Superconducting joint and preparation method thereof

A technology of superconducting joints and superconductors, which is applied in the manufacture of contacts, connecting contact materials, and connections. It can solve problems such as weak pinning ability, influence of superconducting joint connection efficiency, and high heat treatment temperature, so as to increase the grain boundary area. , Improve pinning ability and reduce grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a superconducting joint and a preparation method thereof, specifically as follows:

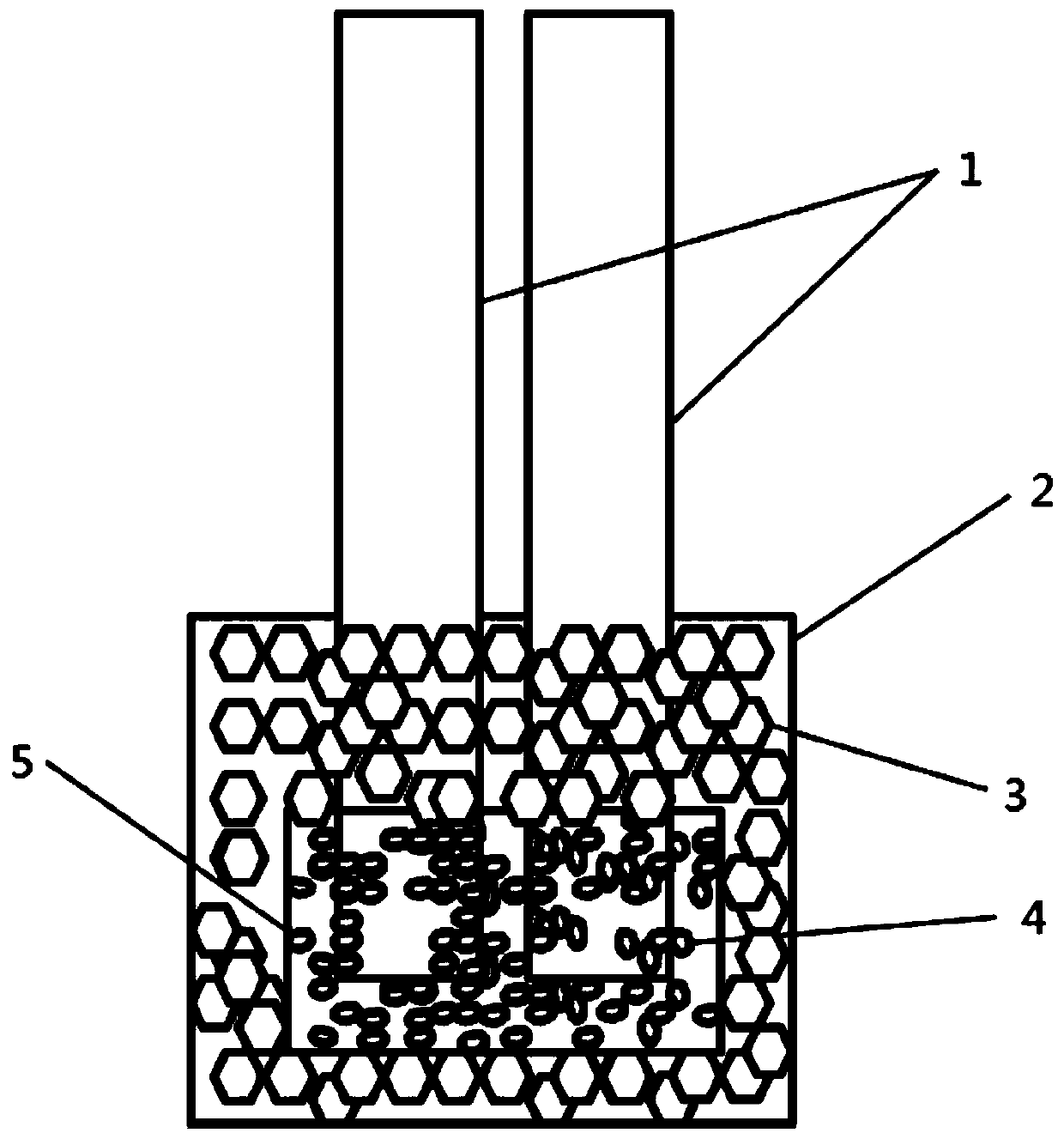

[0047] A superconducting joint, including magnesium diboride single-core wire, boron powder, magnesium powder, an outer metal sheath and an inner single-layer metal sheath, wherein the outer metal sheath is a niobium tube, and the inner single-layer metal The sheath is copper foil, and the molar ratio of boron powder and magnesium powder is 2:1.

[0048] A method for preparing the above-mentioned superconducting joint, specifically,

[0049] In the air environment, grind the ends of the two magnesium diboride single-core wires that need to be connected to expose the superconducting core, bury it in the boron powder, and compact the boron powder to make the density reach 50% of the theoretical density , wrap the superconductor end and boron powder with copper foil, bury it in magnesium powder, and cover it with niobium tube. After welding the niobium sheath, it ...

Embodiment 2-4

[0054] The preparation process of Example 2-4 is the same as that of Example 1 except that the superconductor materials to be connected are different.

[0055] Table 1 Embodiment 2-4 superconductor type and superconducting connector connection efficiency

[0056] example

[0057] Examples 1-4 are compared with Comparative Examples 1-4 respectively, indicating that the connection efficiency of the superconducting joint prepared by the present invention is not limited by the shape of the superconductor, and the pinning ability and connection efficiency are better than the superconducting joint prepared by the comparative example pinning ability.

Embodiment 5

[0059] This embodiment provides a superconducting joint and a preparation method thereof, specifically as follows:

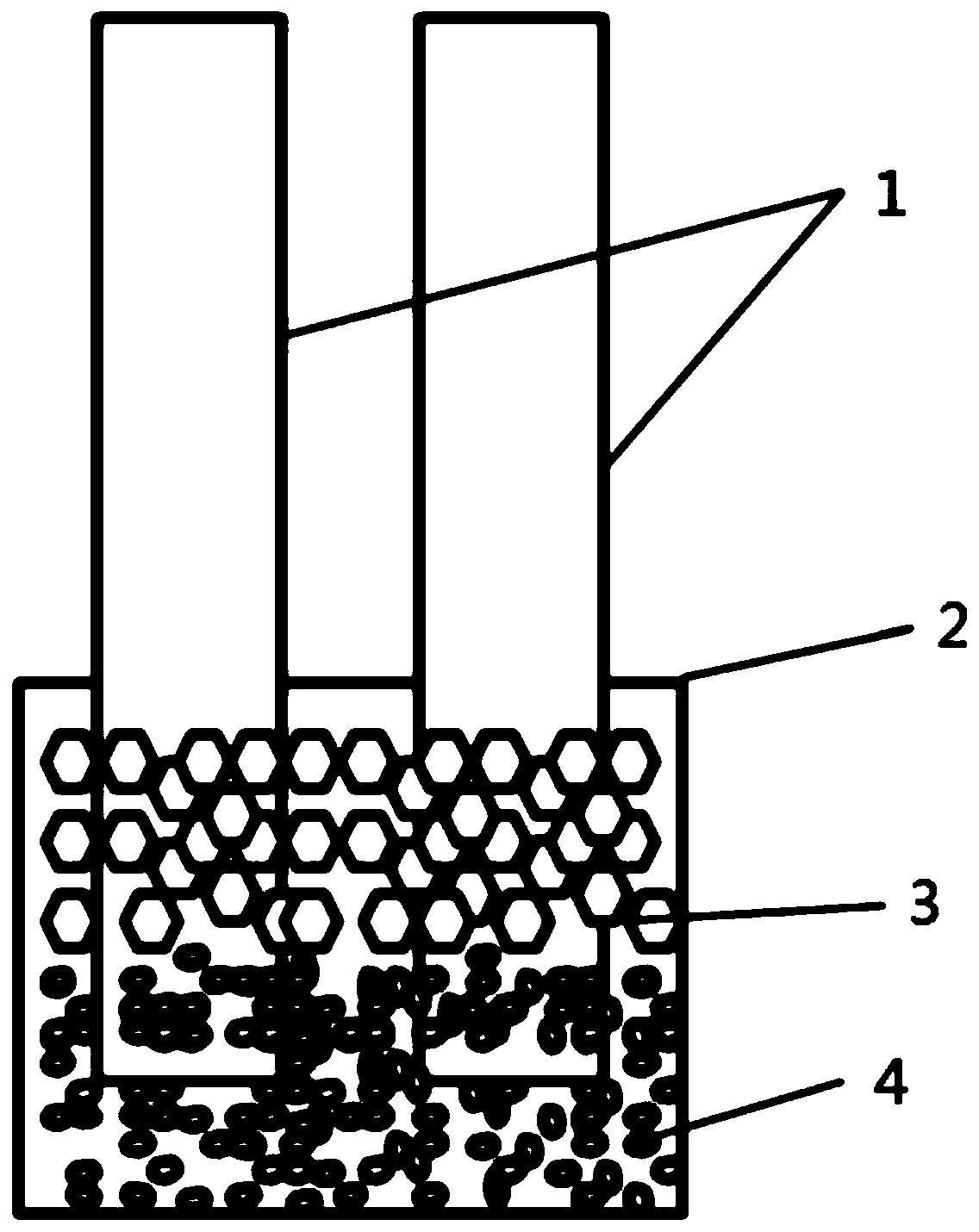

[0060] A superconducting joint, comprising yttrium-barium-copper-oxygen superconductor strips (the number of superconducting cores is 12), boron powder, magnesium powder, an outer metal sheath and an inner single-layer metal sheath, wherein the outer metal sheath is Niobium tube, the inner single-layer metal sheath is copper foil, the molar ratio of boron powder and magnesium powder is 2:1.

[0061] A method for preparing the above-mentioned superconducting joint, specifically,

[0062] In the air environment, grind the ends of the two yttrium-barium-copper-oxide superconductor strips that need to be connected to expose the superconducting core, bury it in boron powder, and compact the boron powder to make the density reach 50% of the theoretical density , wrap the superconductor end and boron powder with copper foil, bury it in magnesium powder, and cover it w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com