Patents

Literature

62 results about "Disc diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A compact disc (CD), or optical disc, is a thin, circular wafer of clear plastic and metal measuring 4.75 inches (120 centimeters) in diameter with a small hole in its center.

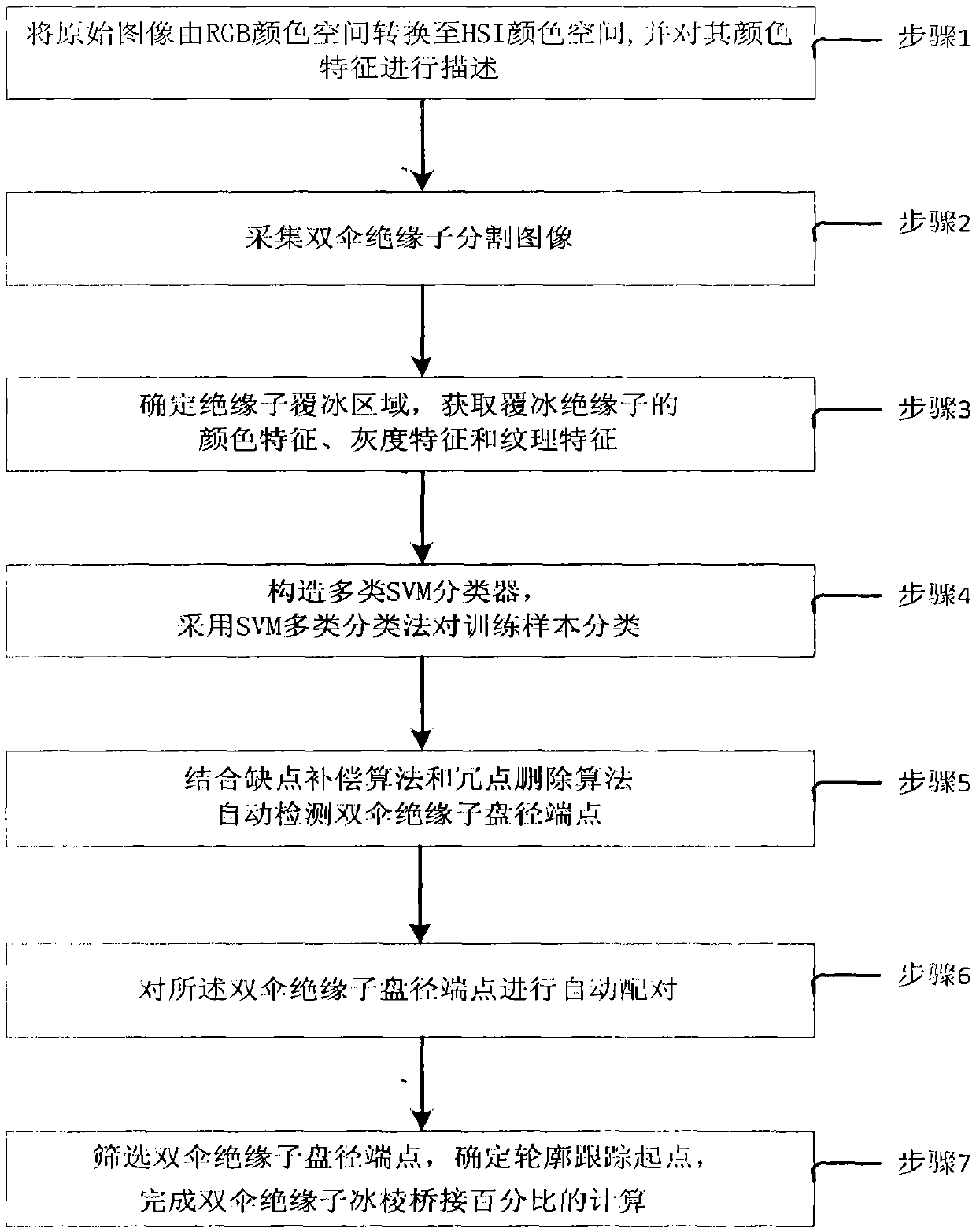

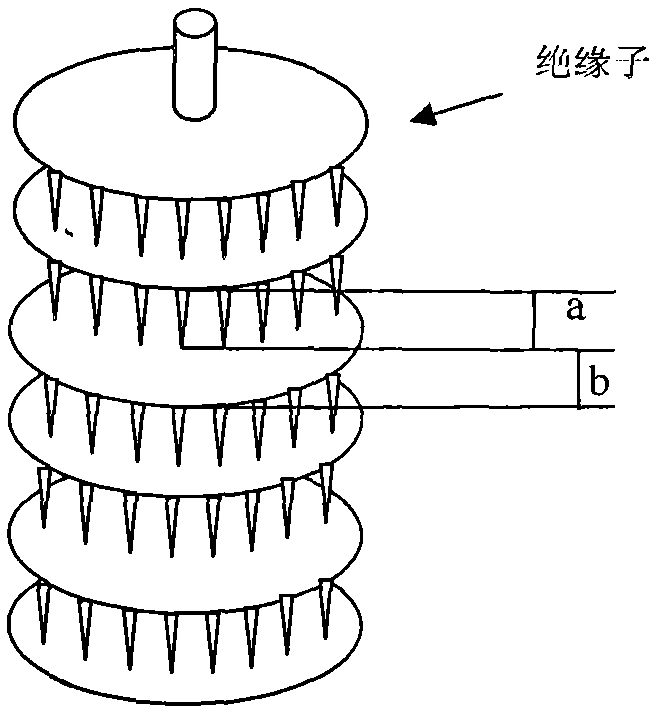

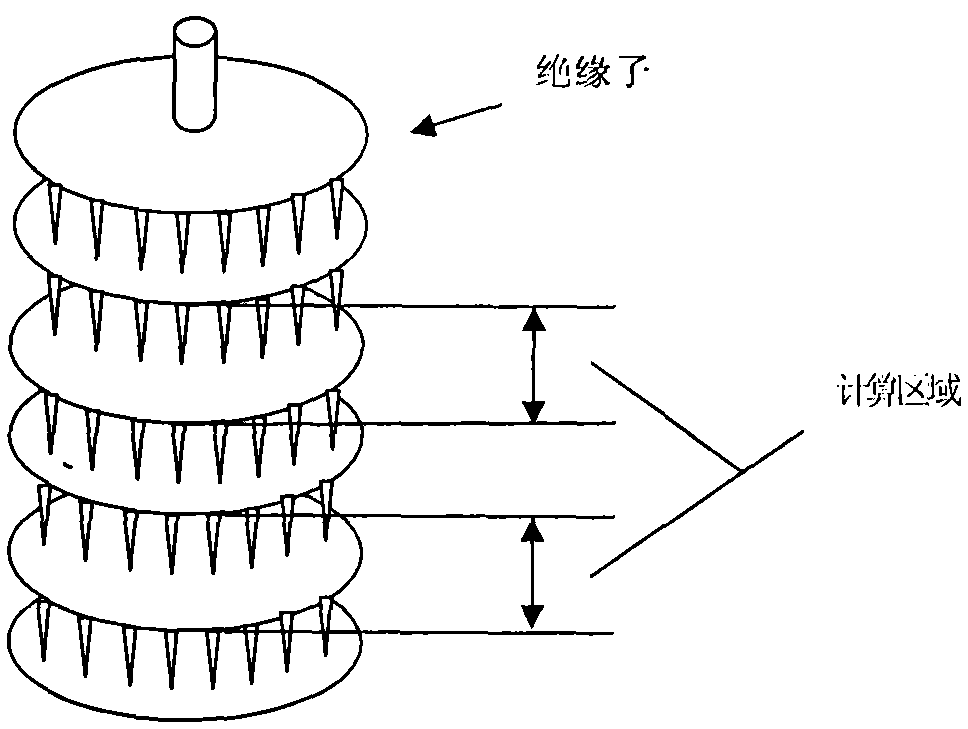

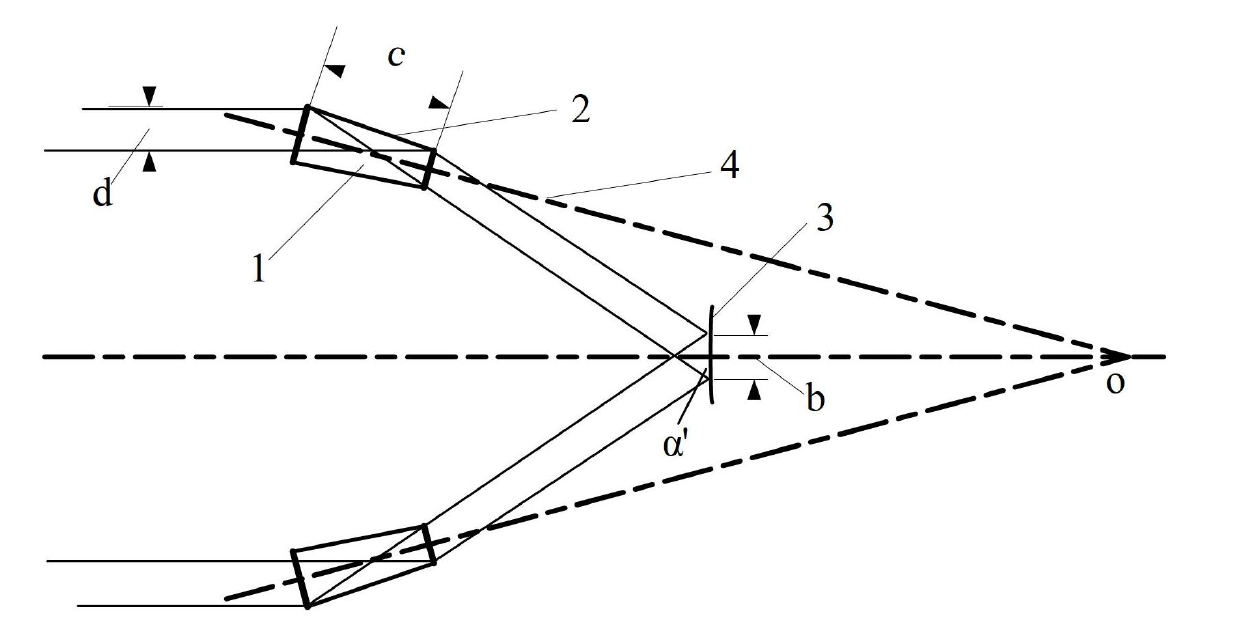

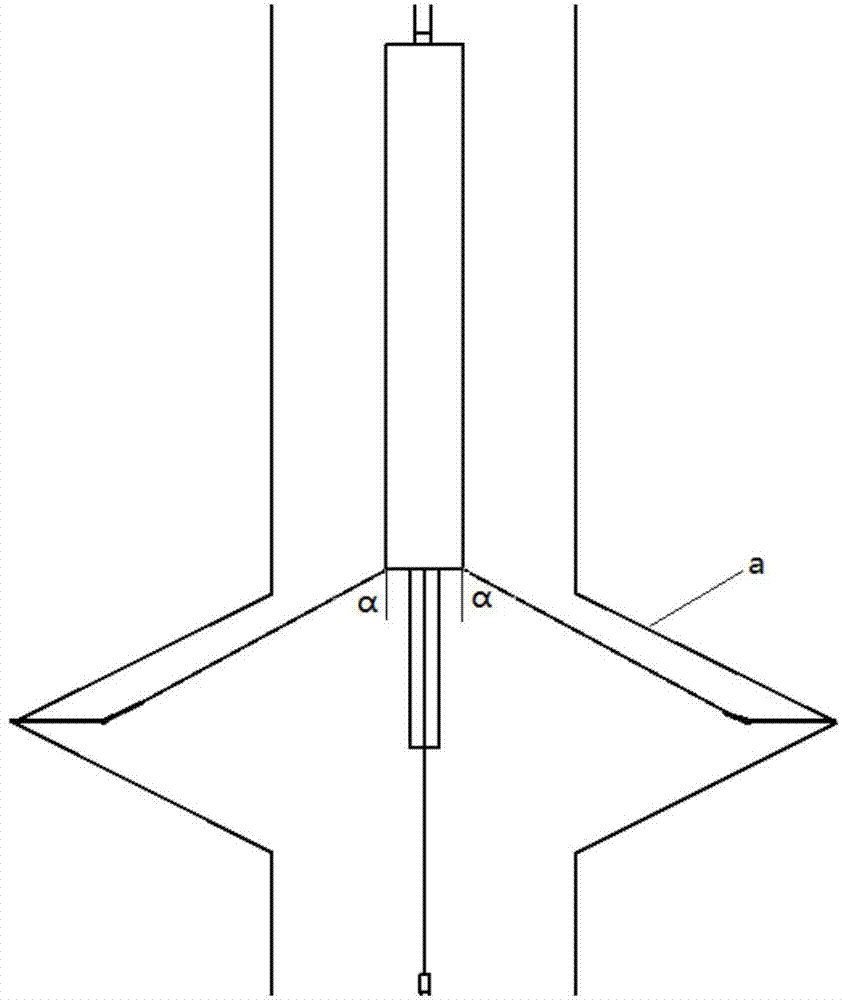

Charged insulator string icing bridging degree intelligent image analysis method

PendingCN105513039AEasy to measureImprove work efficiencyImage enhancementImage analysisImaging analysisSvm classifier

A charged insulator string icing bridging degree intelligent image analysis method comprises the steps of converting an original image from an RGB color space into an HIS color space, and describing color features thereof; acquiring double-umbrella insulator segmented images; determining an insulator icing region, and acquiring a color feature, a gray feature and a texture feature of an icing insulator; constructing a multi-class SVM classifier, and using the multi-class SVM classifier for training sample classification; automatically detecting disc diameter endpoints of a double-umbrella insulator by combining a defect compensation algorithm and a redundant point deletion algorithm; automatically matching the disc diameter endpoints of the double-umbrella insulator; and screening the disc diameter endpoints of the double-umbrella, determining a contour tracing starting point, and completing the calculation of icing bridging percentage of the double-umbrella insulator. Through the icing bridging percentage intelligent analysis of a double-umbrella suspension insulator image, the invention effectively overcomes the defect of the loss of effective information due to traditional image segmentation.

Owner:CHINA ELECTRIC POWER RES INST +2

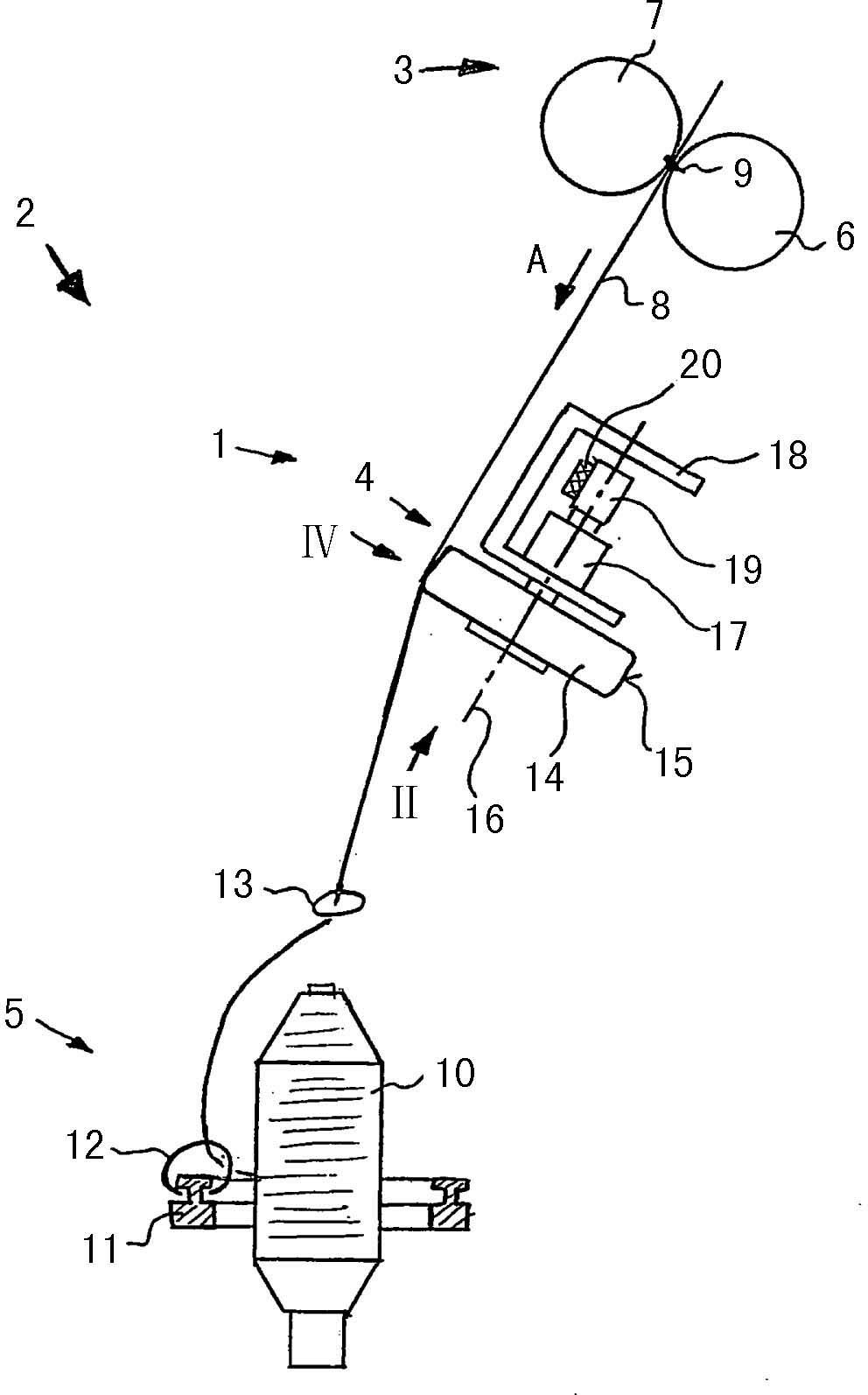

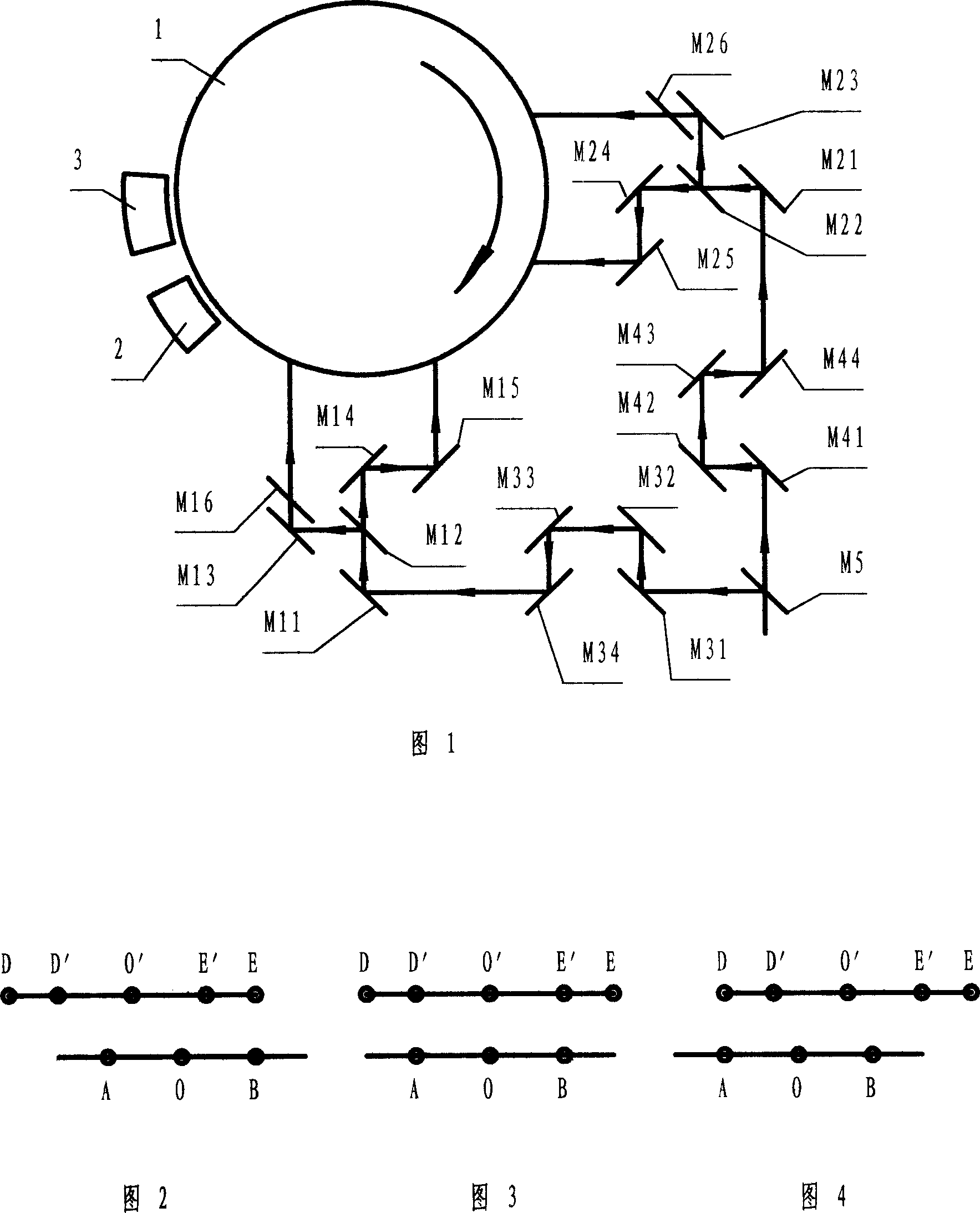

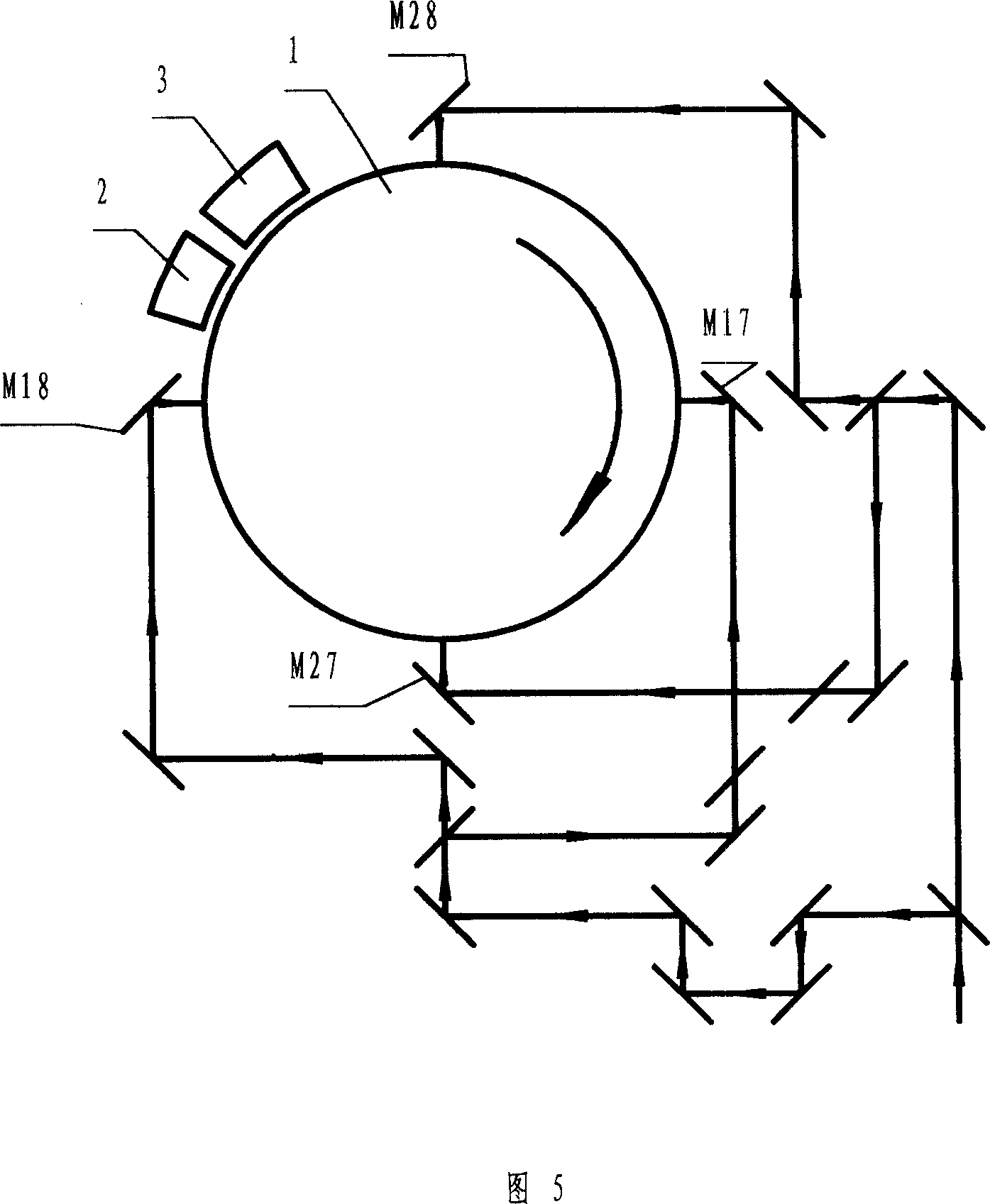

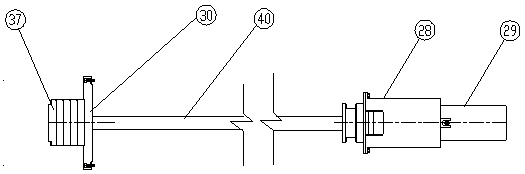

Ring spinning machine having a false twist device

InactiveCN102656302AReduce energy consumptionEasy to twistDrafting machinesContinuous wound-up machinesEngineeringMechanical engineering

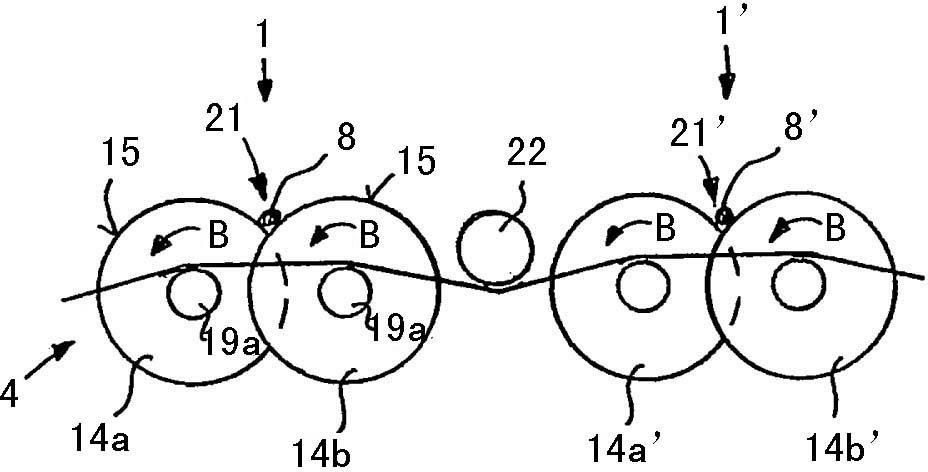

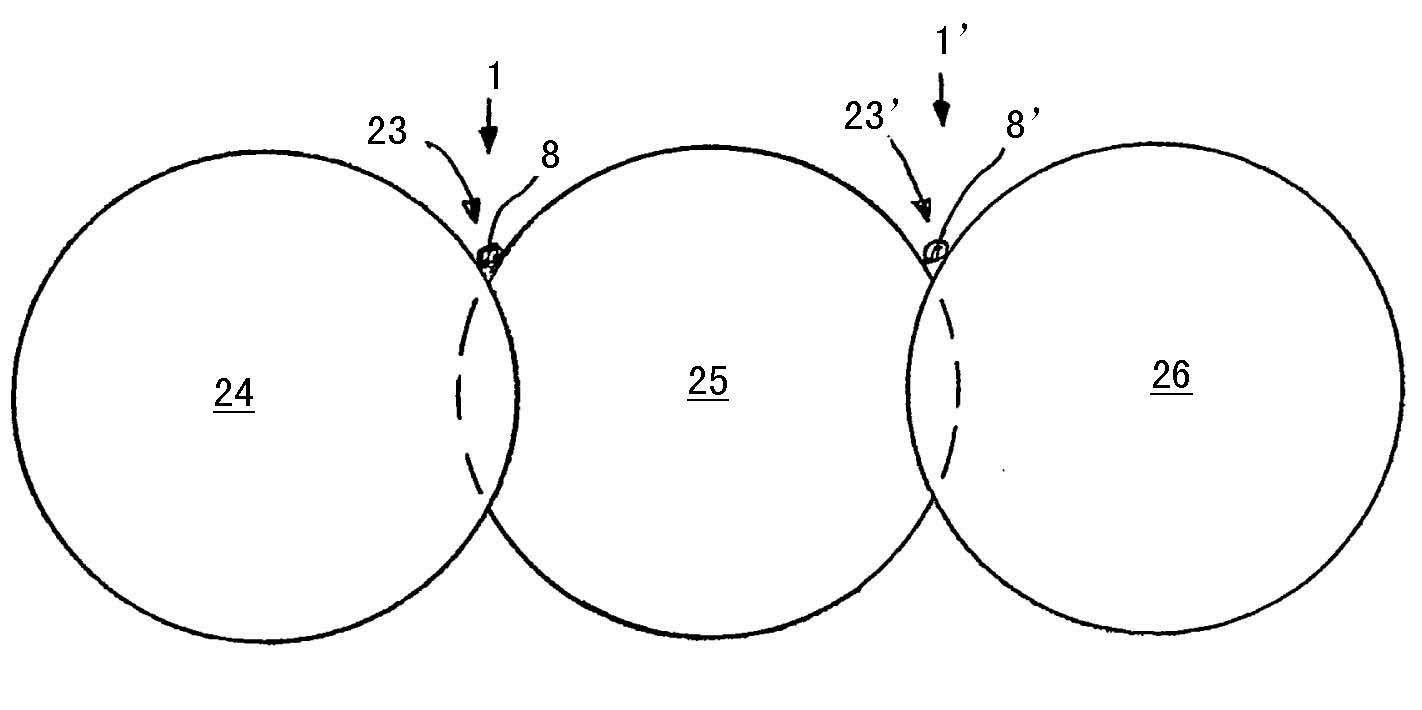

In a ring spinning machine having at least one spinning station (1) that contains a drafting system (3) and a ring spindle (5), a false twist device (4) is arranged between the drafting system (3) and the ring spindle (5). A fibre strand (8) to be rotated can be placed laterally against the false twist device (4). The false twist device (4) comprises at least one rotatable disc (14, 24, 25, 26, 28, 29) having a friction surface (15) for a fibre strand (8). The fibre strand (8) can be guided by two adjacent discs (14a, 14b, 25, 26, 28, 29), which are arranged with a centre distance that is less than the disc diameter.

Owner:MASCHINENFABRIK RIETER AG

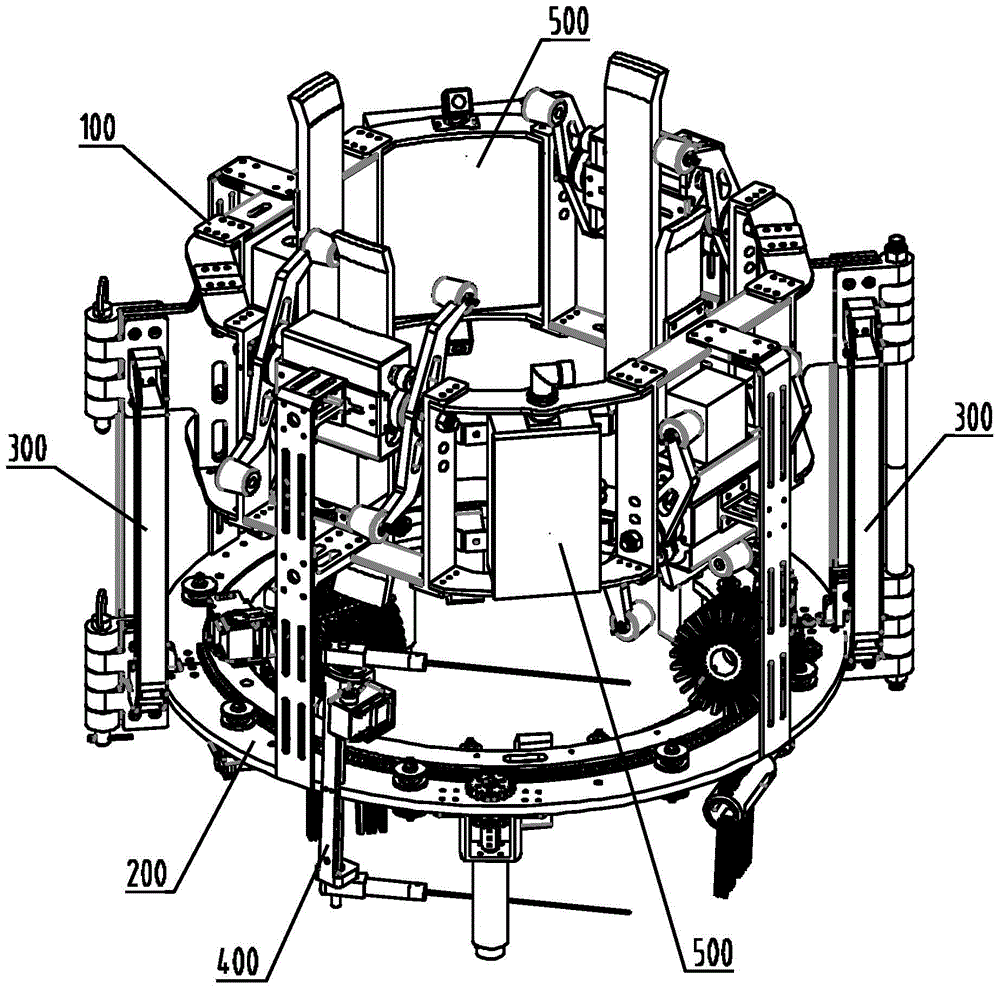

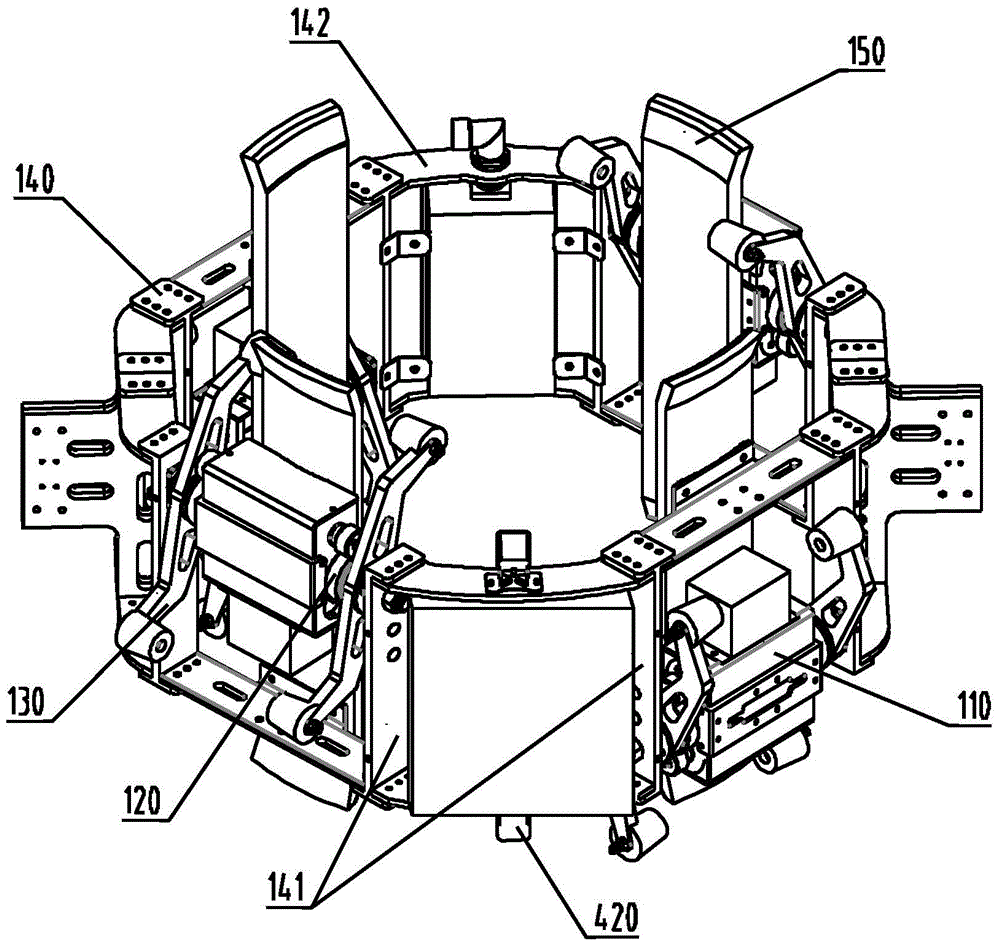

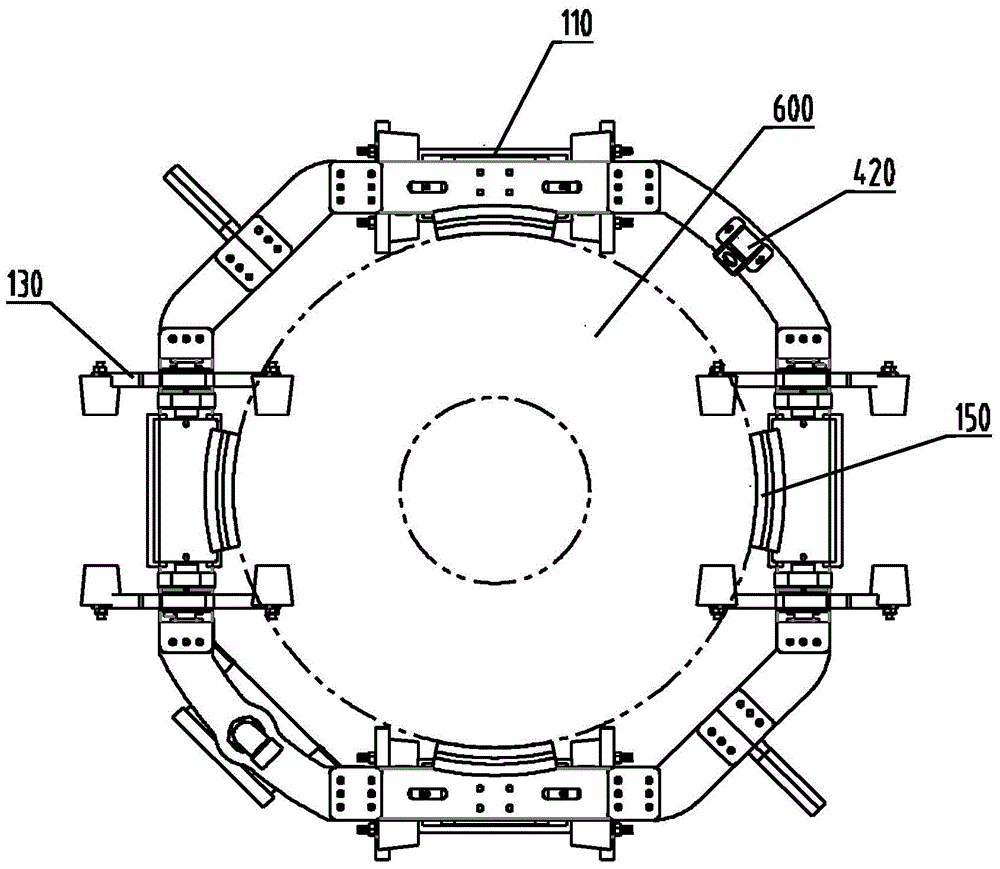

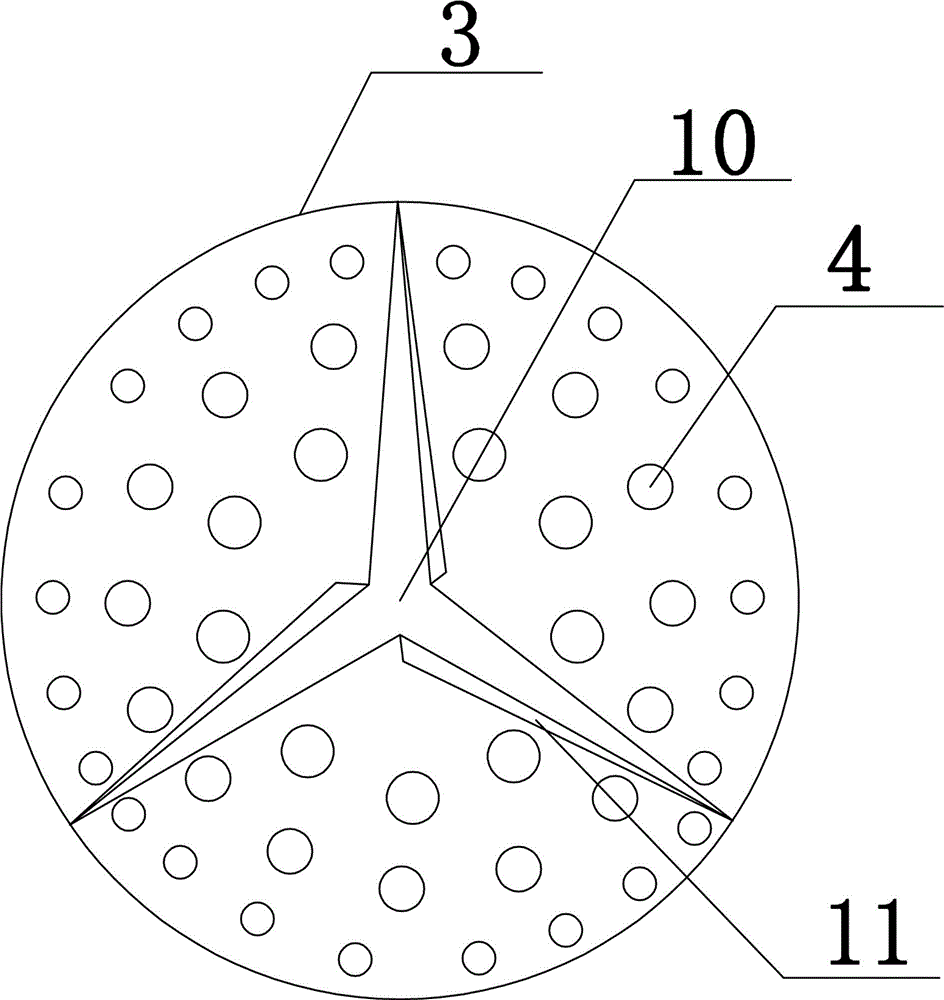

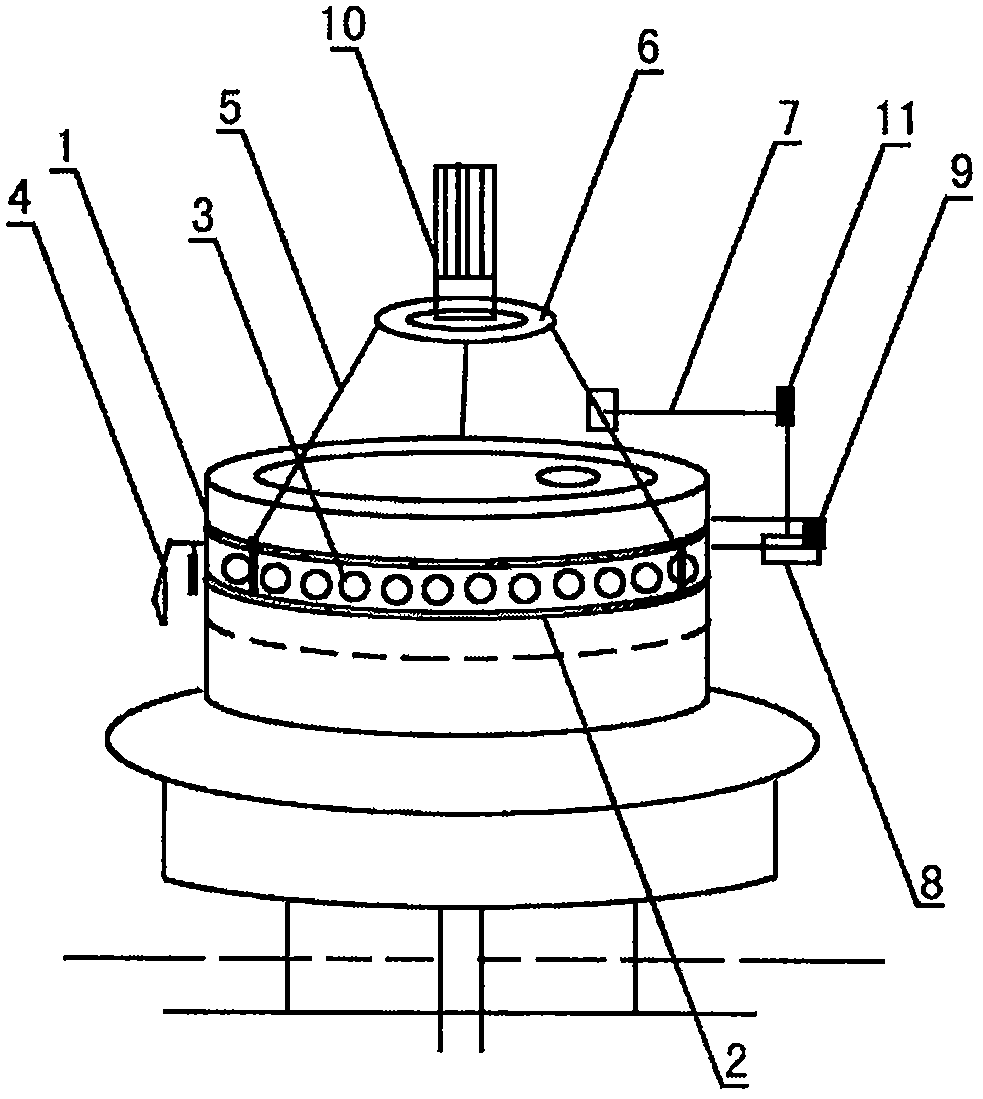

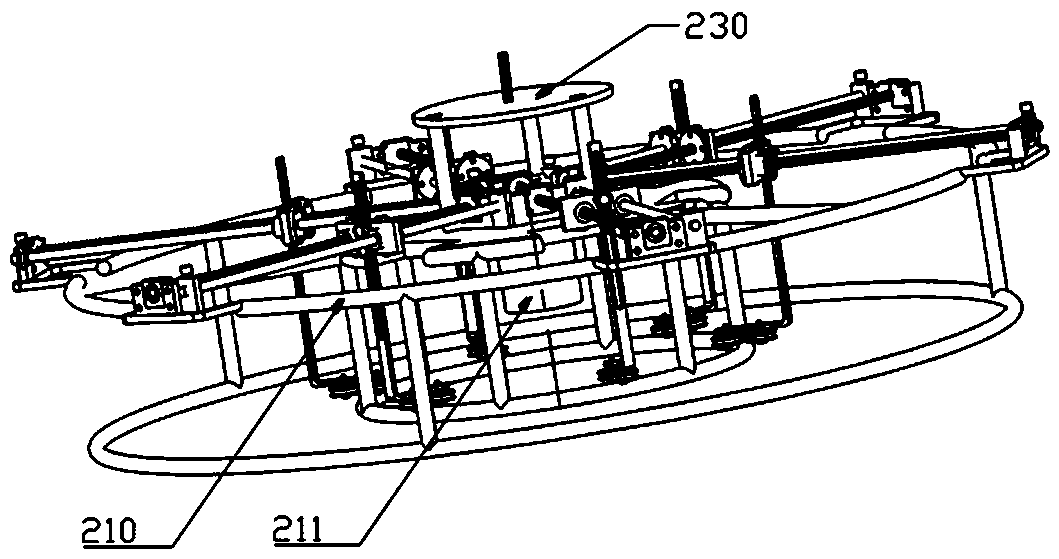

Insulator cleaning robot system

ActiveCN104438165AGuaranteed uptimeMove fastCleaning using toolsApparatus for overhead lines/cablesRobotic systemsLocking mechanism

The invention discloses an insulator cleaning robot system. The insulator cleaning robot system comprises a crawling mechanism, a cleaning mechanism, a locking mechanism, a detection mechanism and a battery control system, wherein the crawling mechanism is of a closed circumferential structure, surrounds an insulator string and drives a robot body to continuously move along the insulator string; the cleaning mechanism is of a closed circumferential structure and surrounds the insulator string; the locking mechanism is evenly arranged on the crawling mechanism, and the crawling mechanism is connected with the cleaning mechanism through the locking mechanism; the detection mechanism is arranged on one side of the locking mechanism, and the battery control system is installed on the crawling mechanism. The insulator cleaning robot system is simple in structure; due to the overall symmetrical structure, the stability of the robot is good; as the continuous type movement mode is adopted, the movement speed is high, the cleaning mode is simple, the cleaning speed is high, abrasion to coatings of insulators is small, locking is reliable, an adjustment mechanism can be suitable for insulator strings different in structural height and disc diameter, and electrification insulator string cleaning operation and insulator sheet quality detection can be carried out.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

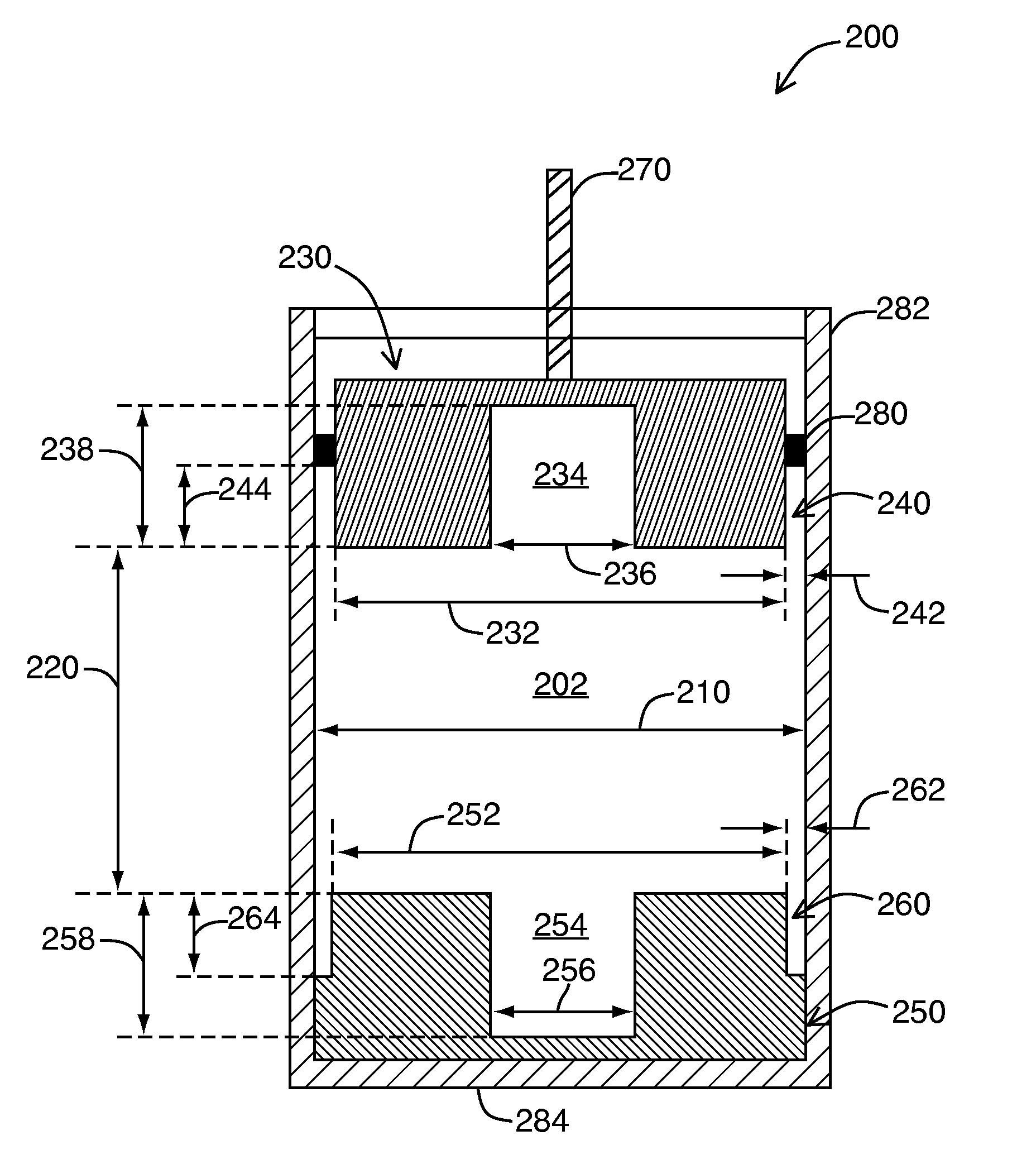

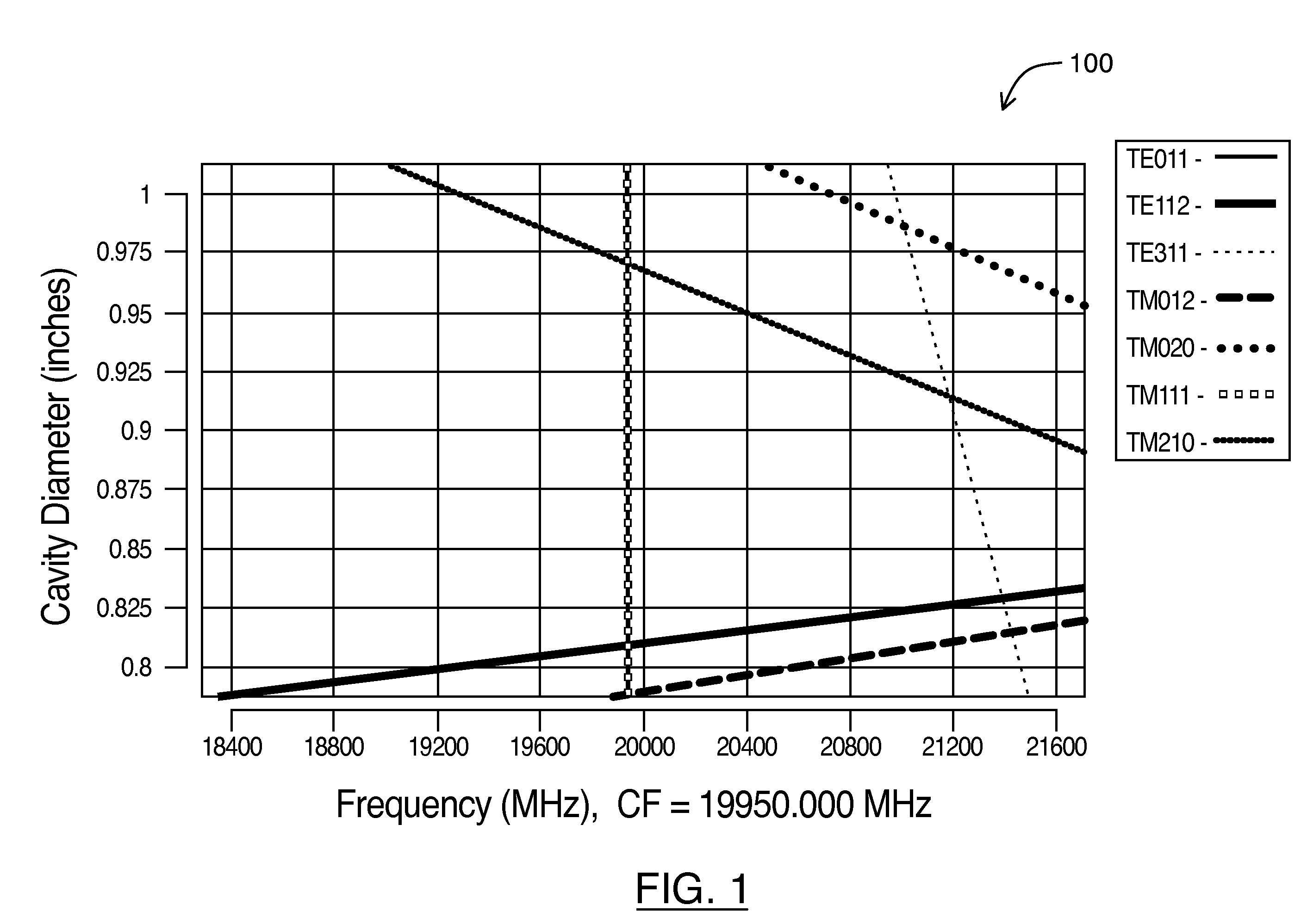

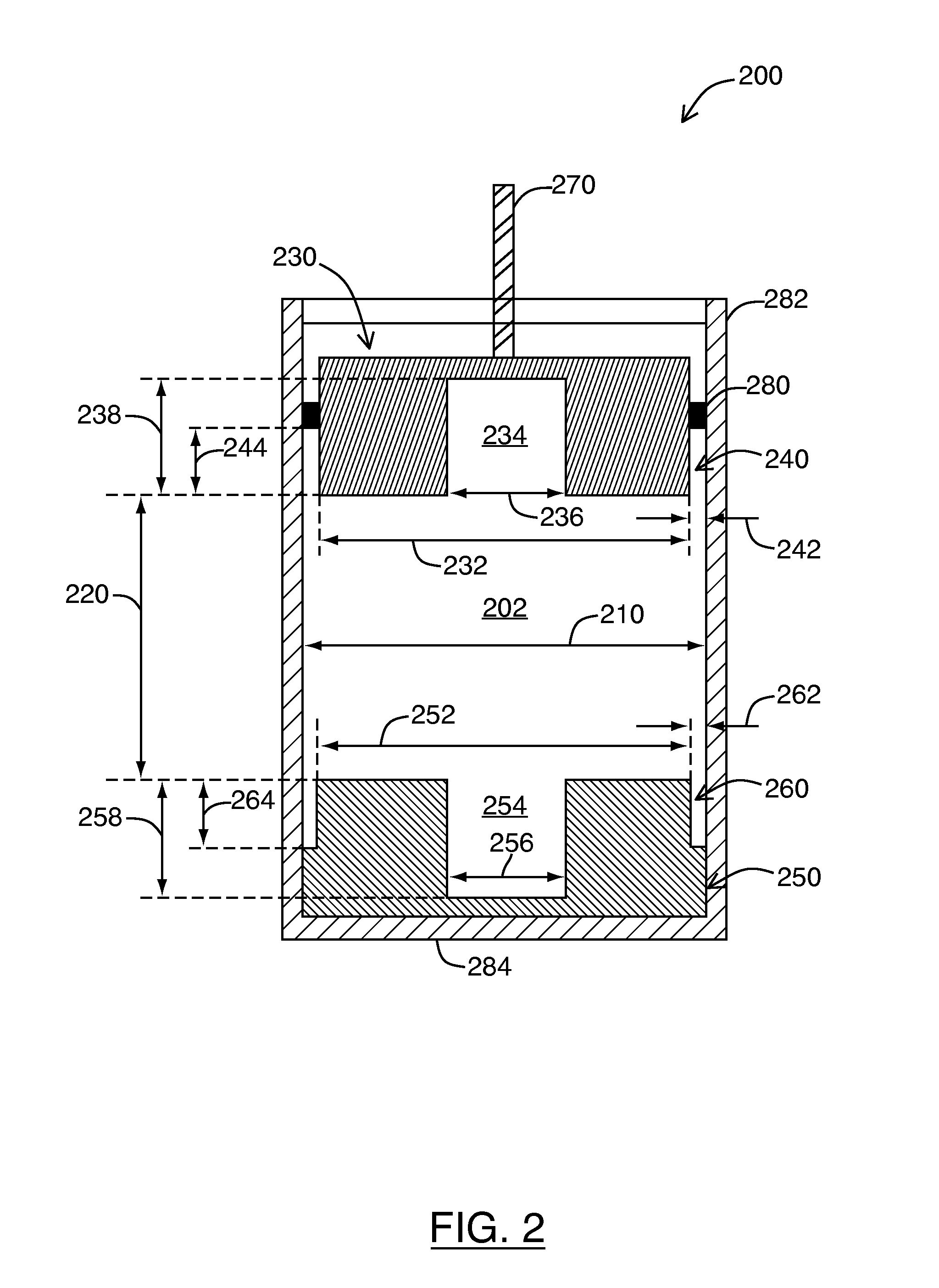

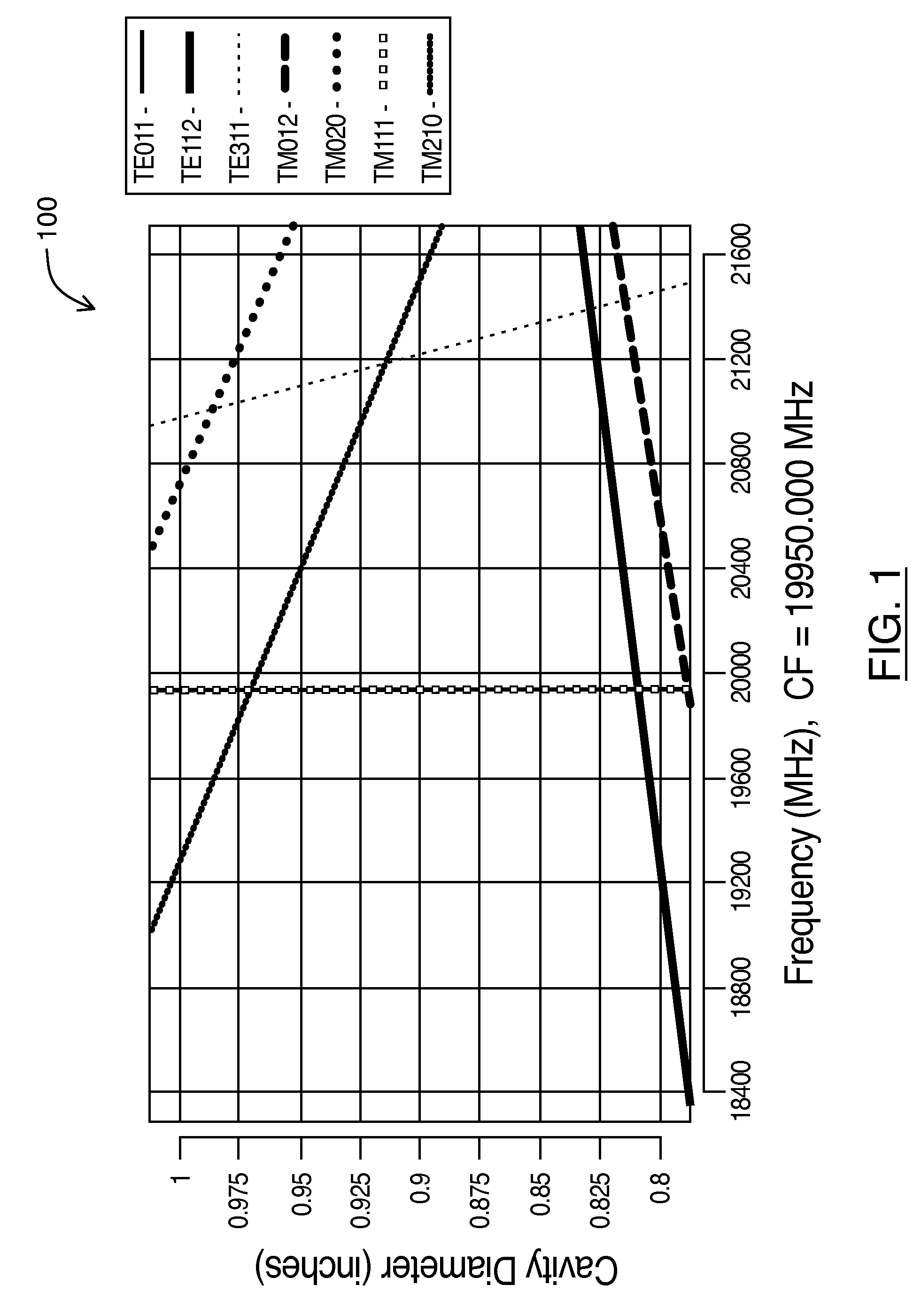

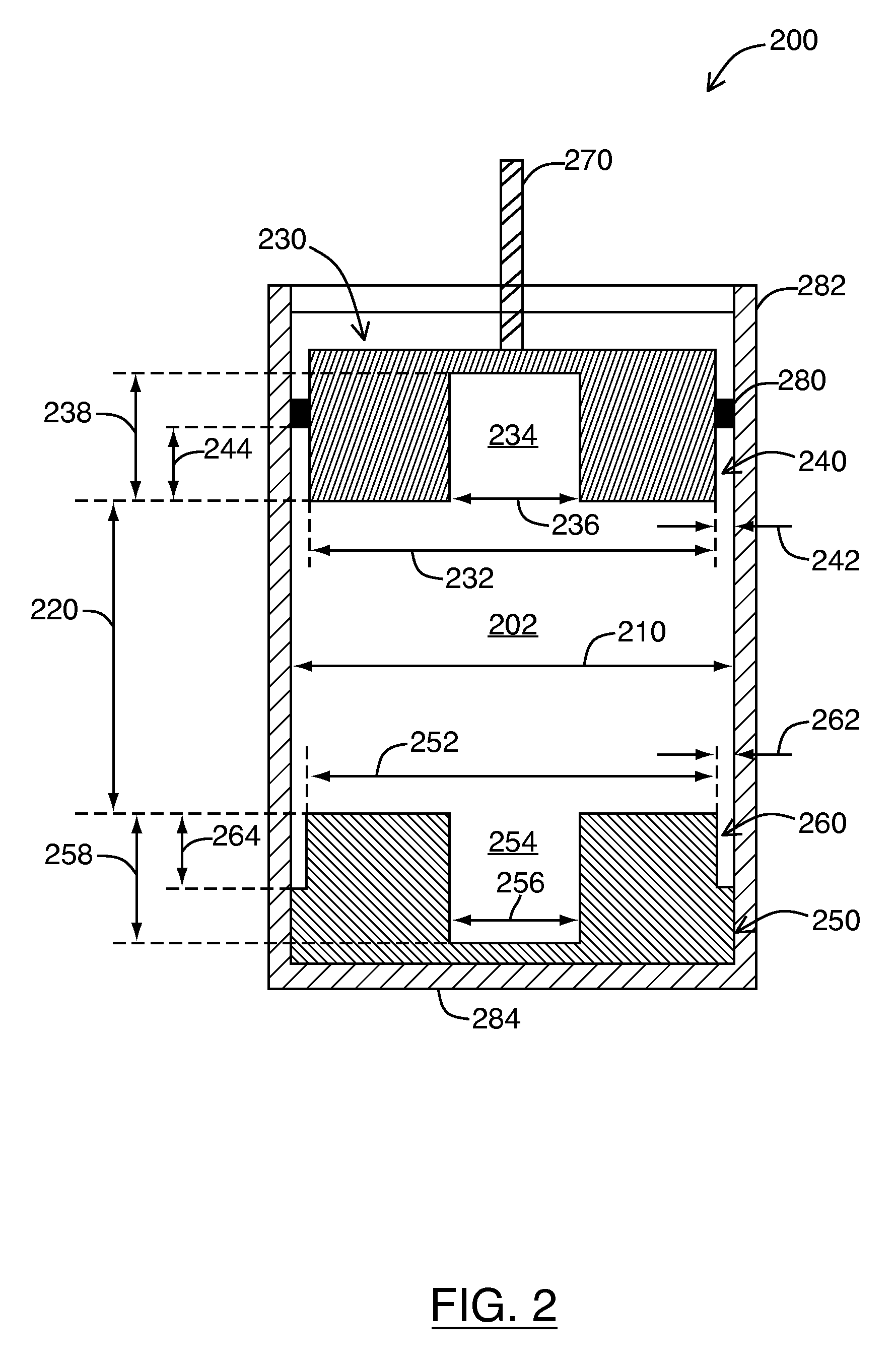

Te011 cavity filter assembly and method

A TE011 cavity filter assembly is disclosed. The system includes at least one resonator operating in TE011 mode having a resonant frequency. The at least one resonator may include a cavity comprising an inner diameter and a cavity length. The at least one resonator may also include a first metal disc inside the cavity. The first metal disc may include a disc diameter and a void in the metal disc, which includes a void diameter and a void depth. The inner diameter of the cavity may be greater than the disc diameter creating a gap with a gap width and a gap depth. The TE011 cavity filter assembly may further include positive coupling.

Owner:COM DEV LTD

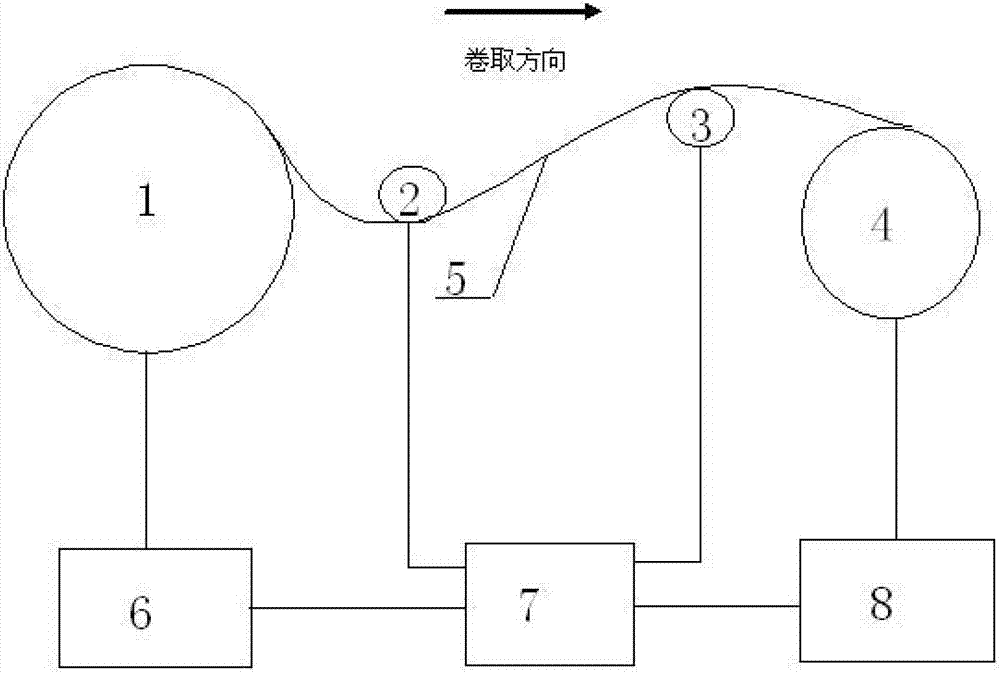

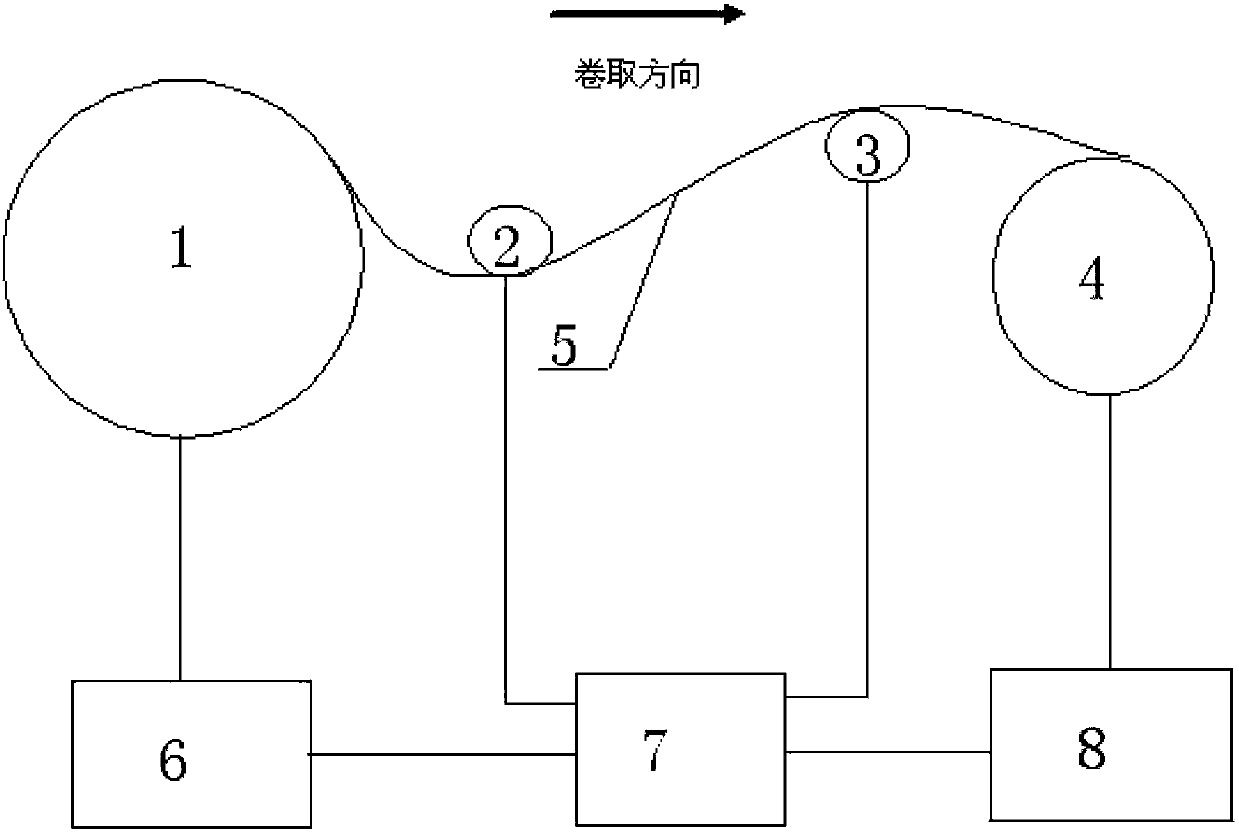

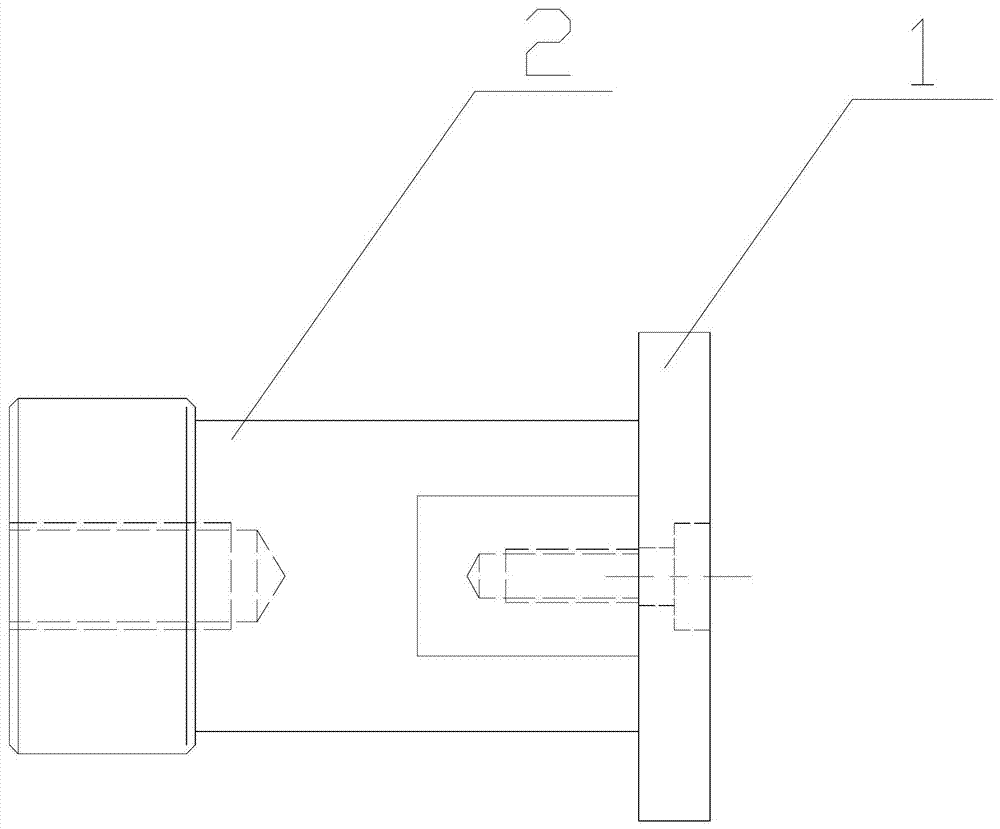

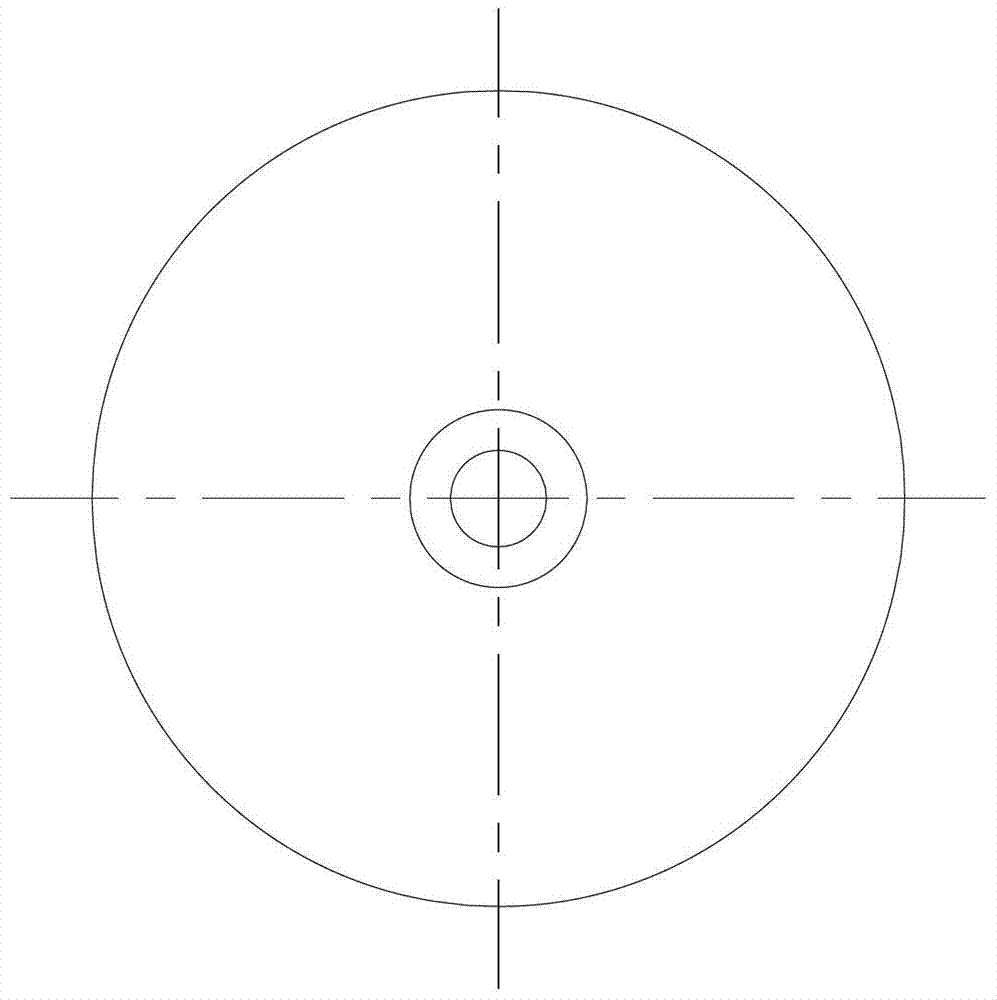

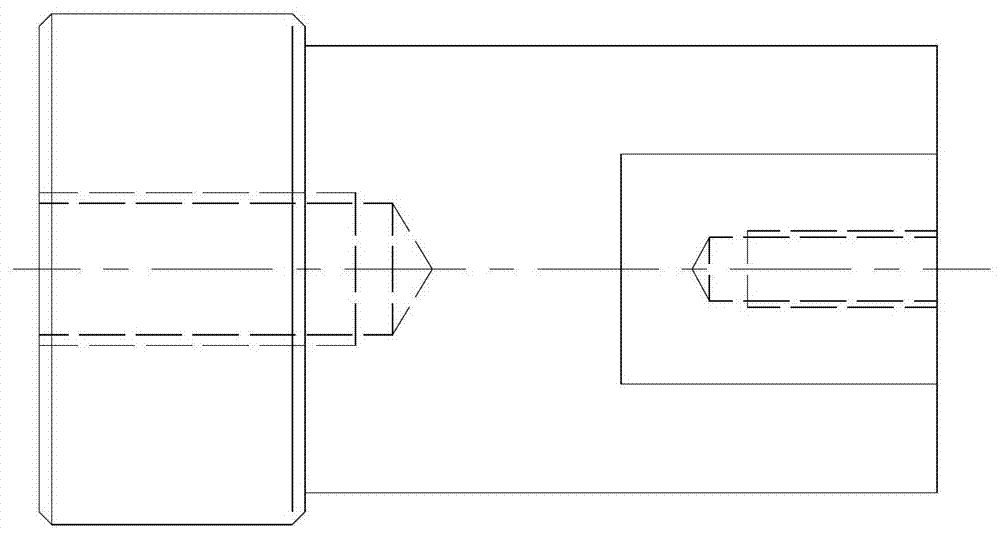

Tipping paper rewinding machine on basis of servo system

InactiveCN103043471ASmooth paperAchieve cycle regulationWebs handlingPulp and paper industryMiddle line

The invention discloses a tipping paper rewinding machine on the basis of a servo system. The tipping paper rewinding machine is characterized in that a linear speed is measured by a speed measuring roll in a tipping paper take-up procedure, real-time disc diameters of an unwinding disc and a winding disc are computed according to the real-time linear speed, a rotational speed of an unwinding motor and a rotational speed of a winding motor, and then the rotational speed of the unwinding motor and the rotational speed of the winding motor are computed according to the obtained disc diameters and a linear speed, which is given by a machine, in the tipping paper take-up procedure, and are adjusted via a central processing unit. The tipping paper rewinding machine has the advantages that circular adjustment is realized, so that the linear speed in a procedure for rolling tipping paper on the rewinding machine is consistent with the given speed, tension on the surface of the tipping paper in the take-up procedure keeps constant, disc surfaces are flat, and the winding quality is improved.

Owner:苏州市博海激光科技有限公司

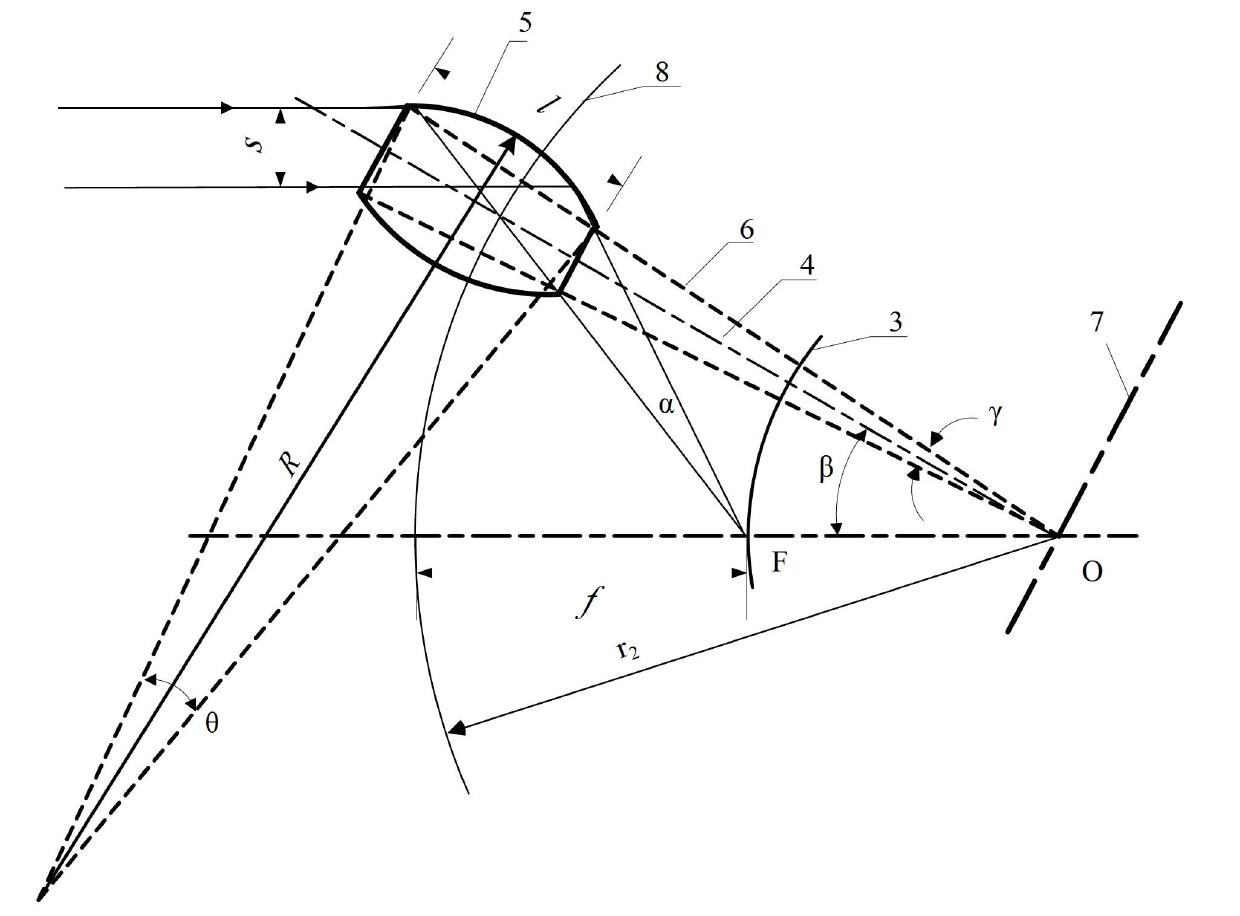

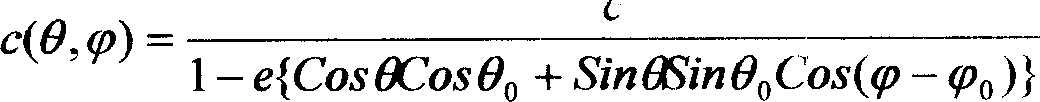

Lobster eye lens with reflection barrier being revolution surface formed by planar circular-arc bus

InactiveCN102681169AImprove spatial resolutionDiffuse spot diameter reductionOptical elementsImage resolutionConfusion

The invention discloses a lobster eye lens with a reflection barrier being a revolution surface formed by a planar circular-arc bus, which belongs to the technical field of optical elements. In the conventional lobster eye lens, a micro-channel tube reflection barrier is a plane, so that the imaging confusion disc diameter is large, and the spatial resolution of the lobster eye lens is difficult to increase. The lobster eye lens provided by the invention consists of a plurality of micro-channel tubes; the axis of each micro-channel tube is the radius of spheres with the same spherical center along each azimuth and pitching direction; and each micro-channel tube is formed by enclosing four same reflection barriers which are symmetrical to the axes of the micro-channel tubes pairwise. The lobster eye lens is characterized in that the reflection barrier is a revolution curved surface reflection barrier which is formed by revolving a planar circular-arc bus; the planar circular-arc bus starts from the incident end of each micro-channel tube and ends at the emergent end of the micro-channel tube; the curvature radius R of the planar circular-arc bus is determined by a formula shown in the specifications; in the formula, l refers to the chord length of the planar circular-arc bus; gamma is the field angle of each micro-channel tube; the extension line of the chord of the planar circular-arc bus intersects with the spherical center O; and the revolving axis of the planar circular-arc bus passes through the spherical center O, and is vertical to the extension line of the chord of the planar circular-arc bus.

Owner:CHANGCHUN UNIV OF SCI & TECH

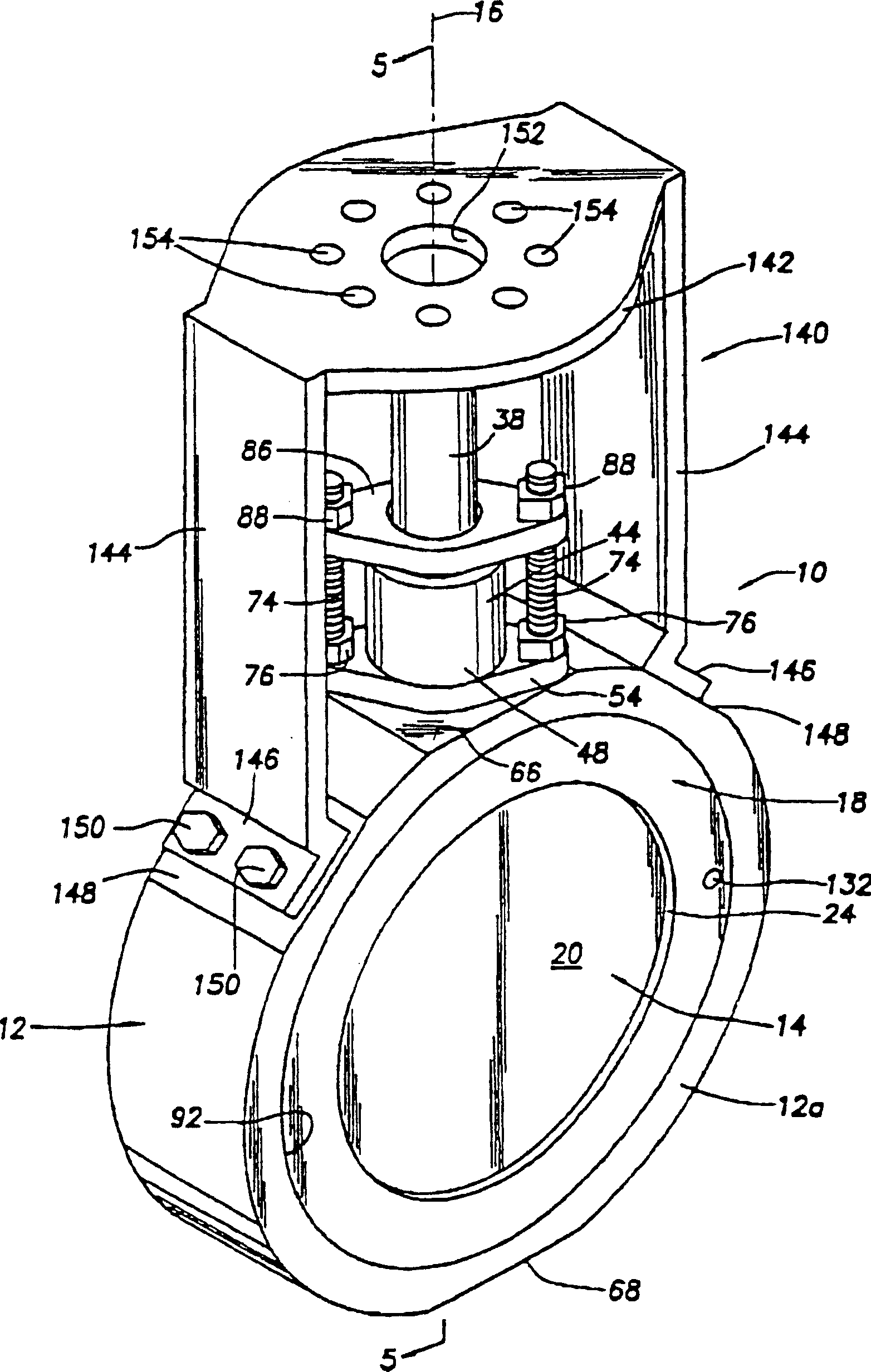

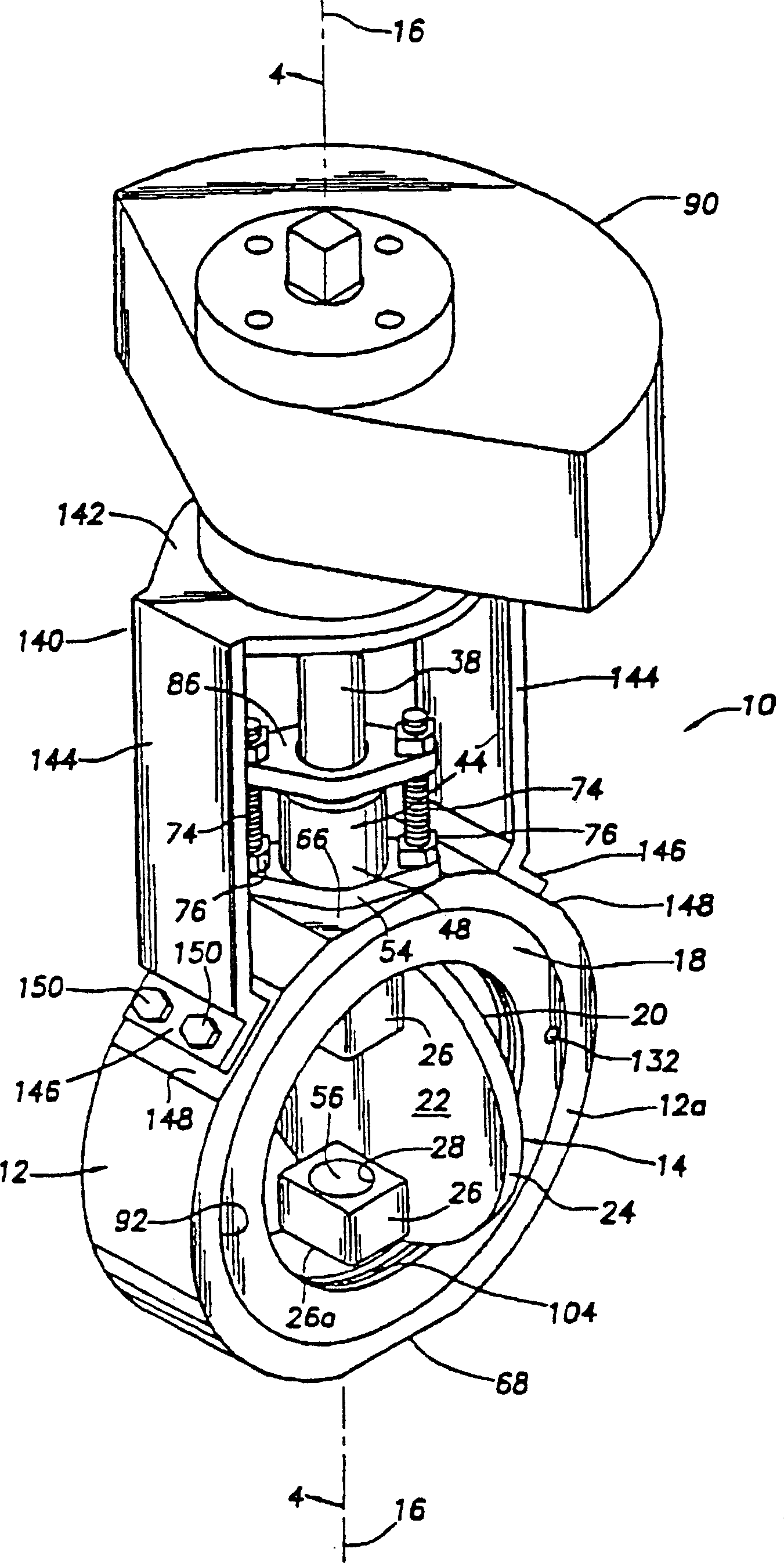

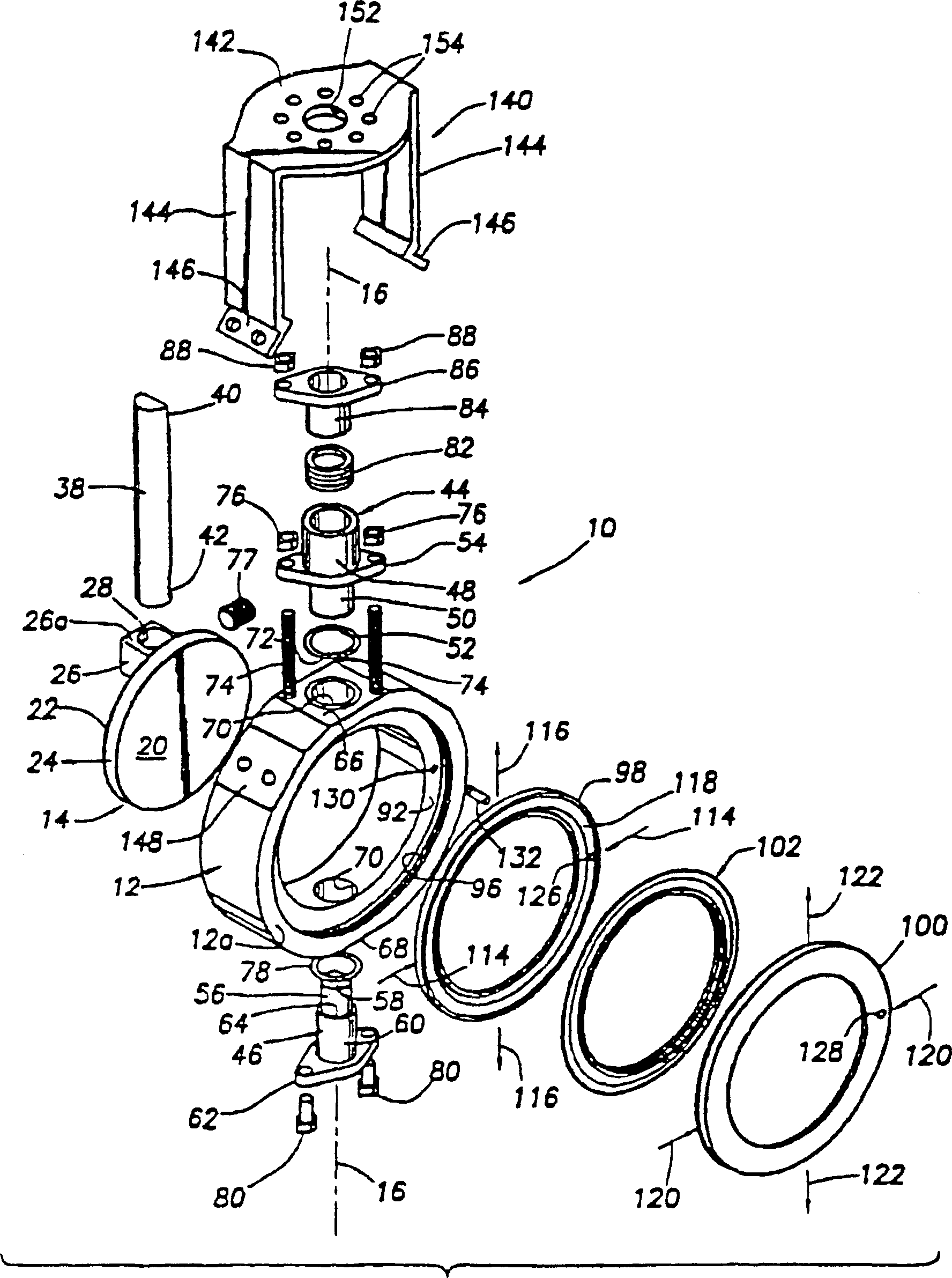

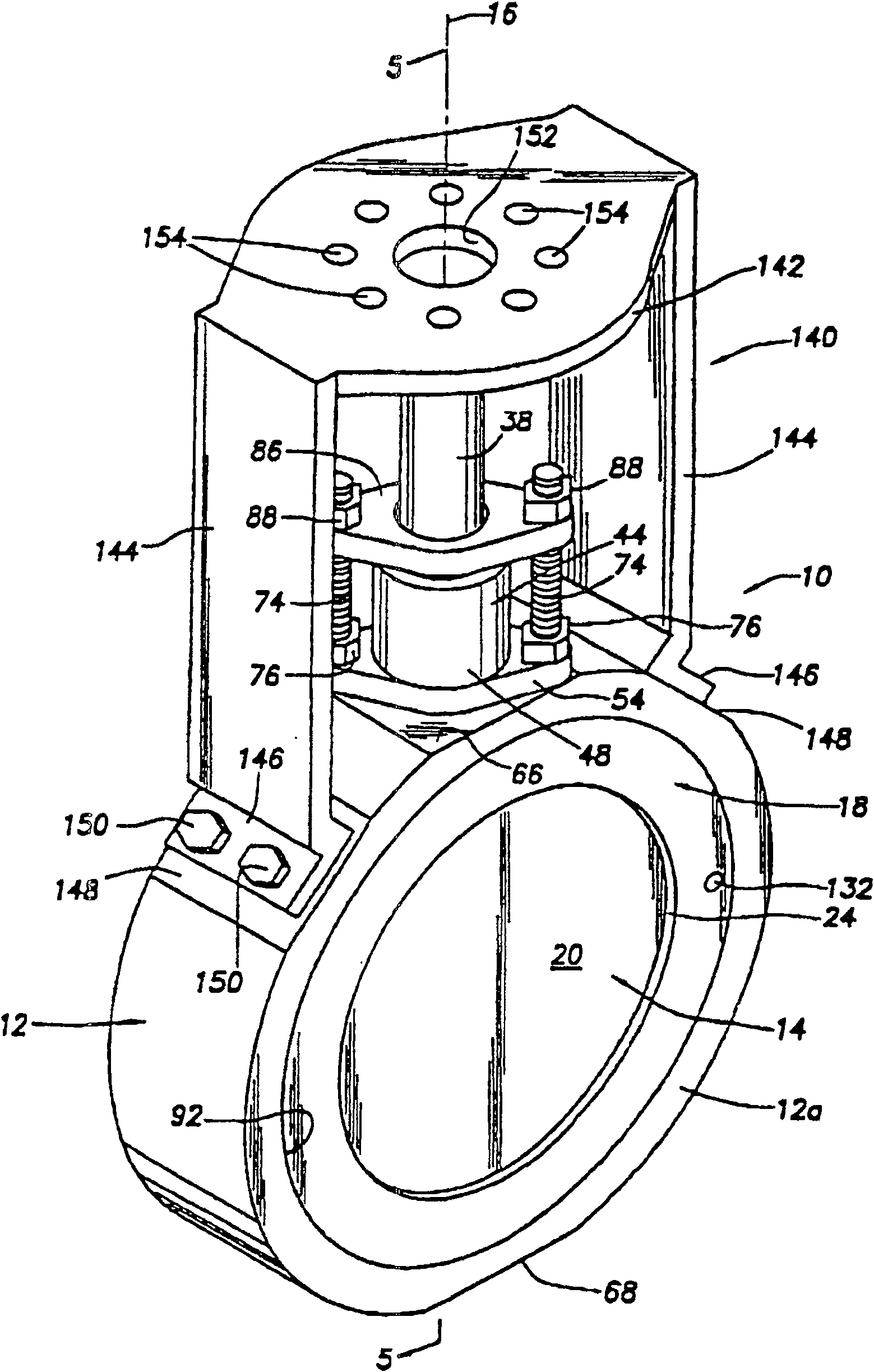

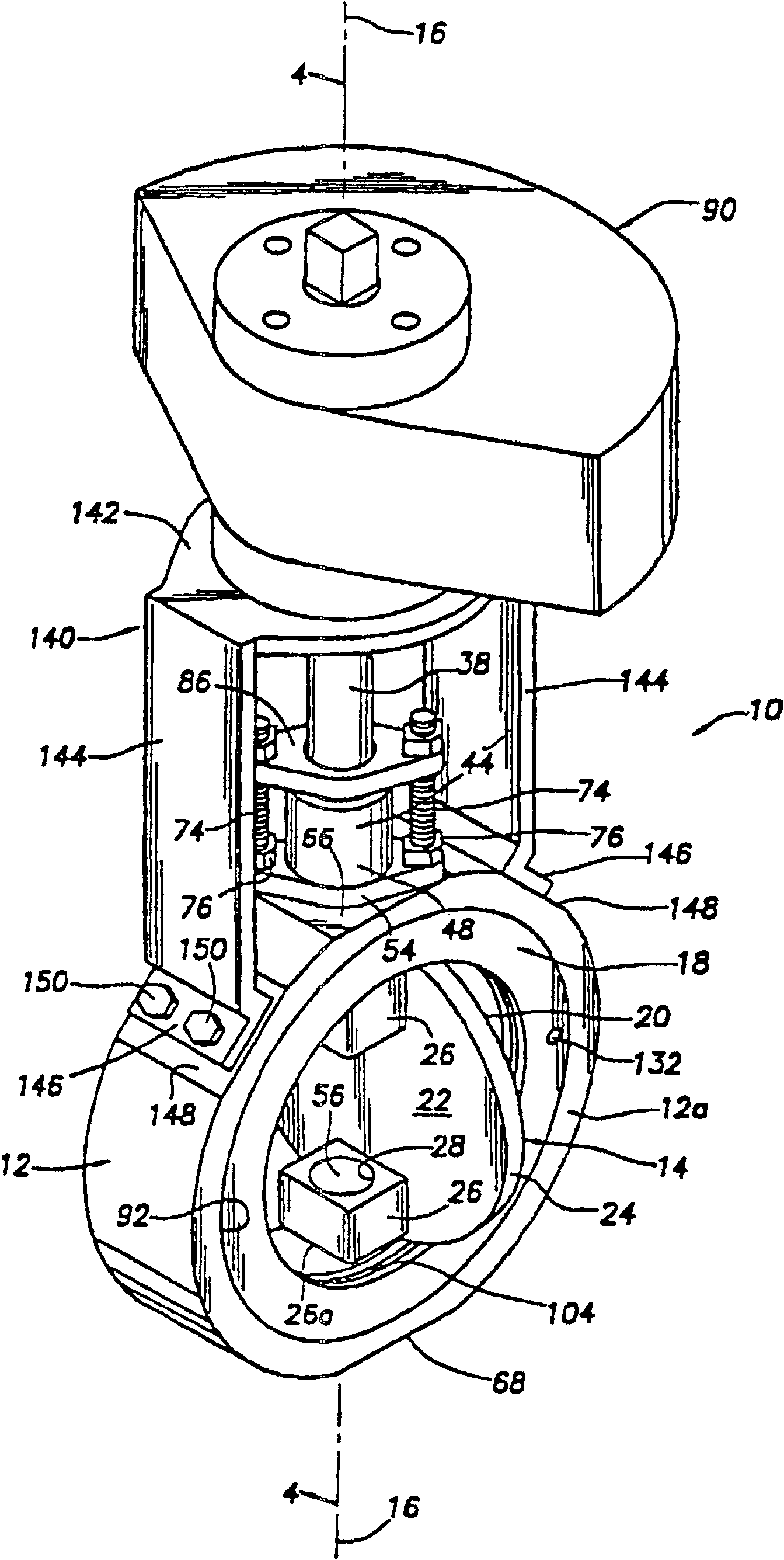

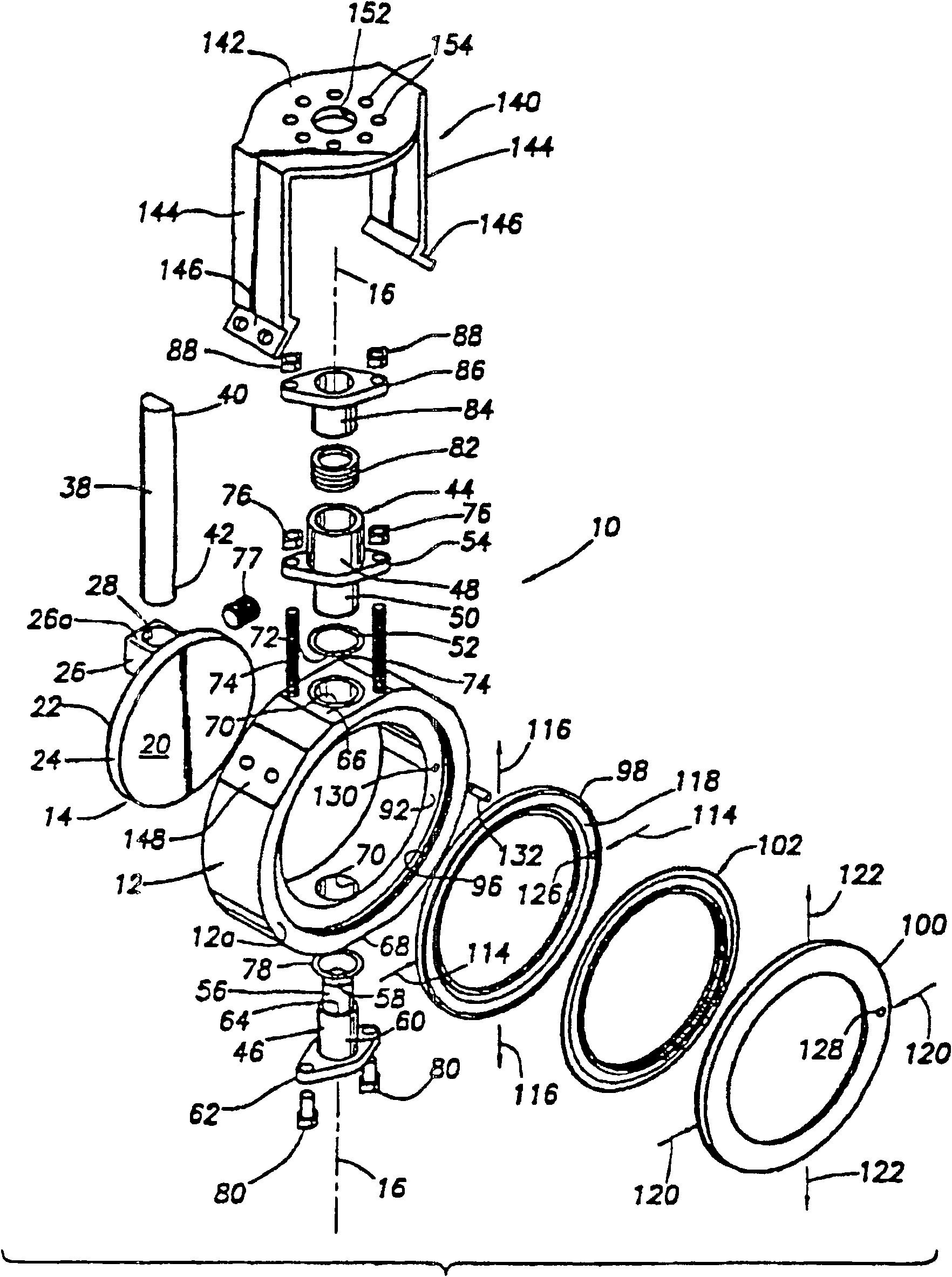

Elliptical sealing surface for butterfly valve

A reduced component wear valve is comprised of a valve body having a passage therethrough and a disc attached to a rotatable shaft. The disc is utilized with a seal forming a gap between the disc and the seal proximate to the rotational axis of the disc. When the disc is in the open position, the seal major axis is greater then the disc diameter and they do not touch. As the disc rotates to near closure, the disc perimeter engages the minor axis of the seal (which is smaller than the disc diameter), and the disc stretches the seal in the minor axis direction thus decreasing the major axis such that the gap is closed. The seal can be pre-formed in an elliptical shape or it can be formed into an elliptical shape by a retaining mechanism. The seal may be a single-piece or a multi-piece assembly press-fit into the valve body. Zero or light disc to seal contact during the majority of the valve disc rotation minimizes valve seal wear and rotational friction.

Owner:FISHER CONTROLS INT LLC

Sewage treatment device

ActiveCN105293600AImprove processing efficiencyGuaranteed treatment effectWater/sewage treatmentGrain treatmentsTreatment effectSewage

The invention relates to a sewage treatment device. The sewage treatment device comprises a treatment cavity, wherein a rotary motor is arranged on the outer side of the treatment cavity and is connected with a cutting disc through a rotation shaft, the cutting disc is longitudinally arranged in the treatment cavity, the two ends of the cutting disc attach to the inner wall of the treatment cavity, and cutting edges are distributed in the cutting disc. The treatment cavity on the two sides of the cutting disc serve as a water inlet cavity and a water outlet cavity, a water inlet pipe is arranged on the side wall of the water inlet cavity, a water outlet pipe is arranged on the side wall of the water outlet cavity, the water inlet pipe and the water outlet pipe are oppositely arranged, and the disc diameter of the cutting disc is greater than the pipe diameters of the water inlet pipe and the water outlet pipe. A storage tank is arranged at the lower portion of the treatment cavity, and the treatment cavity is in spatial communication with the storage tank. The sewage treatment device utilizes power brought by the water pressure difference between the water inlet pipe and the water outlet pipe and the effects of the cutting edges formed in the cutting disc and the rotary force of the cutting disc to enable sewage to be directly layered in a sewage pipe in the sewage cutting and shattering process, directly cuts and shatters easily-treated sewage, improves the sewage treatment efficiency, ensures the sewage treatment effect and does not easily cause sewage blockage.

Owner:AIDI MACHINE HANGZHOU

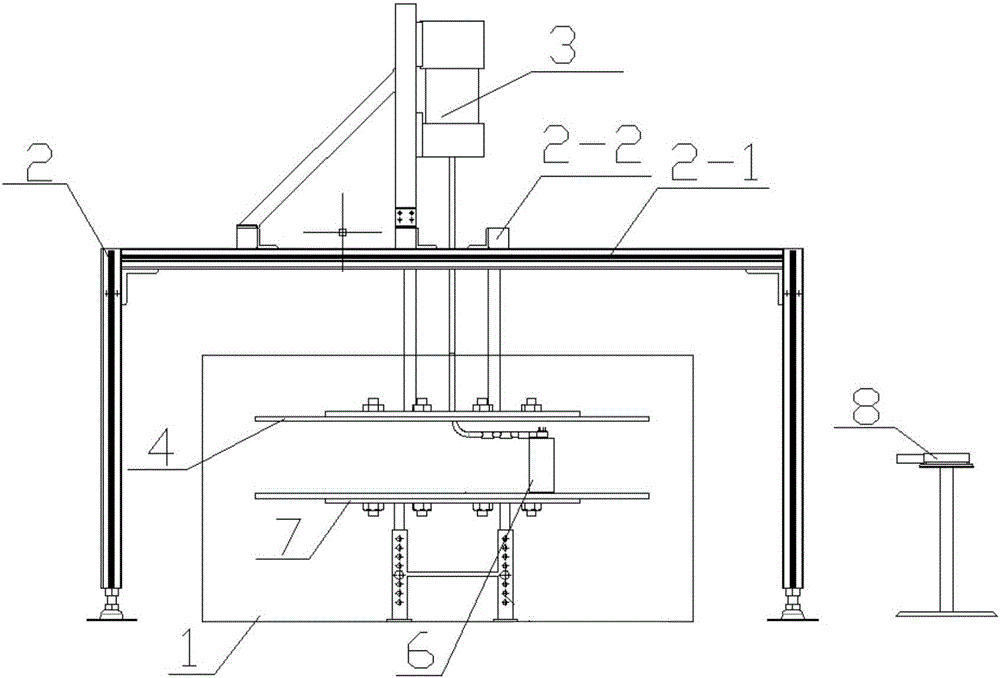

Experiment apparatus for rotary aerofoil device

ActiveCN105784321ABasic theoretical research is beneficialAdjust spacingHydrodynamic testingExperimental researchCircular disc

The invention discloses an experiment apparatus for a rotary aerofoil device. The experiment apparatus comprises a water tank, a fixed support, a rotary structure, a main disc and a detachable circular ring, wherein the fixed support is separated from the water tank, and the rotary structure is positioned on the fixed support. The experiment apparatus allows experiment and observation of the rotation effect of an aerofoil, provides experimental support for theoretical research of a rotation boundary layer of the aerofoil, and is beneficial to basic theoretical research. Experiment and research of an aerofoil under different rotating speed can be realized by adjusting the rotating speed of a motor, different aerofoils can be changed for different research needs, and the attack angle of the aerofoil and rotary radius of blades can be adjusted according to different research needs. The distance between upper and lower discs and the disc diameter can be changed, and experiment related parameters can be adjusted to obtain experiment environments with different fluid Reynolds numbers as needed.

Owner:嘉兴芸诗娇电子商务有限公司

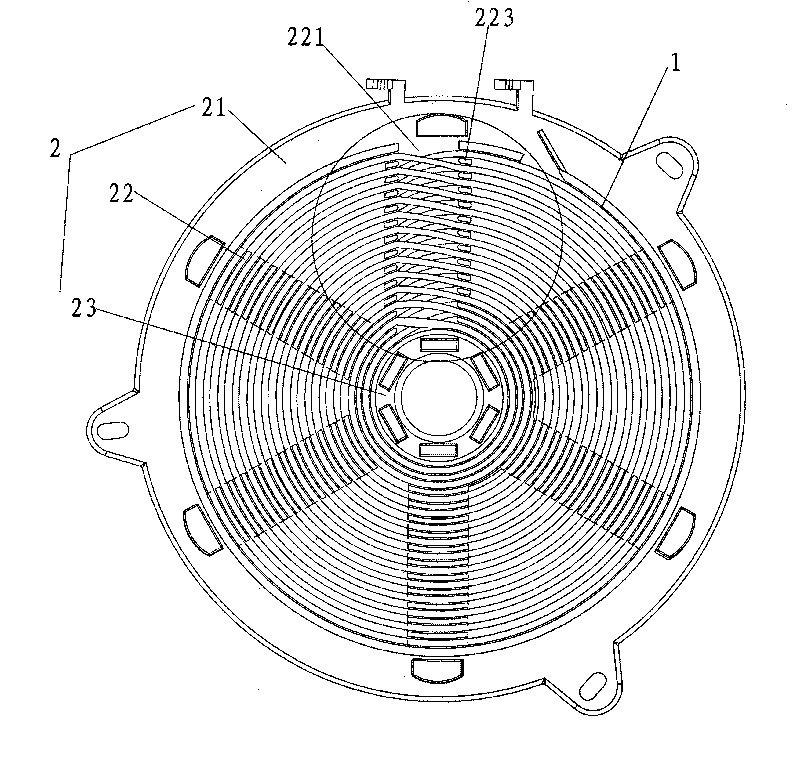

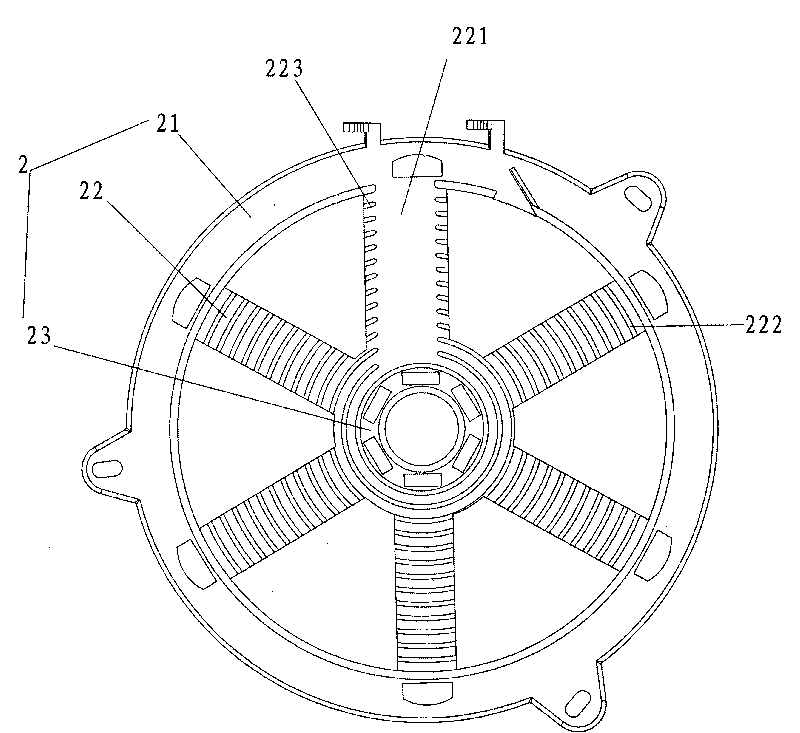

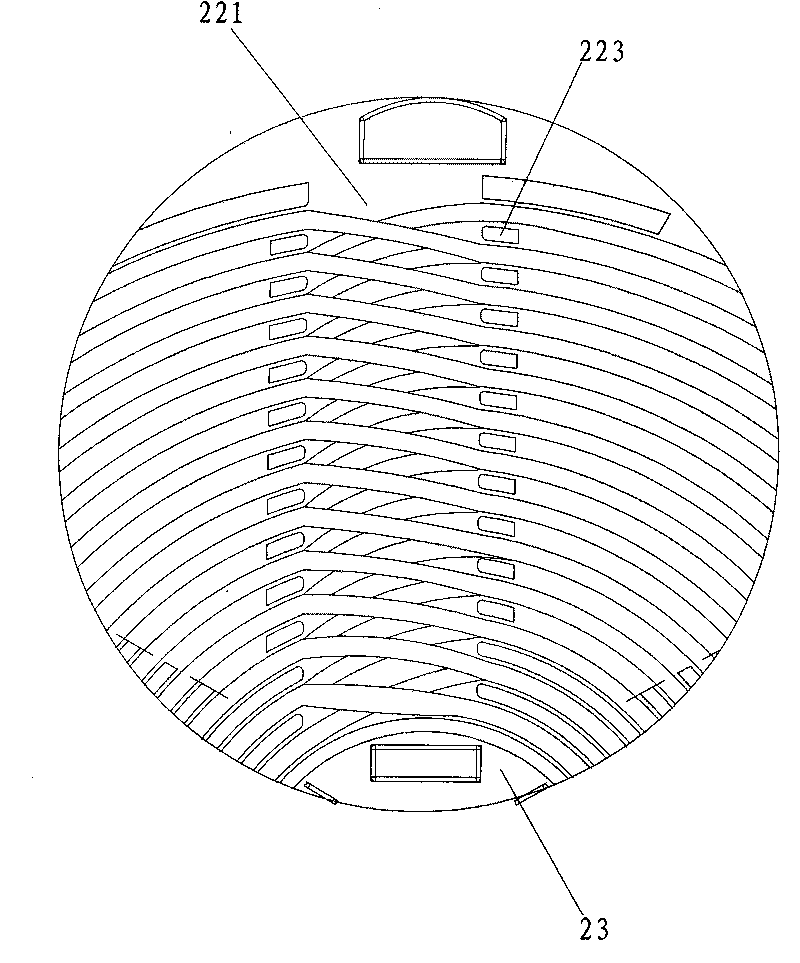

Coil disc for electromagnetic cooker and coiling method thereof

ActiveCN101737829ASmall diameterSolve the cooling problemDomestic stoves or rangesLighting and heating apparatusPower flowEngineering

The invention discloses a coil disc for an electromagnetic cooker and a coiling method thereof. The coil disc comprises a coil, a bracket and a magnetic strip, wherein the bracket comprises an outer frame, a magnetic strip slot and a central circle, wherein two ends of the magnetic strip slot are respectively connected with the central circle and the outer frame, and the magnetic strip is embedded in the magnetic strip; and the coil is wound on the bracket by dividing an upper layer and a lower layer. The coil disc adopts a co-winding double-layer enameled wire, avoids the wire jamming phenomenon and the short-circuit phenomenon among rings, shortens the diameter of the coil, solves the difficult problem of concentric circle coil guide which exists for a long time and the problem of difficult heat dissipation of the coil, reduces the current loss, improves the heat efficiency, reduces the disc diameter of the coil disc by 30 percent compared with the common winding way, averagely improves the Q value by 15 percent, reduces the current loss by 15 percent and prolongs the service life of the coil disc. In addition, the invention achieves the aim of saving the cost on the premise of ensuring the same energy efficiency standard as the coil adopts an aluminum enameled wire.

Owner:上饶市济华实业有限公司

Automatic button sewing machine

The invention provides an automatic button sewing machine which comprises a sewing machine head, a button supplying rotary plate, a sewing machine seat and a button supplying groove. When in an initial position, the button supplying rotary plate is parallel to the sewing machine head, the discharge end of the button supplying groove is connected with button positioning grooves of the button supplying rotary plate separately, buttons fall into the button positioning grooves from a hole formed in the bottom of the button supplying groove, and the position is a button mounting position; and the button supplying rotary plate horizontally rotates by 90 degrees anticlockwise from the button mounting position, the button positioning grooves of the button supplying rotary plate are arranged just below a sewing needle, and the position is a button sewing position. A plurality of button positioning grooves each is in a circular shape and share a center point, and the smaller the size is, the deeper the button positioning groove is; and a negative adsorption device is arranged on the sewing machine head and is used for sucking up the buttons delivered by the button supplying rotary plate and enabling the buttons to suspend so as to enable the button supplying rotary plate to leave and lappet to cover the position. One automatic button sewing machine can be utilized to sew the buttons with various disc diameters on clothing, and the button sewing efficiency is greatly improved.

Owner:广西风华服饰有限责任公司

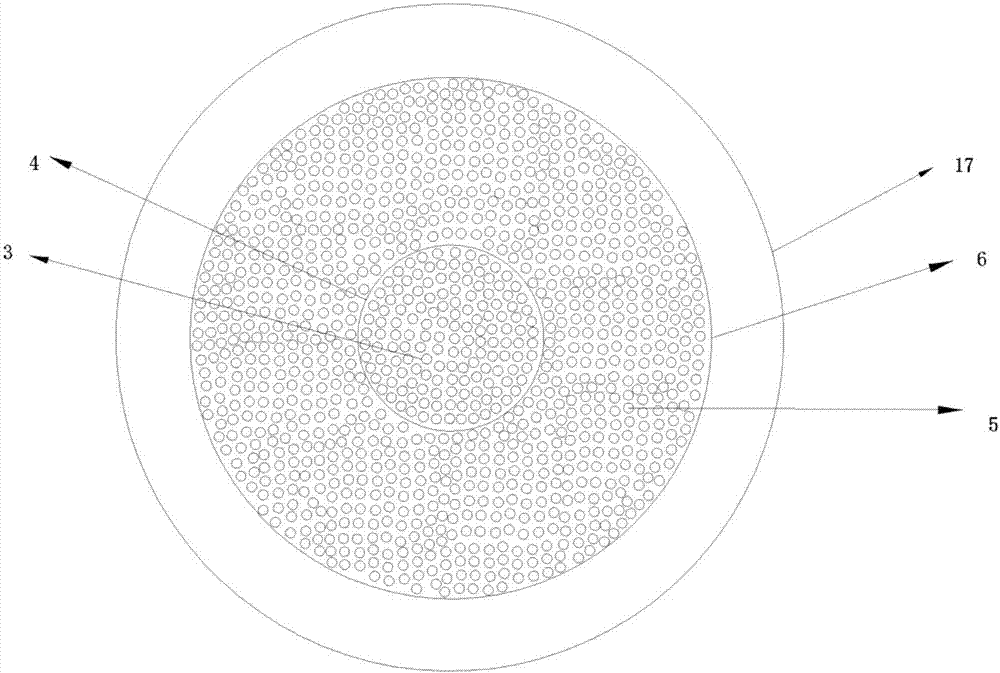

Thin-walled large specification honeycomb ceramic carrier and preparation method thereof

InactiveCN108727054AImprove thermal shock resistanceHigh mechanical strengthCatalyst carriersCeramicwareVolumetric Mass DensityMixed materials

The invention discloses a thin-walled large specification honeycomb ceramic carrier and a preparation method thereof. Raw materials of the carrier comprise kaolin, aluminum oxide, silicon dioxide, talc powder, aluminum titanate micropowder and the like. The preparation method comprises the following steps: mixing kaolin, aluminum oxide, silicon dioxide, talc powder, aluminum titanate micropowder,zirconium phosphate and cerous phosphate, and uniformly stirring the mixture to obtain a mixed material; adding glycerin and hydroxypropyl methyl cellulose into water to obtain an additive solution; mixing the mixed material with the additive solution, uniformly stirring the mixture, and carrying out kneading, ageing and vacuum pugging to obtain a pug; and extruding the pug under pressure by meansof a mold to obtain a cylindrical honeycomb ceramic wet blank, and drying and roasting the cylindrical honeycomb ceramic wet blank to obtain the thin-walled large specification honeycomb ceramic carrier. The disc diameter of the thin-walled large specification honeycomb ceramic carrier provided by the invention can reach 300-350 mm, the pore density can reach 300-400 pore / sq. inch, and the thin-walled large specification honeycomb ceramic carrier meets the demand of treating tail gas of a large discharge diesel vehicle.

Owner:安徽中都环宇新材料科技有限公司

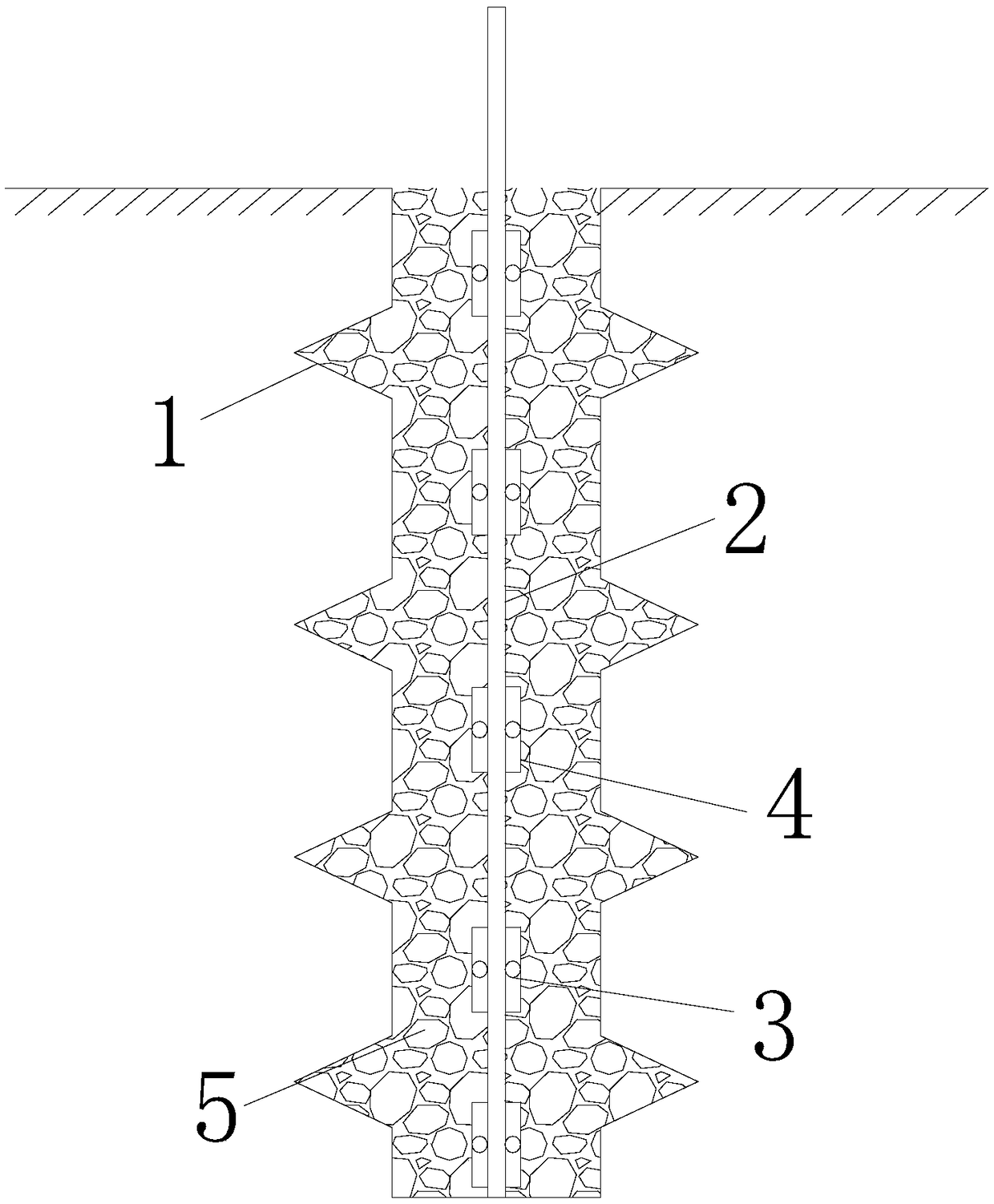

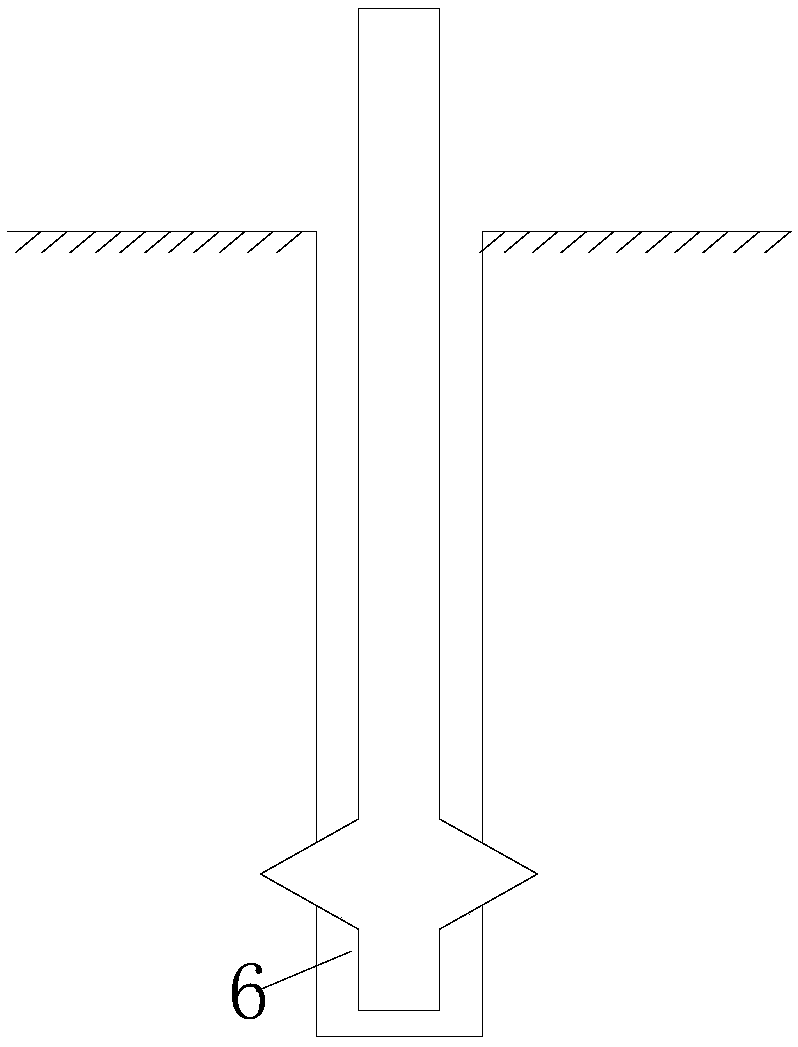

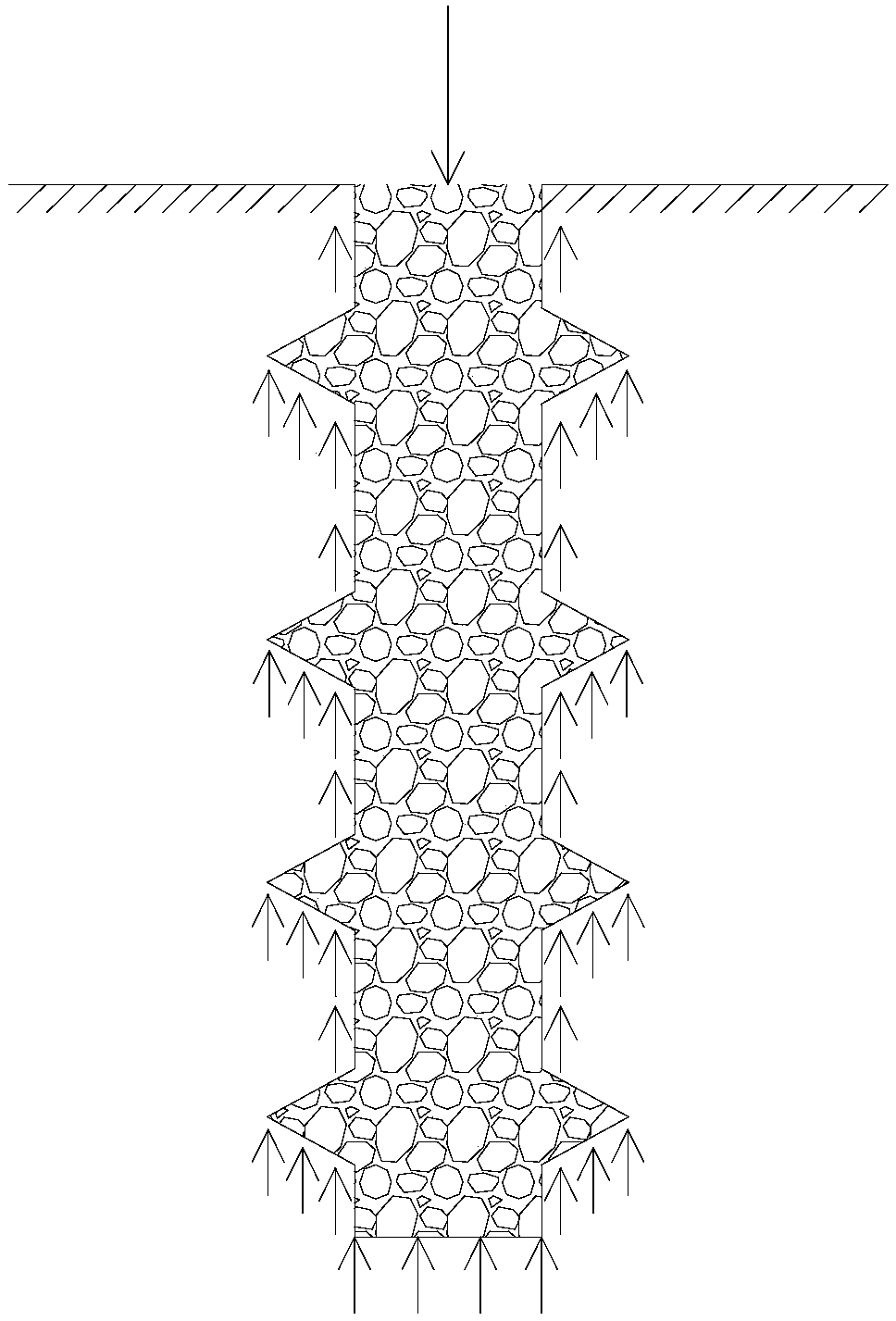

Gravel grouting pile with extruding and expanding supporting discs and construction method thereof

The invention discloses a gravel grouting pile with extruding and expanding supporting discs and a construction method thereof. The gravel grouting pile comprises supporting disc bodies, a grouting pipe, prefabricated holes, geotechnical cloth, gravel and a gravel slurry fixing pile body, the grouting pipe is arranged at the center position of the gravel slurry fixing pile body, the prefabricatedholes are annularly distributed on the pipe wall of the grouting pipe correspondingly, the geotechnical cloth wraps the outer parts of the prefabricated holes, the gravel wraps the upper part of the grouting pipe, the supporting disc bodies are located on the outer wall of the gravel slurry fixing pile body. The gravel grouting pile with the extruding and expanding supporting discs is formed by extruding and expanding through a special extruding and expanding device on the basis of a common gravel grouting pile, and still has the advantages of being free of noise and free of vibration during construction, the bearing disc diameter of an extruding and expanding supporting disc pile can reach about 2 times of the diameter of the pile body, the sum of the bearing area of each disc and each branch can reach several times of the main diameter section of the pile body, and compared with a straight rod pile, the vertical bearing capacity of the extruding and expanding supporting disc pile canbe increased by one time or even more than one time.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD +1

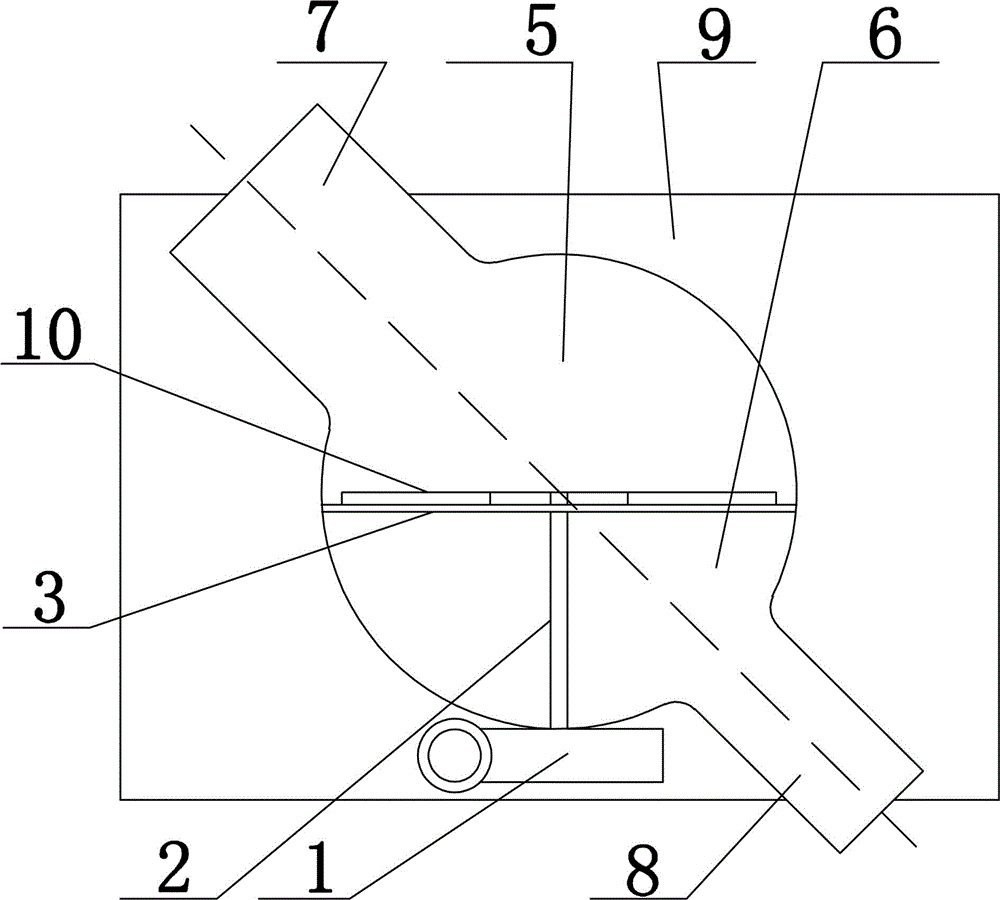

Rolling ball type stone mill guidance labor-saving apparatus

InactiveCN107930759AGuaranteed finenessAvoid artificial labor exportCocoaGrain treatmentsBall typeEngineering

A ball-type stone mill guide labor-saving device, comprising a stone mill movable grinding disc (1), a circular ring frame (2) of equal diameter is arranged on the side of the movable grinding disc (1), and balls (3) distributed at equal intervals are arranged inside. ), the side is a locking structure (4), the upper end of the grinding disc (1) is provided with a triangular linkage base frame (5) connected with the rotating track (6), and the guide part is located above the push handle, including a T-shaped support rod (7), a set Structure (8), governor (9), when in use, the set structure (8) is fixed on both sides of the push handle, and the electric device (10) is started to drive the movable grinding disc (1) to move along the circular circle; a prompting device (11 ), to provide synchronous prompts for the running status of the movable grinding disc (1); it is used in conjunction with the movable grinding disc to effectively ensure the fineness of grinding, avoid human labor output, save time and effort, and form a directional uniform motion. The operation is simple and has strong practicality. Function.

Owner:求晓英

Device and method for treating coking wastewater by utilizing blast furnace slag

ActiveCN106966446AReduce processing costsIncrease vitrification rateWater contaminantsWater/sewage treatmentCircular discSlag

The invention discloses a device and method for treating coking wastewater by utilizing blast furnace slag. The device comprises a first convex disc, a second convex disc, a first pipeline and a second pipeline. The first convex disc is hollow, the upper surface is provided with a plurality of coking wastewater spraying holes, the second convex disc is hollow, and the upper surface is provided with a plurality of cooling air spraying holes. The first convex disc is arranged on the second convex disc, and the first convex disc is smaller than the second convex disc in diameter. One end of the second pipeline is fixedly connected with the center of the bottom of the second convex disc, and the first pipeline penetrates through the second pipeline and the second convex disc to be fixedly connected with the center of the bottom of the first convex disc. A coking wastewater flow channel is formed in the first pipeline and is communicated with the coking wastewater spraying holes through the hollow inside of the first convex disc. A cooling air flow channel is formed between the inner surface of the second pipeline and the outer surface of the first pipeline.

Owner:SHANDONG IRON & STEEL CO LTD

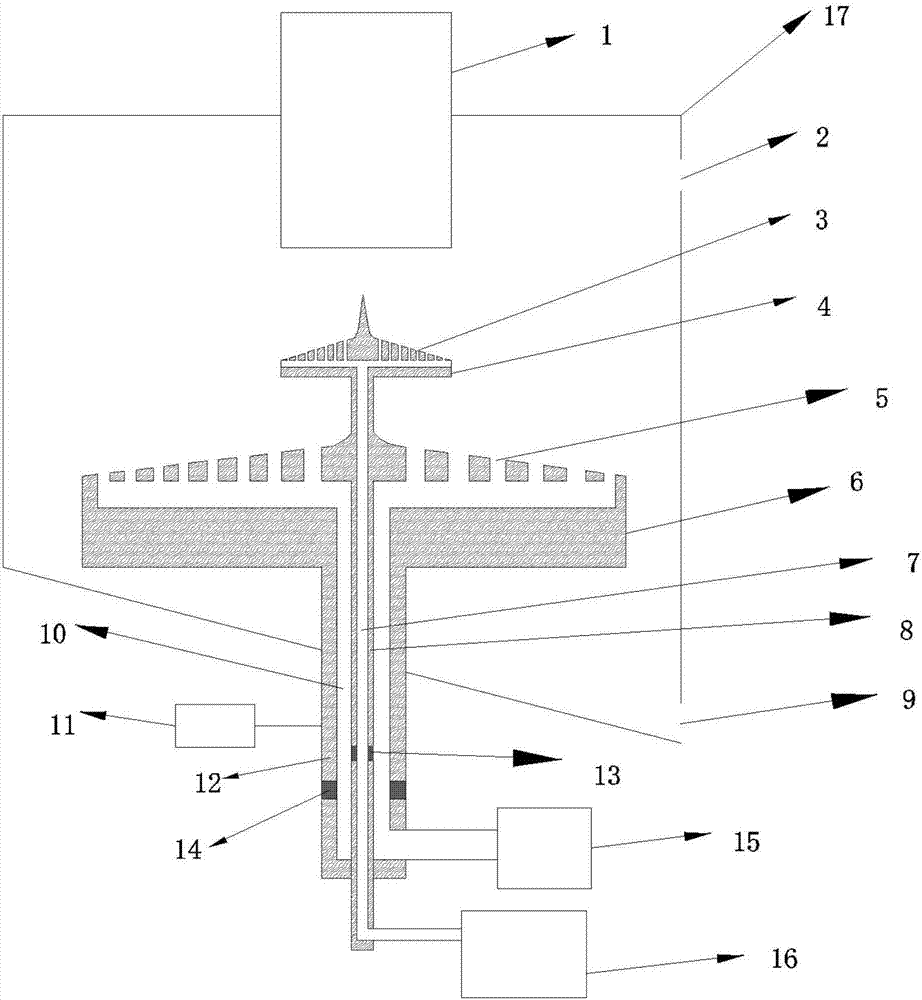

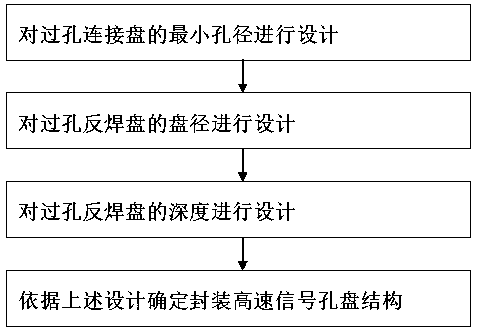

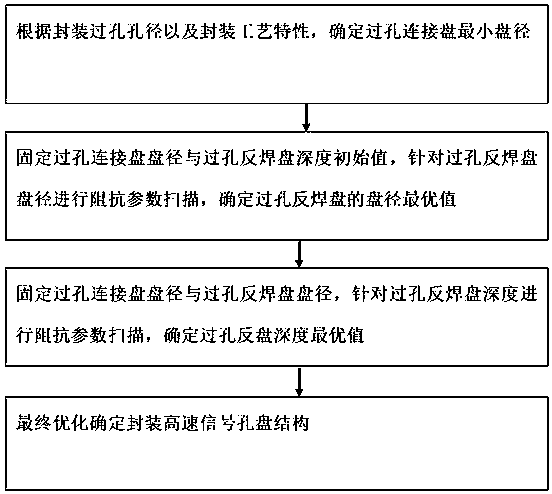

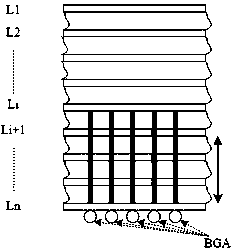

Optimal design method for packaging high-speed signal via hole

InactiveCN110676174AImprove via resistanceLow return lossSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention discloses an optimal design method for a packaging high-speed signal via hole, which comprises the following steps of: (1) designing the minimum hole diameter of a via hole connecting disc, (2) designing the diameter of the via hole anti-bonding pad, (3) designing the depth of the via hole anti-bonding pad, and (4) determining the structure of the packaging high-speed signal hole disc according to the design. The method aims at the impedance discontinuity characteristic of the BGA bonding pad position of a packaging pin, the multi-dimensional parameters such as via hole connecting disc diameter, the via hole anti disc diameter and the via hole anti disc depth are integrated for via hole impedance scanning, a packaging high-speed signal hole disc structure is optimized and determined, the packaging high-speed signal via hole impedance can be effectively improved, return loss of the packaging high-speed signal is reduced, and the transmission characteristics of the packaging high-speed signal are improved.

Owner:JIANGNAN INST OF COMPUTING TECH

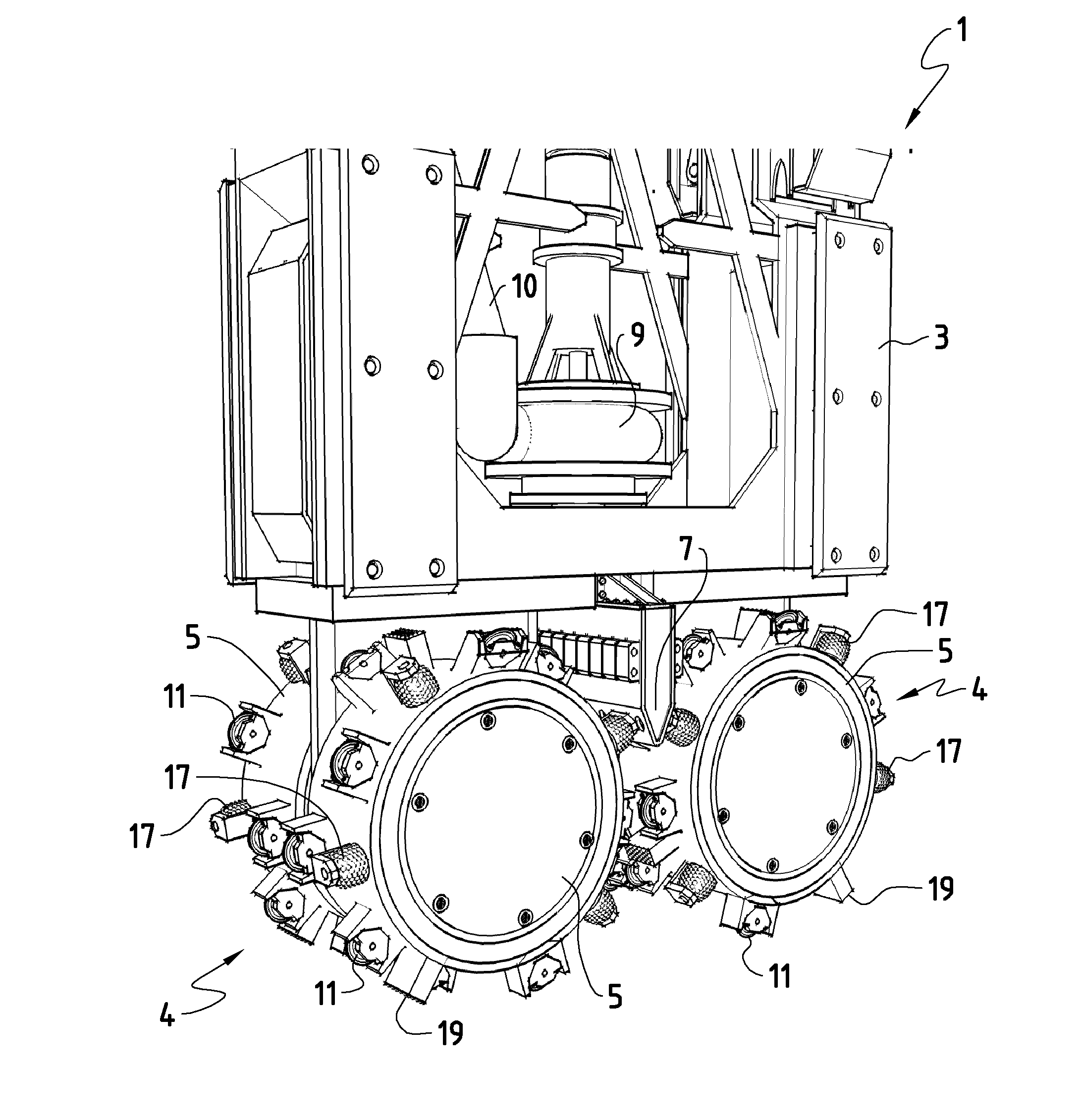

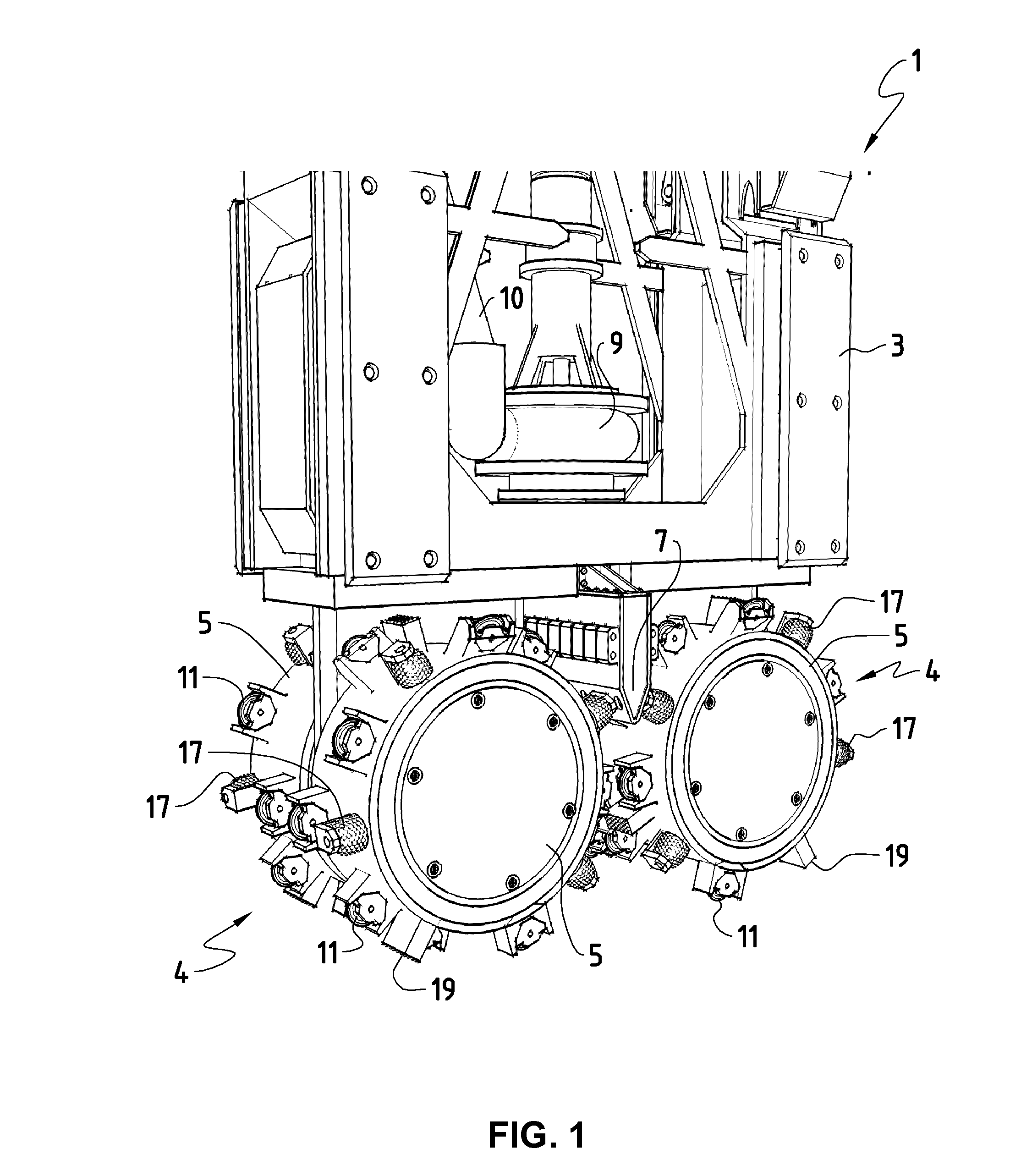

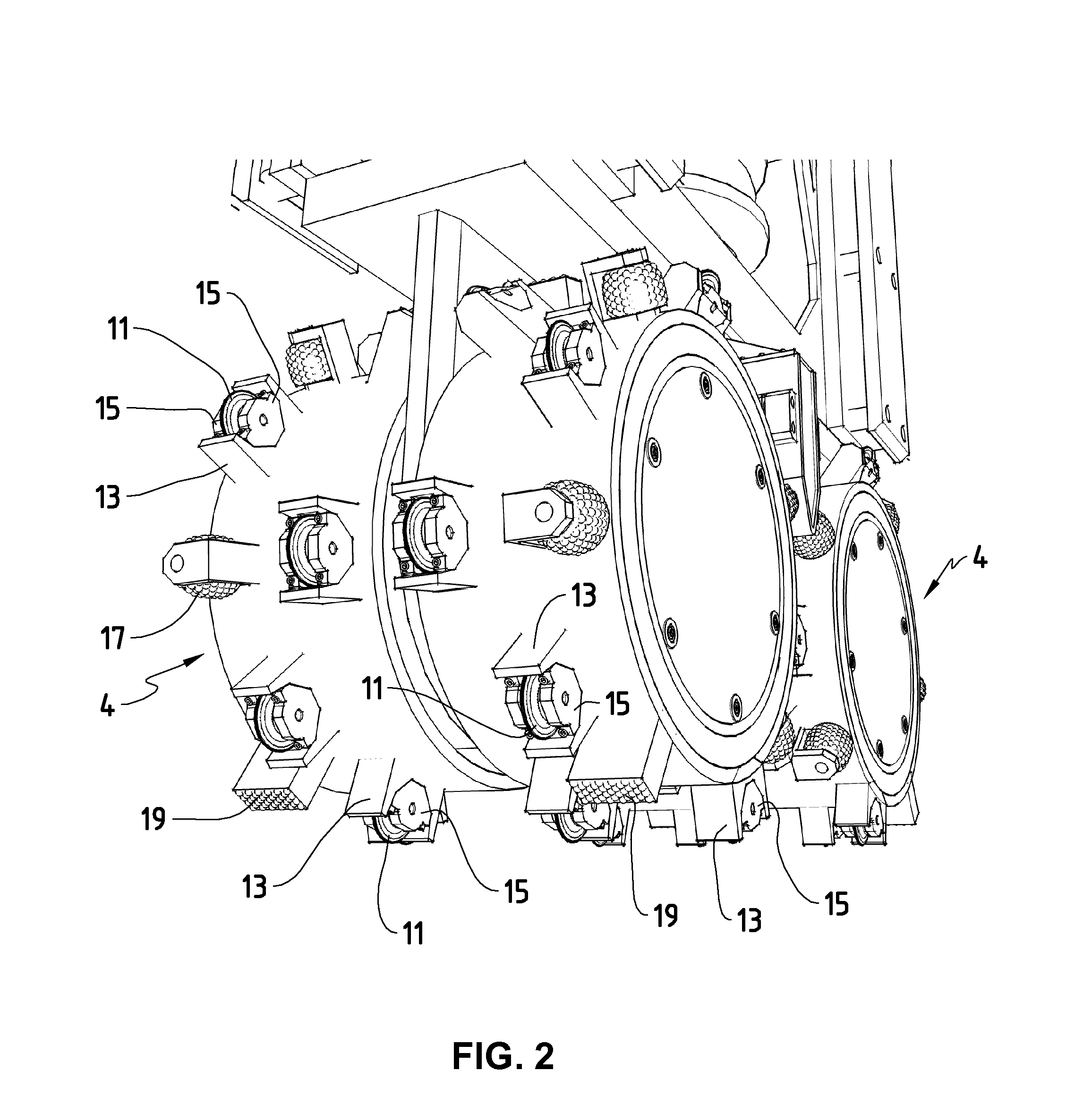

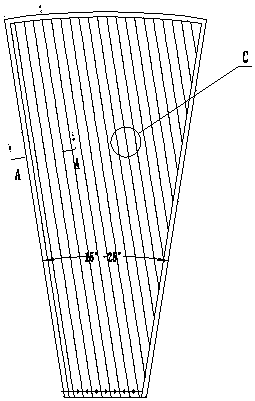

Hydromill wheel with single disc cutting rollers

ActiveUS20150322644A1Small surface areaExcavating trenches efficientlyMachines/dredgers working methodsDrill bitsCircular discDisc cutter

The present invention concerns a hydromill wheel (5) for excavating a trench in hard rock. The wheel comprises a drum (4) arranged to be rotated about its axis (A, B). The wheel (4) further comprises a plurality of single disc cutters (11) mounted on the periphery of the drum (5), the single disc cutter (11) having a rotatable single cutting disc (11) arranged to come in contact with and crush the rock during excavation. The spacing of the projection of at least some of the cutting discs (11) on the drum axis (A, B) is 20% to 70% of the cutting disc diameter.

Owner:VSL INT AG

Chipping assistant device

The Chipping Assistant was designed as a visual aid for use with most irons. The invention is a black, ¼″ thick wafer-like disc approximately 1.25″ in diameter which attaches to the face of the club with pressure sensitive two-sided tape which serves as a visual aid for golfers to hit the sweet spot and assist in golfer's keeping their head down and eye on the ball to connect with the ball and reduce mis-hits with most irons.

Owner:FELLOWS EDWIN E +1

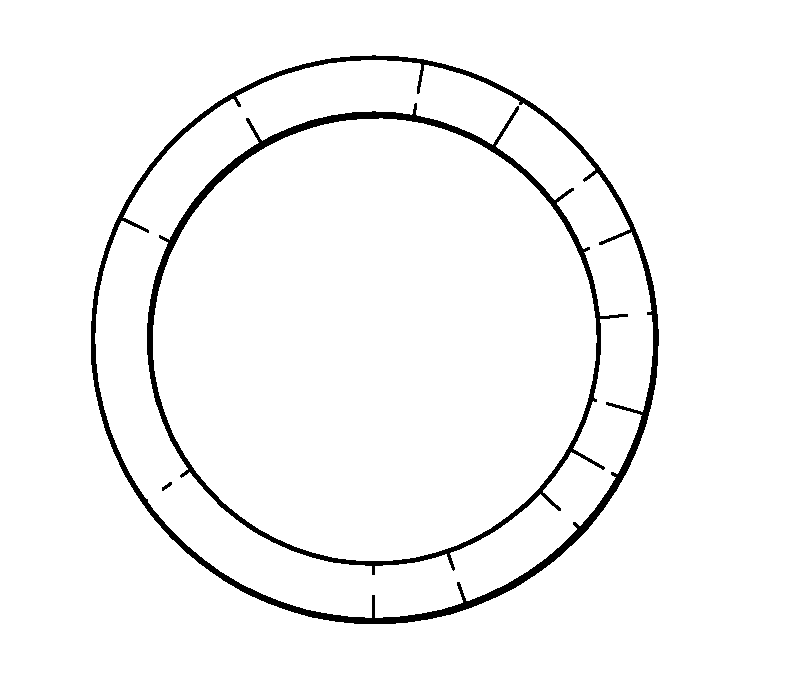

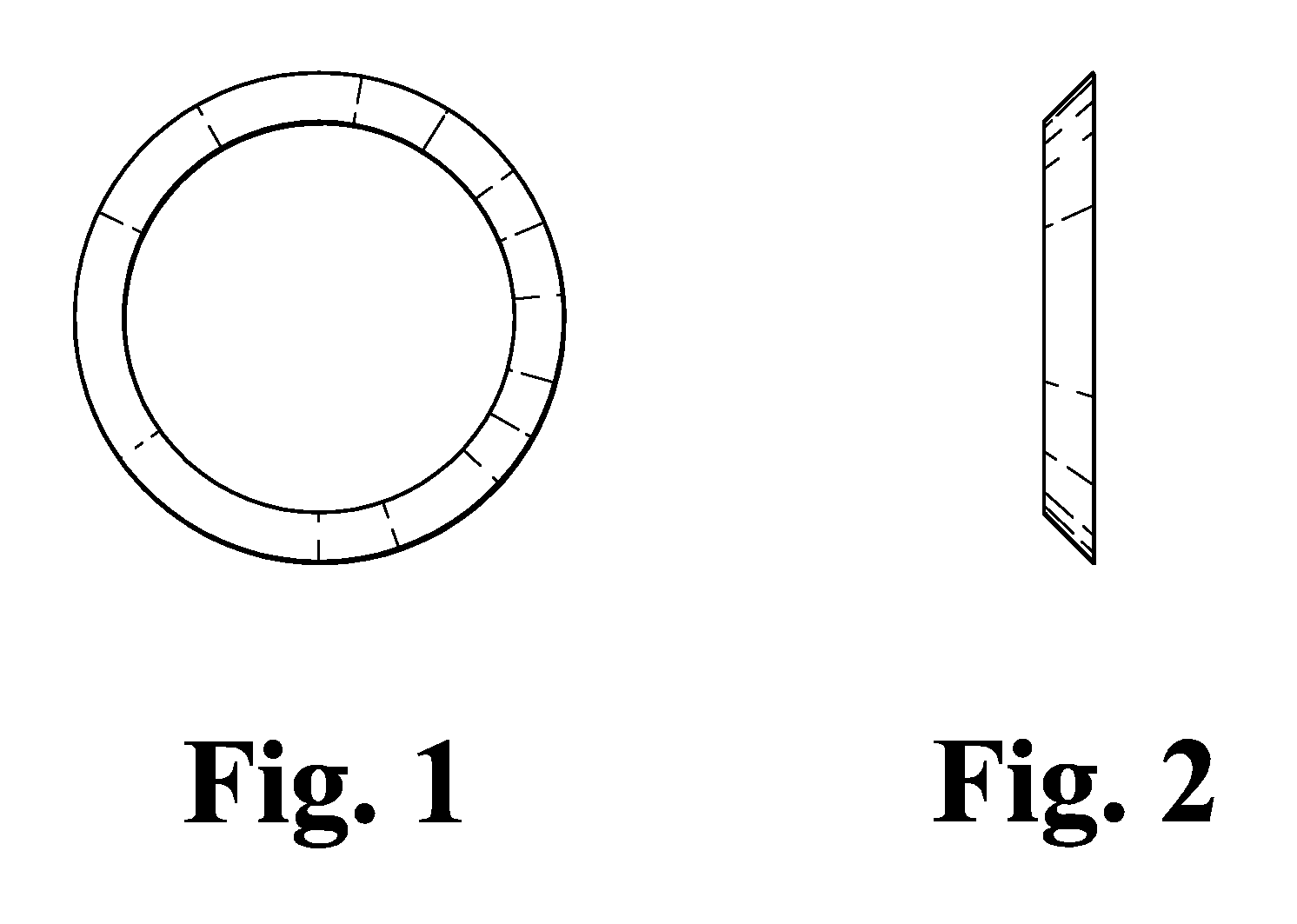

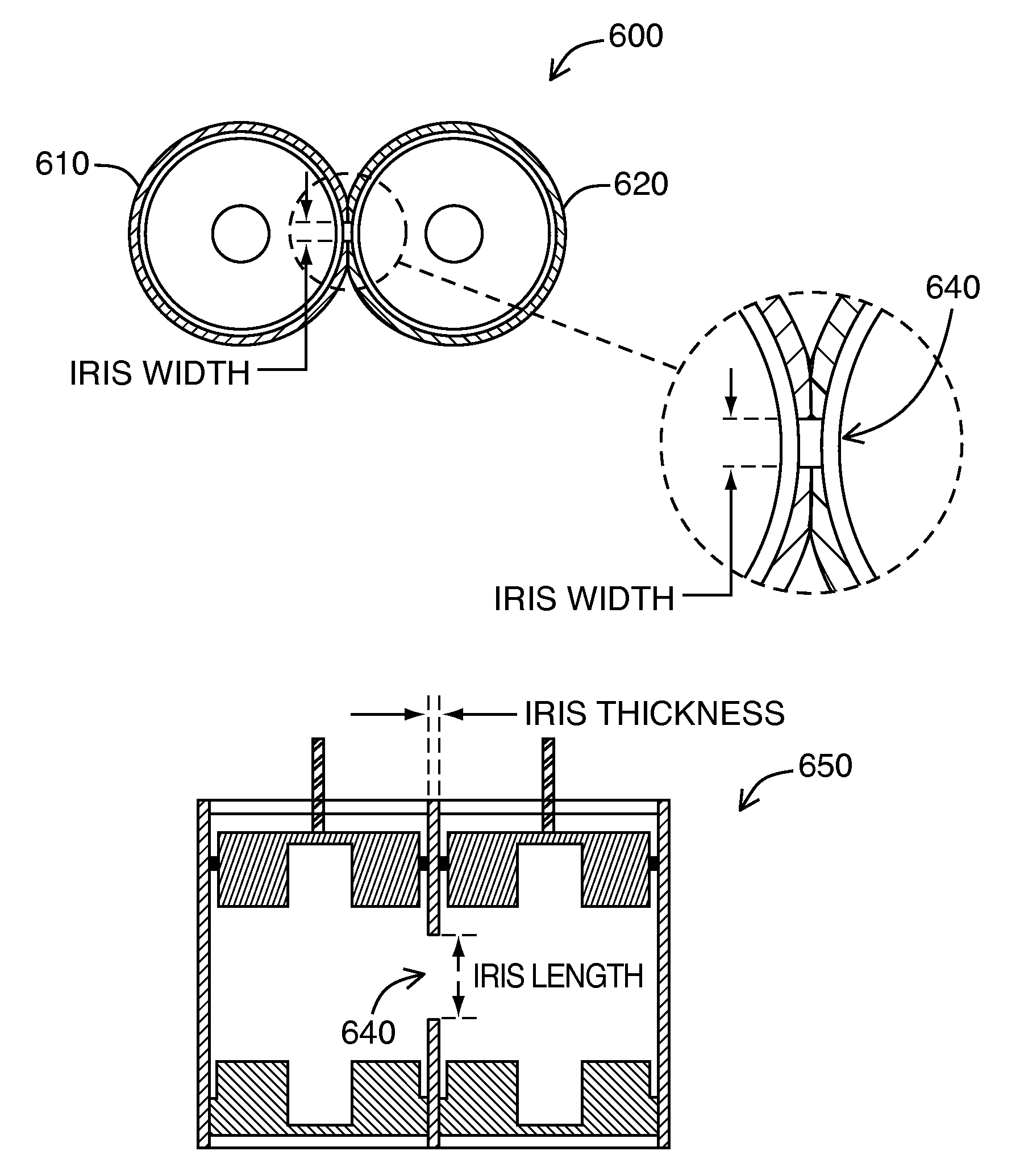

TE011 cavity filter assembly

A TE011 cavity filter assembly is disclosed. The system includes at least one resonator operating in TE011 mode having a resonant frequency. The at least one resonator may include a cavity comprising an inner diameter and a cavity length. The at least one resonator may also include a first metal disc inside the cavity. The first metal disc may include a disc diameter and a void in the metal disc, which includes a void diameter and a void depth. The inner diameter of the cavity may be greater than the disc diameter creating a gap with a gap width and a gap depth. The TE011 cavity filter assembly may further include positive coupling.

Owner:COM DEV LTD

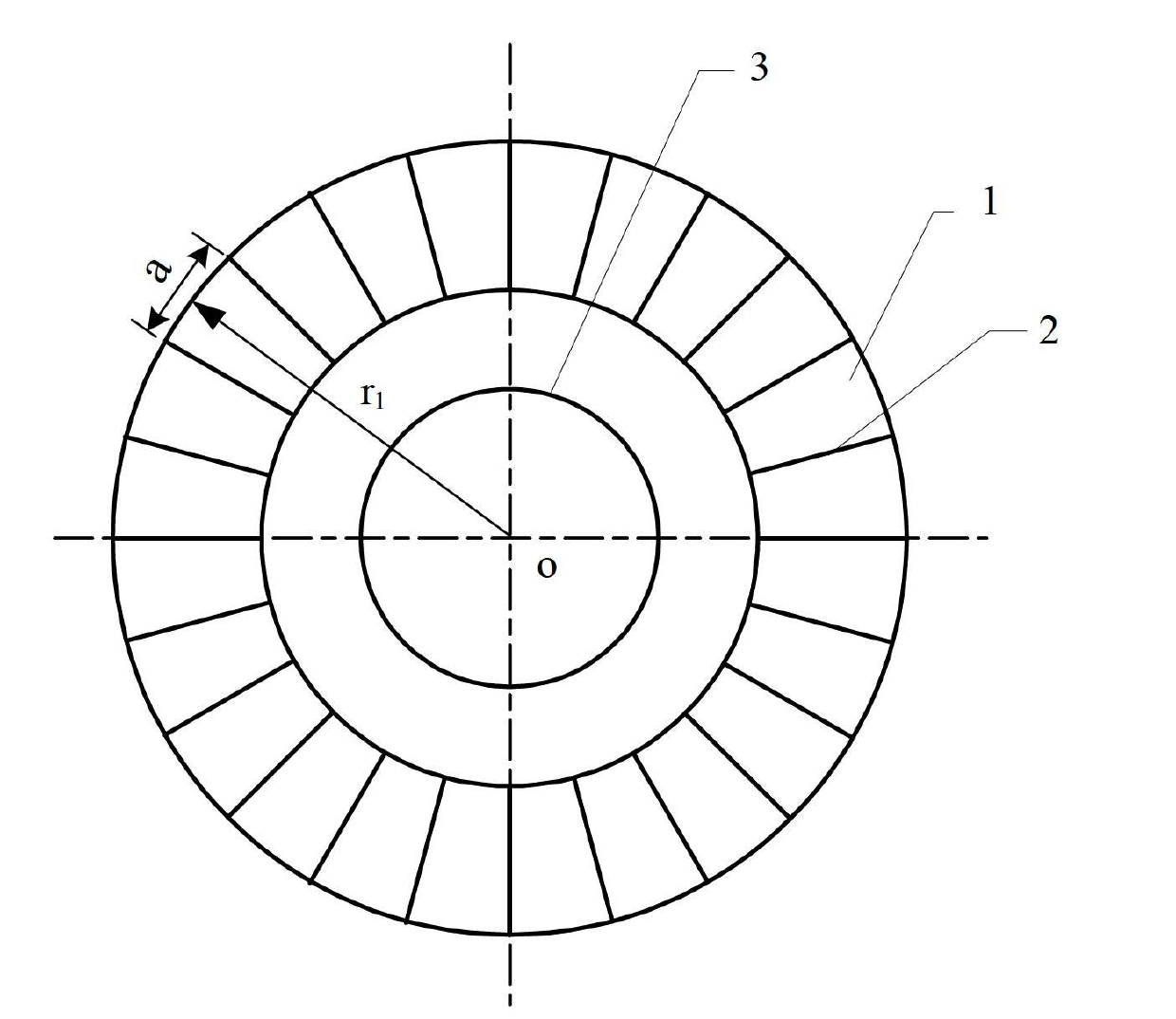

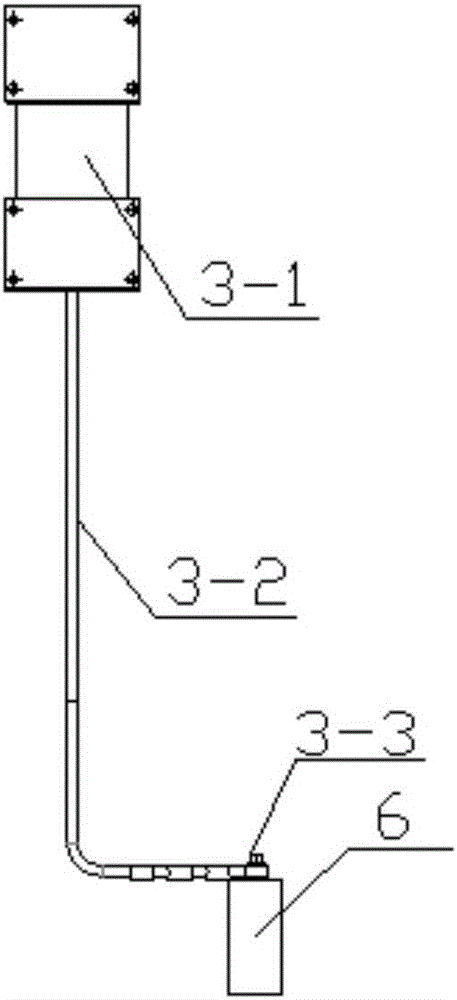

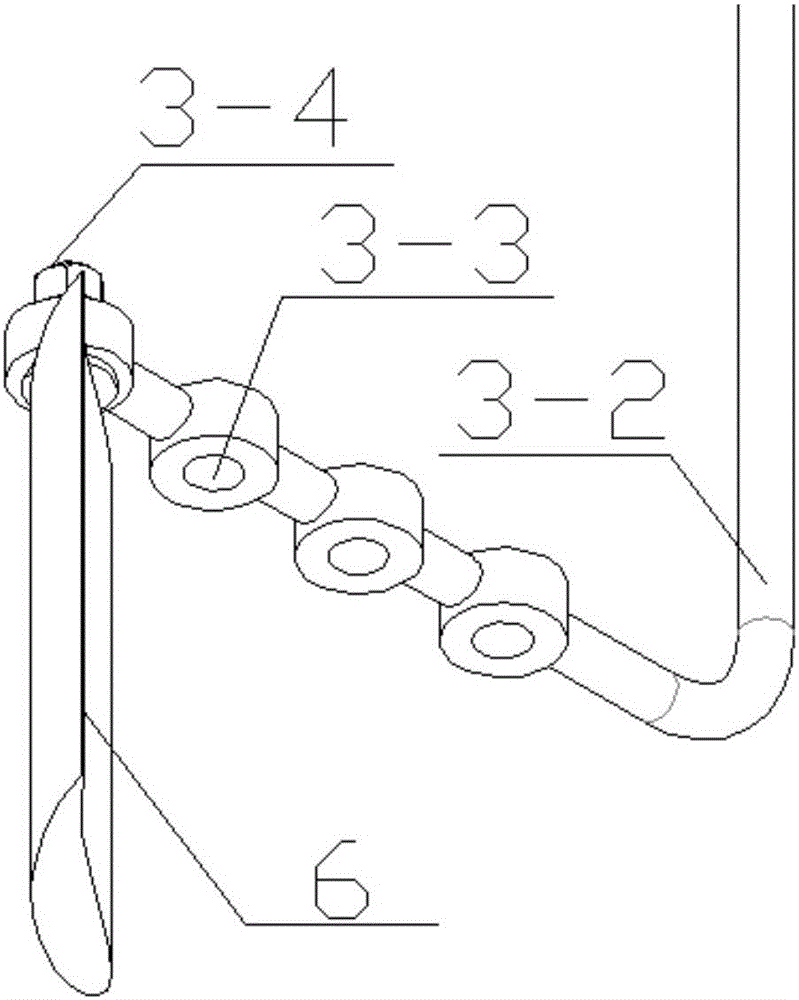

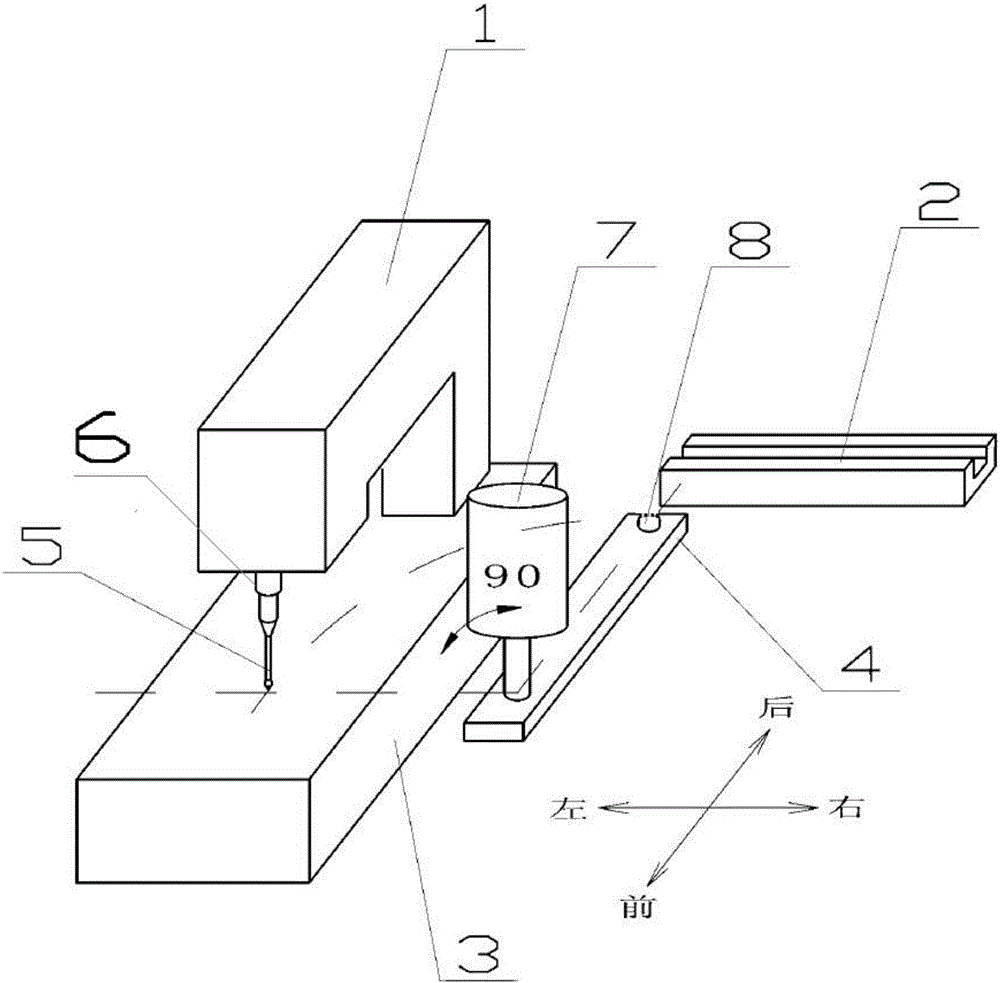

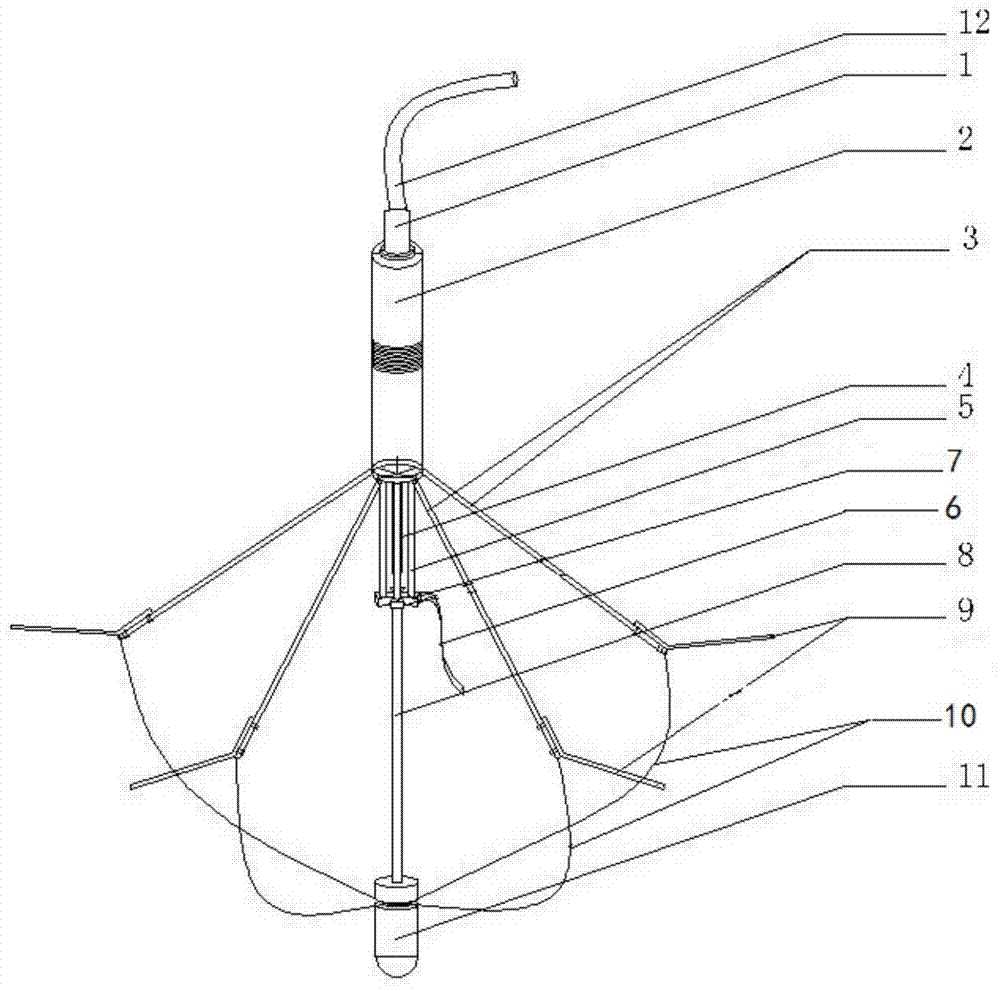

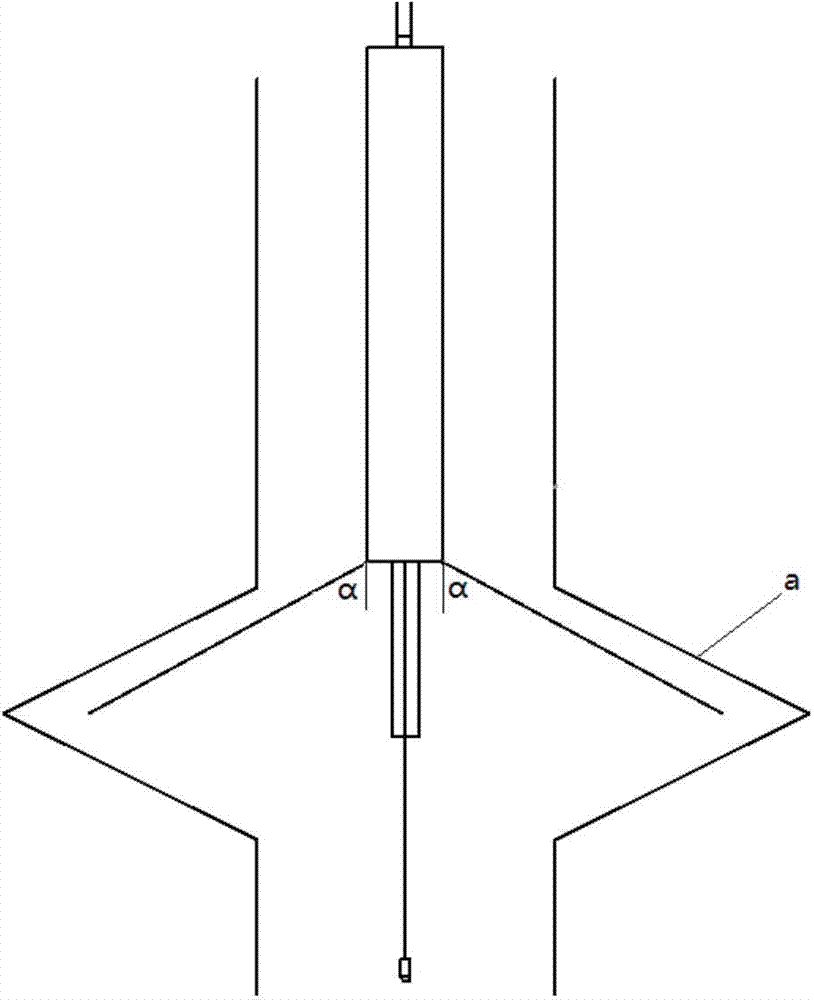

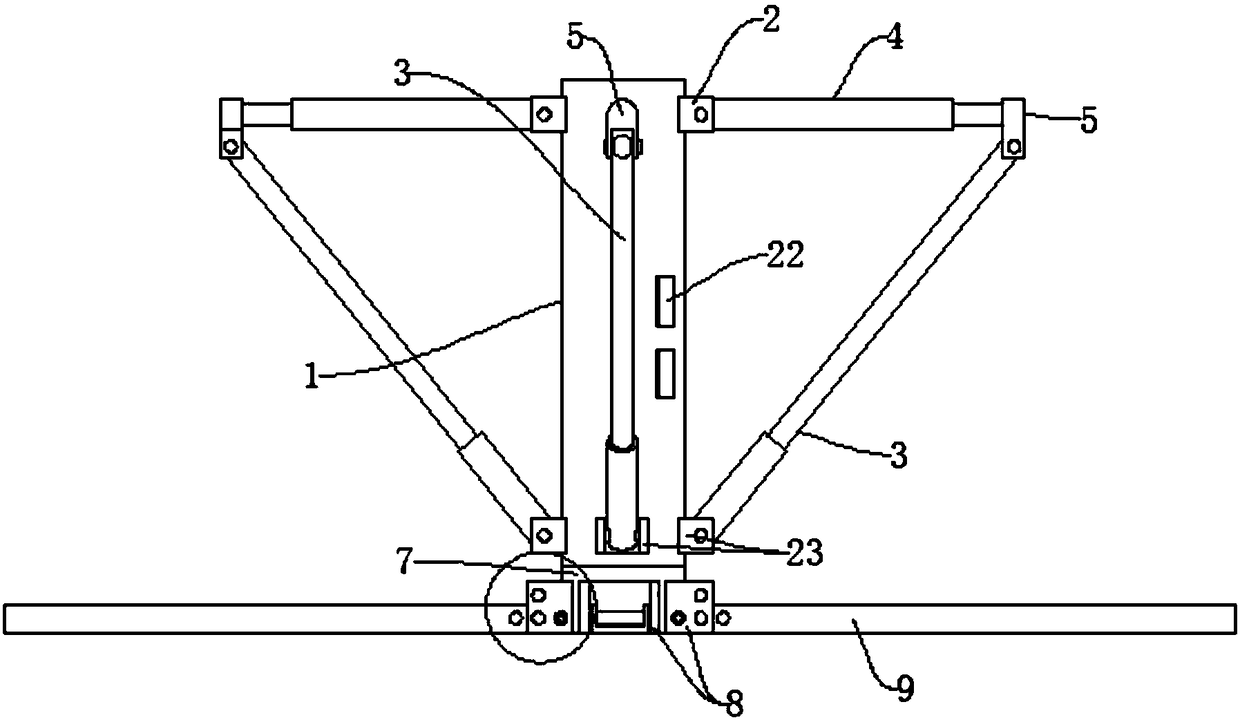

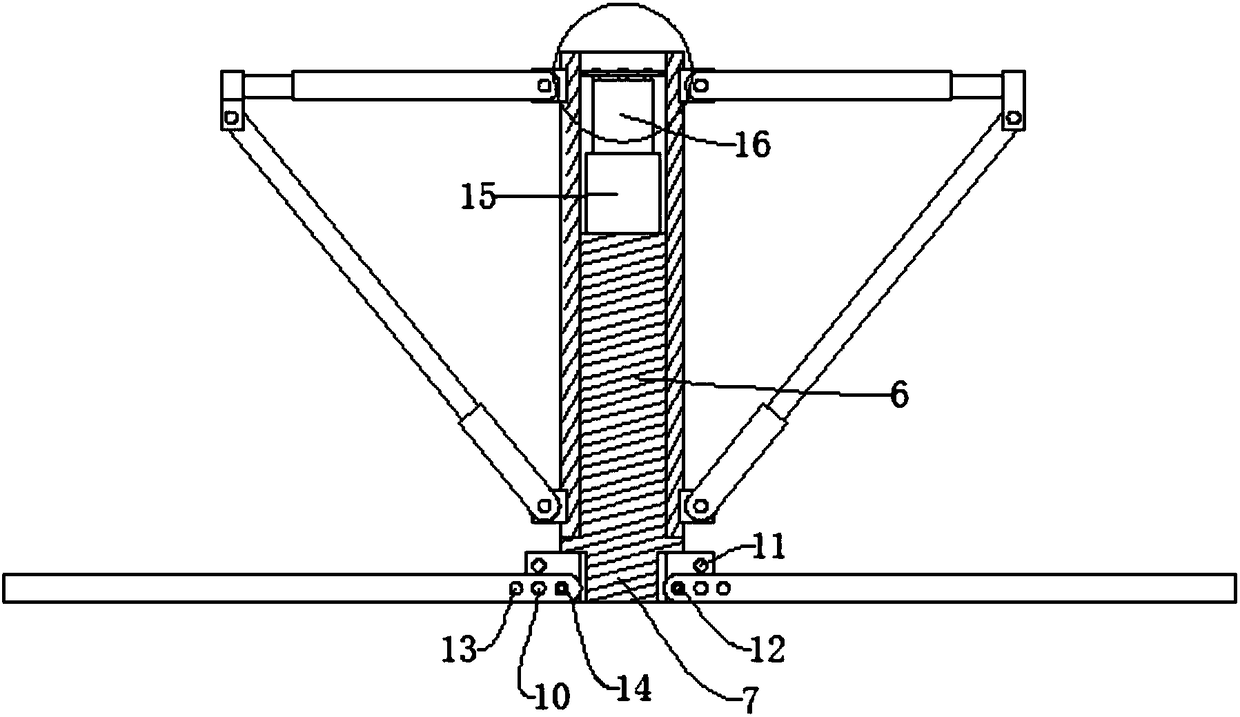

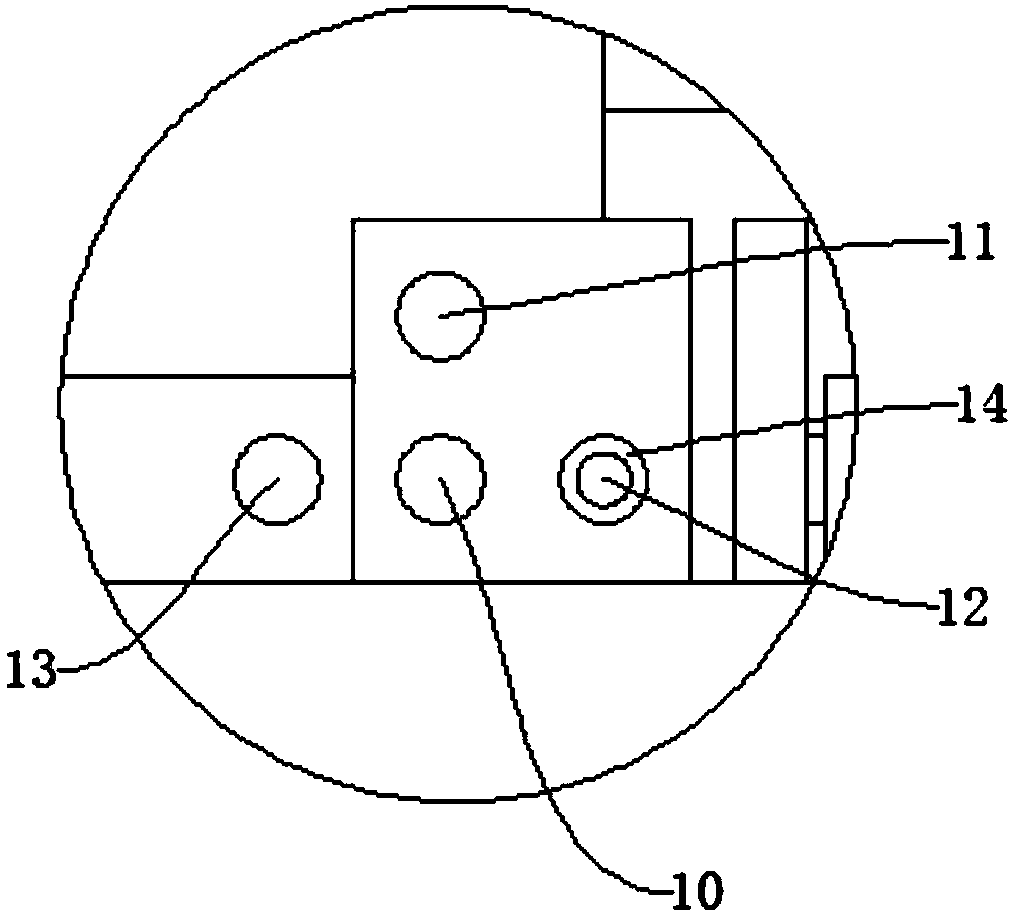

Disc diameter detector

ActiveCN104746539ALarge measuring rangeAccurately control the openingSurveyFoundation testingEngineeringDisc diameter

The invention provides a disc diameter detector which comprises a sleeve, a well descending cable, measuring legs, a supporting pillar, a connection rod, pull wires, a pressure compensator and a binding belt. The sleeve is internally provided with a sealing cylinder in a sealed mode. The sealing cylinder is internally provided with a sliding potentiometer. The well descending cable is connected with the upper portion of the sleeve in a sealed mode. The upper ends of the measuring legs are connected with the lowermost end of the cylinder wall of the sleeve, and the lower ends of the measuring legs are fixedly connected with legs on the outer sides. The upper end of the supporting pillar is connected with the lower portion of the sleeve, and the lower end of the supporting pillar is connected with a plum-blossom-shaped disc. The upper end of the connection rod is fixedly connected with the plum-blossom-shaped disc, and the lower end of the connection rod is connected with a control motor. One end of each pull wire is fixedly connected with the lower end of the corresponding measuring leg, and the other end of each pull wire is wound on the control motor. The pressure compensator is an oil-resisting rubber pipe and communicated with the sealing cylinder. The binding belt is fixed to one side face of the plum-blossom-shaped disc. By means of the disc diameter detector, disc diameters of different sizes can be measured, meanwhile detection efficiency is improved, and the success rate of hole descending detection is increased.

Owner:HONGYUANZHONGKE BEIJING FOUND ENG CO LTD

Elliptical sealing surface for butterfly valve

Owner:FISHER CONTROLS INT LLC

Production of FeNi-expansion alloy

InactiveCN101029370AReduce manufacturing costShort production processVacuum induction furnaceInduction furnace

Production of Fe-Ni expansion alloy is carried out by smelting by non-vacuum or vacuum induction furnace, adding grain refining agent into steel water, rolling while keeping stable, casting blank by continuous casting machine, scaling, wiredrawing to obtain wire blank in proportion of wire blank diameter: disc diameter=1.1-1.5:1-1.1:1, deforming and wire drawing. It costs low by 50-60%, shortens production flow path, simplifies production process and improves lumber recovery by 30%.

Owner:UNIV OF SCI & TECH BEIJING +1

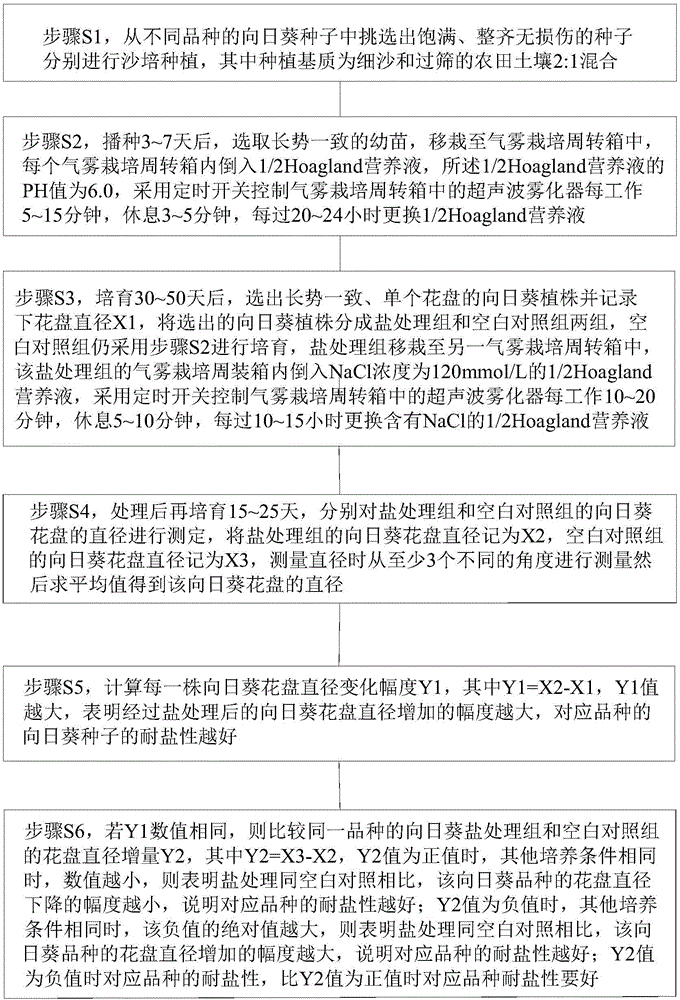

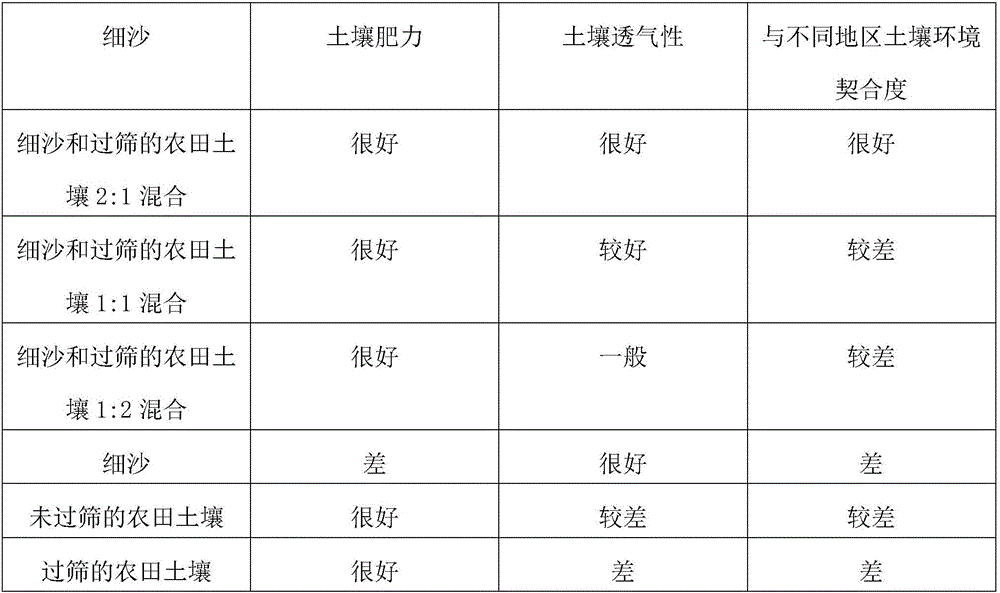

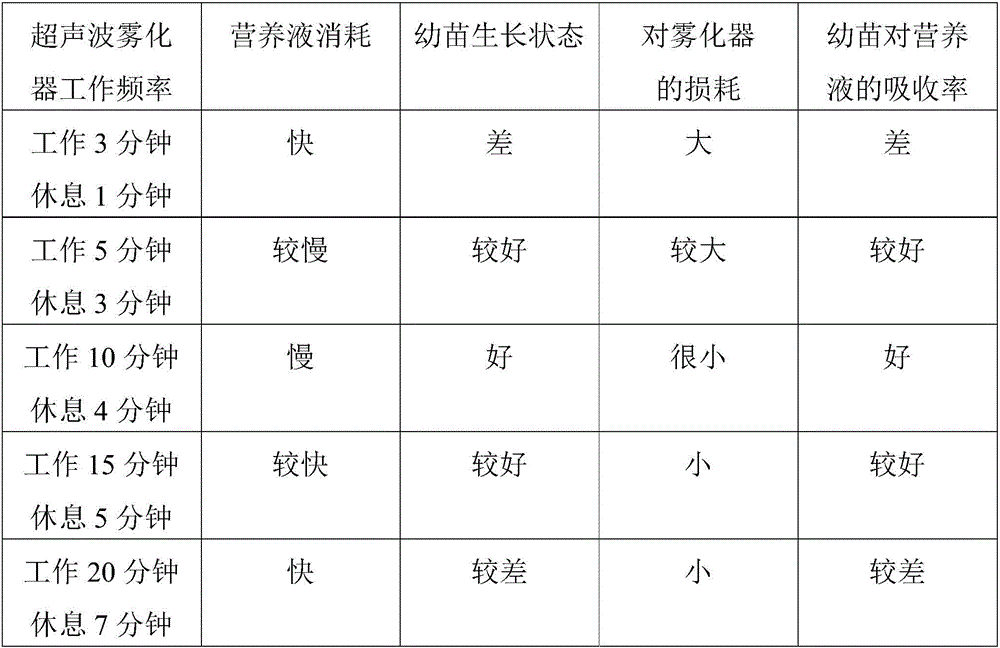

Method for screening salt-resistant sunflower varieties

InactiveCN105830915AGuaranteed germination rateEasy unified controlPlant cultivationCultivating equipmentsSalt resistanceHelianthus annuus seed

The invention provides a method for screening salt-resistant sunflower varieties. The method comprises the following steps: selecting full and even complete seeds from the sunflower seeds of different varieties, and performing sand culture planting using the same planting matrix respectively; after seeding for a period of time, selecting the seedlings with consistent growth vigor and transplanting into an aerosol cultivation turnover box with 1 / 2 Hoagland nutrient solution to cultivate sunflower plants; selecting the plants with consistent growth vigor and single flower disc, recording the diameter X1 of the flower disc, and dividing the groups into a salt treatment group and a blank control group; performing aerosol cultivation of the blank control group using the 1 / 2 Hoagland nutrient solution; performing aerosol cultivation of the salt treatment group using the 1 / 2 Hoagland nutrient solution added with 120mmol / L NaCl; after the preset time, measuring the diameter of the sunflower disc of the salt treatment group and blank control group respectively; and screening out the sunflower variety with better salt resistance by analyzing and comparing the flower disc diameter data. With low cost, the method is easy to operate and facilitates promotion and implementation in various places.

Owner:YUNCHENG UNIVERISTY

Horizontal type cable placing disc with adjustable disc diameter size for heavy type cable

The invention discloses a horizontal type cable placing disc with the adjustable disc diameter size for a heavy type cable. The cable placing disc comprises a base and a supporting column fixedly installed at the upper end of the base, a sleeve pipe sleeves outside the supporting column, a plurality of first small mounting bases and a second small mounting base are fixedly installed at the upper end and the lower end of the outer side face of the sleeve pipe respectively, first electric hydraulic push rods are hinged to the first small mounting seats, a second electric hydraulic push rod is hinged to the second small mounting seat, and the other ends of the first electric hydraulic push rods and the other end of the second electric hydraulic push rod are hinged together through a hinge base. The horizontal type cable placing disc with the adjustable disc diameter size for the heavy type cable has the beneficial effects that the horizontal type cable placing disc can bear the relatively-large-size and heavy large-bundle cable, the mechanical strength is high, after cable placing is finished, the cable placing disc can be folded and contracted, so that the cable placing disc is smallin size, convenient to carry and good in practicability.

Owner:周桂林

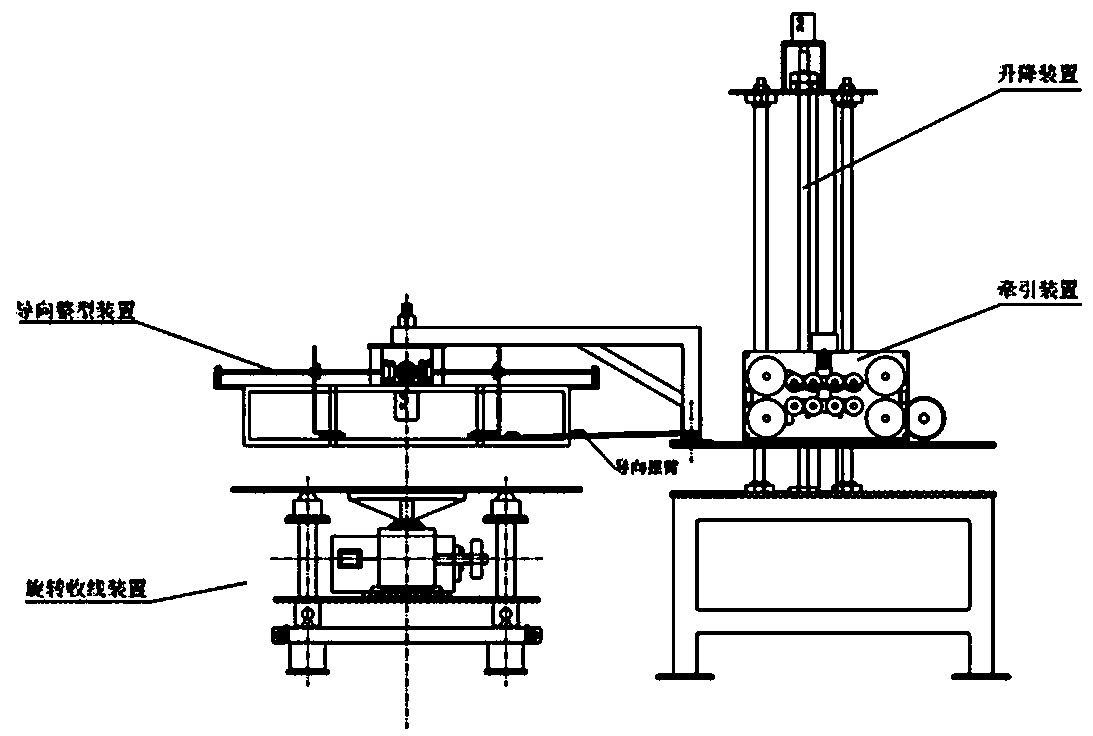

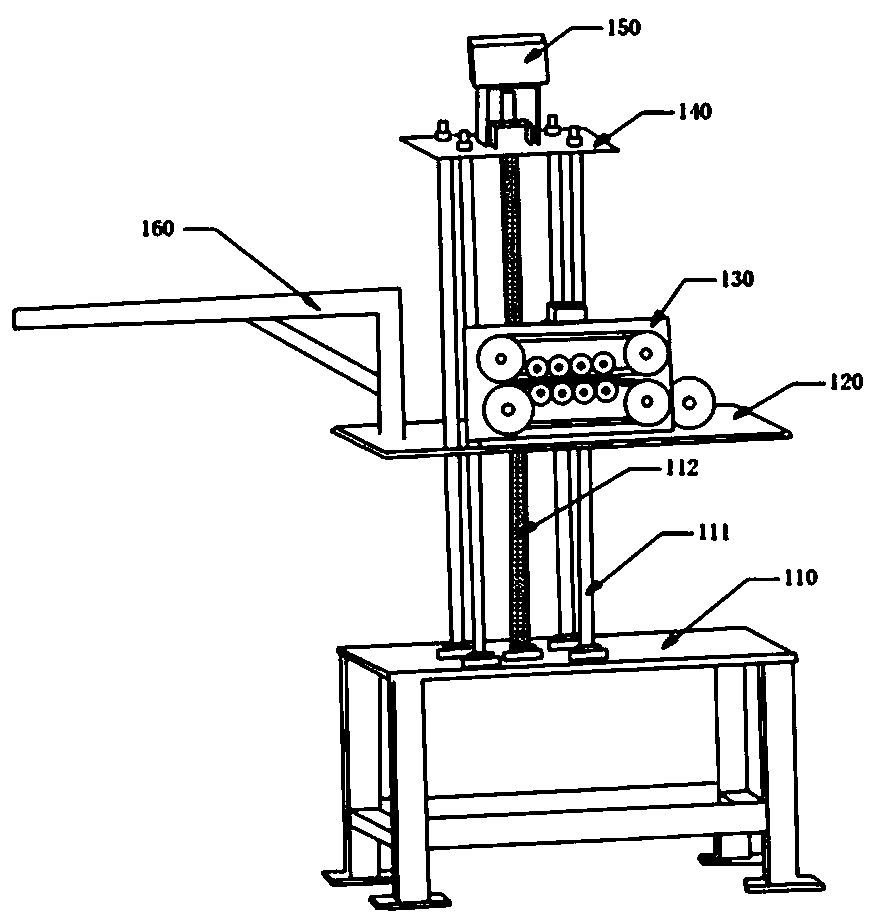

Metal pipe rolling machine

PendingCN109704144AUniform row of pipesReduced Gravity SqueezeFilament handlingDisc WeightMechanical engineering

The invention relates to a metal pipe rolling machine comprising a horizontally arranged guide shaping rounding device and a lifting device. A rotary take-up device is arranged under the guide shapingrounding device. The lifting device is used for fixing the guide shaping rounding device and is arranged vertically. The guide shaping rounding device is fixed to the lifting device through a first support. The lifting device is further provided with a traction device. After penetrating out of the traction device, a metal pipe surrounds the guide shaping rounding device by a circle. After prebentby the guide shaping rounding device, the metal pipe falls on the rotary take-up device. The lifting device drives the guide shaping rounding device to move up and down. The rotary take-up device winds the metal pipe into a disc body through rotation. The rotary take-up device comprises a tray base and a tray. The tray base and the tray are slidably connected. The tray at least comprises two setsof take-up units. The metal pipe rolling machine can meet requirements of different clients for disc diameters (inner diameters and outer diameters) and disc weight, metal pipe arrangement is more even, and the surfaces of metal pipes are not liable to scratches.

Owner:ZHEJIANG KANGSHENG CO LTD

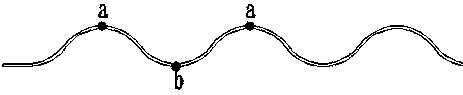

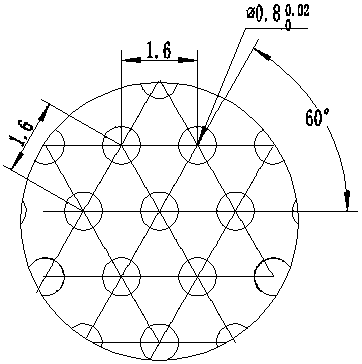

Mesh bag free corrugated filter board

The invention discloses a mesh bag free corrugated filter board. The mesh bag free corrugated filter board is prepared from 316L stainless steel material, and is designed to be a fan-shaped plate; thefan-shaped plate is uniformly provided with a plurality of phi 0.8mm pores, the distance between adjacent pores is controlled to be 1.6mm, the surface of the fan-shaped plate is provided with wave shaped patterns, the vertical distance of a wave peak to a corresponding wave bottom of the wave patterns on the surface of the fan-shaped plate is controlled to be 8 to 12mm, the distance between eachpair of adjacent wave peaks is controlled to be 32 to 40mm, the peripheral arc corresponding central angle of the fan-shaped plate is controlled to be 15 to 25 DEG. According to the mesh bag free corrugated filter board, the surface of the mesh bag free corrugated filter board is provided with a sieve plate with the phi 0.8mm pores with a pore distance of 1.6mm, so that a technical problem that filtering function can be achieved only through providing the fan-shaped plate with a mesh bag is solved, and increased cost and influences on production caused by changing of the mesh bags are avoided. According to the mesh bag free corrugated filter board, compared with a filter board with a mesh bag, when the disc diameter is the same, the filtering area is increased by 20% or larger, and the production capacity is increased by 20% or larger.

Owner:青州三得不锈钢机械有限公司

Tipping Paper Rewinder Based on Servo System

The invention discloses a tipping paper rewinding machine on the basis of a servo system. The tipping paper rewinding machine is characterized in that a linear speed is measured by a speed measuring roll in a tipping paper take-up procedure, real-time disc diameters of an unwinding disc and a winding disc are computed according to the real-time linear speed, a rotational speed of an unwinding motor and a rotational speed of a winding motor, and then the rotational speed of the unwinding motor and the rotational speed of the winding motor are computed according to the obtained disc diameters and a linear speed, which is given by a machine, in the tipping paper take-up procedure, and are adjusted via a central processing unit. The tipping paper rewinding machine has the advantages that circular adjustment is realized, so that the linear speed in a procedure for rolling tipping paper on the rewinding machine is consistent with the given speed, tension on the surface of the tipping paper in the take-up procedure keeps constant, disc surfaces are flat, and the winding quality is improved.

Owner:苏州市博海激光科技有限公司

A concentric boring positioning mechanism

ActiveCN102896361BReasonable designSimple structurePositioning apparatusBoring/drilling componentsEngineeringScrew thread

A concentric boring positioning mechanism of the present invention comprises: an upper disc and a center rod; the upper disc is a solid disc with a diameter of 55 mm and a thickness of 8 mm, and a countersink hole with a diameter of 6.5 mm in the center; the center rod The length is 71mm, the diameter of the top is 40mm, the upper and lower ends of the top are provided with chamfers, and the top surface has M12 threaded holes; the diameter of the bottom end of the central rod is 35mm, and the bottom surface has M6 threaded holes, which can be used for bolts Secure with the upper disc. Through the above method, a concentric boring positioning mechanism of the present invention has a reasonable design and a simple structure, and the one-step processing of concentric circular holes can be realized through the tooling, the production steps can be optimized, and the production efficiency can be improved.

Owner:SUZHOU ERIC MECHANICS & ELECTRONICS CO LTD

One-way light velocity instrument

InactiveCN101000265ASimple structureBreak the logic loopLight velocity measurementPoint lightOptoelectronics

The invention supplies a one way light velocity measuring device. It includes tail-wagging sensitization disc, reading device, erasing device, two sets of prismatic light paths, delay light path, ultra-short pulse light source, and control device. Light pulse respectively enter the two sets of prismatic light paths through main spectroscope and delay light path, then aim at sensitization disc center, transmit with equivalent distance along opposite direction, irradiate at the two ends of the sensitization disc diameter to form cursor. The reading and erasing device is used to read and erase. If the one way light velocity is unequal, the included angle at the two points light will be unequal to 180 degree of which deviation is relevant to the one way light velocity. In order to eliminate rotate speed influence, increase detecting precision, the included angle of the two normal directions can be compared; and the light velocity difference of the two directions can be measured by adjusting delay quantity. One way light velocity can be worked out by spheroid relationship.

Owner:朱筱杰

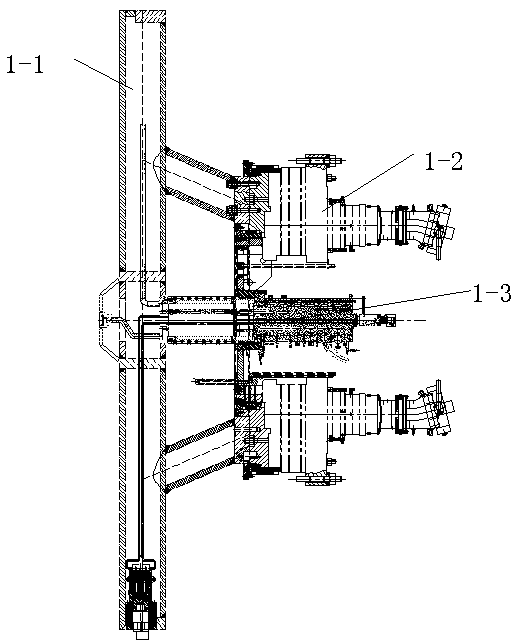

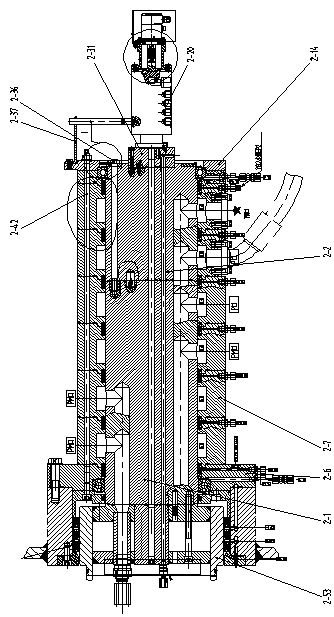

Shield machine rotary joint

The invention discloses a shield machine rotary joint, comprising a small rotary joint (29), a rotor, a stator, a sealing assembly and a rotary support, the stator is sleeved outside the input end of the rotor, and the sealing assembly and the rotary support are arranged between the stator and the rotor Between, the small rotary joint (29) is connected with the input end of the rotor, the stator includes the shell (28), the connection seat (9), the retaining ring (14) and the bolt one (15), the connection seat (9) passes through Bolt one (15) is fixed on the front portion of the casing (28), and the retaining ring (14) is fixed on the front portion of the connecting seat (9) by bolt one (15). The rotary joint of the shield machine of the invention has good integrity, takes up little space, and can inject medium in layers, and solves the technical problem that the rotary joint cannot be installed due to the small diameter of the cutter head of the small shield machine and the limited central driving space.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com