Disc diameter detector

A detector and disk diameter technology, applied in the field of building foundation engineering, can solve problems such as affecting measurement efficiency, high technical requirements, delaying concrete pouring, etc., to achieve the effect of improving detection efficiency, increasing measurement range, and ensuring normal implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate those skilled in the art to understand the technical solutions and beneficial effects of the present invention, specific implementation methods are described below in conjunction with the accompanying drawings.

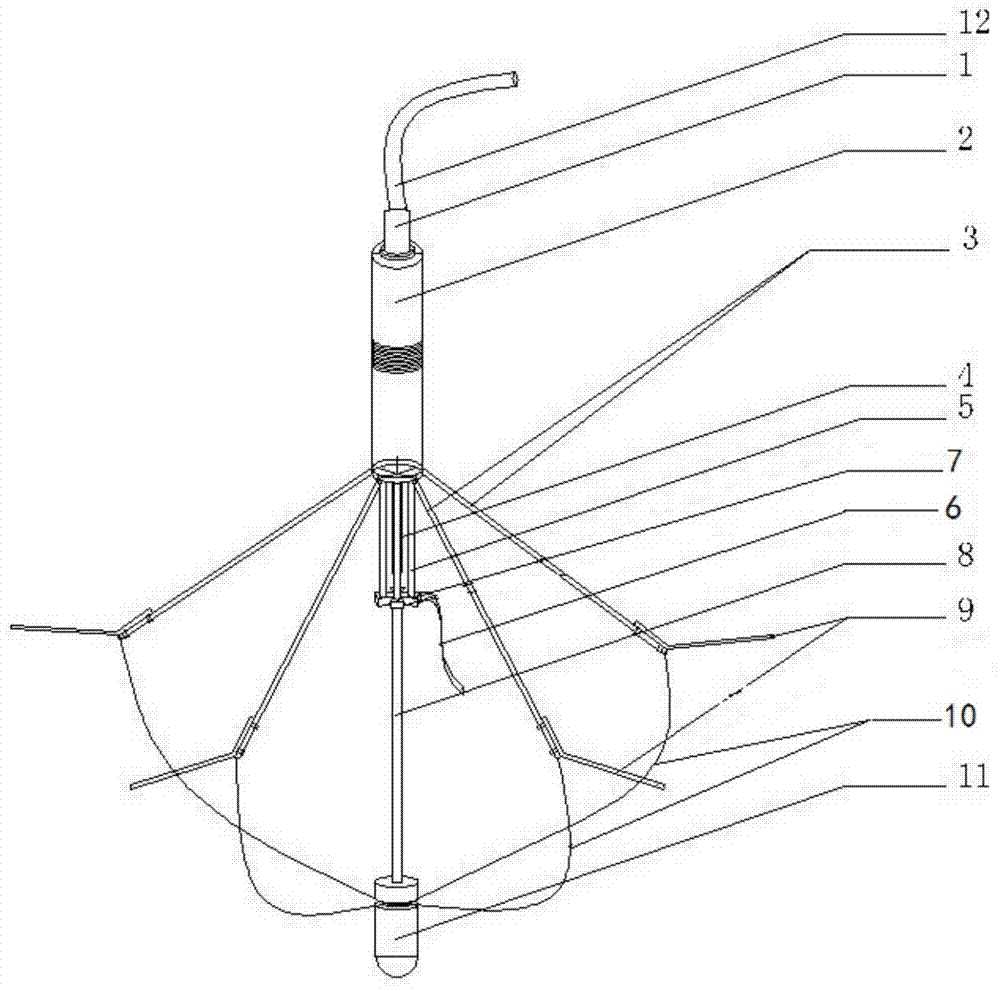

[0029] see figure 1 As shown, it is a schematic structural view of the disk diameter detector of the present invention, including a downhole cable 12, which is connected to the upper part of the sleeve 2, and the connection is socketed with a rubber protective sleeve 1, which can be directly held by the downwell cable 12. The disc diameter detector is put into the pile hole, and the weight of the whole instrument is borne by the downhole cable 12. The rubber protective sleeve 1 can reduce the external impact force, and prevent the joint of the downhole cable 12 and the sleeve 2 from colliding with the wellhead frame due to excessive swing when the disc diameter detector puts out the wellhead, so as to protect the downhole cable 12 from be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com