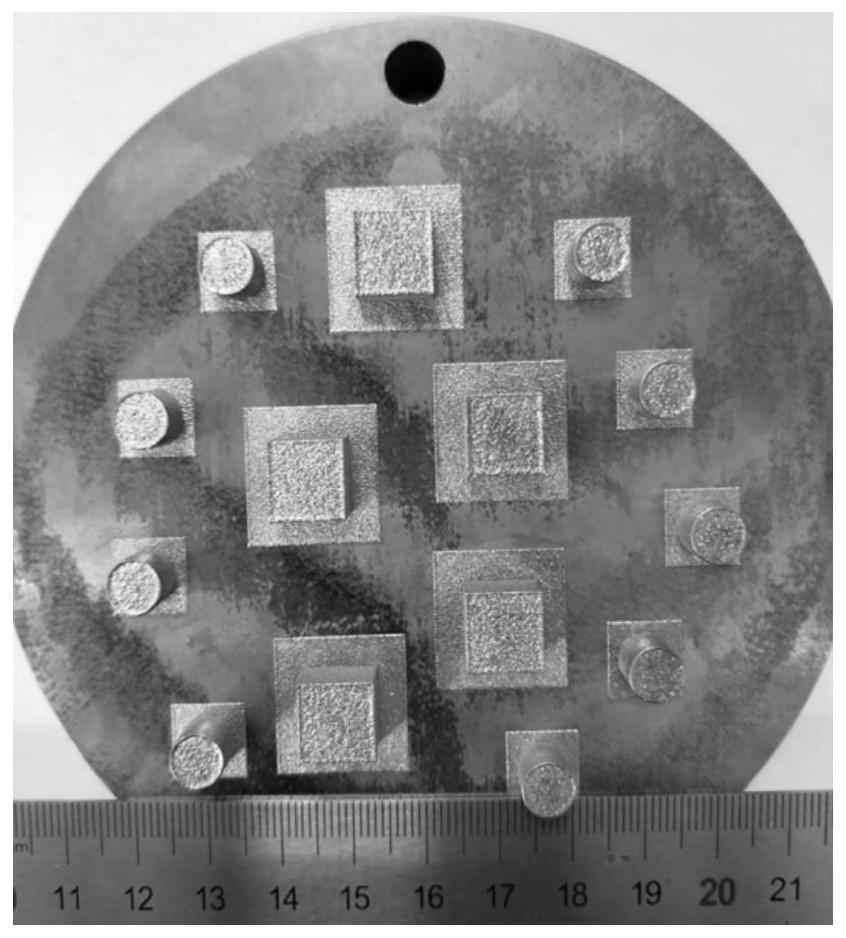

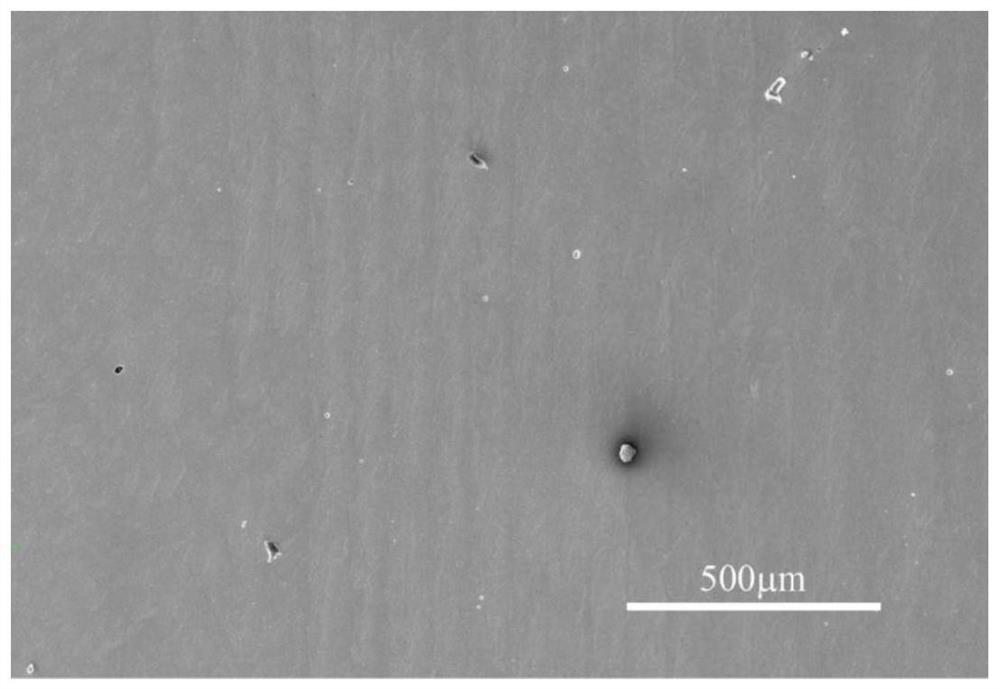

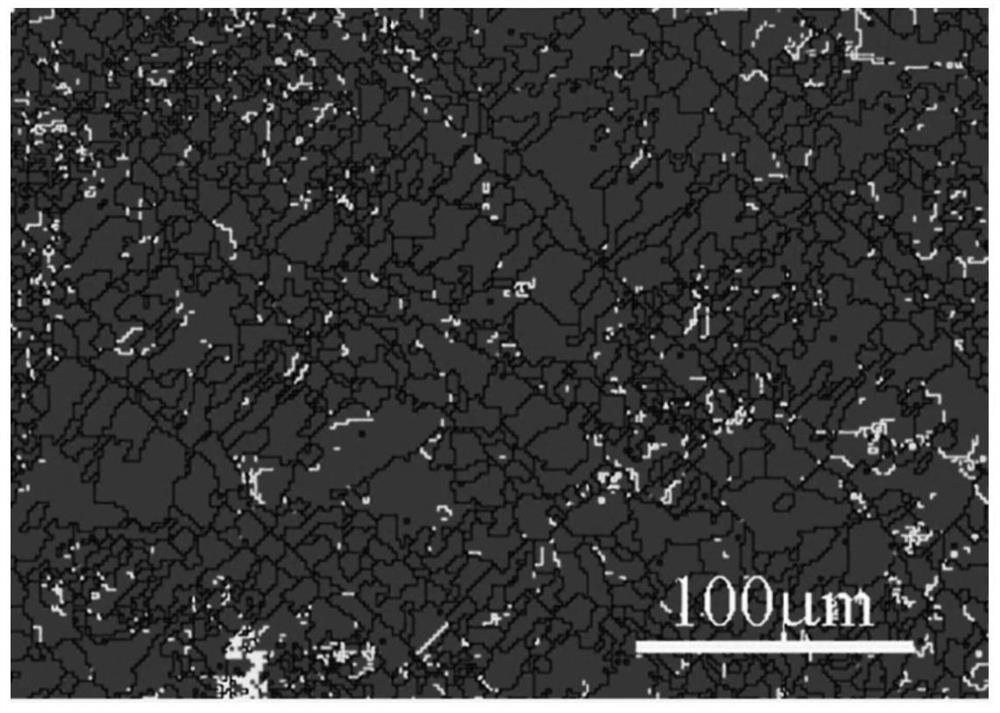

Manufacturing method of molybdenum targets

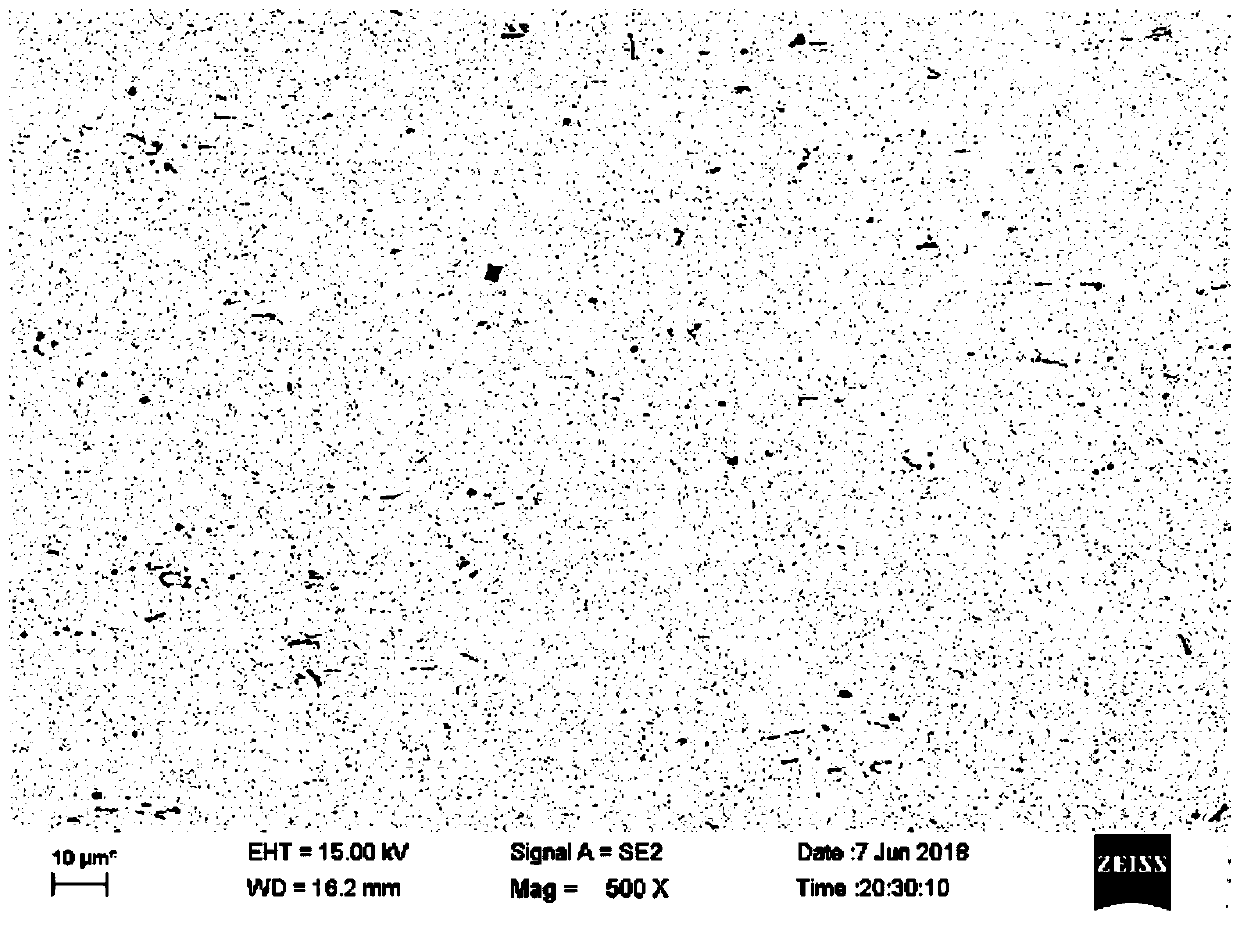

ActiveCN103567445AIncreased dislocation densityIncrease grain boundary areaVacuum evaporation coatingSputtering coatingMaterials scienceMolybdenum

Disclosed is a manufacturing method of a molybdenum target. The method comprises providing molybdenum powder; performing a first densification process on the molybdenum powder through isostatic pressing to obtain a first molybdenum target blank; putting the first molybdenum target blank into a sheath and vacuumizing the sheath; performing a second densification process on the first molybdenum target blank inside the sheath through cold isostatic pressing to form a second molybdenum target blank; after the second densification process, removing the sheath and performing a third densification process on the second molybdenum target blank through induction sintering to form a third molybdenum target blank; after the third densification process, rolling the third molybdenum target blank through hot rolling to form a fourth molybdenum target blank; after the hot rolling process, performing annealing on the fourth molybdenum target blank to obtain the molybdenum target. The manufacturing method of the molybdenum target can help produce full-density molybdenum targets, the uniformity of the internal organizational structure and the size, the purity and the surface dimension of grains of the molybdenum targets can well meet the ever-increasing requirements of the sputtering technology.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

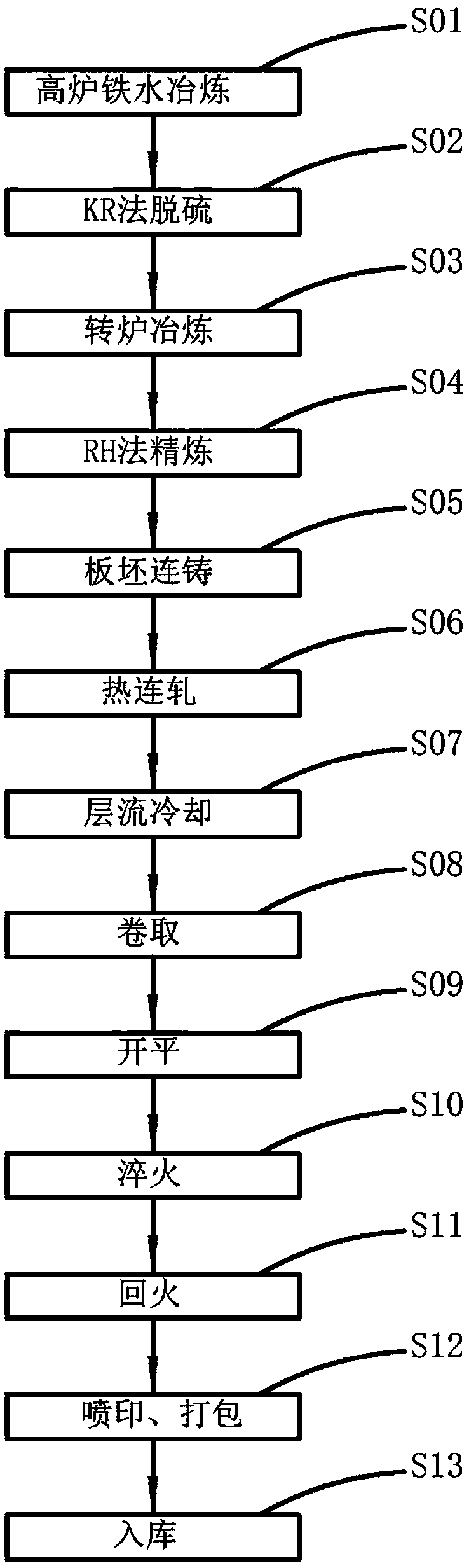

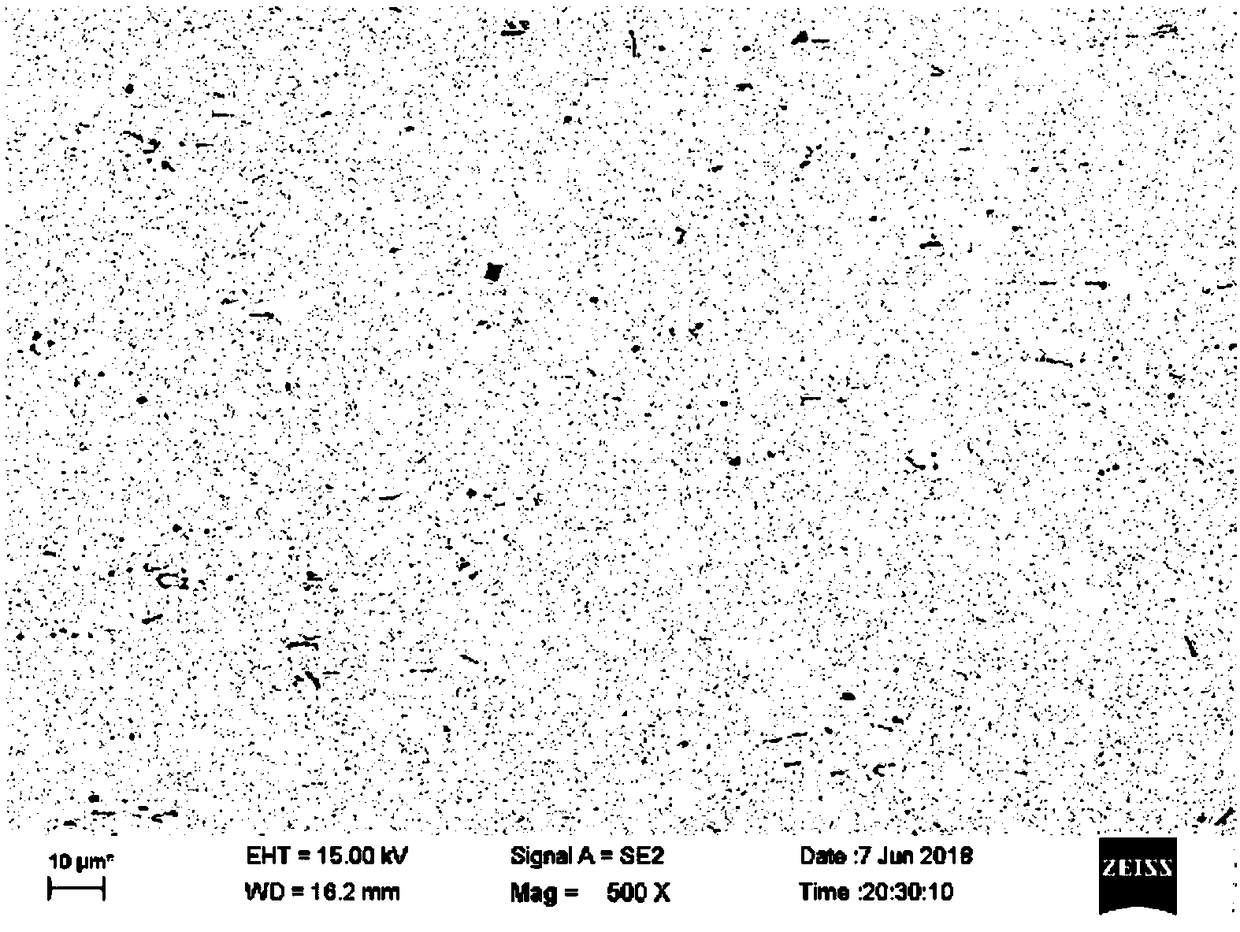

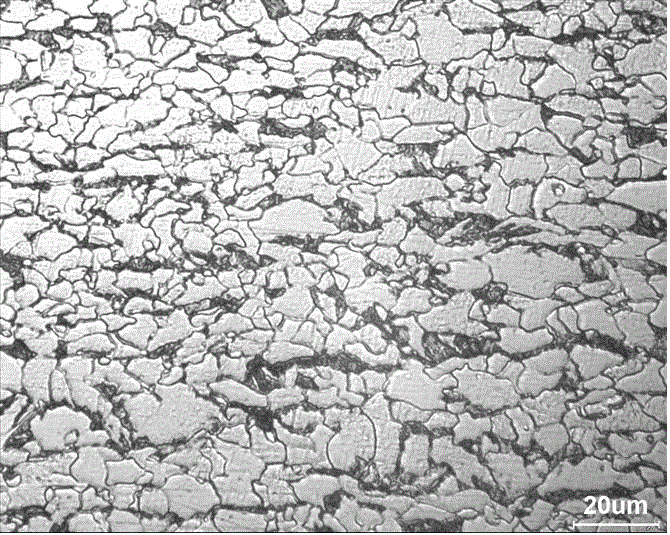

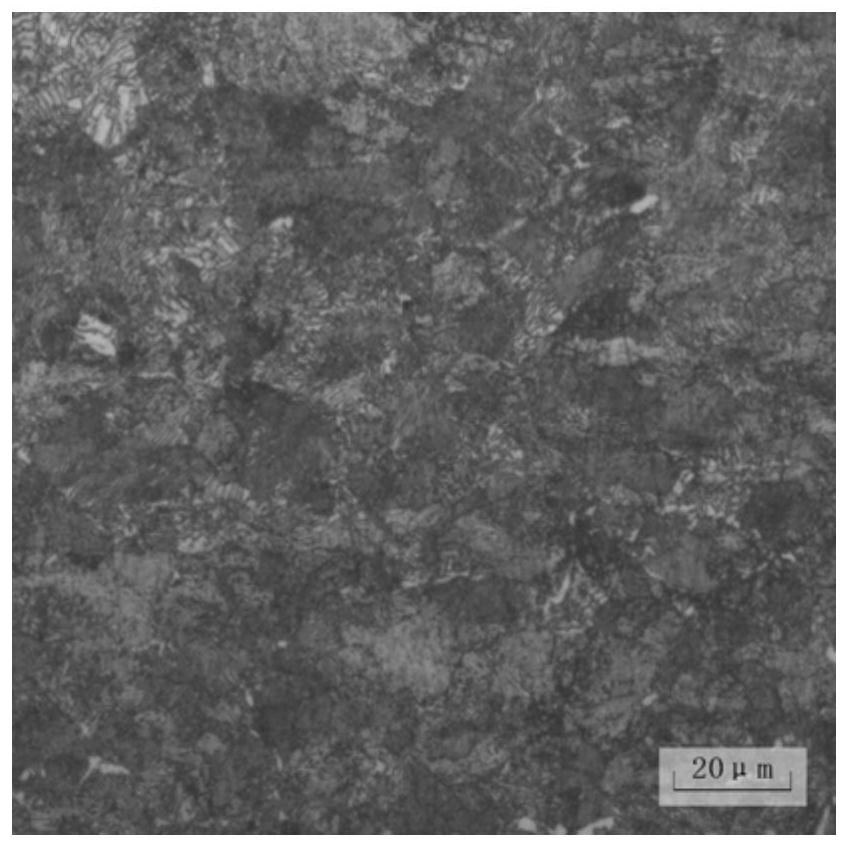

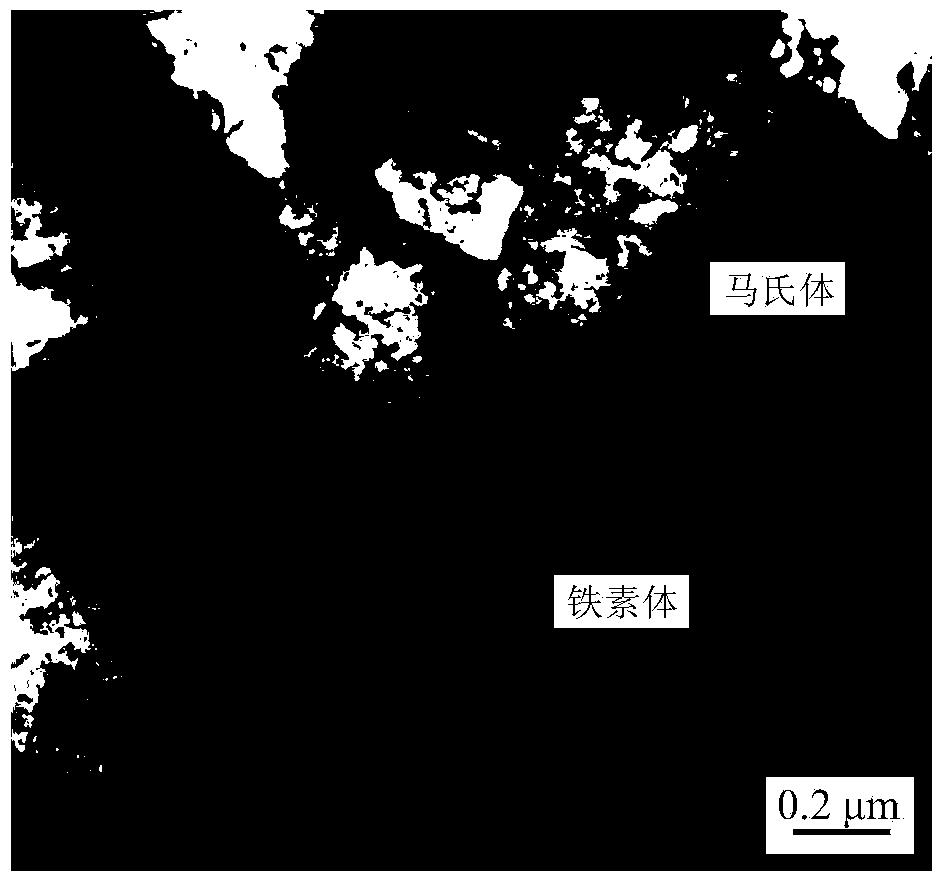

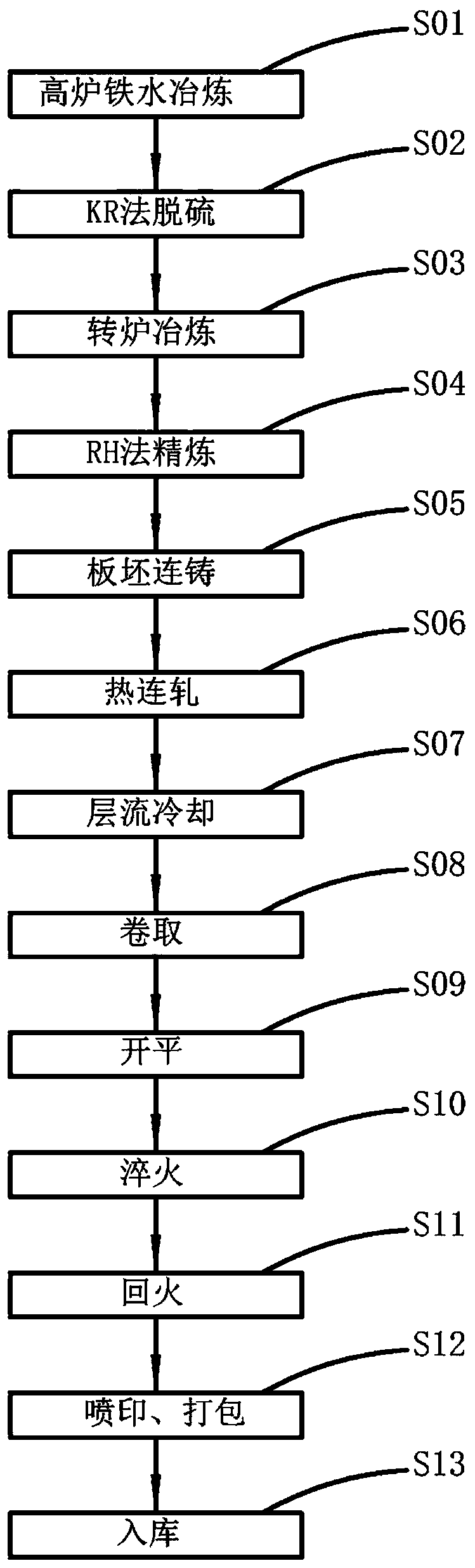

Martensitic wear-resistant steel plate with high wear resistance and manufacturing method thereof

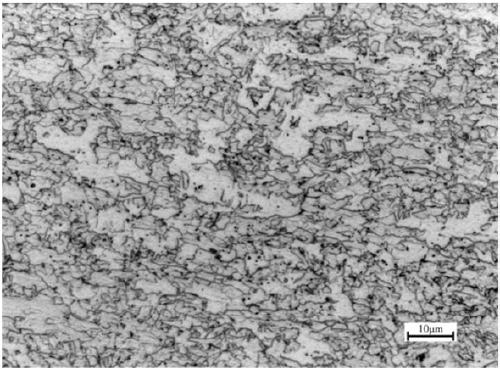

ActiveCN109207853AImproved fine grain strengtheningFine grain strengtheningAustenite grainWear resistant

The invention discloses a martensite wear-resistant steel plate with high wear resistance, belonging to the technical field of steel manufacturing. According to a technical scheme in the invention, the martensite wear-resistant steel plate comprises the following chemical components by weight: 0.32 to 0.38 % of C, 0.02 to 0.30% of Si, 0.8 to 1.0% of Mn, 0.6 to 0.8% of Ti, 0.02 to 0.03% of Nb, 0.15-0.20% of Mo, 0.35-0.45% of Cr, 0.0010-0.0020% of B, no more than 0.003% of S and no more than 0.012% of P, with the balance being Fe and unavoidable impurity elements. In the process of hot continuous rolling in the invention, TiC particles precipitated through continuous casting are gradually fragmented and homogenized along a rolling direction; through rolling fragmentation and solid-state precipitation of nano-sized TiC, most of the micron-sized TiC particles precipitated through continuous casting disappear; and nano-sized TiC can refine original austenite grains and improve ductility andtoughness.

Owner:NORTHEASTERN UNIV +2

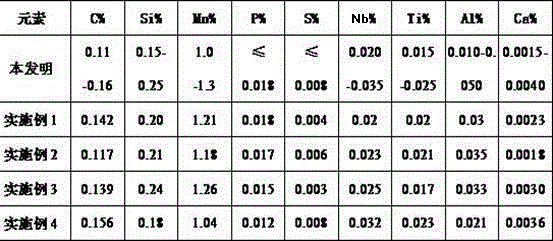

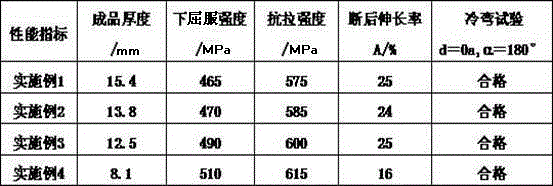

thick hot rolled sheet steel with 450MPa grade yield strength and manufacturing method thereof

The invention relates to a thick hot rolled sheet steel with 450MPa grade yield strength and a manufacturing method thereof, and solves the technical problems of cost increase and hot rolling equipment energy consumption increase due to adding of precious alloy elements in existing 450MPa grade yield strength thick hot rolled sheet steel. The thick hot rolled sheet steel with 450MPa grade yield strength provided by the invention comprises the following chemical components by weight percentage: 0.11%-0.16% of C, 0.15%-0.25% of Si, 1.0%-.3% of Mn, less than or equal to 0.018% of P, less than or equal to 0.008% of S, 0.020%-0.035% of Nb, 0.015%-0.025% of Ti, 0.010%-0.050% of Alt, 0.0015%-0.0040% of Ca, and the balance iron and unavoidable inclusions. The product involved in the invention can be used for construction, ocean engineering, engineering machinery and other industries.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

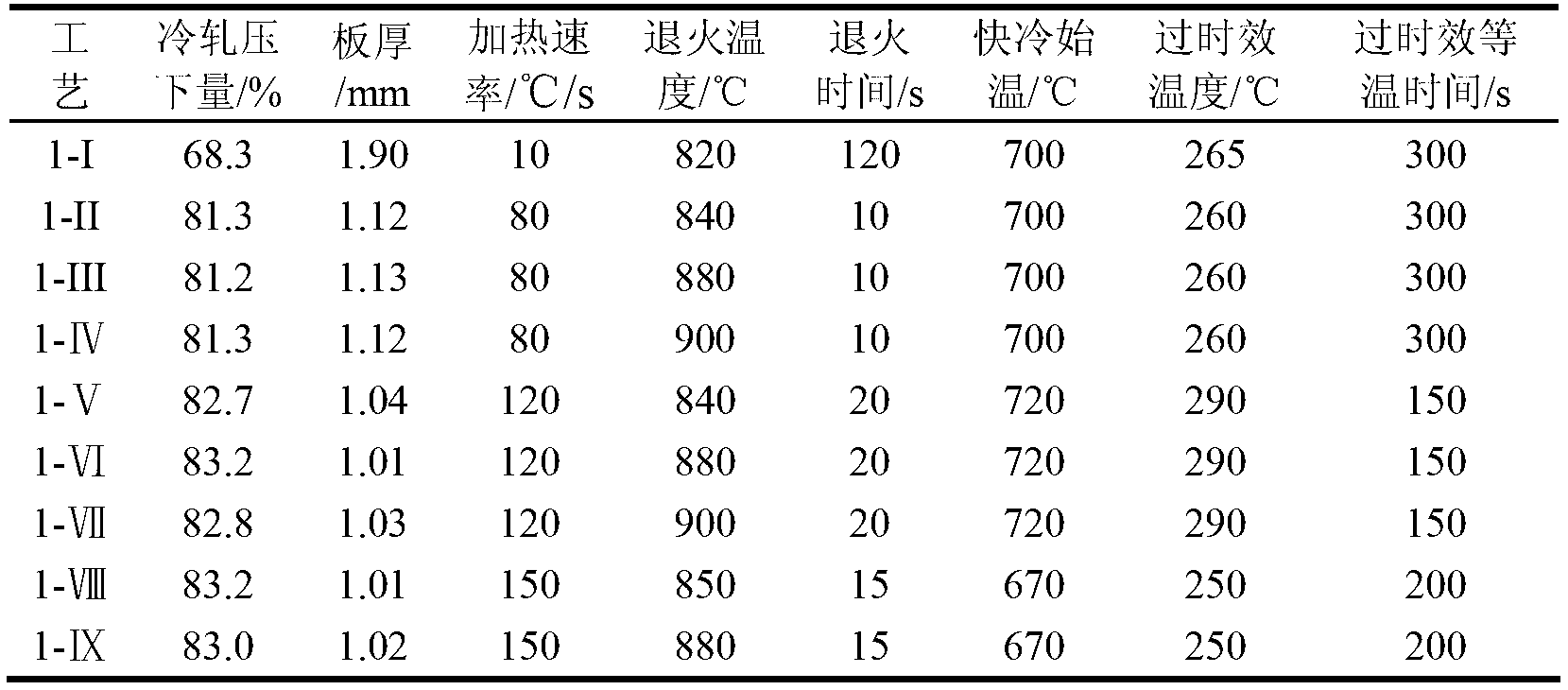

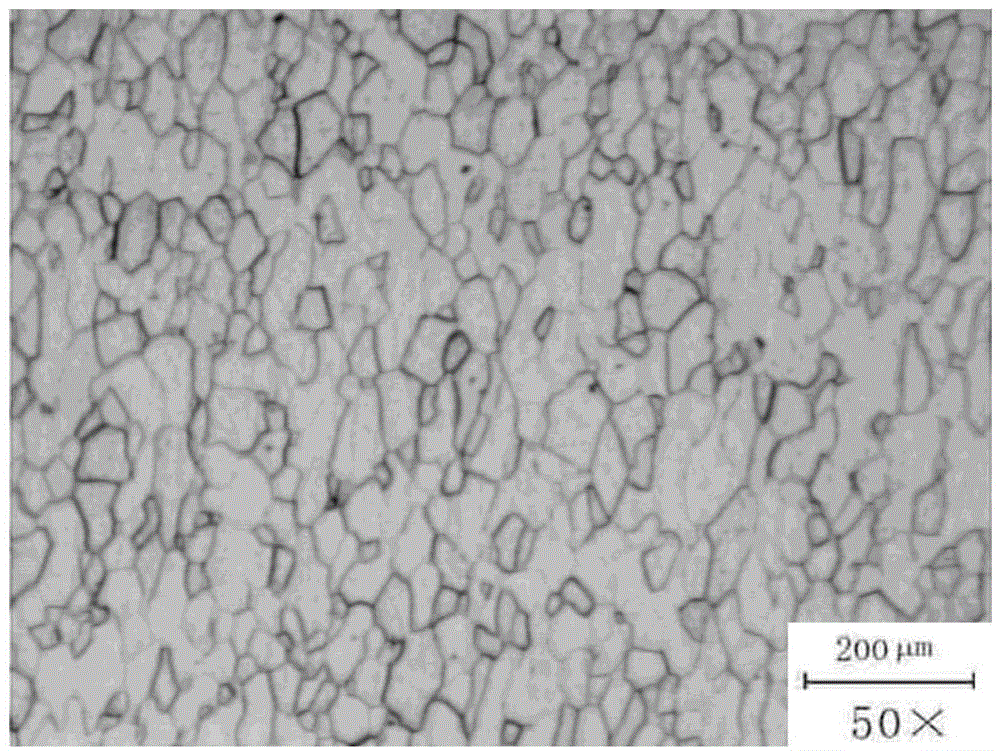

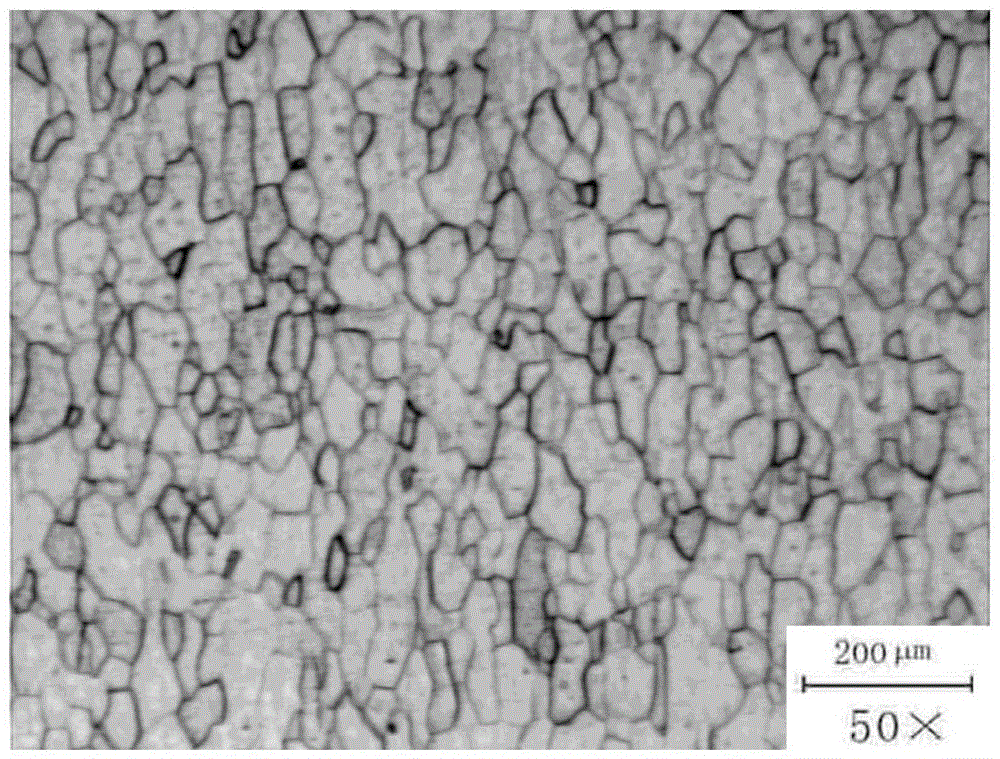

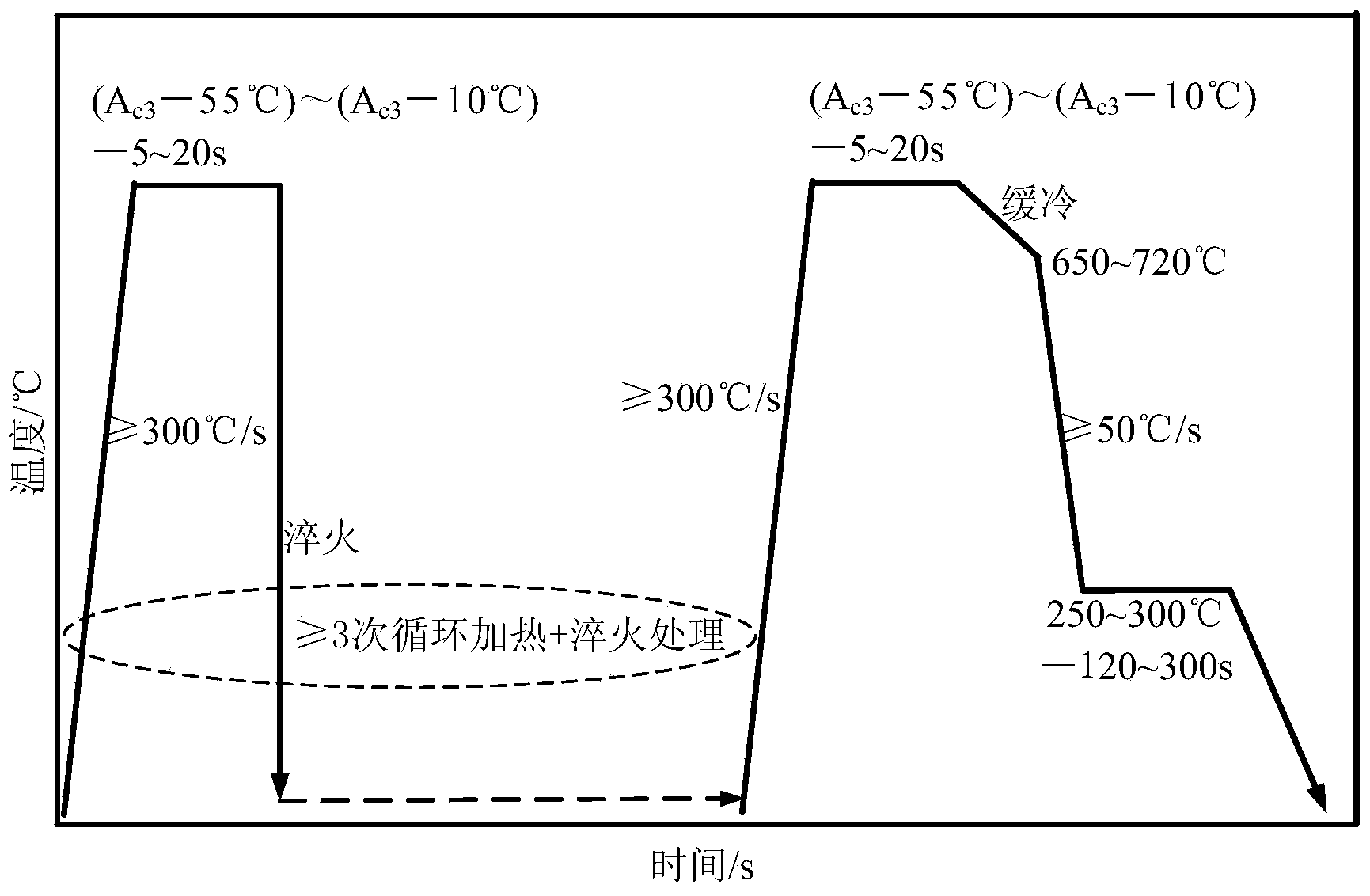

Method for improving mechanical property of low-carbon silicomanganese series cold rolling dual-phase steel

The invention belongs to the technical field of roll steel and relates to a method for improving the mechanical property of low-carbon silicomanganese series cold rolling dual-phase steel. The method comprises the following steps of: smelting and forging the low-carbon silicomanganese series cold rolling dual-phase steel to manufacture a plate blank, heating to 1100-1250 DEG C, carrying out heat preservation, carrying out rough rolling and finish rolling at 820-1100 DEG C, wherein the hot rolling and finish rolling temperature is (Ar3+30) DEG C-(Ar3+100) DEG C, then carrying out laminar cooling to (Ar3-50) DEG C-(Ar3-100) DEG C at cooling rate of 20 DEG C, and carrying out air cooling to room temperature; pickling, heating to (Ac3-50 DEG C)-(Ac3+100 DEG C) after cold rolling by adopting higher than or equal to 80% of rolling reduction, carrying out annealing treatment for 10-20s, carrying out slow cooling to 600-720 DEG C at rate of 5-8 DEG C / s, cooling to 250-300 DEG C at rate of higher than or equal to 30 DEG C / s for isothermal treatment, and carrying out air cooling and water-cooling or naturally cooling to room temperature. A cold rolling dual-phase steel plate with excellent mechanical property can be obtained by adopting the preparation method; the strength, the total percentage elongation after fracture and the work-hardening index of the cold rolling dual-phase steel plate are improved; and the strength of the cold rolling dual-phase steel plate is obviously improved.

Owner:LAIWU IRON & STEEL GRP

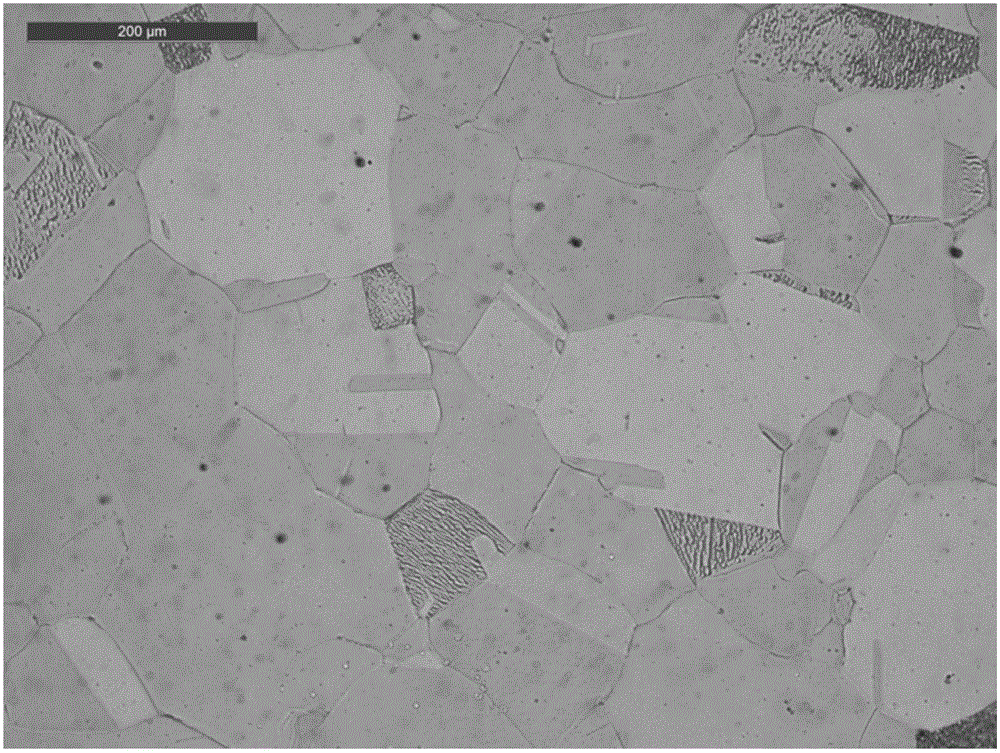

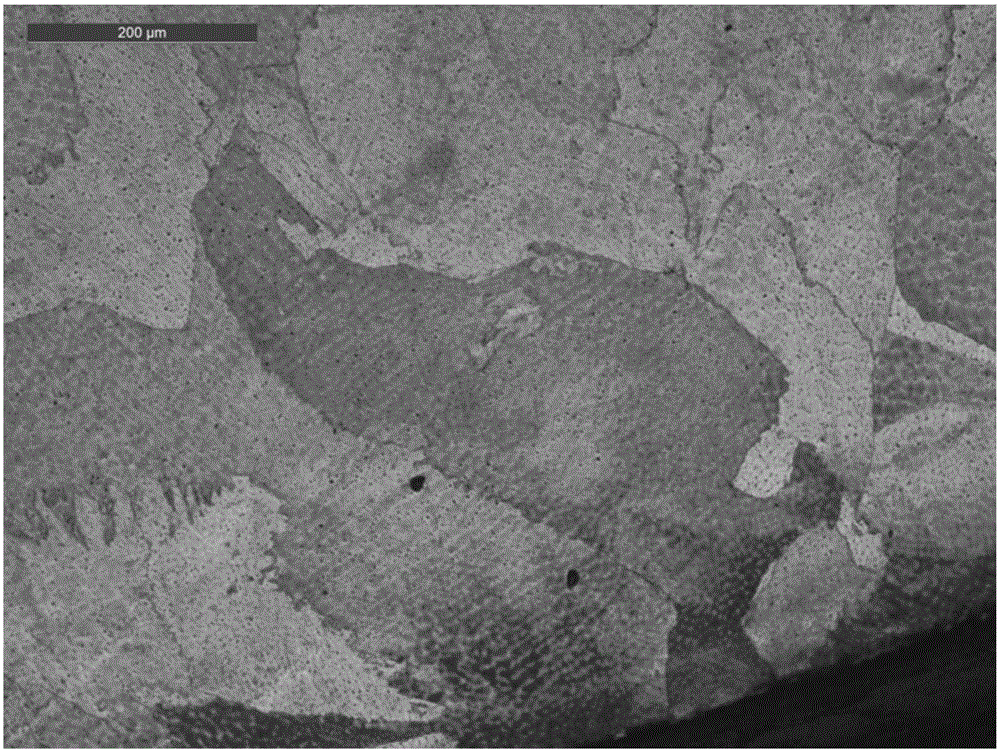

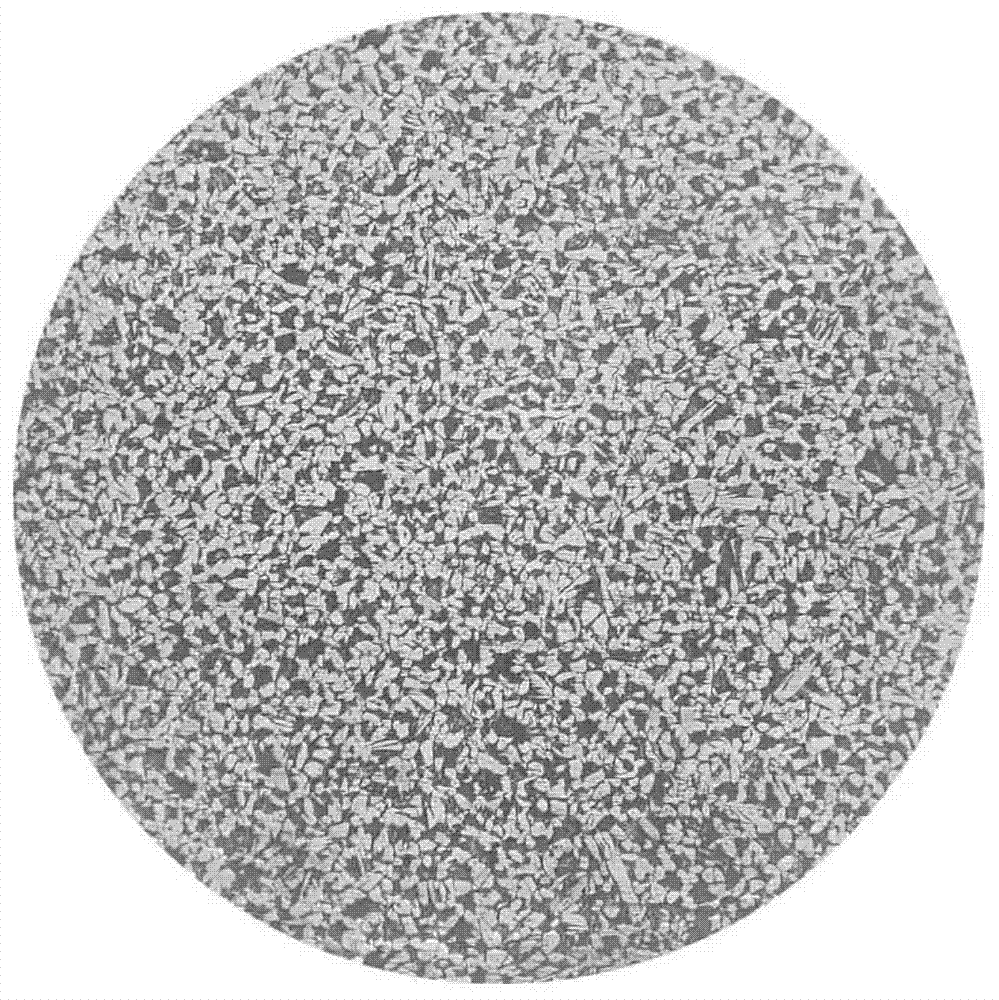

Preparation method of shaped charge liner tantalum 5 tungsten material

The invention provides a preparation method of a shaped charge liner tantalum 5 tungsten material. The preparation method comprises the following steps: A) performing hot forging on a tantalum 5 tungsten cast ingot for three times, wherein a hot forging way is axial upsetting and radial stretching, the upsetting ratio of the axial upsetting is 1.5-2.0, and the stretching ratio of the radial stretching is 0.8-1.0; performing annealing treatment on a tantalum 5 tungsten blank subjected to the hot forging for three times; B) rolling the tantalum 5 tungsten blank subjected to the annealing treatment, wherein the processing rate of rolling is 70-85 percent; C) performing annealing treatment on the tantalum 5 tungsten blank obtained in the step B) to obtain the shaped charge liner tantalum 5 tungsten material. In the process of preparing the tantalum 5 tungsten material, the grain structure inside the prepared tantalum 5 tungsten material is small by adopting the processing methods of the hot forging for three times and the rolling and through controlling parameters in forging and rolling processes, and all mechanical properties are uniform.

Owner:NINGXIA ORIENT TANTALUM IND

Single-ferrite-precipitated steel plate with high strength and high pore-expansion property and preparation method for same

The invention discloses a single-ferrite-precipitated steel plate with high strength and a high pore-expansion property and a preparation method for the same. Steel comprises 0.05%-0.12% of C, 0.1%-0.7% of Si, 0.8%-2.2% of Mn, 0.05%-0.10% of Ti, less than 0.035% of P, less than 0.035% of S, 0.015%-0.060% of Als, 0.0015%-0.0050% of Ca, less than 0.0050% of Mg and less than 0.005% of N, at least oneof ingredients including 0.15%-0.3% of Cr and 0.05%-0.3% of Mo, at least one of ingredients including 0.02%-0.06% of Nb and 0.05%-0.25% of V as well as the balance being Fe and inevitable impurities.The linear speed of Si-Ca feeding is more than or equal to 3.5m / s, and a superheat degree of the molten steel is less than or equal to 30 DEG C; and the heating temperature of a casting blank is 1150-1250 DEG C, the multi-pass rolling total reduction rate is more than or equal to 80%, the final rolling temperature of hot rolling is 850-950 DEG C, the after-rolling cooling rate is 15-45 DEG C / s, and the rolling temperature is 550-650 DEG C. The finished steel plate has the good pore-expansion property.

Owner:ANGANG STEEL CO LTD

Heat treatment process for optimizing 42CrMo low-temperature impact absorbing energy

The invention provides a heat treatment process for optimizing 42CrMo low-temperature impact absorbing energy. According to the heat treatment process, during forging discharging, chemical compositions are controlled, the B element is added, and the hardenability is improved; and after forging, different high normalizing temperatures, different high hardening temperatures and the faster cooling manner are adopted, and the better low temperature impact toughness is obtained. In the discharging process, the chemical compositions are added, the B element is added, then forging is performed, forged materials are subjected to high-temperature normalizing and high-temperature tempering, then rough machining is carried out, materials obtained after rough machining is subjected to modulation treatment, and modulation treatment specifically includes high-temperature quenching and high-temperature tempering, and stress relief annealing is carried out after semifinishing.

Owner:WUXI HONGDA HEAVY IND

Preparation method of lead-acid battery grid alloy containing lead tin-rare earth-graphene

ActiveCN105977496AImproved grain boundary propertiesSmall grain sizeLead-acid accumulatorsElectrode carriers/collectorsRare-earth elementCerium

The present invention discloses a preparation method of a lead-acid battery grid alloy containing lead tin-rare earth-graphene. The method includes a first step of preparing a lead-graphene composite material; a second step of preparing a grid mother alloy; and a third step of preparing the grid alloy, wherein the grid alloy includes the following components by mass percentage: 0.1-1.0% of tin, 0.01-0.2% of lanthanum, 0.05-0.5% of cerium, 0.5-10.0% of lead-graphene composite material, and the balance of lead. In the method, due to addition of the rare earth element, grain and grain boundary characteristics of the alloy are improved remarkably, grain size is reduced substantially, grain boundary area is increased, and corrosion amount is reduced substantially under the same current density. A lead-graphene composite material is deposited on a pure lead plate by using a composite electroplating technology, so as to be directly used as a material to be smelted in later preparation process of the grid alloy, so that the preparation method of the grid alloy is simplified.

Owner:TIANNENG BATTERY GROUP

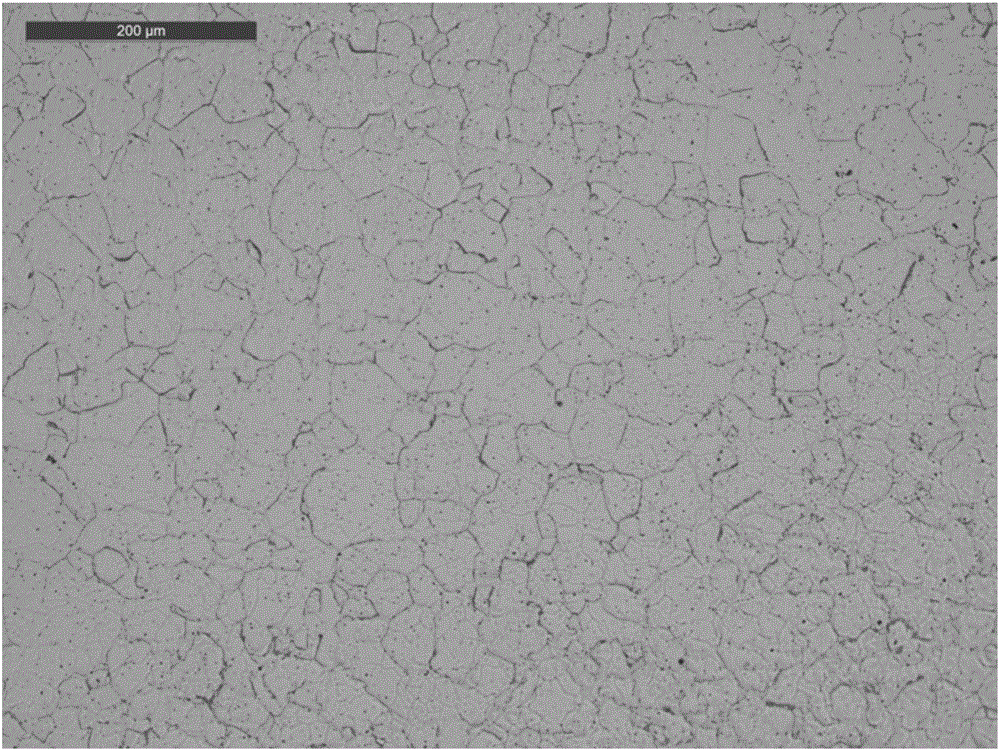

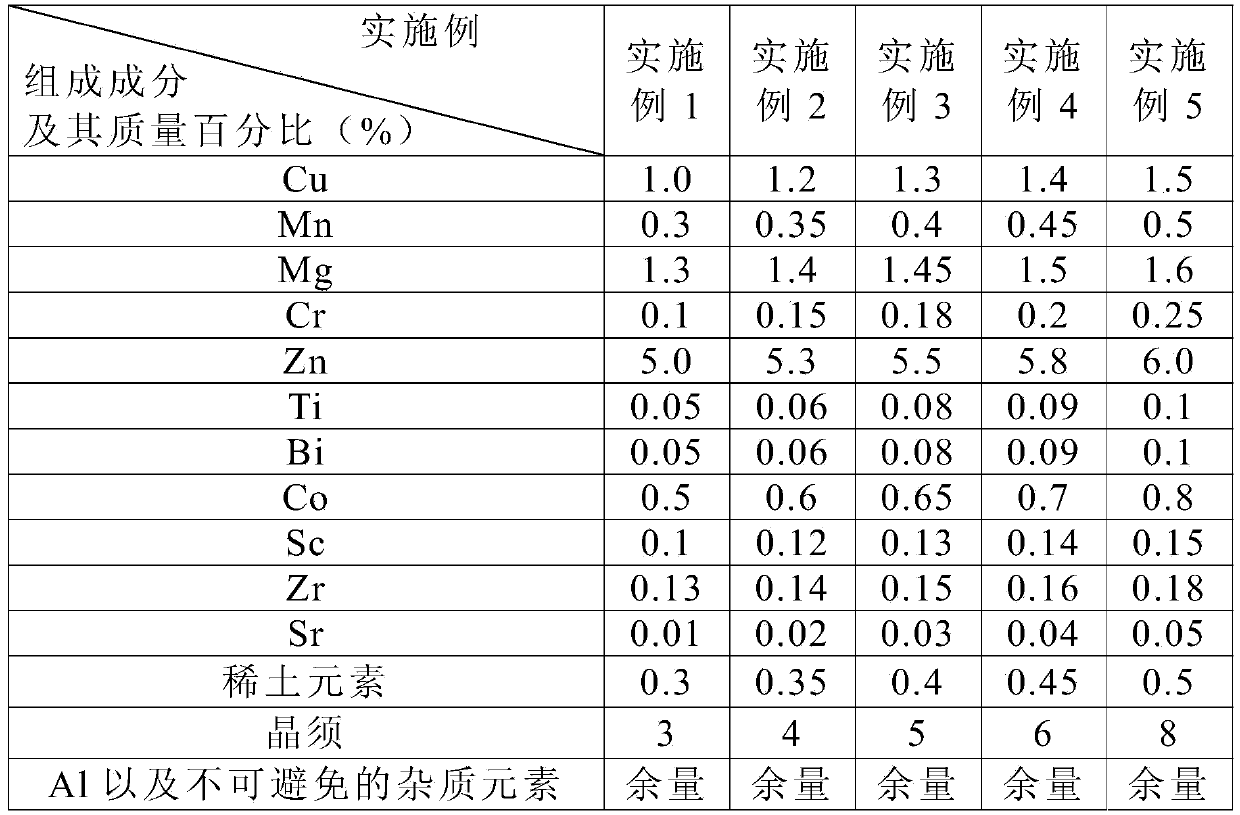

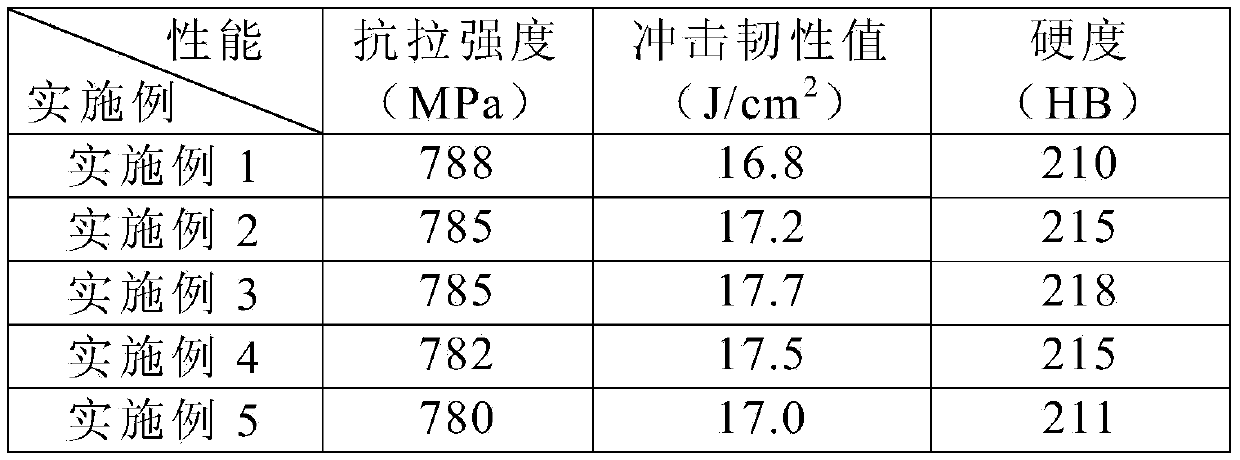

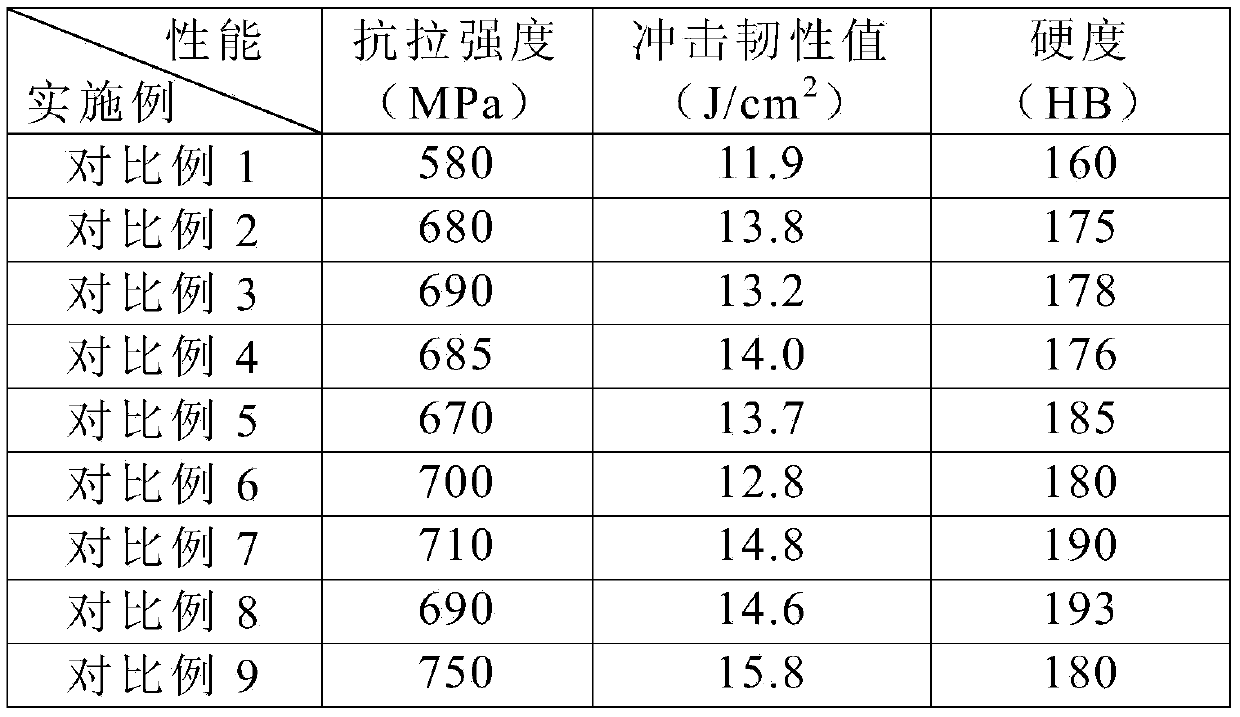

Valve core

The invention relates to a valve core. The valve core comprises a valve core body made of aluminum alloy. The aluminum alloy is composed of, by mass, 1.0%-1.5% of Cu, 0.3%-0.5% of Mn, 1.3%-1.6% of Mg, 0.10%-0.25% of Cr, 5.0%-6.0% of Zn, 0.05%-0.1% of Ti, 0.05%-0.1% of Bi, 0.5%-0.8% of Co, 0.1%-0.15% of Sc, 0.13%-0.18% of Zr, 0.01%-0.05% of Sr, 0.3%-0.5% of rare earth elements, 3%-8% of crystal whiskers, and the balance Al and inevitable impurity elements. The valve core is made of the aluminum alloy and has the advantages of being light, high in strength, resistant to corrosion and the like. Besides, a cold heading process is added to a manufacturing method of the valve core, so that the material utilization rate is increased.

Owner:NINGBO YINZHOU YINXIN ALUMINUM CO LTD

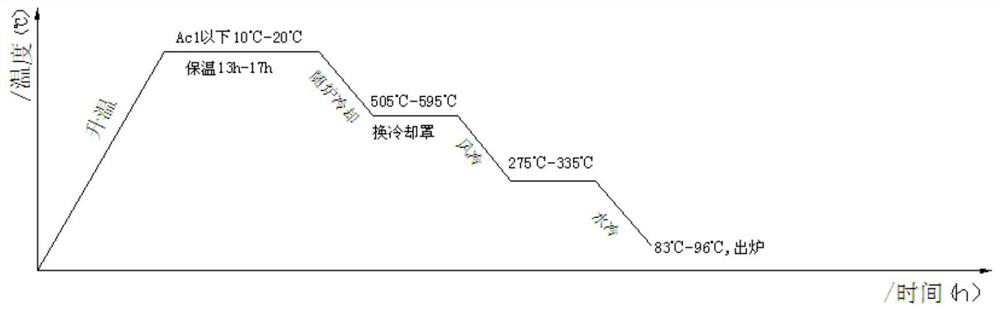

Cold roll bulk heat treatment process

InactiveCN108103302AImprove plasticityGood welding performanceFurnace typesIncreasing energy efficiencyCold treatmentMedium frequency

The invention discloses a cold roll bulk heat treatment process. A roll is subjected to normalizing, annealing, quenching and tempering, medium-frequency hardening and cold treatment, the hardness, toughness and impact resistance of a final structure meet the operation requirements, and the service life of the roll is greatly prolonged. A batch-type furnace and a well type electric furnace are used for heating, an overall rapid heating and hardening method is adopted, and the hardening quality of 60CrMnMo steel cold roll can still be ensured.

Owner:CHANGZHOU ECCO ROLLER

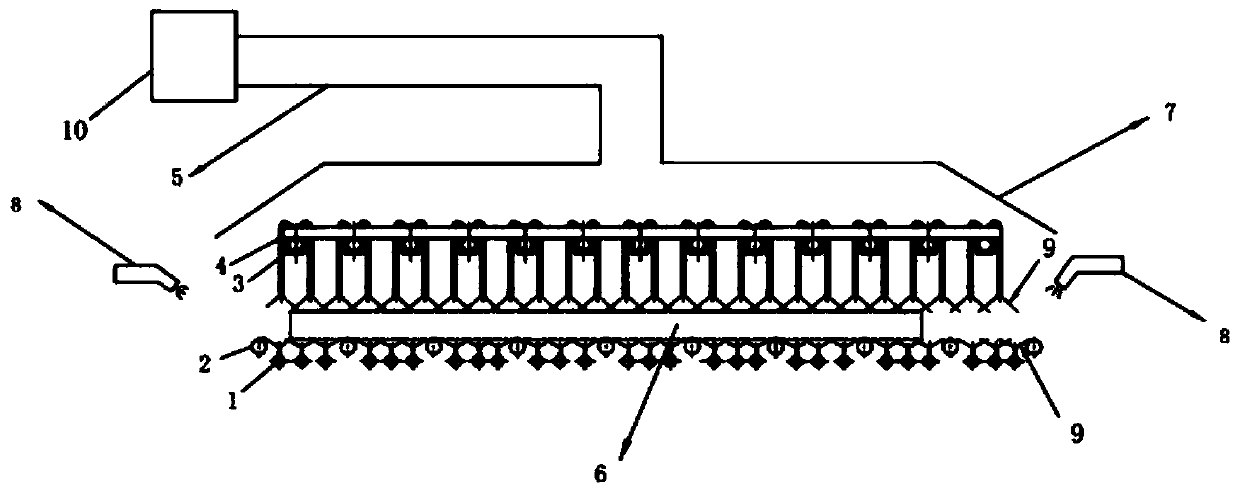

Quick-cooling device for reducing surface crack generation rate of hot-feeding casting blank

The invention discloses a quick-cooling device for reducing the surface crack generation rate of a hot-feeding casting blank. The quick-cooling device comprises a first round quick-cooling device, andthe quick-cooling device further comprises a second round quick-cooling device and a vapor-removing cover; the second round quick-cooling device comprises a transport roller way, a plurality of rowsof upper cooling nozzle sets are arranged above the transport roller way, a plurality of rows of lower cooling nozzle sets are arranged below the transport roller way, and high temperature meters arearranged at an inlet and an outlet of the transport roller way correspondingly; 2-3 rows of upper cooling nozzle sets and lower cooling nozzle sets are uniformly arranged between every two conveying rollers of the transport roller way; the vapor-removing cover is in communication with a vapor collection device through a vapor channel; and the vapor-removing cover covers the second round quick-cooling device. The quick-cooling device can be used for refining the grain size of the surface of the casting blank, and after two rounds of quick cooling, the average grain size of the surface of the casting blank can reach 25 um or below.

Owner:SHANDONG IRON & STEEL CO LTD

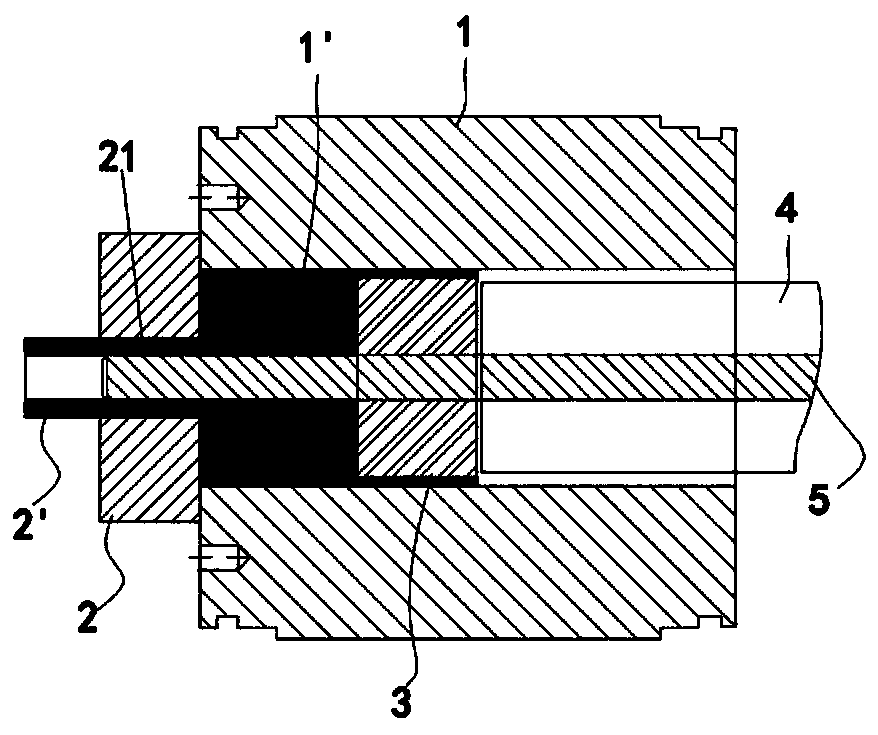

Superconducting joint and preparation method thereof

ActiveCN109802247AConnection Efficiency LimitSmall grain sizeContact member manufacturingCoupling contact membersElectrical conductorReaction rate

The invention belongs to the technical field of superconductor preparation, and specifically relates to a superconducting joint and a preparation method thereof. The superconducting joint comprises boron powder, magnesium powder, superconductors, an outer metal sheath and an inner metal sheath, wherein the superconductors and boron powder are coated by the inner metal sheath, a low-melting-point alloy phase is formed at the junction of the inner metal sheath and the magnesium powder when heat treatment is carried out, a liquid phase can be formed when the temperature is lower than 600 DEG C, and the diffusion rate and reaction rate of magnesium for entering the boron powder are accelerated, so that the reaction of the boron powder and the magnesium powder can be conducted at a temperaturelower than 600 DEG C, the crystal grain size of a product MgB2 is reduced, the crystal boundary area is increased, and thus the pinning ability of MgB2 is improved. In addition, the setting of the inner metal sheath can enable the connection efficiency of the superconducting joint not to be limited by the shape of the superconductors.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Ultrathin 65Mn cold-rolled wide steel strip and manufacturing method thereof

ActiveCN113399456AImprove rolling effectReduce cooling stressFurnace typesProcess efficiency improvementSteel beltRolling mill

The invention provides an ultrathin 65Mn cold-rolled wide steel strip and a manufacturing method of the ultrathin 65Mn cold-rolled wide steel strip. According to optimal cold-rolling technological parameters such as the reduction schedule, the rolling force, the rolling speed and the tension for joint production of the ultrathin 65Mn cold-rolled wide steel strip by adopting a 1450mm single-machine-frame six-roller reversible rolling mill and a Sendzimir twenty-roller reversible rolling mill, front-pass large-reduction rough rolling of the six-roller rolling mill and rear-pass thin-specification finish rolling of the twenty-roller rolling mill are achieved, the complementary advantages of equipment are fully achieved, the technical problems that rolling of the ultrathin 65Mn cold-rolled wide steel strip is unstable, the strip is prone to breakage, the plate shape control is difficult, and the rolling difficulty is high are solved, and the situations that the size precision of products is high, the plate shape is flat, and the quality is stable are guaranteed.

Owner:新余钢铁股份有限公司

High-strength and abrasion resisting copper alloy contact wire and preparation technology thereof

InactiveCN109504872AHigh chemical activityHigh affinityTrolley linesRare-earth elementSolution treatment

The invention relates to the field of copper alloy technical processing, in particular to a high-strength and abrasion resisting copper alloy contact wire and a preparation technology thereof. The high-strength and abrasion resisting copper alloy contact wire is prepared from the raw materials in percentage by weight: 0.01-0.30% of a rare earth element, 0.01-0.10% of a metallic oxide, and the balance of the copper alloy. The preparation method comprises alloy product preparation, semi-solid state treatment, horizontal continuous casting, continuous extrusion, first cold working, solution treatment, second cold working, two-stage aging, and drawing forming. The high-strength and abrasion resisting copper alloy contact wire has good electrical conductivity, high strength, high high-temperature resistance, and abrasion resistance, and can be used as a contact wire material for high speed railways, especially for a high-speed railway with speed of more than 400 kilometers per hour.

Owner:SHANDONG YANGGU CABLE GROUP

High-performance aluminum alloy for casting thin-walled structural parts and preparation method of high-performance aluminum alloy

ActiveCN111254325AGood casting performanceImprove filling abilityUltimate tensile strengthMaterials science

The invention discloses a high-performance aluminum alloy for casting thin-walled structural parts and a preparation method of the high-performance aluminum alloy. The aluminum alloy is prepared fromthe following components in percentage by weight: 9.5-11.0% of Si, less than or equal to 0.15% of Fe, 0.26-0.35% of Mg, less than or equal to 0.05% of Zn, 0.5-0.6% of Mn, less than or equal to 0.03% of Cu, 0.05-0.15% of Ti, less than or equal to 0.002% of Ca, less than or equal to 0.002% of Na, less than or equal to 0.002% of P, less than or equal to 0.005% of Sb, 0.010-0.025% of Sr, less than orequal to 0.01% of Cd, less than or equal to 0.001% of Li and the balance of Al. According to the high-performance aluminum alloy for casting the thin-walled structural parts and the preparation methodof the high-performance aluminum alloy, design and study are carried out in terms of composition design, material selection, purification treatment, casting process and the other aspects, and the aluminum alloy with greater than or equal to 220 MPa of tensile strength, greater than or equal to 130 MPa of yield strength and greater than or equal to 6.0% of elongation is provided, and can meet theproduction demand of automobile shock absorber towers.

Owner:保定隆达铝业有限公司 +2

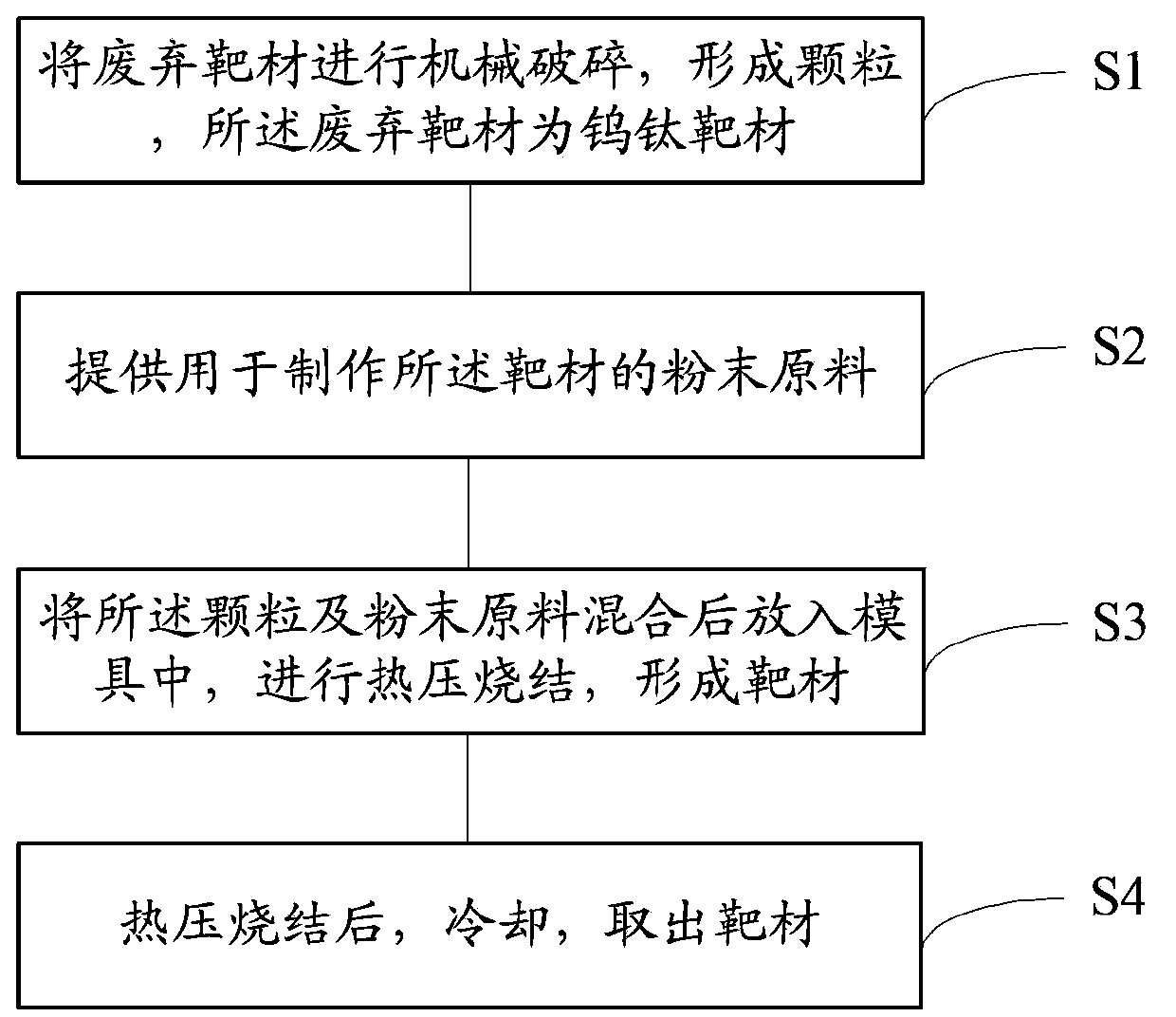

Manufacture method of tungsten-titanium target material

InactiveCN104213083AIncrease profitAvoid wastingVacuum evaporation coatingSputtering coatingTitaniumTungsten

The invention provides a manufacture method of a tungsten-titanium target material. The manufacture method includes the steps: mechanically crushing a waste target material, to form particles, wherein the waste target material is a tungsten-titanium target material; providing a powder raw material for manufacturing the target material; after mixing the particles and the powder raw material, putting into a mold, carrying out hot pressing sintering, and forming a target material; and after hot pressing sintering, cooling, and taking out the target material. The manufacture method of the target material can greatly improve the utilization rate of the target material, so as to avoid the waste of materials of the target material and save costs. In addition, compared with a process of directly carrying out hot pressing sintering on the waste target material and the powder raw material, the hot pressing sintering process has low temperature and low pressure intensity when the waste target material is recycled, and thus process costs can be further saved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

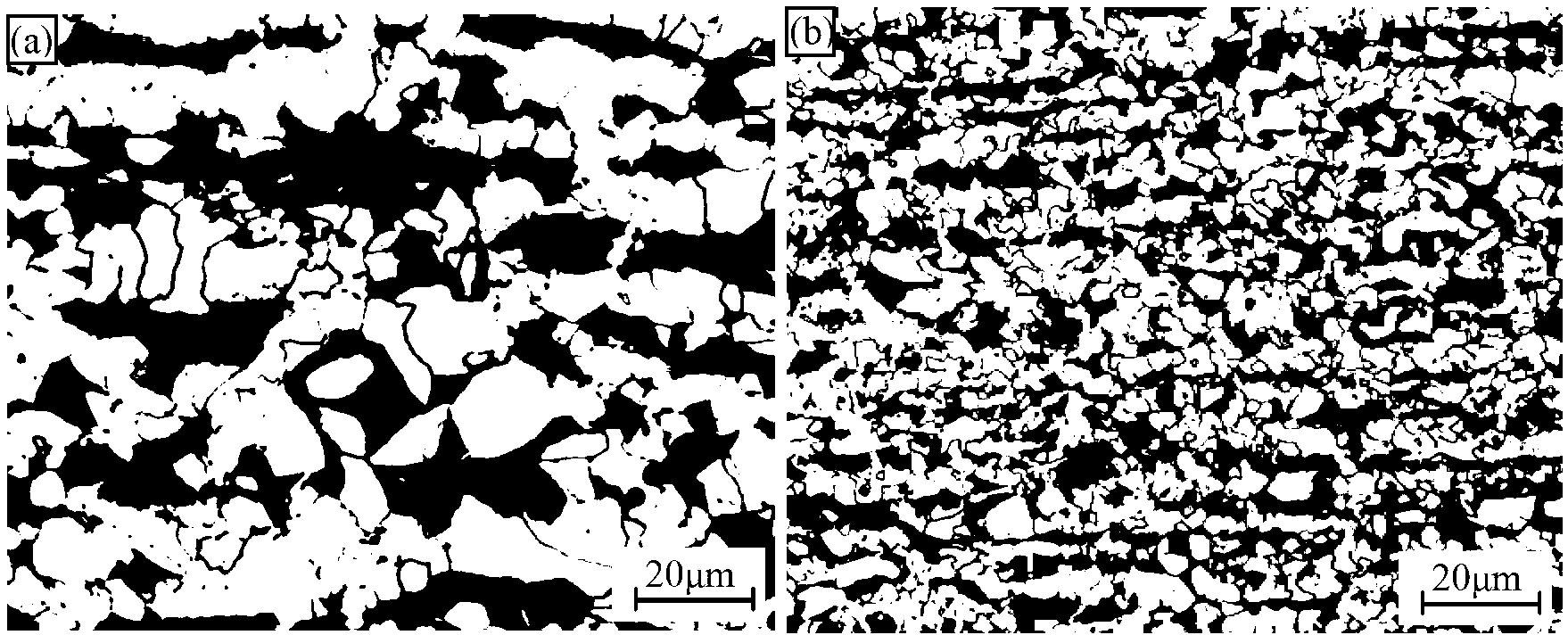

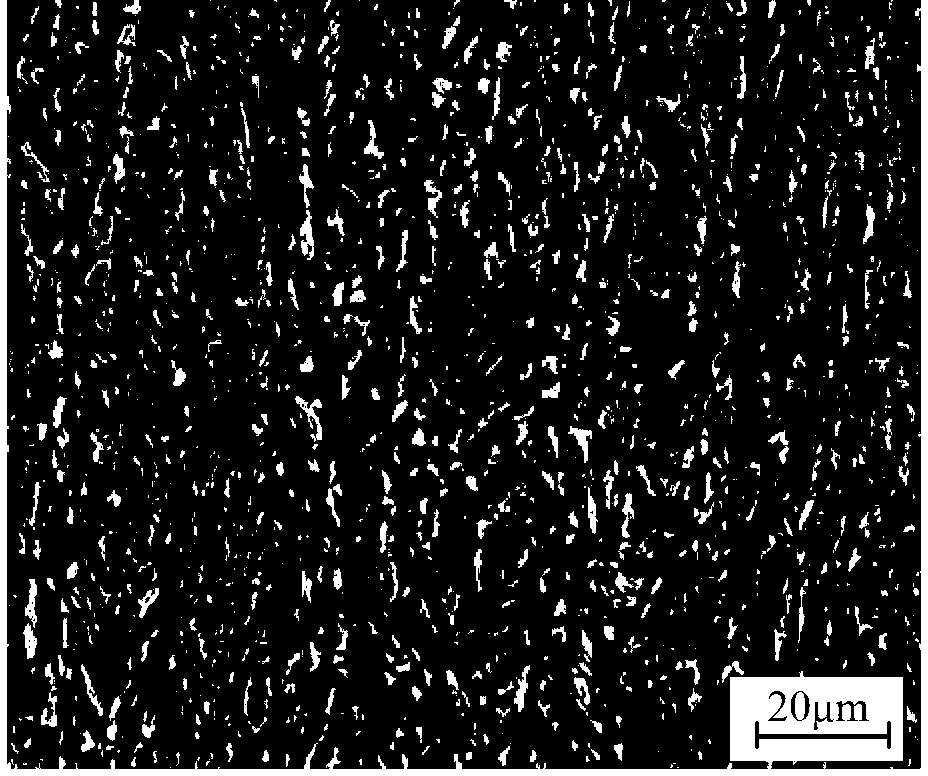

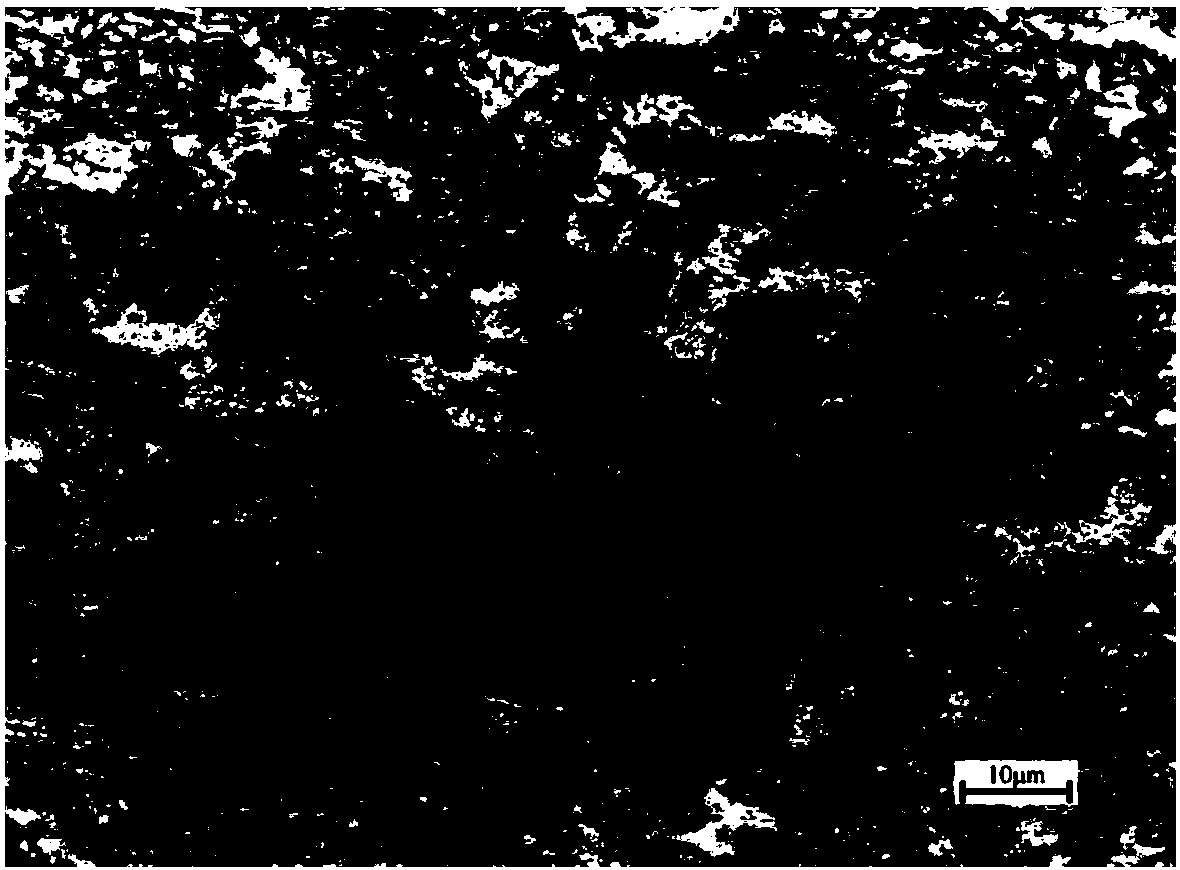

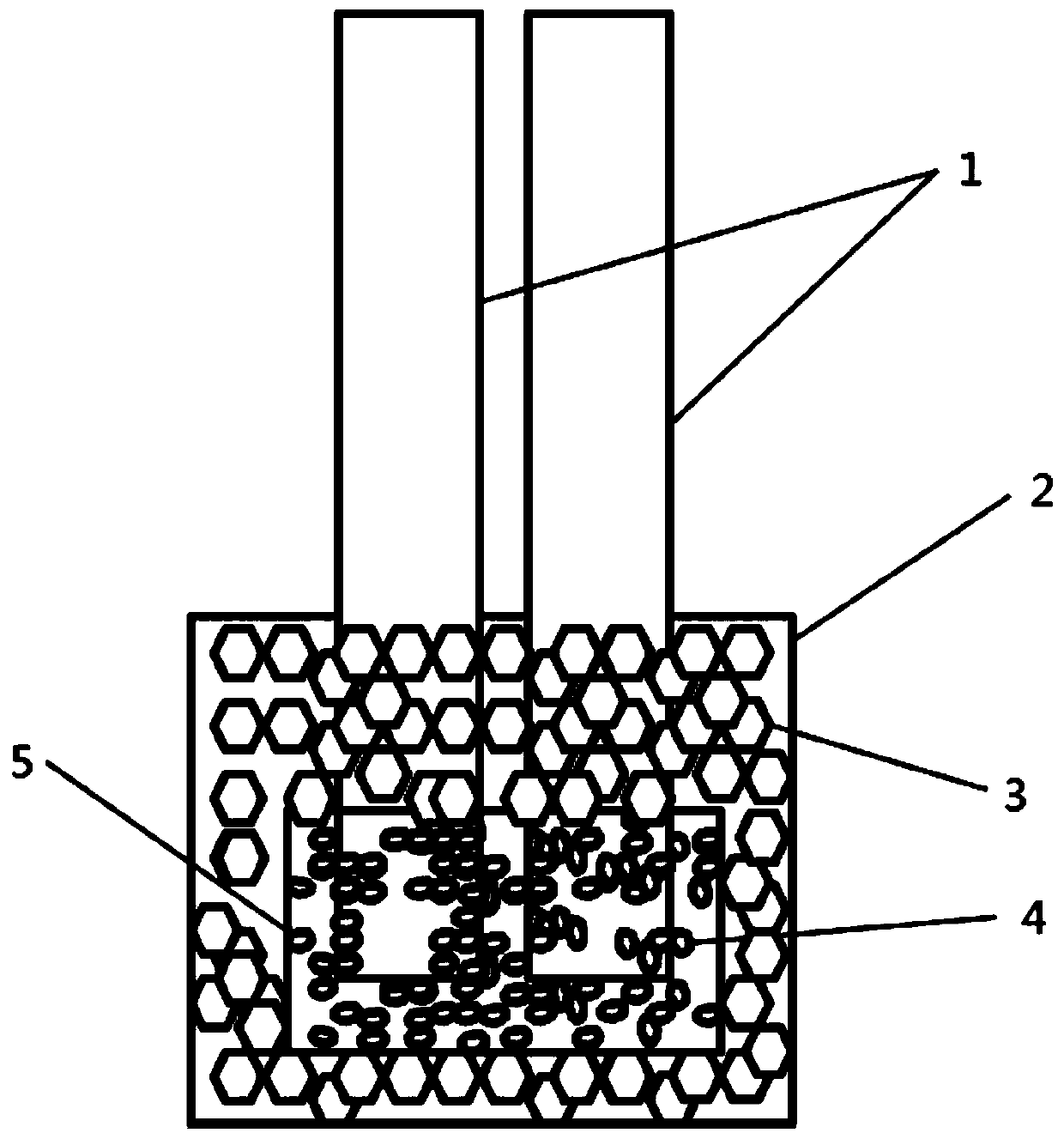

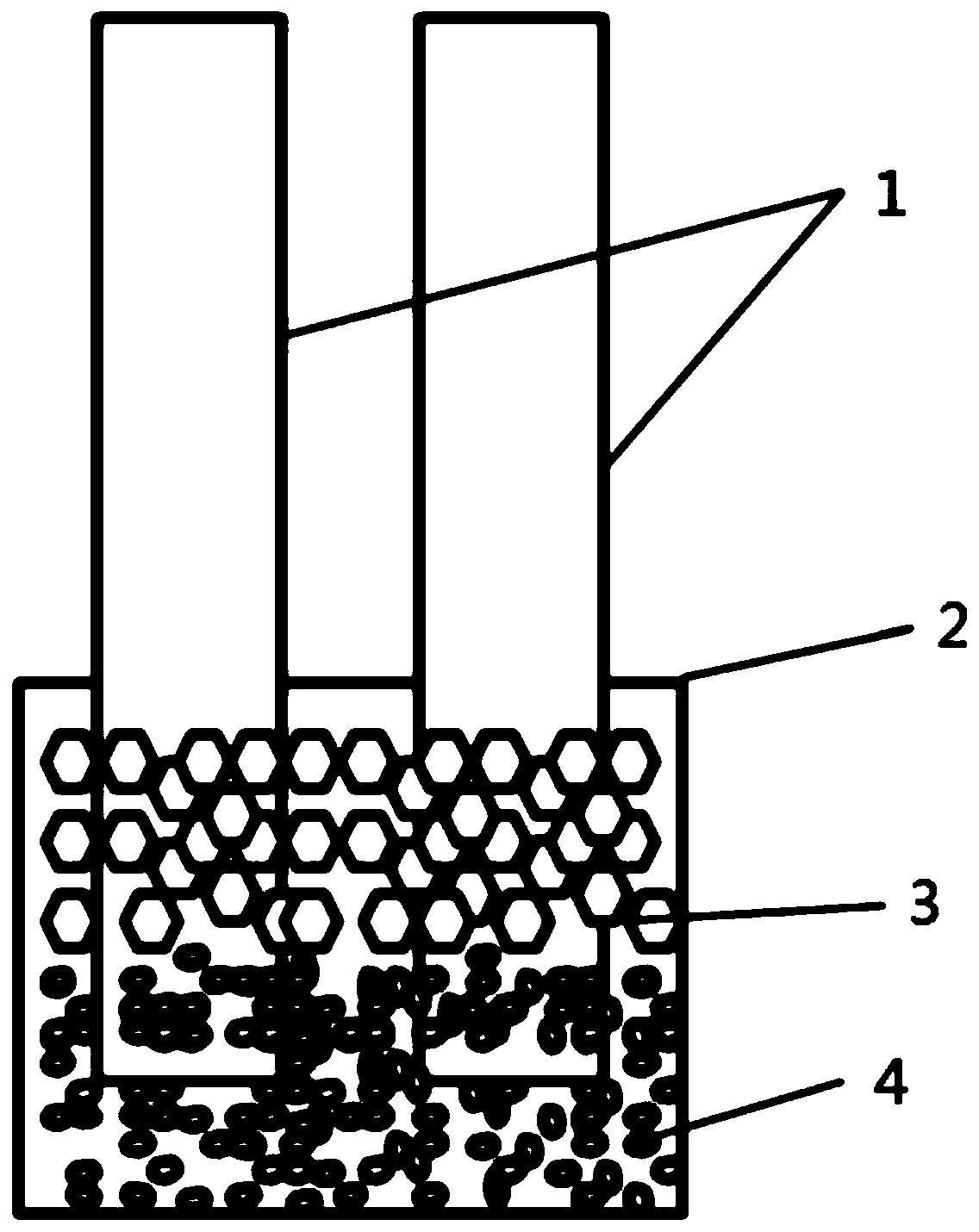

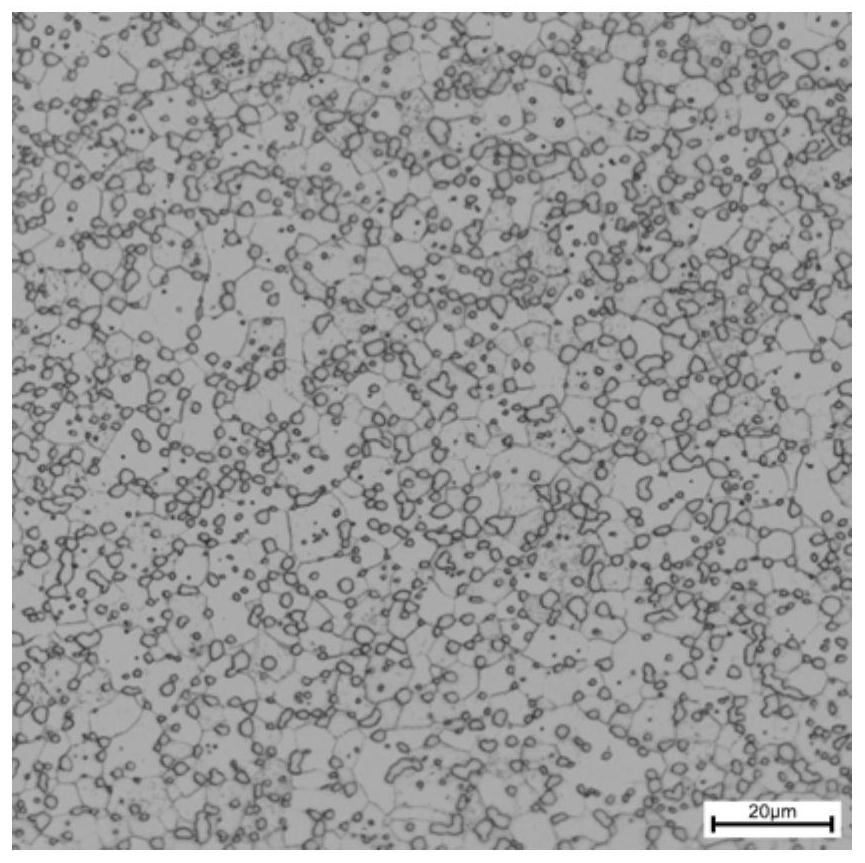

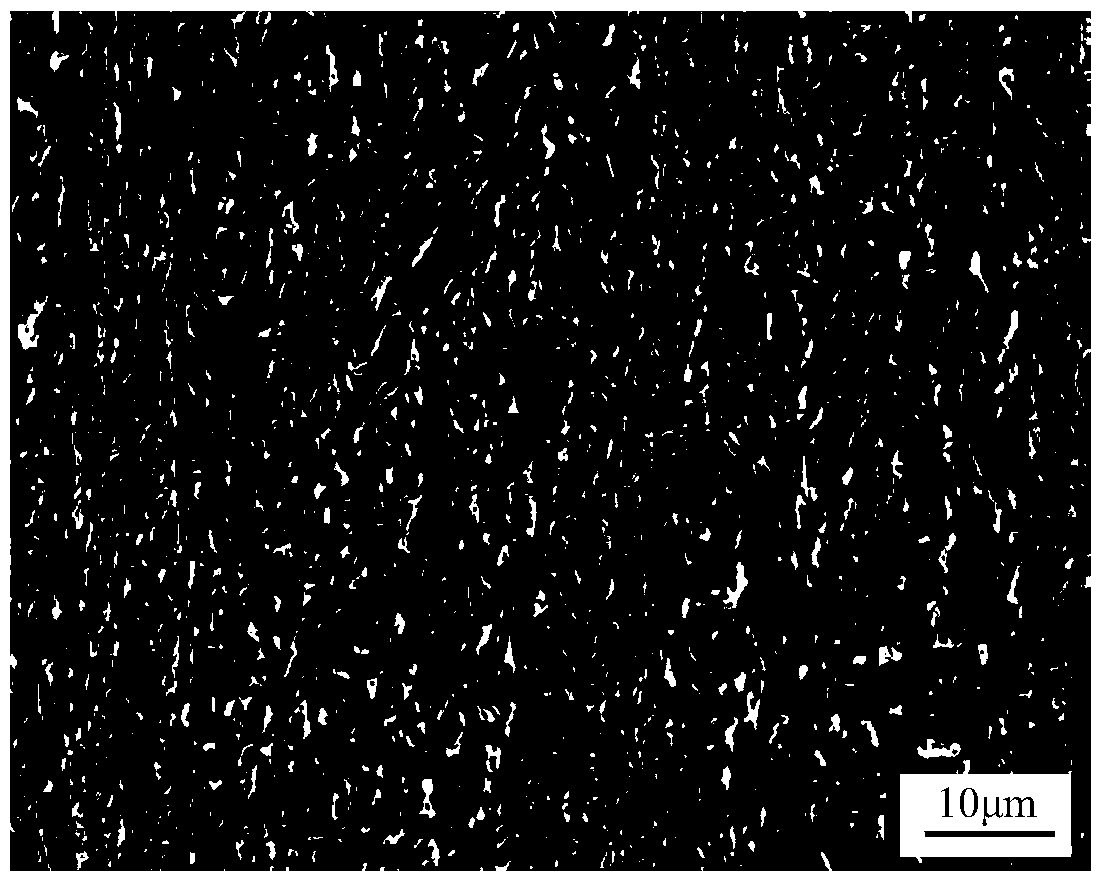

Method for manufacturing low-cost ultrafine grain dual-phase steel seamless tube on line

The invention belongs to the field of steel tube manufacturing and relates to a method for manufacturing a low-cost ultrafine grain dual-phase steel seamless tube on line. The method comprises the following steps: processing a cast ingot to obtain a seamless cold-drawn steel tube, then carrying out cycle heating for more than three times and quenching by adopting an intermediate frequency heating induction coil, and finally carrying out air cooling, water cooling or natural cooling to room temperature, thus obtaining the ultrafine grain dual-phase steel seamless tube. According to the method disclosed by the invention, the ultrafine grain dual-phase steel seamless tube with favorable comprehensive mechanical performance can be produced by using chemical components of common low-carbon steel, so that the cost is relatively low, the tensile strength is larger than or equal to 790MPa, the yield ratio is less than or equal to 0.53, the ductility is larger than or equal to 24.2 percent, the work-hardening index is larger than or equal to 0.24, the average crystallite size of microscopic structure is less than or equal to 3.0mu m, wherein the martensite volume fraction is within 15.0-26.0 percent.

Owner:LAIWU IRON & STEEL GRP

Preparation method of anti-dezincification lead-free bismuth arsenic brass pipe

The invention relates to the field of copper alloys for toilet and kitchen industries, and provides a preparation method of an anti-dezincification lead-free bismuth arsenic brass pipe. The preparation method comprises the steps of casting as a copper ingot-extrusion as a copper pipe blank-stretching-annealing-inspection of a finished copper pipe-warehousing of the finished copper pipe after smelting of the following raw materials in percentage by mass: 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, Pb not more than 0.1%, and the balance of Zn and impuritieswith a total amount not more than 0.25%.

Owner:龙岩市鸿航金属科技有限公司

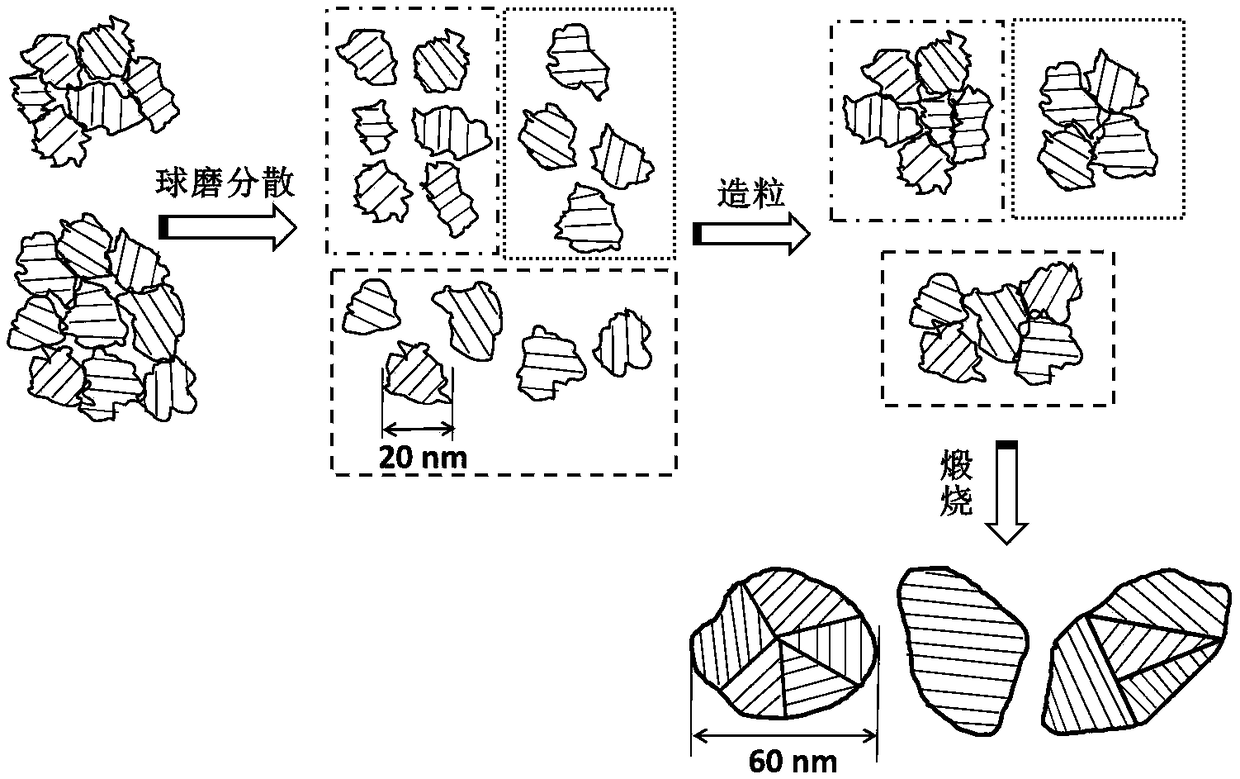

Method for improving wet process formability and sinterability of ceramic nano-powder

The invention provides a method for improving wet process formability and sinterability of ceramic nano-powder and belongs to the field of ceramic preparation. According to the invention, ceramic nano-powder is treated by the combination of pelleting and calcining, on the one hand, the nanoscale and high activity (high crystal boundary area has high sintering promoting power) of the ceramic nano-powder are kept, on the other hand, multiple primary particles are controllably calcined together to form second particles (polycrystals or single grain crystals), and therefore, the particles (grain crystals) of the ceramic nano-powder are enlarged, and forming becomes easy. Meanwhile, the crystalline degree of the particles of the ceramic nano-powder is increased by calcining, defects on the surfaces of the particles are reduced, original microcrystals with multiple surface defects (uneven surface) are transformed into microcrystals with relatively smooth surfaces, the specific surface area is reduced, a sizing agent reaches a relatively high solid content in wet process forming, the density of a formed green body is greatly improved, and further a dense sintering body is obtained at relatively low temperature, and the bottleneck problem of difficulty in forming and sintering of the ceramic nano-powder can be effectively solved.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Method for preparing Fe-Ga-In-Tb alloy bar by filtering and undercooling ceramic

The invention discloses a method for preparing Fe-Ga-In-Tb alloy bar by filtering and undercooling ceramic. A Fe-Ga-In-Tb novel magnetostriction alloy component system is used for overcoming the defect that the iron gallium binary component system alloy is hard to smelt. The method comprises the following steps: firstly filtering an alloy melt through a nano-porous ceramic filter to improve the purity of the Fe-Ga-In-Tb melt, undercooling the alloy melt, and then heating the alloy, enabling an alloy liquid metal to stimulate directional crystallization growth through an undercooling directional crystallization system. The alloy bar prepared by the method disclosed by the invention is smooth in surface, high in directional degree, precise and uniform in component, and good in comprehensive performance.

Owner:NANCHANG INST OF TECH

The production method of molybdenum target

ActiveCN103567445BIncreased dislocation densityIncrease grain boundary areaVacuum evaporation coatingSputtering coatingMaterials scienceFull density

Disclosed is a manufacturing method of a molybdenum target. The method comprises providing molybdenum powder; performing a first densification process on the molybdenum powder through isostatic pressing to obtain a first molybdenum target blank; putting the first molybdenum target blank into a sheath and vacuumizing the sheath; performing a second densification process on the first molybdenum target blank inside the sheath through cold isostatic pressing to form a second molybdenum target blank; after the second densification process, removing the sheath and performing a third densification process on the second molybdenum target blank through induction sintering to form a third molybdenum target blank; after the third densification process, rolling the third molybdenum target blank through hot rolling to form a fourth molybdenum target blank; after the hot rolling process, performing annealing on the fourth molybdenum target blank to obtain the molybdenum target. The manufacturing method of the molybdenum target can help produce full-density molybdenum targets, the uniformity of the internal organizational structure and the size, the purity and the surface dimension of grains of the molybdenum targets can well meet the ever-increasing requirements of the sputtering technology.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Preparing method for anti-dezincification leadless bismuth arsenic extruded brass rod

The invention relates to the field of copper alloys for the bathroom and kitchen industry and provides a preparing method for an anti-dezincification leadless bismuth arsenic extruded brass rod. The preparing method comprises the step of smelting 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, smaller than 0.1% of Pb, the balance Zn and smaller than or equal to 0.25% of impurities to obtain the solid brass rod by the processes of lead casting and extruding.

Owner:龙岩市鸿航金属科技有限公司

Method for reducing cracks in titanium-aluminum alloy printed through selective laser melting

PendingCN112756624AImprove deformation abilityImprove toughnessAdditive manufacturing apparatusSelective laser meltingThermal dilatation

The invention discloses a method for reducing cracks in titanium-aluminum alloy printed through selective laser melting. The method comprises the following steps that (1) high-niobium titanium-aluminum alloy spherical powder is prepared from a titanium-aluminum alloy bar containing a high-niobium component under the protection of inert gas, wherein the powder comprises 43-49 at% of aluminum element, 6-9 at% of niobium element, no more than 2 at% of trace elements and the balance titanium element; (2) selective laser melting is conducted under the protection of high-purity inert gas to form the titanium-aluminum alloy, wherein the scanning speed is higher than or equal to 1000 mm / s, and the thickness of a powder layer is 20-40 microns; and (3) after forming is finished, a titanium-aluminum alloy formed part is obtained after natural cooling, wherein the microstructure of the titanium-aluminum alloy formed part is homogenized into an alpha2 phase, and the volume fraction of the alpha2 phase is larger than or equal to 90%. According to the method, the residual stress caused by the difference of thermal expansion coefficients among different phase regions is reduced, the microstructure of the titanium-aluminum alloy shows high strength and toughness, grains are fine, and therefore cracks are inhibited.

Owner:丹阳层现三维科技有限公司

Production method of anti-dezincification and unleaded lead-cast brass ingot

The invention relates to the field of copper alloys for kitchenware industries, and provides a production method of an anti-dezincification and unleaded lead-cast brass ingot which is good in anti-dezincification corrosion property, high in strength, and good in machining property. The production method comprises the steps that the following raw materials of, by mass, 61-63% of Cu, 0.5-0.9% of Bi,0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, less than 0.1% of Pb and the balance Zn and impurities with the total amount being less than or equal to 0.25% are smelted, and then subjected to lead casting, and the brass ingot is prepared.

Owner:龙岩市鸿航金属科技有限公司

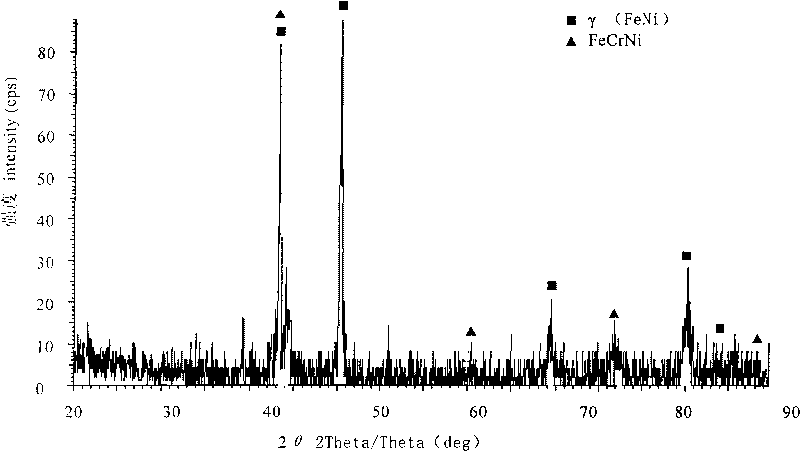

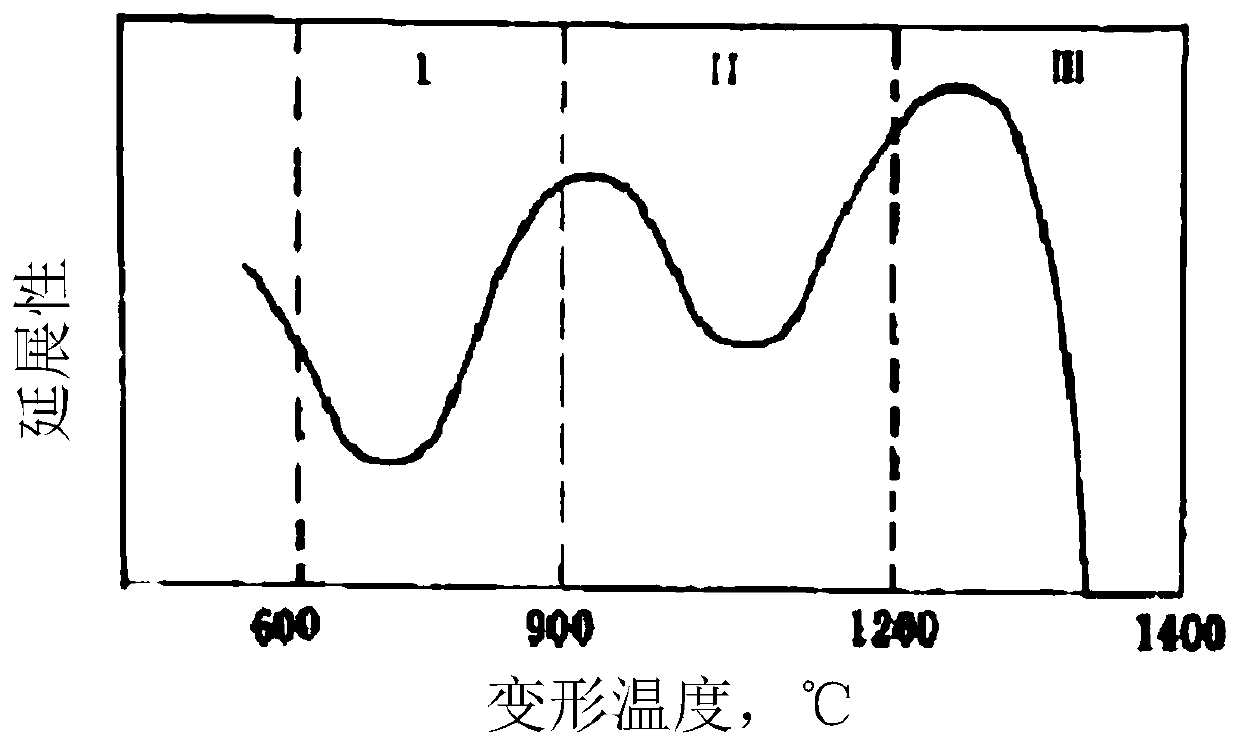

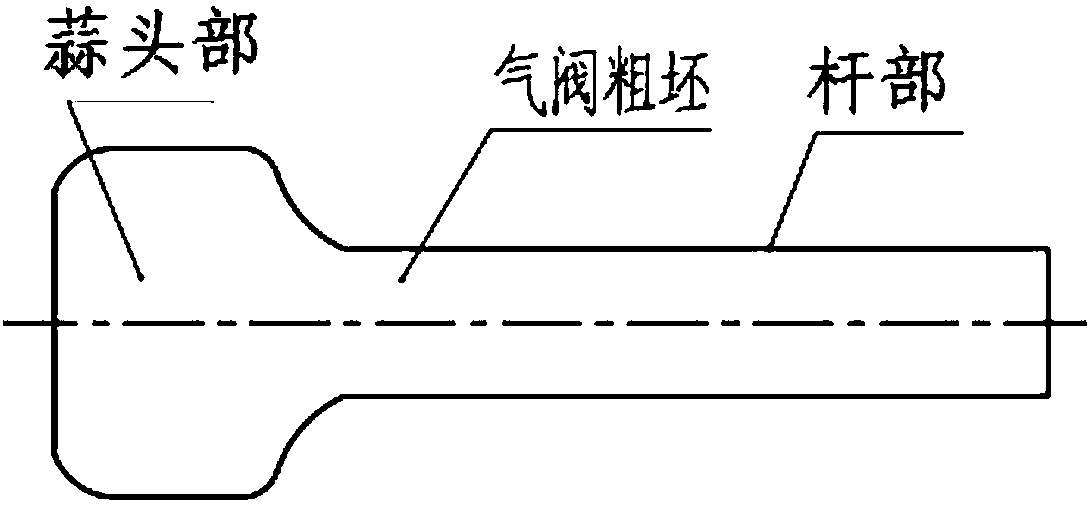

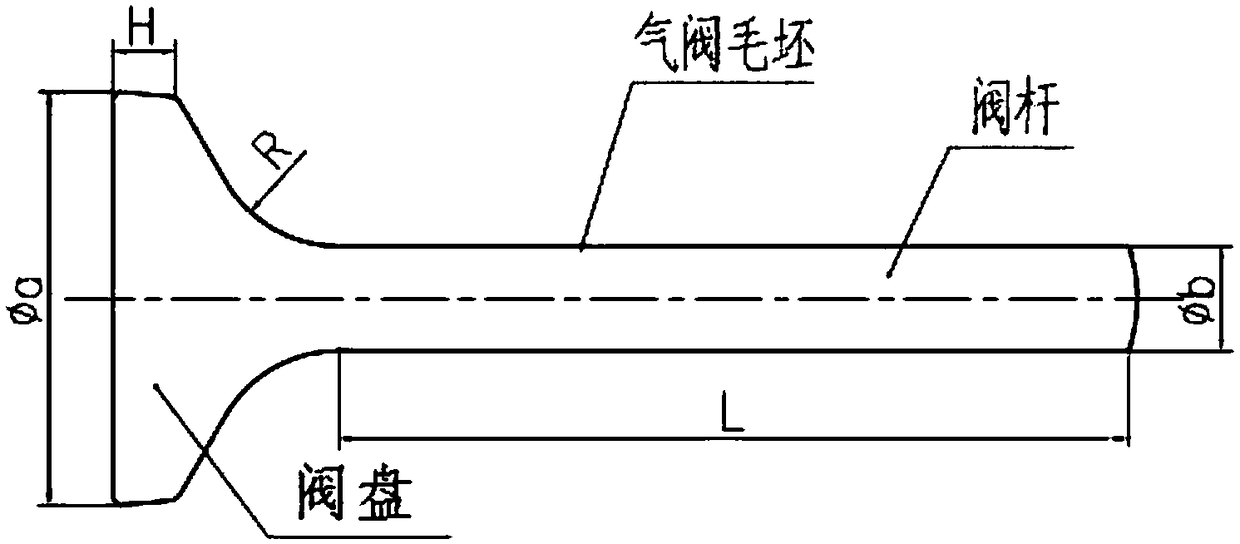

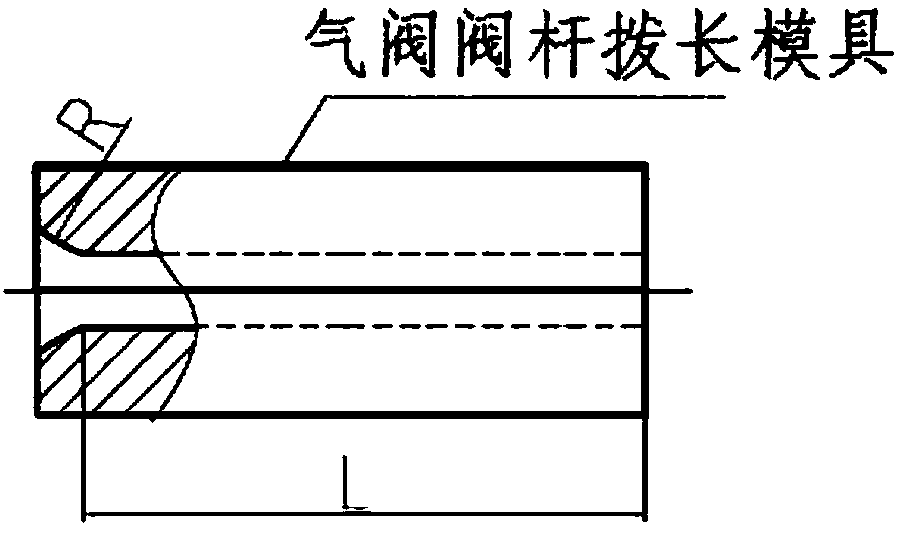

Thermal Processing Technology of 4cr14ni14w2mo Gas Valve

The invention discloses a hot working technology for a 4Cr14Ni14W2Mo air valve, and belongs to the technical field of working technologies. The hot working technology comprises the following steps of1 air valve rough blank upsetting, 2 solid solution, 3 strain strengthening and 4 aging treatment. According to the technology, air valve rough blank upsetting and strain strengthening are additionally conducted on the basis of traditional solid solution and aging treatment, and the water cooling time, the air cooling time, the initial forging temperature, the forging frequency and the deformationwhich are generated before valve rod portion and garlic head portion forging machining are strictly controlled. According to the technology, the tensile strength and the yield strength of the 4Cr14Ni14W2Mo air valve can be significantly improved, the plasticity indexes (including the percentage elongation after fracture and the percentage reduction of area) are not decreased or slightly increased, the metallographic structure is more ideal, and the 4Cr14Ni14W2Mo air valve produced through the technology has the advantages that the fatigue strength, the safety and the reliability are significantly improved, and the service life is significantly prolonged.

Owner:CHONGQING YUEJIN MACHINERY

A kind of high wear resistance martensitic wear-resistant steel plate and its manufacturing method

ActiveCN109207853BImproved fine grain strengtheningFine grain strengtheningAustenite grainHigh wear resistance

Owner:NORTHEASTERN UNIV LIAONING +2

Preparation method of lead battery grid alloy containing lead-tin-rare earth-graphene

ActiveCN105977496BImproved grain boundary propertiesSmall grain sizeLead-acid accumulatorsElectrode carriers/collectorsRare-earth elementCerium

The present invention discloses a preparation method of a lead-acid battery grid alloy containing lead tin-rare earth-graphene. The method includes a first step of preparing a lead-graphene composite material; a second step of preparing a grid mother alloy; and a third step of preparing the grid alloy, wherein the grid alloy includes the following components by mass percentage: 0.1-1.0% of tin, 0.01-0.2% of lanthanum, 0.05-0.5% of cerium, 0.5-10.0% of lead-graphene composite material, and the balance of lead. In the method, due to addition of the rare earth element, grain and grain boundary characteristics of the alloy are improved remarkably, grain size is reduced substantially, grain boundary area is increased, and corrosion amount is reduced substantially under the same current density. A lead-graphene composite material is deposited on a pure lead plate by using a composite electroplating technology, so as to be directly used as a material to be smelted in later preparation process of the grid alloy, so that the preparation method of the grid alloy is simplified.

Owner:TIANNENG BATTERY GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com