Device and method for treating coking wastewater by utilizing blast furnace slag

A technology for coking wastewater and blast furnace slag, which is applied in the field of iron and steel metallurgy, can solve the problems of high pollutant concentration, threaten human health, and be difficult to degrade, and achieve the effects of low content of harmful substances, saving drying costs, and improving vitrification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

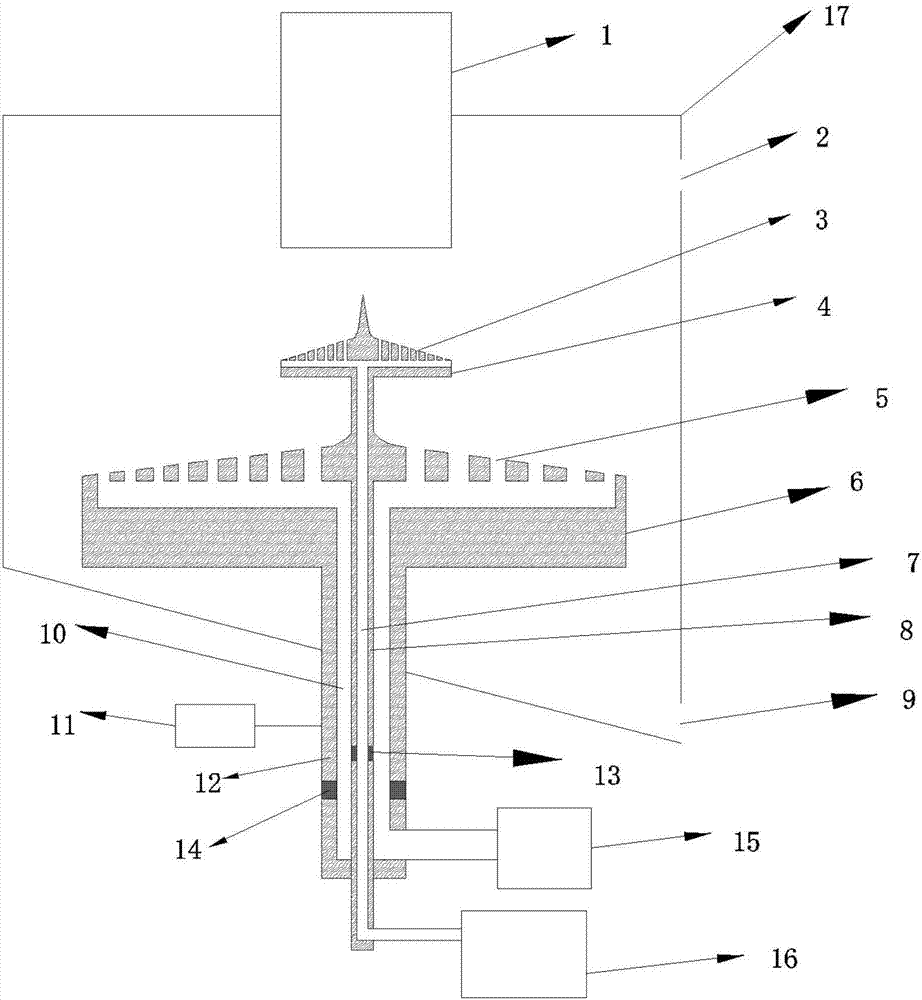

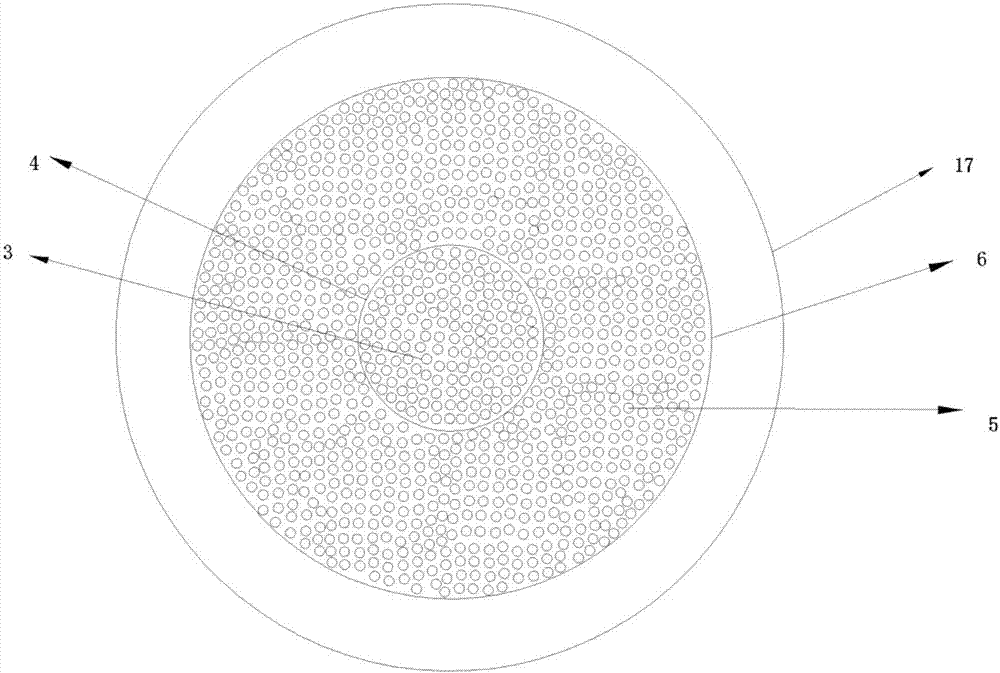

[0035] The following examples are shown together with the device figure 1 , 2 A device for treating coking wastewater with blast furnace slag is further described.

[0036] use as figure 1 , figure 2 The equipment shown in the figure performs two-step treatment of blast furnace slag. The first step is: after the blast furnace slag falls from the circular slag inlet 1, the coking waste water and blast furnace slag are used for convective spraying to cool the blast furnace slag to 700 ~1000°C, the blast furnace slag is granulated during the cooling process, and the organic matter in the coking wastewater is combusted and decomposed to generate CO 2 、H 2 O and other substances. The second step is: using the cooling air to further cool the blast furnace slag, the cooling air and the blast furnace slag convective heat transfer and convective drying, and the blast furnace slag can be further cooled, granulated and dried.

[0037] use as figure 1 , figure 2 The shown perfor...

Embodiment 2

[0041] The following examples are shown together with the device figure 1 , 2 A method for treating coking wastewater by using blast furnace slag is further explained.

[0042] use as figure 1 , figure 2 The equipment shown in the figure performs two-step treatment of blast furnace slag. The first step is: after the blast furnace slag falls from the circular slag inlet 1, the coking waste water and blast furnace slag are used for convective spraying to cool the blast furnace slag to 700 ~1000°C, the blast furnace slag is granulated during the cooling process, and the organic matter in the coking wastewater is combusted and decomposed to generate CO 2 、H 2 O and other substances. The second step is: using the cooling air to further cool the blast furnace slag, the cooling air and the blast furnace slag convective heat transfer and convective drying, and the blast furnace slag can be further cooled, granulated and dried.

[0043] use as figure 1 , figure 2 The shown pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com