Ultrathin 65Mn cold-rolled wide steel strip and manufacturing method thereof

A manufacturing method and specification technology, applied in the field of metal material forming, can solve the problems of high difficulty in cold-rolling wide steel strips, high resistance to cold-rolling deformation, and high difficulty in rolling, so as to achieve increased grain boundary area, increased deformation energy, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

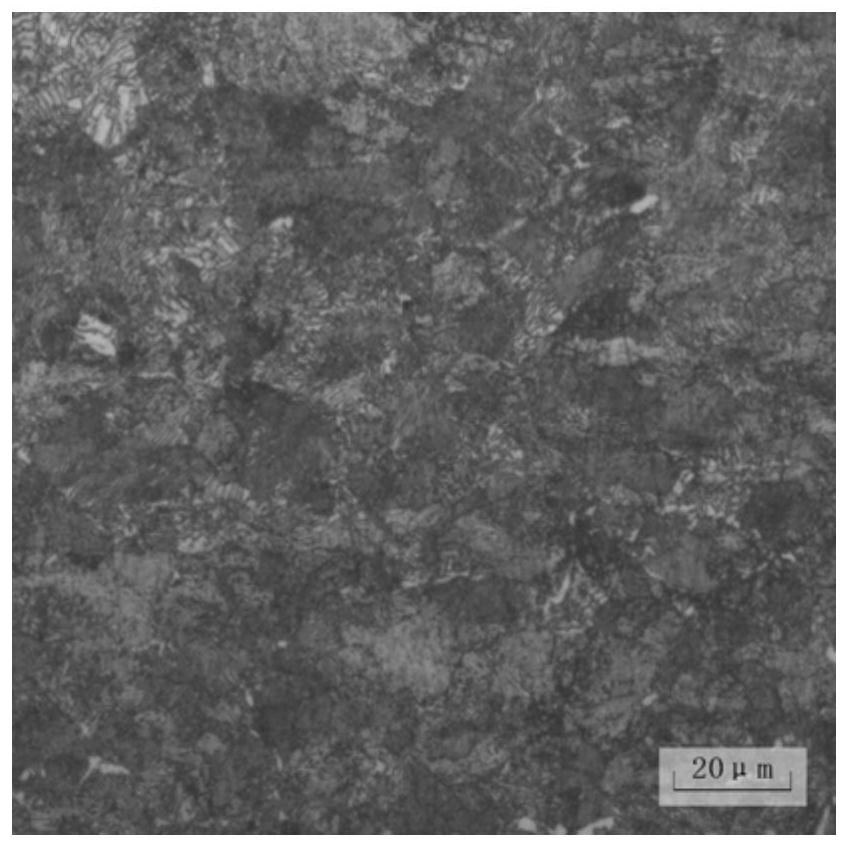

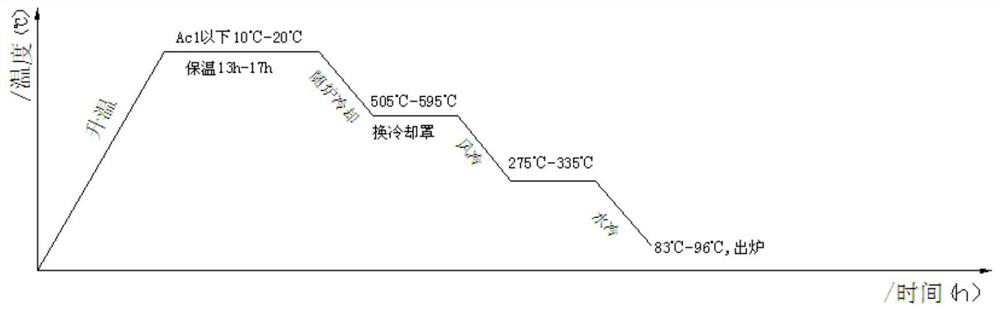

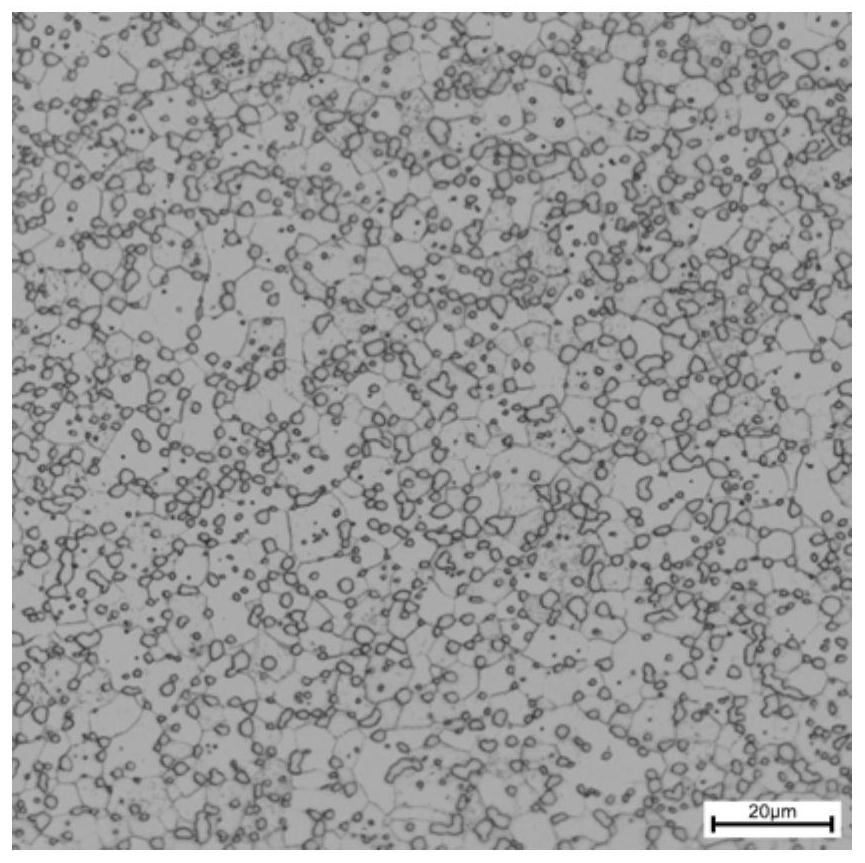

[0082] A method for producing an ultra-thin cold-rolled wide strip 65Mn specifications, the choice of hot-rolled coil of steel material is 65Mn, its main chemical composition of C: 0.66%, Mn: 0.98%, S: 0.003%, P: 0.018 %, Si: 0.22%, Cr: 0.14%, Ni: 0.01%, Cu: 0.03%, the balance being Fe and unavoidable impurities. Material specifications for 3.00mm × 1250mm, after cold rolling to final gauge 0.30mm × 1230mm, production steps are as follows:

[0083] 1) slow cooling: 3.0mm thickness of the material hot coil suspended into 65Mn Xinyu Iron & Steel invention, "slow-cooling device excellent in high-carbon steel hot strip (Patent No. ZL2020 2 1216515.2)" Slow after cooling 66h, coil temperature is lowered to 75 deg.] C until a pit, transported to the pickling line library materials;

[0084] 2) Pickling: pickling line using the push-pull pickling the hot-rolled wide strip, pickling speed of 123m / min, the acid concentration of 125g / l, using steam heating the acid, the acid temperature...

Embodiment 2

[0094] A method for producing an ultra-thin cold-rolled wide strip 65Mn specifications, the choice of hot-rolled coil of steel material is 65Mn, its main chemical composition of C: 0.67%, Mn: 0.97%, S: 0.002%, P: 0.017 %, Si: 0.23%, Cr: 0.14%, Ni: 0.02%, Cu: 0.03%, the balance being Fe and unavoidable impurities. Material specifications for 2.75mm × 1180mm, after cold rolling to final gauge 0.22mm × 1160mm:

[0095] 1) slow cooling: 2.75mm thickness of the material hot coil suspended into 65Mn Xinyu Iron & Steel invention, "slow-cooling apparatus preferably high carbon hot-rolled steel strip (Patent No. ZL2020 2 1216515.2)" Slow after cooling 65h, coil temperature is lowered to 74 deg.] C until a pit, transported to the pickling line library materials;

[0096] 2) Pickling: pickling line using the push-pull pickling the hot-rolled wide strip, pickling speed of 124m / min, the acid concentration of 125g / l, using steam heating the acid, the acid temperature is 73 ℃;

[0097] 3) Fi...

Embodiment 3

[0106] A method for producing an ultra-thin cold-rolled wide strip 65Mn specifications, the choice of hot-rolled coil of steel material is 65Mn, its main chemical composition of C: 0.66%, Mn: 0.98%, S: 0.003%, P: 0.015 %, Si: 0.21%, Cr: 0.16%, Ni: 0.02%, Cu: 0.02%, the balance being Fe and unavoidable impurities. Material specifications for 2.50mm × 1150mm, after cold rolling to final gauge 0.15mm × 1120mm:

[0107] 1) slow cooling: 2.50mm thickness of the material hot coil suspended into 65Mn Xinyu Iron & Steel invention, "slow-cooling apparatus preferably high carbon hot-rolled steel strip (Patent No. ZL202021216515.2)" Slow 62 h cold, until the coiling temperature after the pit 76 deg.] C, transported to a pickling line library materials;

[0108] 2) Pickling: pickling line using the push-pull pickling the hot-rolled wide strip, pickling speed of 126m / min, the acid concentration of 165g / l, using steam heating the acid, the acid temperature is 76 deg.] C;

[0109] 3) First R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com