Automatic button sewing machine

A button sewing machine, sewing machine technology, applied in sewing machine components, sewing equipment, textiles and papermaking, etc., can solve the problems of increasing burden and manufacturing costs, unable to configure multiple button feed slots at the same time, and low button button efficiency, etc. The effect of reducing cost burden, improving buttoning efficiency and reducing site occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

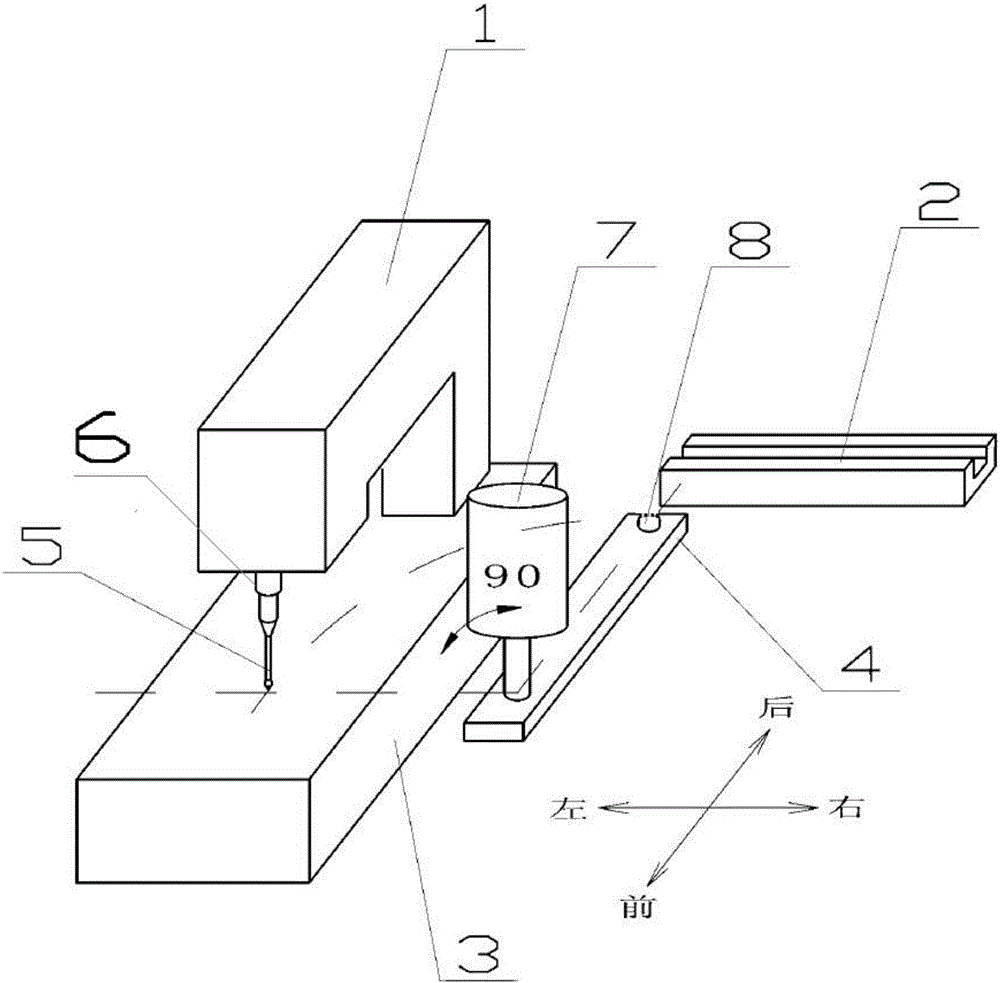

[0018] Reference attached figure 1 , The automatic button sewing machine includes a sewing head 1, a button sending rotary plate 4, a sewing machine base 3 and a button sending groove 2.

[0019] The sewing machine head 1 is in the shape of a right angle "7" vertically arranged front and rear, its rear end is a vertical end, fixedly installed on the sewing machine base 3 table, the front end is a cantilever end, and the bottom of the cantilever end is installed with a sewing needle 5 that can be vertically lifted up and down. , There is a space between the sewing needle 5 and the sewing machine base 3 tabletops below it.

[0020] A horizontal buckle-feeding rotating plate 4 is arranged on the right side of the sewing machine head 1. The height of the buckle-feeding rotating plate 4 is located between the sewing machine base 3 table and the sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com