Method for improving wet process formability and sinterability of ceramic nano-powder

A nano-powder, wet-forming technology, applied in the field of ceramic preparation, can solve the problems of increasing the sintering temperature of the powder, reducing the sintering activity of the powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

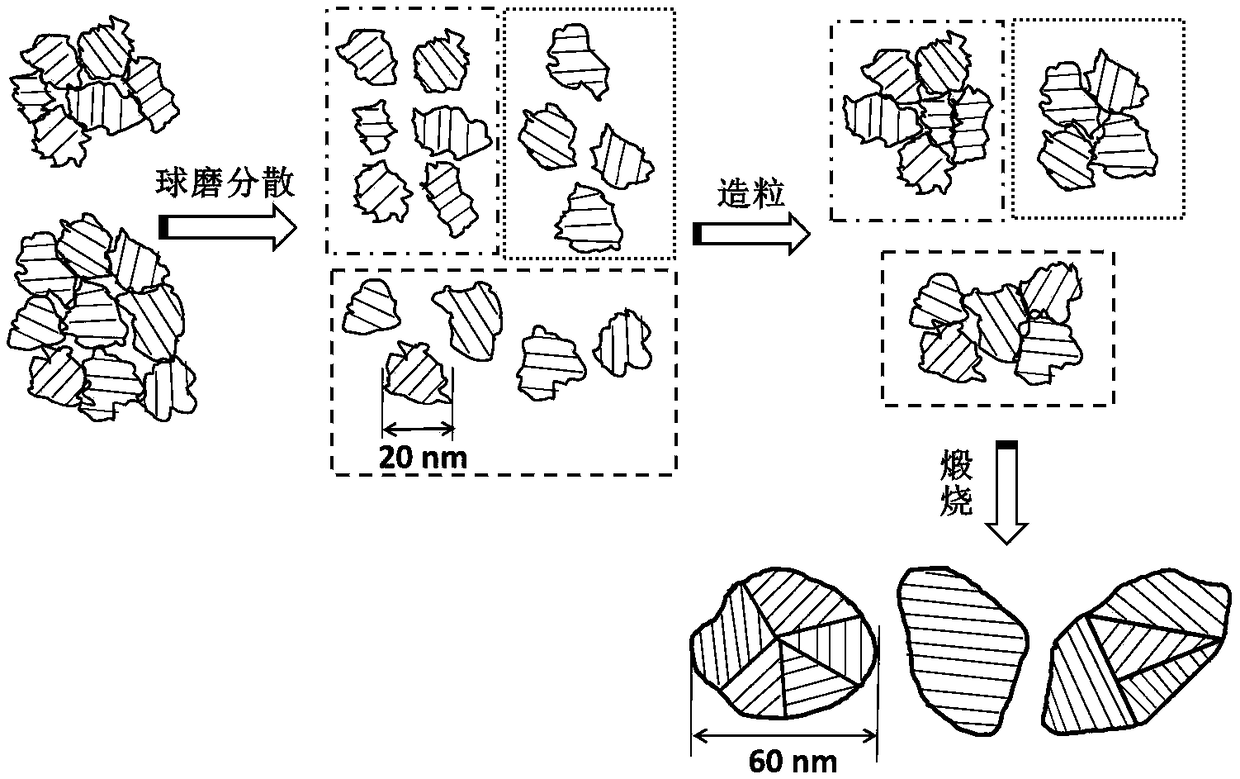

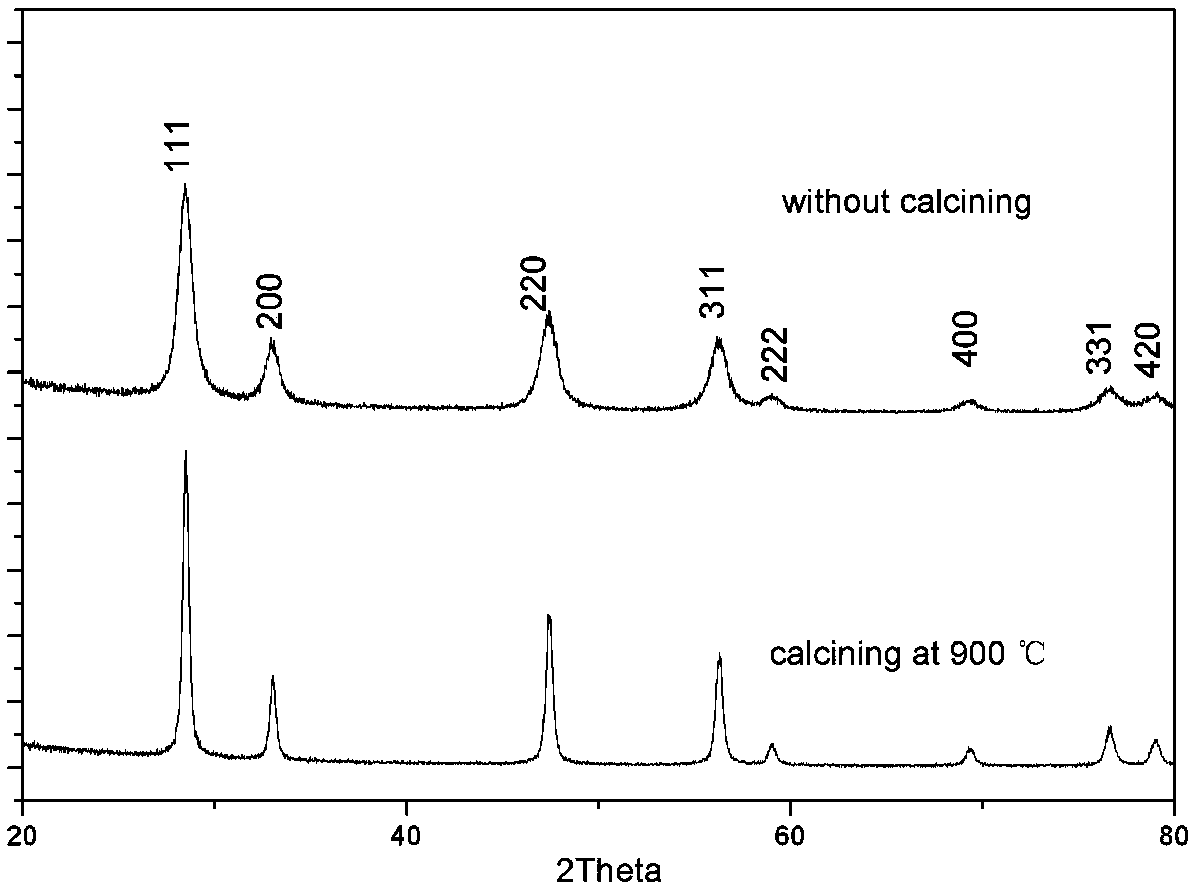

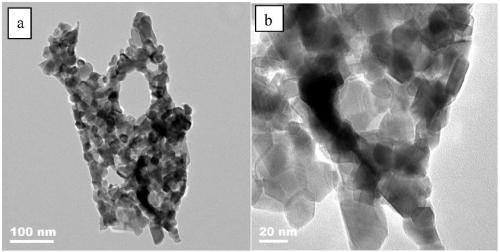

[0057] The specific surface area is 75m 2 / g Nano-GDC (Gd 0.1 Ce 0.9 o 1.95 ) powder 100g was added to 200g absolute ethanol, 1g acetylacetone was added, ball milled at 400 rpm for 60min, then ball milled at 200 rpm for 5h, after adding 3gPVB, ball milled at 200rpm for 12h (zirconia balls with a diameter of 0.3 mm). After the ball-milled slurry is dried at 80°C, it is granulated in a mortar (the pressure used during granulation is 30 MPa), and the particle size is 75-250 μm (60-200 mesh screen). The granulated powder was calcined at 900°C for 4h. Then, the calcined powder is ball milled by a general ball milling process to eliminate the aggregates that may be generated during calcination, and the modified nanometer GDC powder is obtained. According to the XRD data and the Scherrer formula, the GDC grains before and after calcination at 900°C were 11nm and 30nm, respectively. It can be seen from TEM that the GDC powder is composed of agglomerated polycrystalline particles...

Embodiment 2

[0062] Set the specific surface area to 25m 2 100 g of nano-NiO powder per gram is added in 120 g of absolute ethanol, 1 g of acetylacetone is added, ball milled at 200 rpm for 5 hours after ball milling at 400 rpm for 20 minutes, and ball milled at 200 rpm for 5 hours after adding 2 g of PVB (zirconia mill ball, 0.8 mm in diameter). The ball-milled slurry is dried at 80° C. and then granulated in a mortar, with a particle size of 41-94 μm (160-325 mesh screen). The granulated powder was calcined at 800°C for 4h. Then, the calcined powder is ball milled by a general ball milling process to eliminate the aggregates that may be generated during calcination, and the modified NiO powder is obtained. According to the XRD data and the Scherrer formula, the NiO grains before and after calcination are 18nm and 530nm, respectively. Calcined NiO and 5YSZ powders and pore-forming agents (PMMA, polymethyl methacrylate) are mixed in a certain proportion by tape casting, and the percenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com