Thermal Processing Technology of 4cr14ni14w2mo Gas Valve

A thermal processing and gas valve technology, which is applied in the field of thermal processing of 4Cr14Ni14W2Mo diesel engine gas valves, can solve problems such as valve safety, reliability, service life is not ideal, tensile strength of strength index is unqualified, and design requirements cannot be met. , to achieve reasonable distribution of precipitated phases, improved service life and reliability, improved tensile strength and yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of thermal processing technology of 4Cr14Ni14W2Mo gas valve, comprises the following steps:

[0035] The first step: Upsetting the rough blank of the valve;

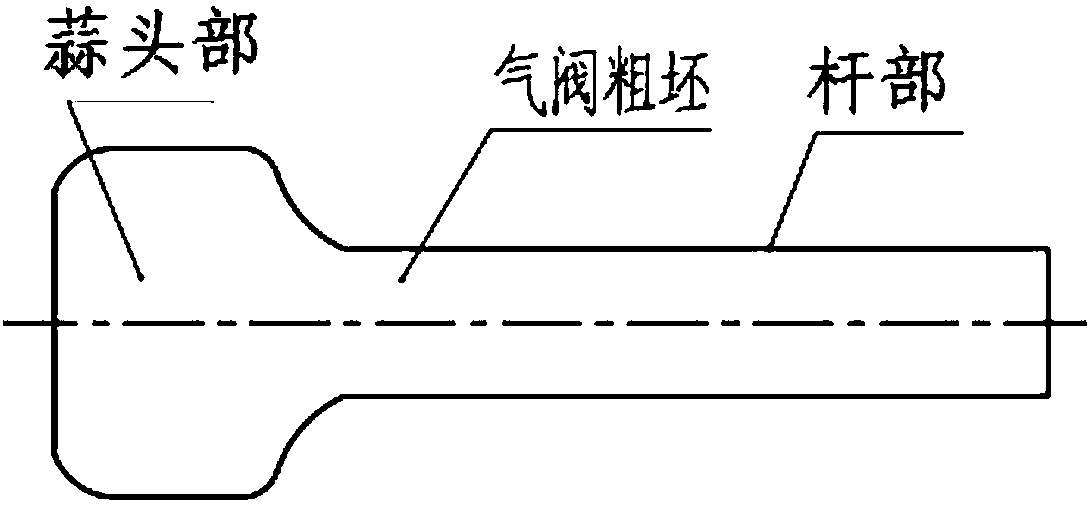

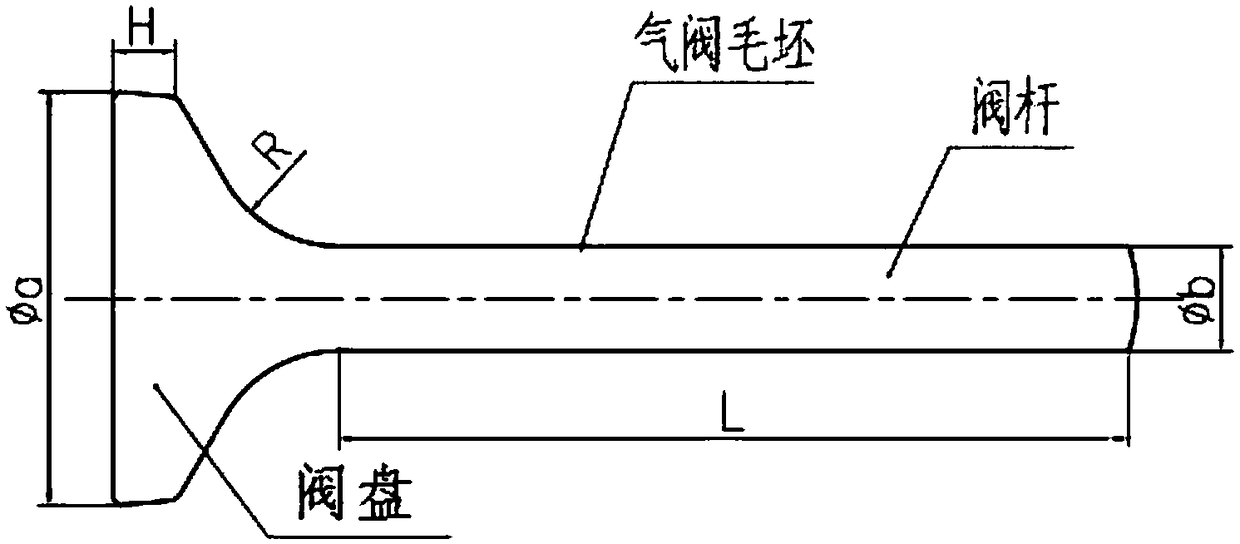

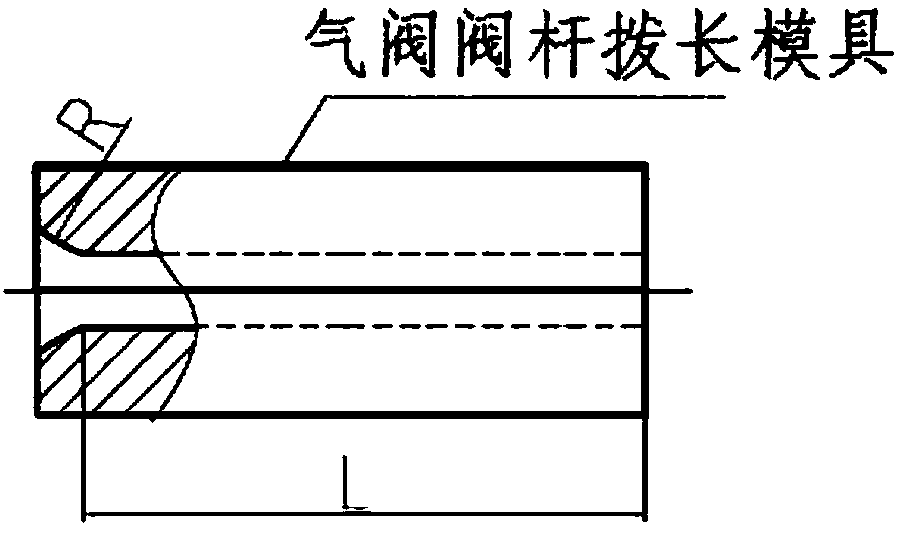

[0036] The air valve rough blank with garlic head is made by upsetting round bar. The diameter of the garlic head of the air valve rough blank is smaller than the valve disc diameter of the air valve blank, and the diameter of the stem part of the air valve rough blank is larger than the valve of the air valve blank. rod diameter, figure 1 Air valve blank shown, figure 2 Air valve blank shown.

[0037] The second step: solid solution;

[0038] A through-type continuous operation high-temperature furnace is used to load a rough billet of air valve every 90 seconds, and keep warm at 1180°C for 1.5 hours in sequence, and the furnace is loaded first and the furnace is taken out in sequence every 90 seconds. , and then air-cooled for 6 seconds after the water outlet, at this time the surface temperature of ...

Embodiment 2

[0046] A kind of thermal processing technology of 4Cr14Ni14W2Mo gas valve, comprises the following steps:

[0047] The first step: Upsetting the rough blank of the valve;

[0048] The air valve rough blank with garlic head is made by upsetting round bar. The diameter of the garlic head of the air valve rough blank is smaller than the valve disc diameter of the air valve blank, and the diameter of the stem part of the air valve rough blank is larger than the valve of the air valve blank. rod diameter, figure 1 Air valve blank shown, figure 2 Air valve blank shown.

[0049] The second step: solid solution;

[0050] A through-type continuous operation high-temperature furnace is used to load a rough billet of air valve every 100 seconds, and keep warm at 1165°C for 105 minutes in sequence, and the furnace is loaded first and then taken out in sequence every 100 seconds, and the workpieces after being released from the furnace are quickly cooled in water for 6 seconds , and t...

Embodiment 3

[0058] A kind of thermal processing technology of 4Cr14Ni14W2Mo gas valve, comprises the following steps:

[0059] The first step: Upsetting the rough blank of the valve;

[0060] The air valve rough blank with garlic head is made by upsetting round bar. The diameter of the garlic head of the air valve rough blank is smaller than the valve disc diameter of the air valve blank, and the diameter of the stem part of the air valve rough blank is larger than the valve of the air valve blank. rod diameter, figure 1 Air valve blank shown, figure 2 Air valve blank shown.

[0061] The second step: solid solution;

[0062] A through-type continuous operation high-temperature furnace is used to load a rough billet of air valve at an interval of 95 seconds, and keep warm at 1150°C for 2 hours in sequence, and the furnace is loaded first and then taken out in sequence at an interval of 95 seconds, and the workpiece after being released from the furnace is quickly cooled in water for 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com