Elliptical sealing surface for butterfly valve

A valve-sealed, oval-shaped technology used in rotary or "butterfly" valves to address issues such as increased installation and adapter construction complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

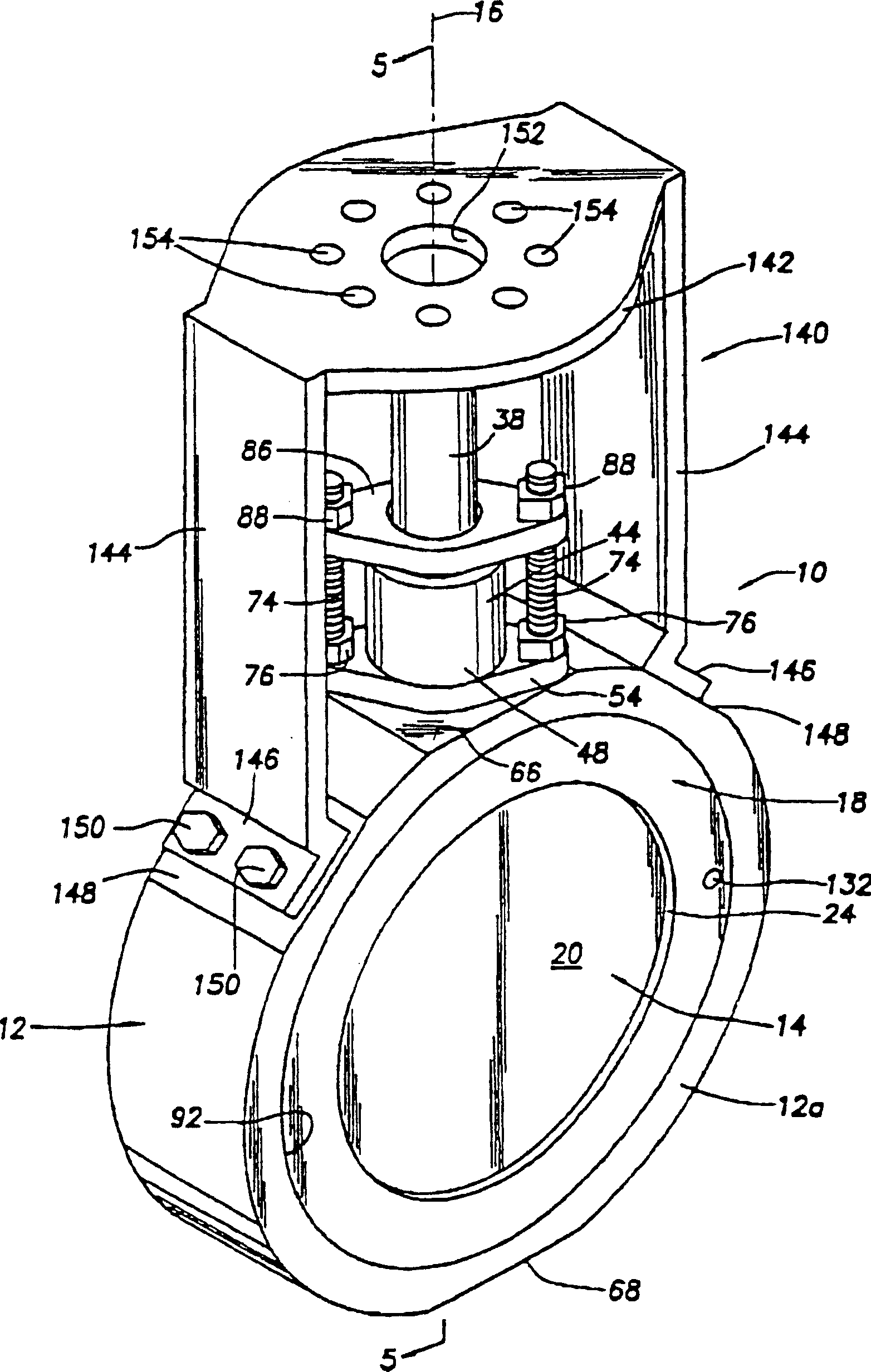

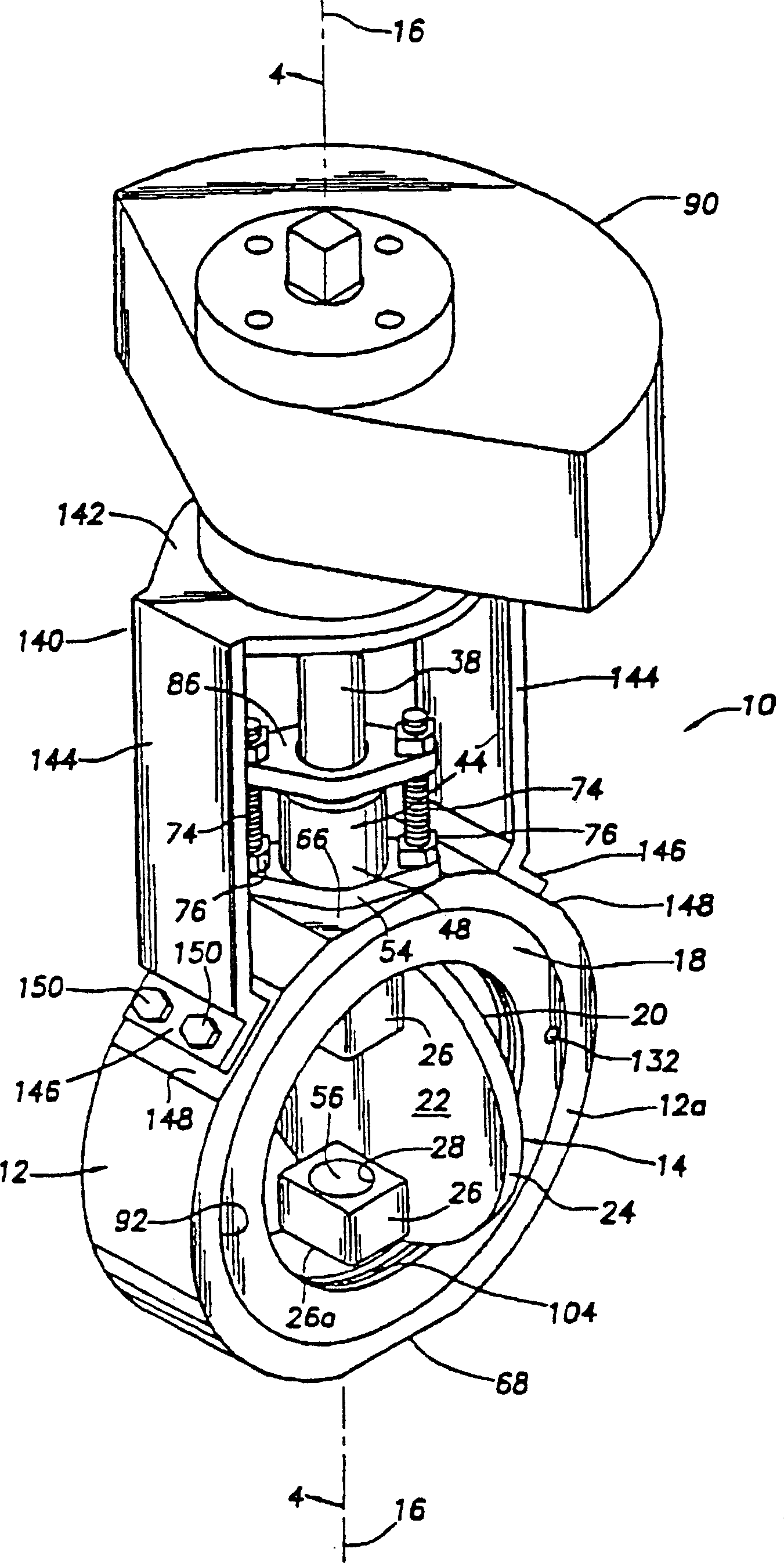

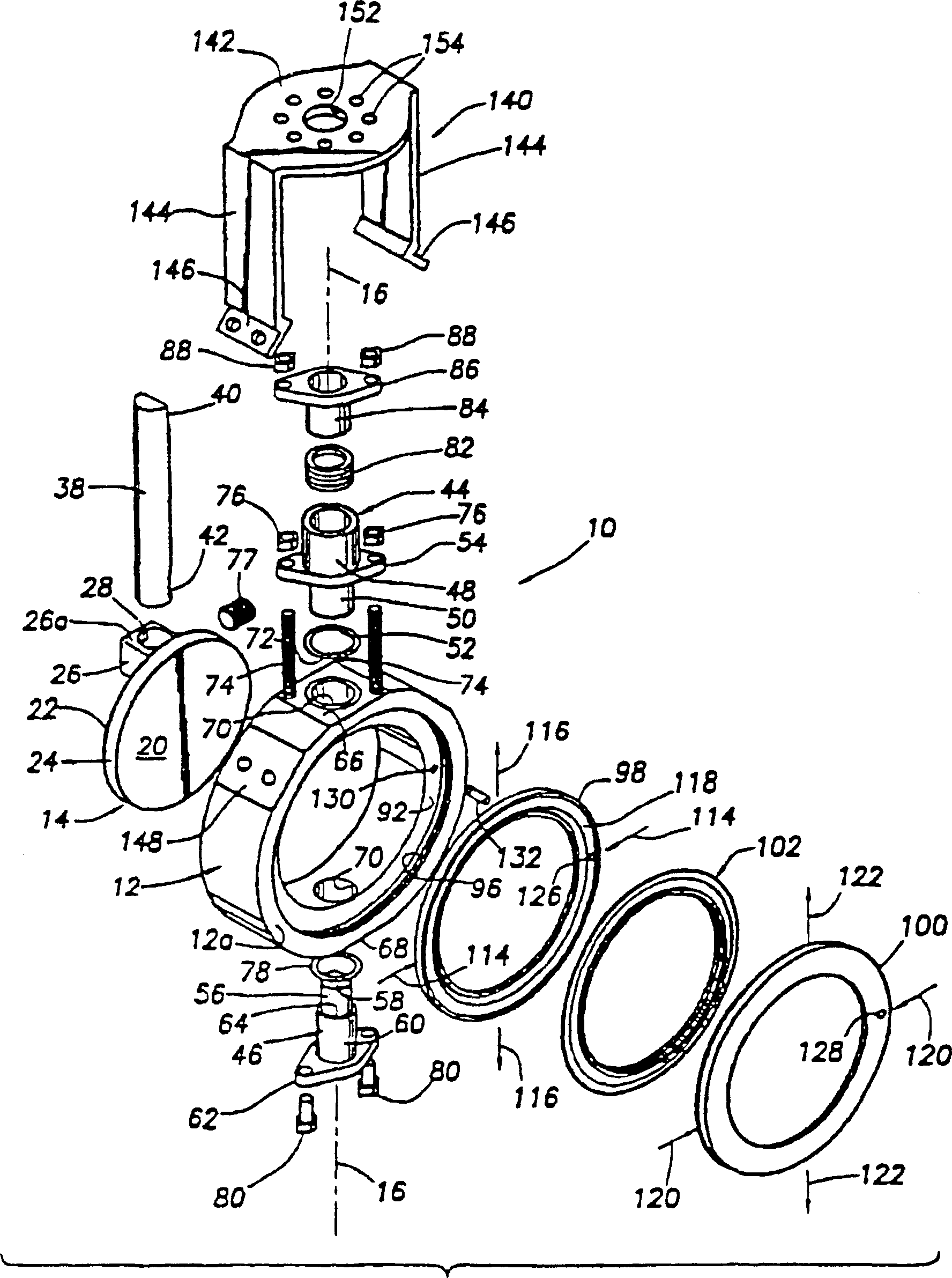

[0040] Figure 1-3 One embodiment of a rotary valve 10 is shown, commonly referred to as a "butterfly" valve, comprising a generally annular metal body portion 12, a metal closure disc 14 and an annular sealing sleeve structure 18, wherein the The metal closure disc 14 is in the closed position and the open position (respectively in figure 1 and 2 shown in ) about an axis 16 extending diametrically through the body portion 12 . figure 1 The valve disc 14 is shown mating with a sealing sleeve structure 18 in a closed position, preventing fluid flow through the interior of the body portion 12 and operably connected to a conduit portion (not shown) on the opposite side of the body portion 12 . Alternatively, in figure 2 Illustrated in is the valve disc 14 in the open position, which allows fluid to flow through the interior of the valve body 12 and the conduits operably connected to the valve body 12 .

[0041] Turning to FIGS. 7-8B , the valve disc 14 has a body portion wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com