Patents

Literature

42results about How to "Save on drying costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel method for producing superfine calcium carbonate by using carbide slag as raw material

InactiveCN101993104ASolve the possibility of industrializationRealize the possibility of industrializationCalcium/strontium/barium carbonatesCosmetic preparationsSlagCarbide

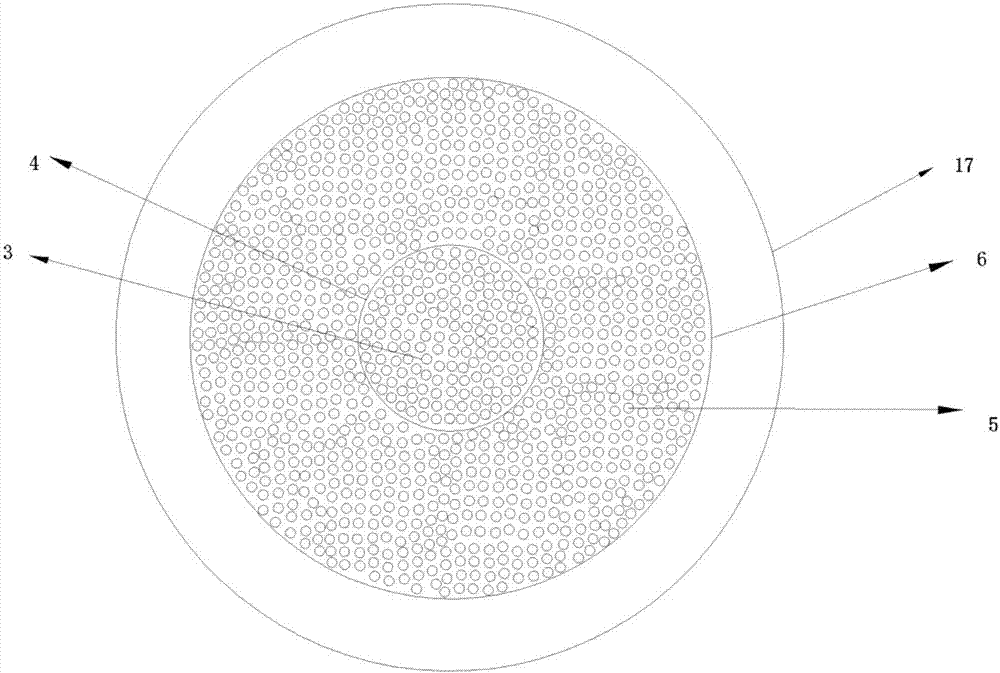

The invention relates to a method for preparing superfine calcium carbonate by adopting glycine as a dissolving agent, a modifying agent and an acid-binding agent, extracting effective calcium from calcium sources, such as carbide slag or lime, and the like and charging carbon dioxide into a reactor for calcifying, filtering and washing and application of the superfine calcium carbonate to paper making, paint production, and the like.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

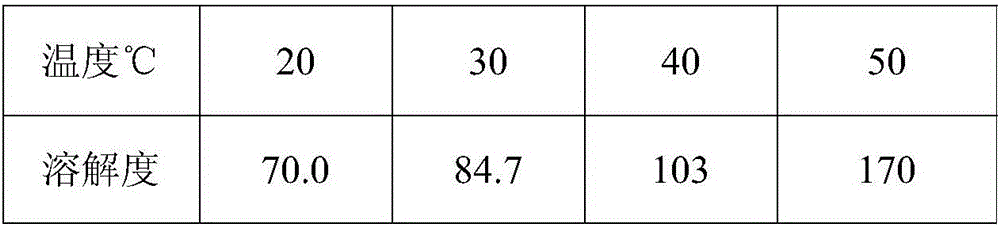

Wet production process for feed-grade active zinc oxide

The invention discloses a novel wet production process for feed-grade active zinc oxide, belonging to the field of feed additives. The process comprises steps such as neutral leaching, ammonia leaching, acid leaching, primary purifying, secondary purifying, carbonization reaction, washing and filtering, drying, heating for decomposing, and the like. In the process, active zinc oxide is produced by directly carbonizing an acid immersion liquid and an ammonia immersion liquid, so that cheap zinc flue dust is utilized, ammonia water in the ammonia immersion liquid and ammonium hydrogen carbonateare taken as carbonization precipitating agents of the acid immersion liquid, ammonia water and ammonium hydrogen carbonate are not additionally used, an ammonia evaporation step is eliminated, and production cost is reduced greatly; the bulk density of the obtained active zinc oxide can be up to 0.9-1.1 g / cm<3> and even higher, the higher requirements of the feed additive industry on the fluidity and bulk density of active zinc oxide are met; and the moisture content is lowered, so that the drying cost on every ton of product is lowered by about 200 yuan.

Owner:GUANGHAN LONGDA FEED

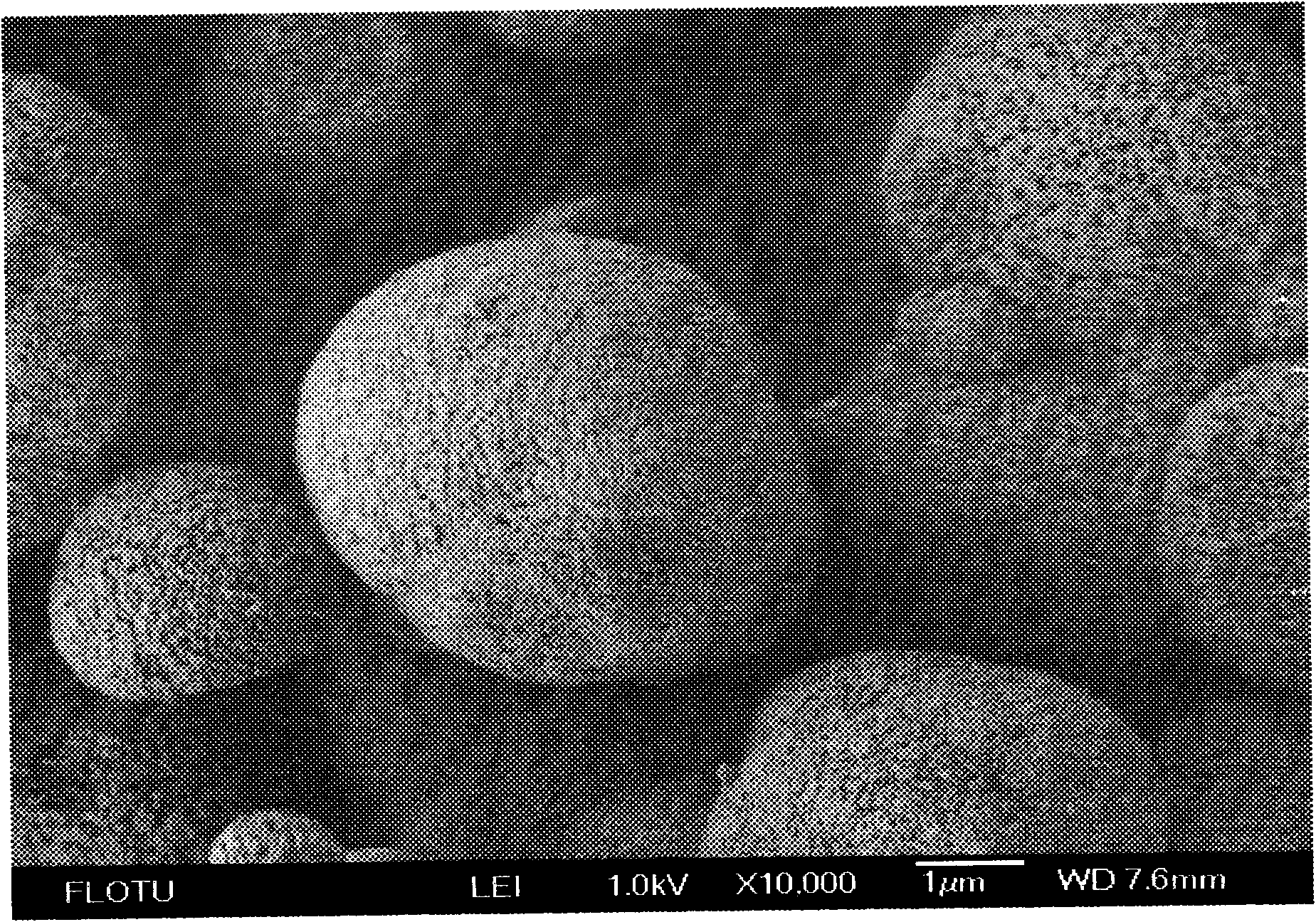

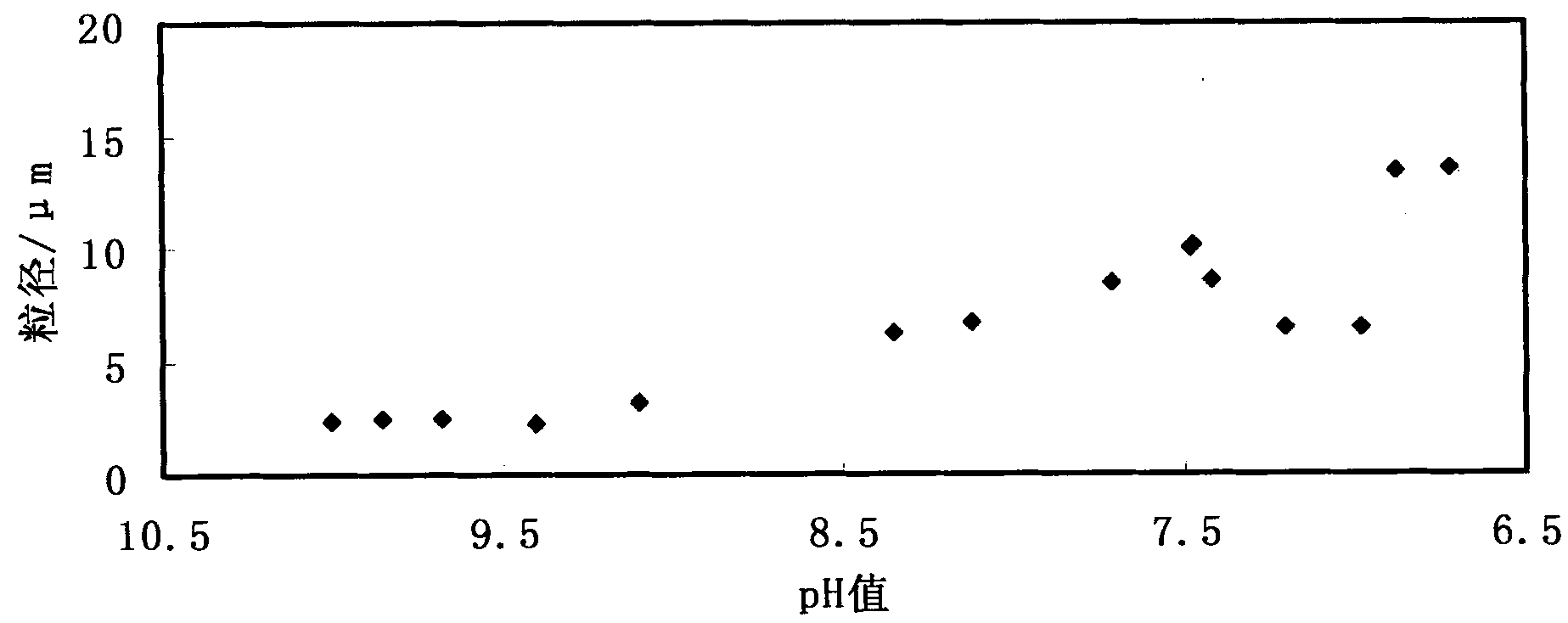

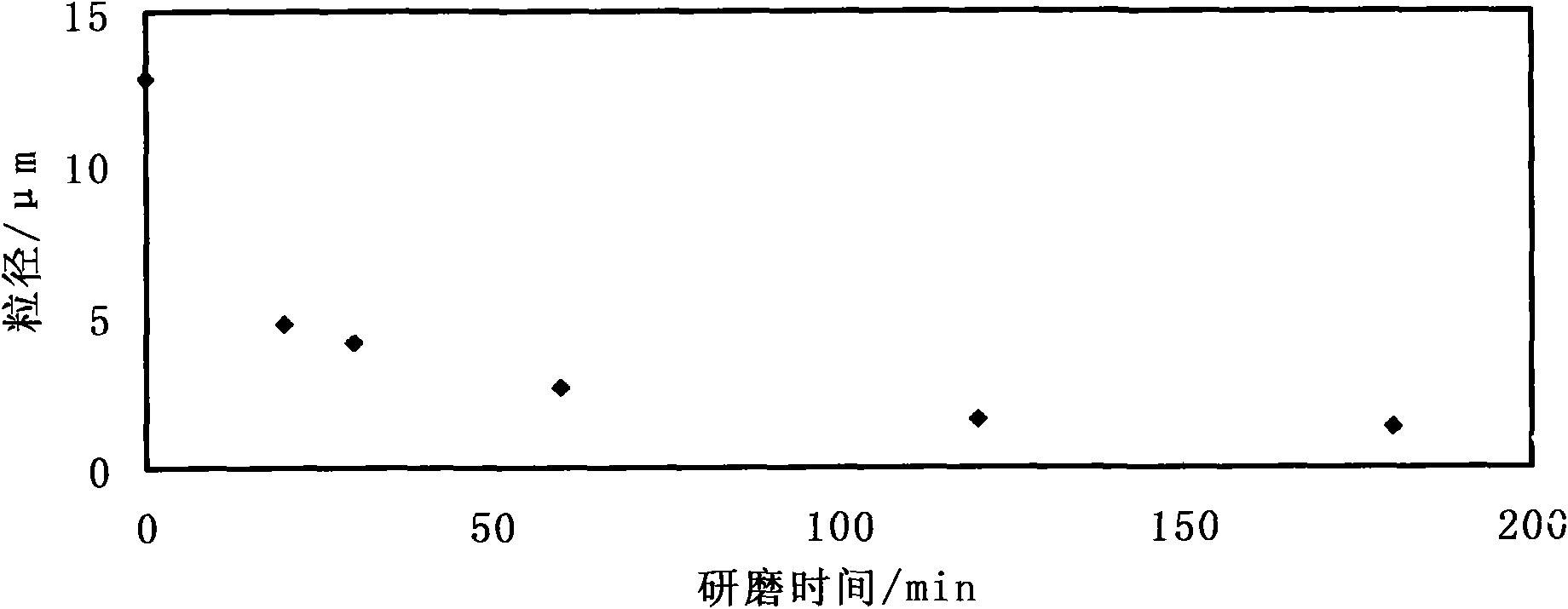

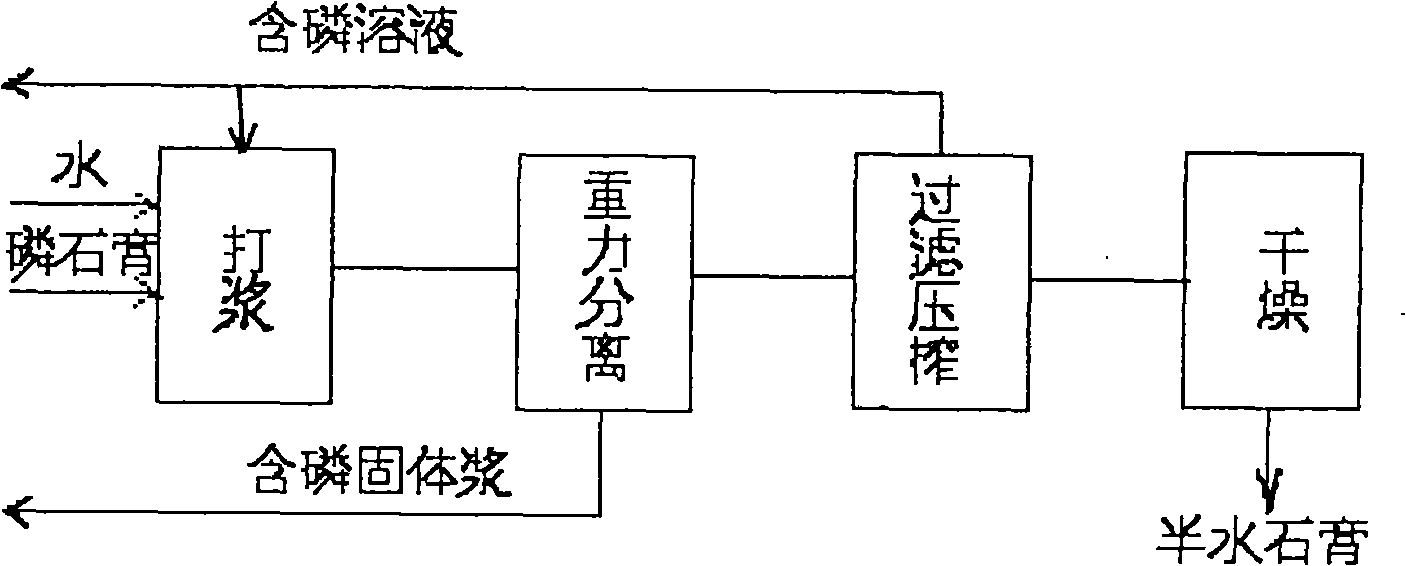

Fine purification and energy-saving dewatering process for phosphogypsum

The present invention discloses a method for the purification and the energy-saving dehydration of phosphorous gypsum, and comprises the steps: the insolubale phosphate and other solid foreign matters are separated with gravity from the phosphorous gypsum; the soluble phosphate and other soluble foreign matters are separated in pressurizing and filtering way; after being pressed and compressed, the phosphorous gypsum is dried in air and is dehydrated with machine, and the semi-hydrate gypsum powder product is obtained after being dried. The purity of the product is high, the foreign matter is less and the usage is wide; since the non-thermolics mechanical dehydration is adopted, the free water in the phosphorous gypsum is decreased from 25 to 30 percent to 10 percent, thus saving the drying energy consumption, and greatly reducing the production cost.

Owner:龚家竹

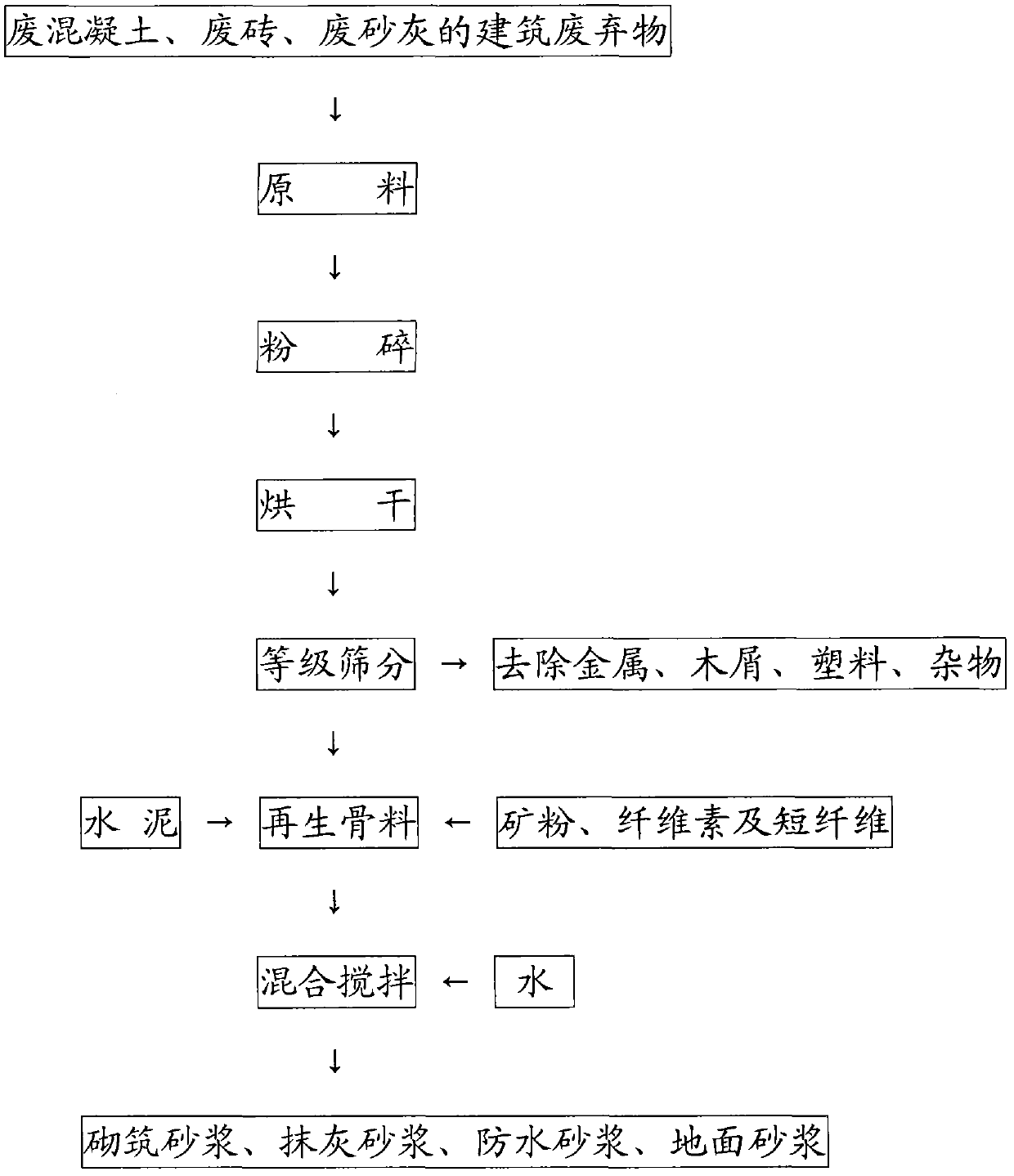

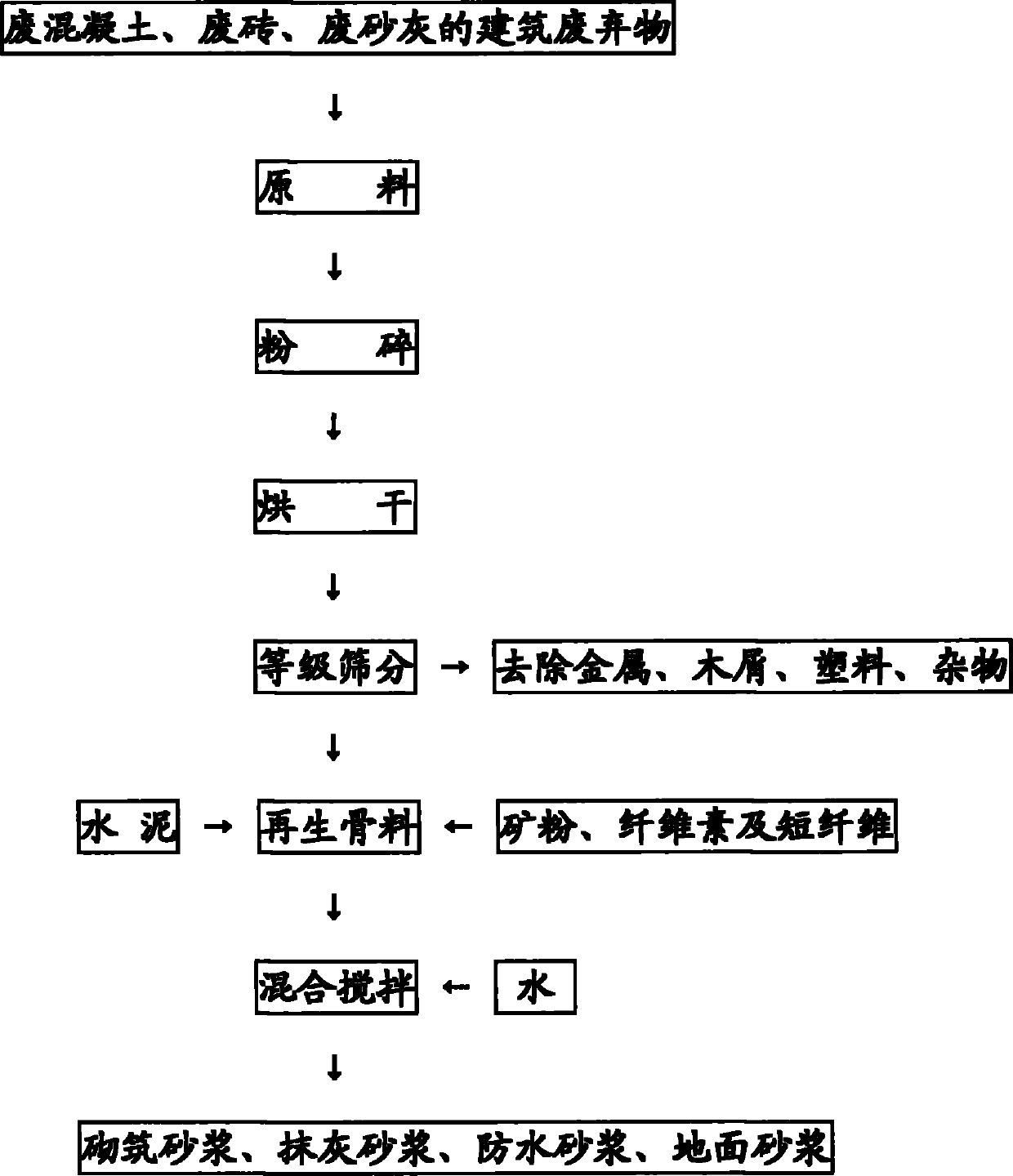

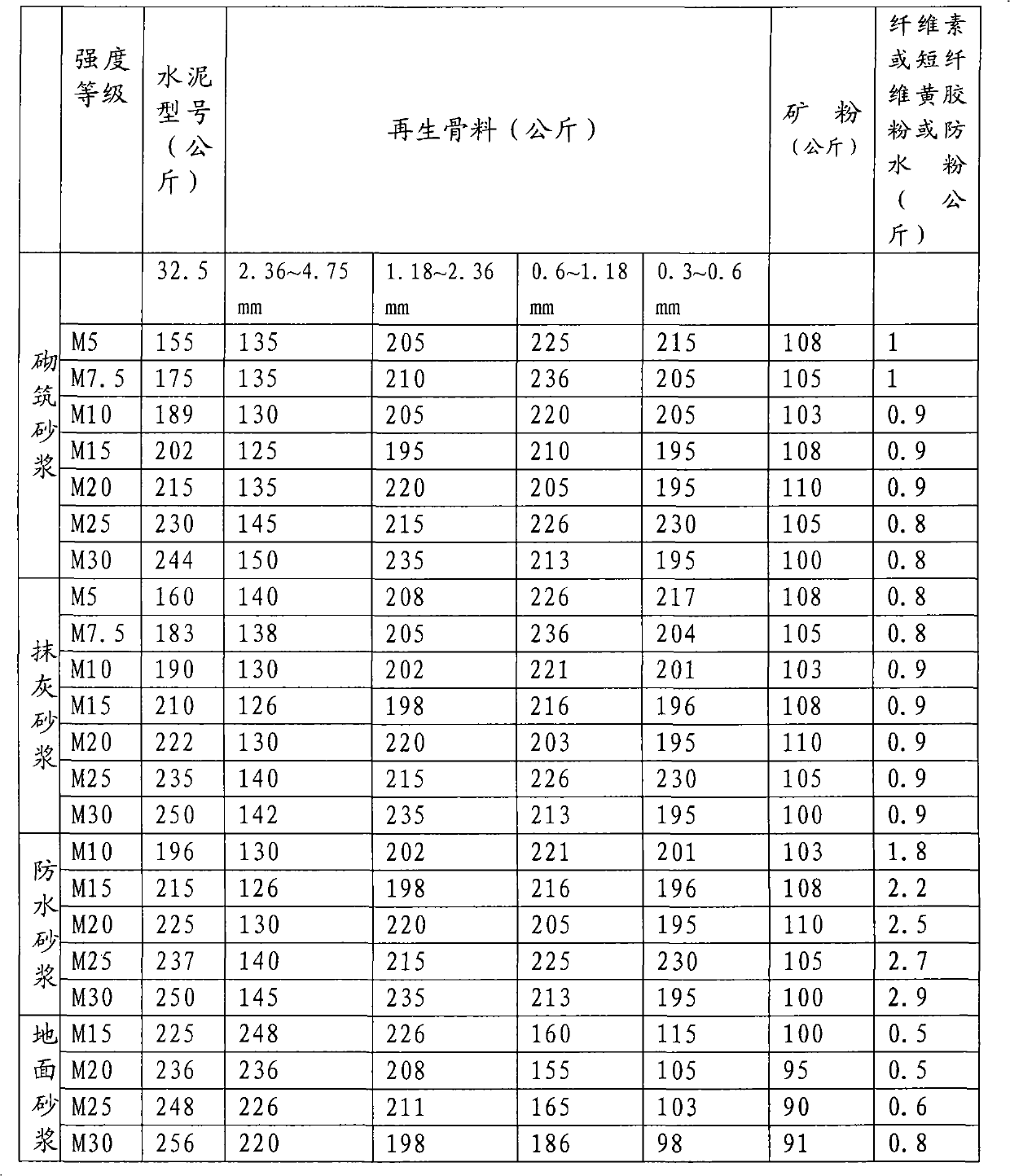

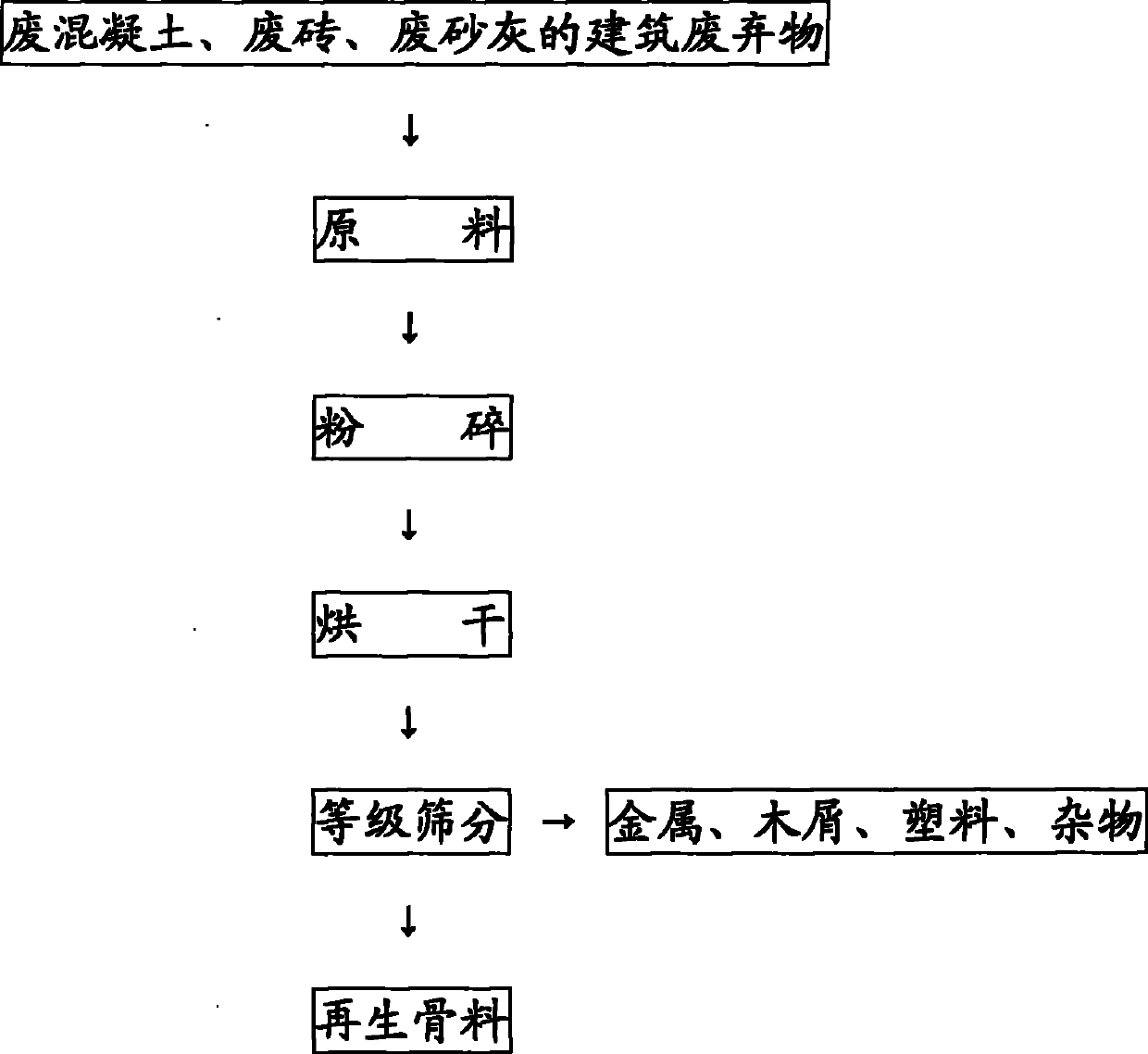

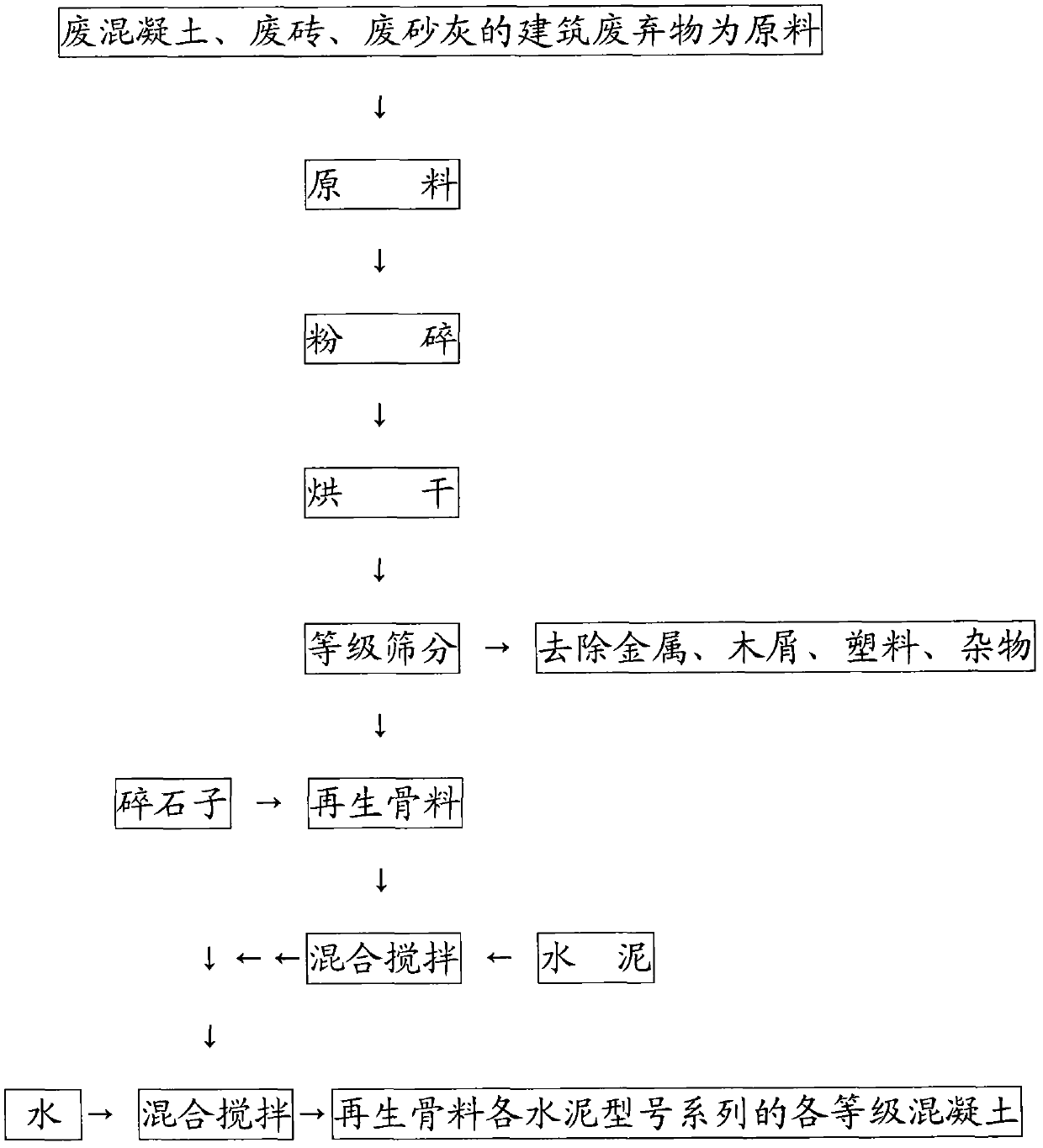

Preparation method of recycled aggregate ready-mixed mortar

InactiveCN102701647AEffective protectionEffective consumptionSolid waste managementFiberNatural resource

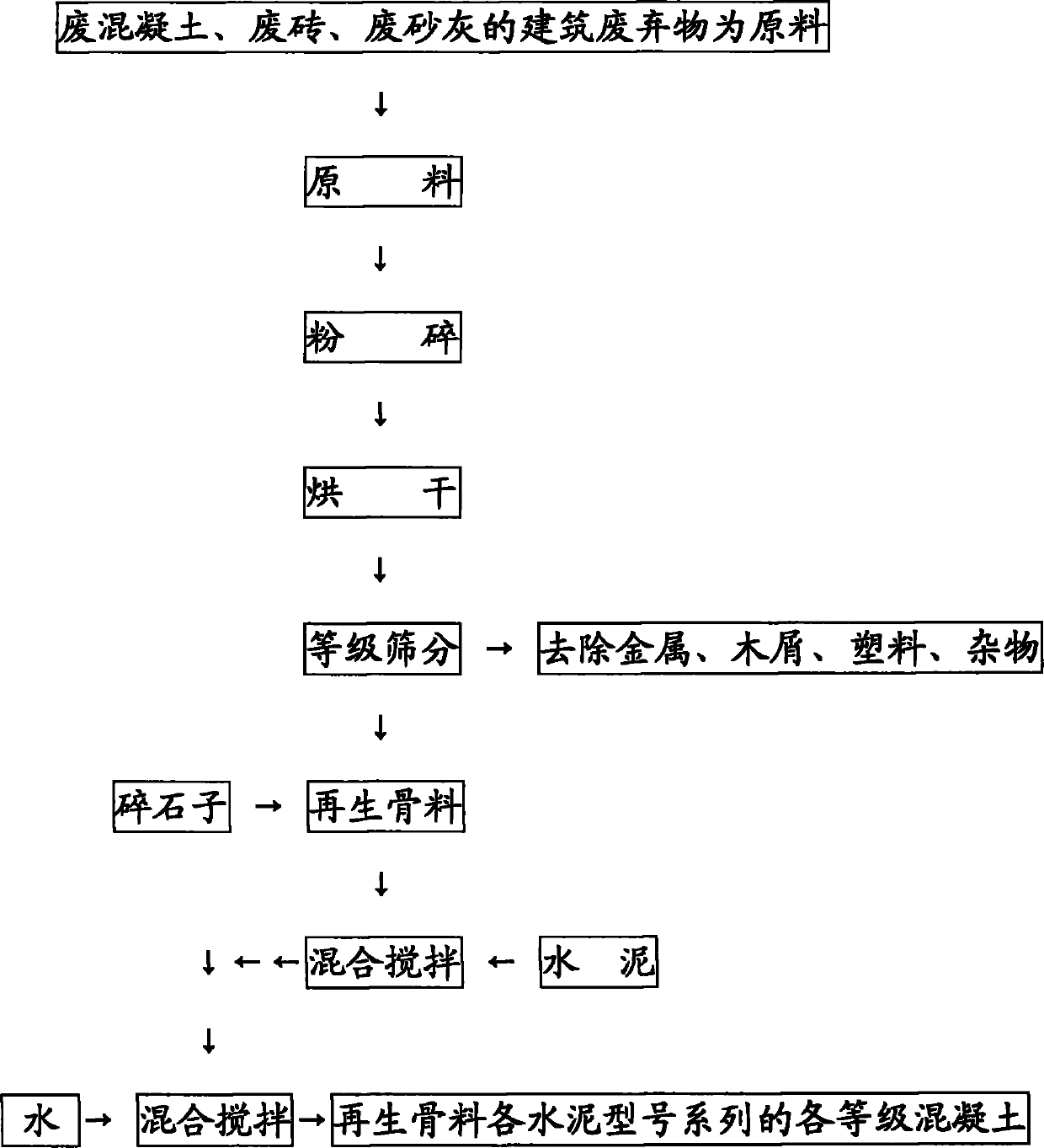

The invention relates to a preparation method of recycled aggregate ready-mixed mortar, belonging to the field of building raw materials. The preparation method comprises the following steps of: taking waste concrete, waste bricks and waste sand-lime building materials, which are smaller than 690mm, as raw materials, determining the quantity according to the needs, crushing and drying till the water content is not more than 0.5%, and then performing graded screening so as to prepare recycled aggregate with the particle sizes of 0.075-0.15 mm, 0.15-0.3 mm, 0.3-0.6 mm, 0.6-1.18 mm, 1.18-2.36 mm, 2.36-4.75 mm, 4.75-10 mm and 10-32 mm, wherein metal, wood chips, plastics and other sundries are removed in the graded screening, and the masonry, plastering, waterproof or ground mortar can be respectively prepared by enabling the proportion of the sum of one of the recycled aggregate, cement, powdered ore and cellulose, and short fiber, xanthan gum powder and waterproof powder to the added water to be 1: 0.18. The recycled aggregate ready-mixed mortar can be used as a building raw material. The preparation method has the advantages of protecting natural resources, saving labor, saving time, saving effort, realizing low cost, changing the wastes into valuable things, and meeting the requirements of low-carbon production and living.

Owner:伏开磊 +1

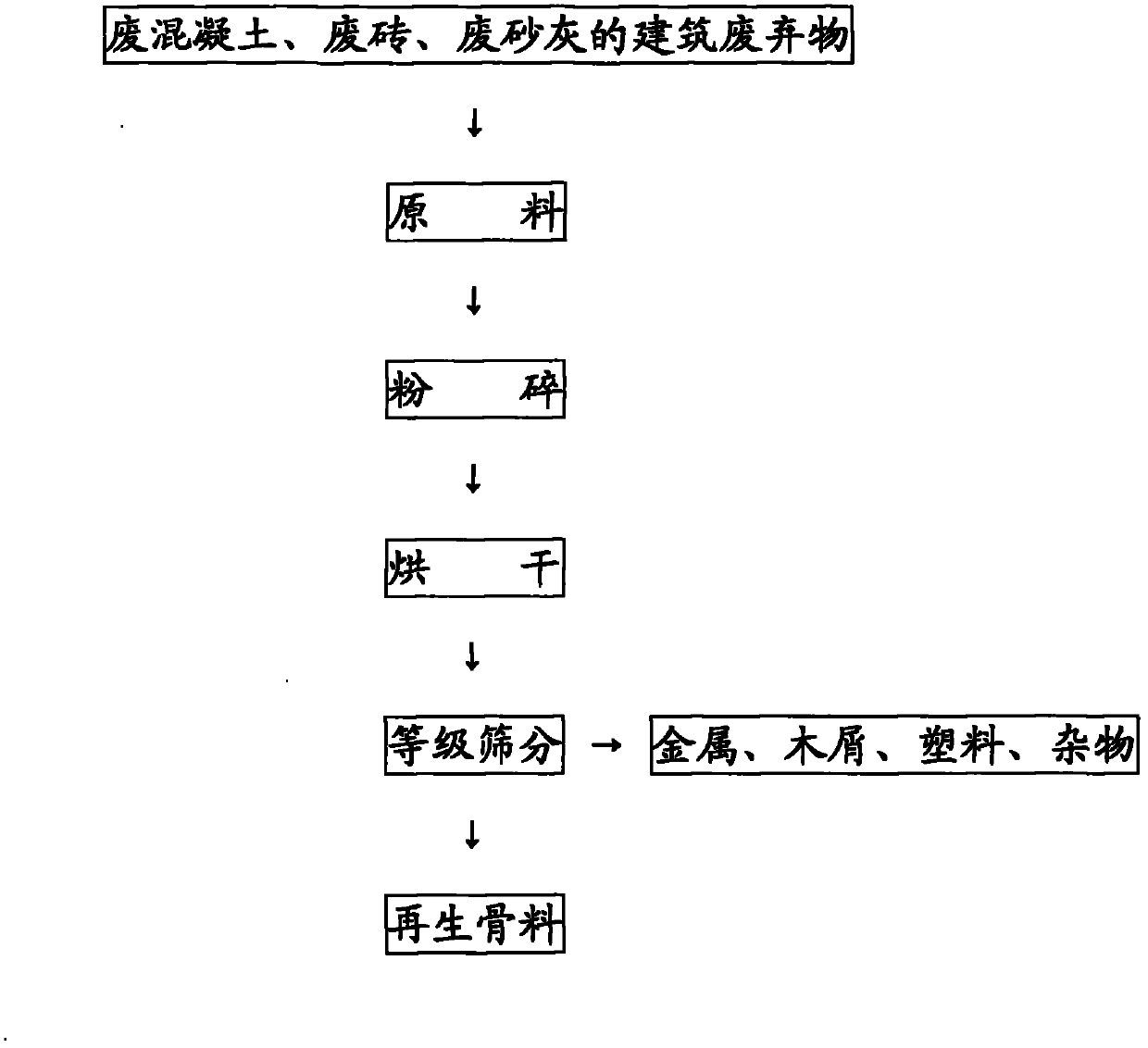

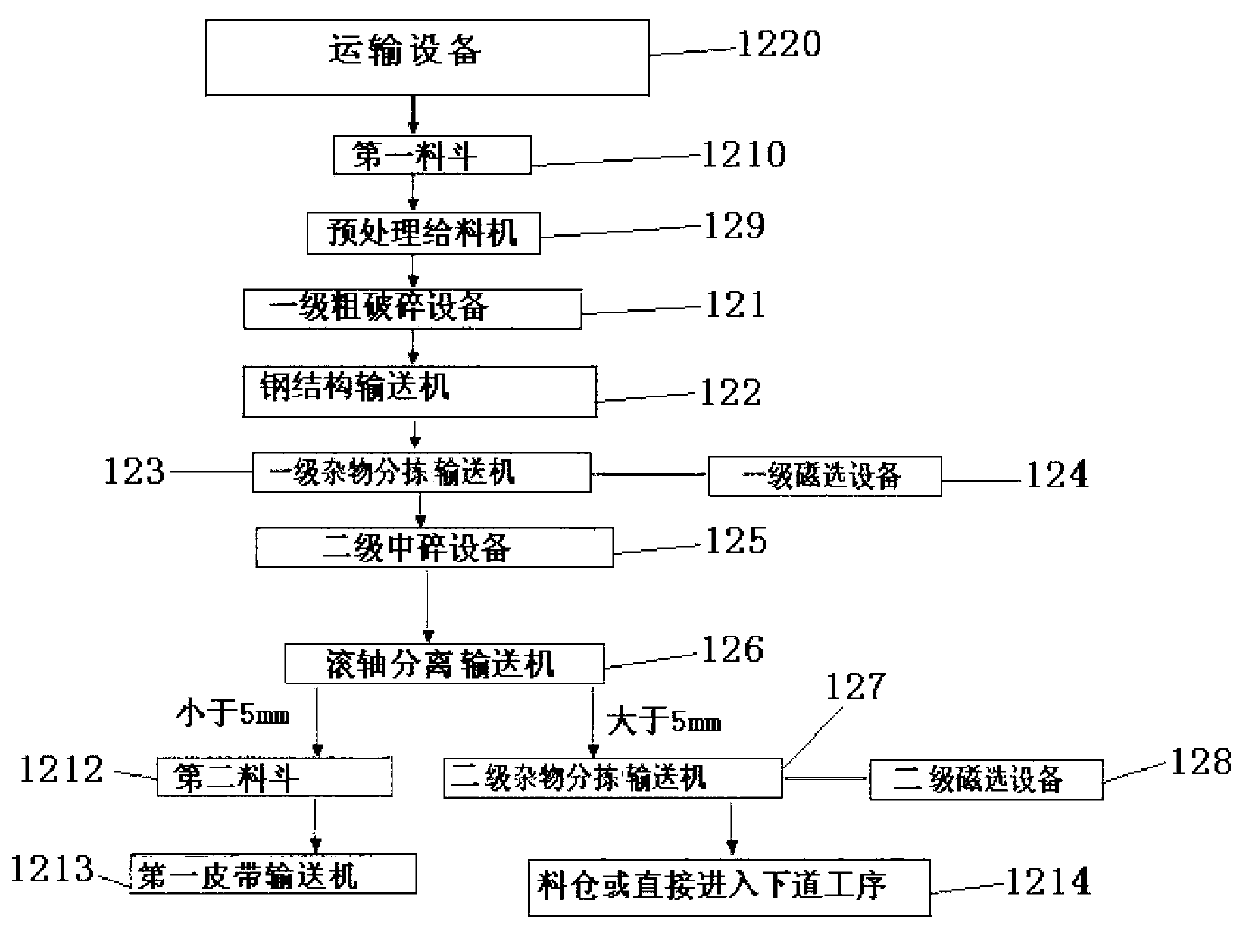

Preparation method of recycled aggregate from building wastes

The invention discloses a preparation method of recycled aggregate from building wastes, relating to the technical field of building raw materials. The preparation method comprises the following steps of: adopting a waste utilization technology, taking waste concrete, waste bricks and waste sand-lime building materials, which are smaller than 690mm, as raw materials, determining the quantity according to needs, crushing, further drying till the water content is not more than 0.5%, and then performing graded screening so as to prepare the recycled aggregate with the particle sizes of 0.075-0.15 mm, 0.15-0.3 mm, 0.3-0.6 mm, 0.6-1.18 mm, 1.18-2.36 mm, 2.36-4.75 mm, 4.75-10 mm and 10-32 mm and store the recycled aggregate with the different particle sizes respectively, wherein a magnet is applied in the graded screening process for removing metal as well as removing wood chips, plastics and other sundries according to the specific gravity. The recycled aggregate can be used as a building raw material. The preparation method has the advantages of protecting natural resources, saving labor, saving time, saving effort, realizing low cost, changing the wastes into valuable things, and meeting the requirements of low-carbon production and low-carbon living.

Owner:伏开磊 +1

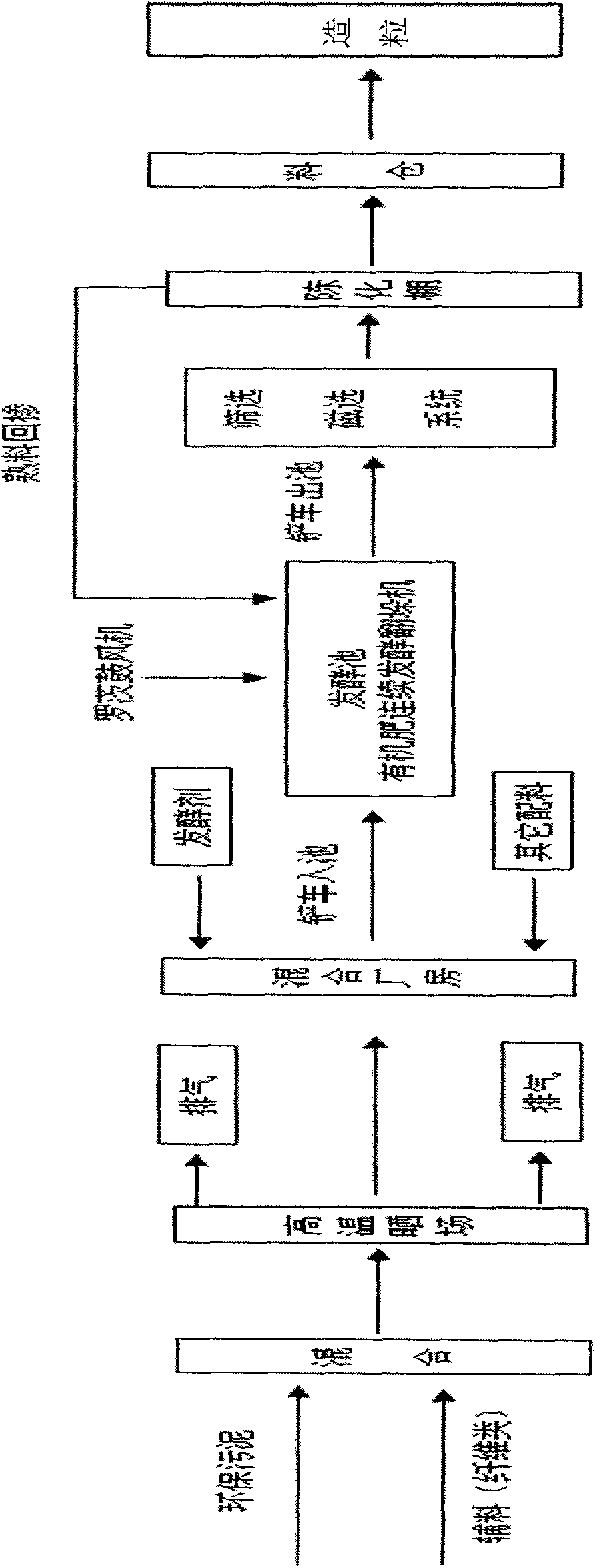

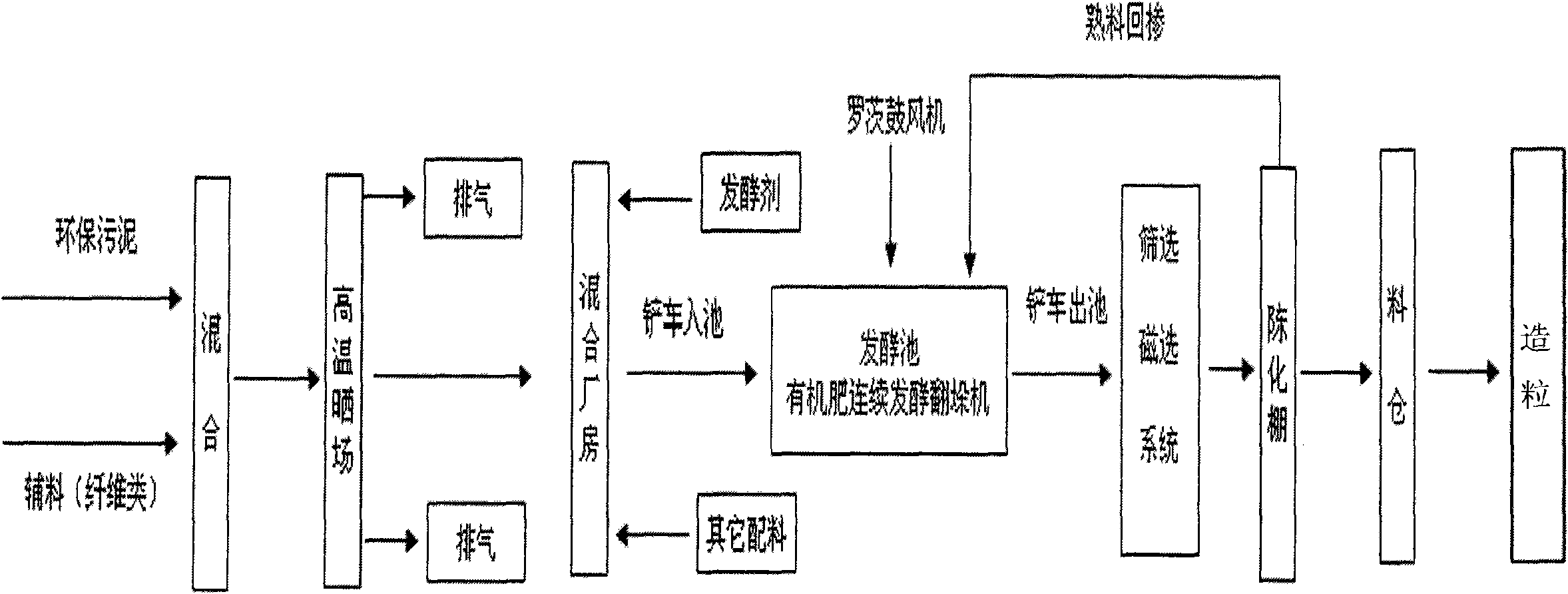

Method for preparation of granular organic fertilizer by industrial floc sludge

InactiveCN101786909AShort processLow running costBio-organic fraction processingClimate change adaptationSludgeOrganic fertilizer

The invention belongs to the comprehensive utilization of wastes in the field of environmental protection, more particularly to a technological method for the preparation of granular organic fertilizer by citric acid industrial floc sludge by means of high-temperature air-drying, fermentation of fermentation strain agent and granulation of a novel continuous granulator, the environmentally-friendly floc sludge is dehydrated, air-dried and added with fermentation strain, the water content of clinker is 25-35% after the fermentation for 7 to 8 days, a part of the sludge is back-admixed to finely adjust the water content of the sludge prior to fermentation technology, then the sludge is screened, magnetically separated and aged to enter a granulation area, powdery organic fertilizer is addedwith a fixed amount of bonding agent, followed by evenly mixing, the mixture is subject to continuous granulation of the novel granulator, drying, cooling and screening to produce the granular organic fertilizer. The fertilizer has the characteristics of abundant nutrition, lasting fertilizer effect and easy storage and simultaneously settles the current problem that the environmentally-friendly floc sludge is hardly treated.

Owner:RIZHAO JINHE BOYUAN BIOCHEM

Method for processing feed through waste water microalgae

ActiveCN104982731AEnsure biosecurityOmit the drying stepAnimal feeding stuffTrichoderma longibrachiatumPathogenic bacteria

The invention discloses a method for processing feed through waste water microalgae. According to the method, the microalgae cultured, collected and deposited through waste water is mixed with cornhusk and bacillus subtilis, then the mixture is accumulated on the ground and subjected to aerobic fermentation, and high temperature generated in the fermentation process is fully used for killing bacteria; cooled microalgae materials obtained after aerobic fermentation are mixed with pig overhead price compound feed, lactobacillus plantarum and trichoderma longibrachiatum are added in the mixing process, the moisture content is adjusted to be 40-50%, and the feed is taken out and fed to pigs after the feed is subjected to anaerobic fermentation and the pH is 3.5-5.0. By means of the method, the utilization rate of waste water is increased, drying cost of the microalgae is reduced, pathogenic bacteria in the waste water are killed, bio-security of microalgae utilization is improved, and feed-based utilization of the microalgae is promoted. The feed processed through the waste water microalgae is high in probiotic content, and productivity of the pigs is increased.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

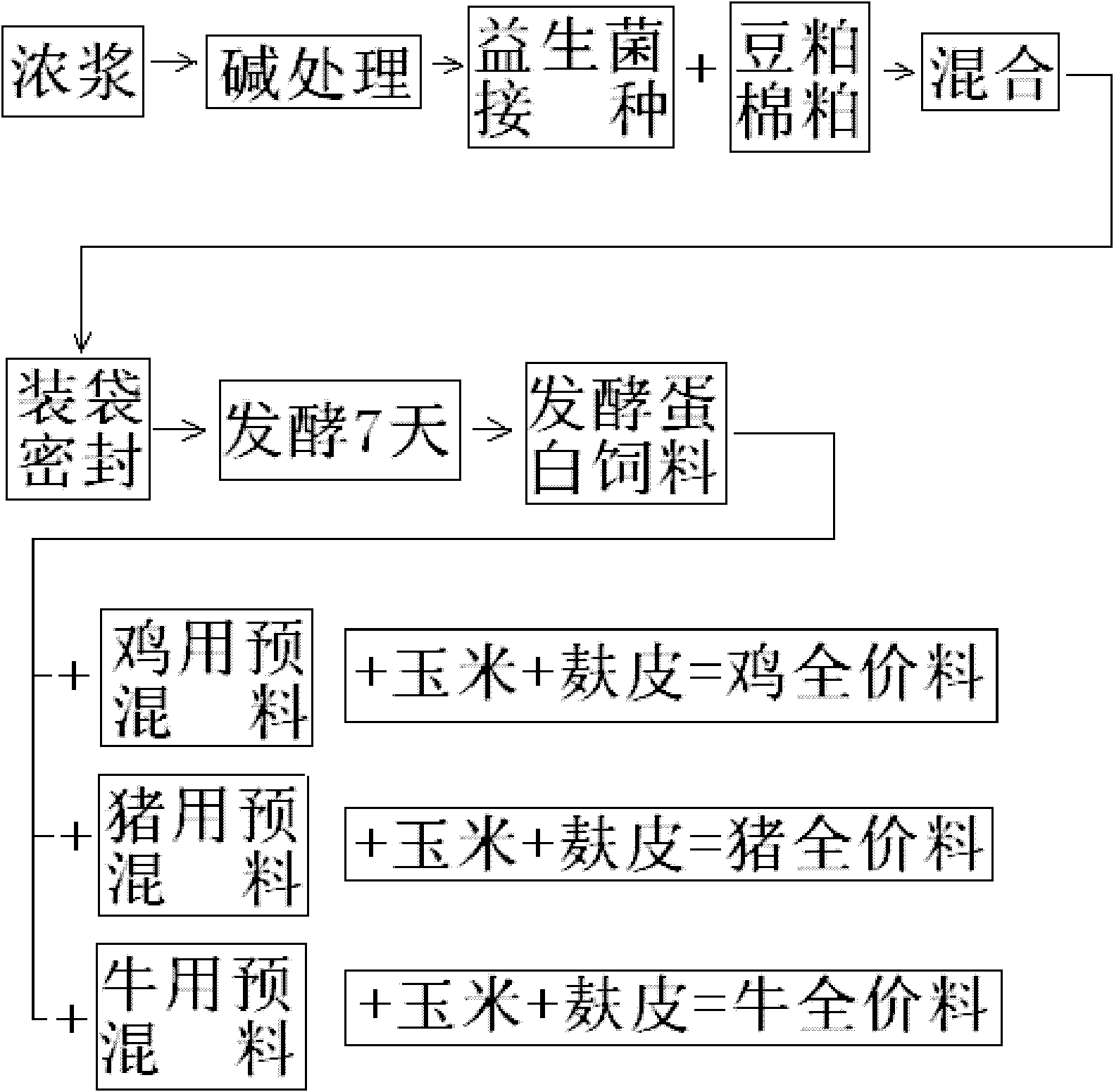

Technology for preparing fermented protein concentrated feed from dense slurry

InactiveCN102726598APrevent dryingSave on drying costsFood processingAnimal feeding stuffCalcium hydroxideSlurry

The invention discloses a technology for preparing fermented protein concentrated feed from dense slurry and relates to a technology for producing feed. The technology comprises the following steps of 1), a dense slurry alkali-treatment process comprising adding an alkali and calcium hydrate into dense slurry so that a pH value is in a range of 6.8 to 7.2, 2), a probiotic addition process comprising controlling a temperature of dense slurry in a range of 37 to 41 DEG C, adding probiotics into the dense slurry obtained by the step 1 with stirring and with determining a pH value of the dense slurry, and when the pH value is in a range of 5.8 to 6.2, stopping probiotic addition, 3) a dense slurry-dry material mixing process comprising adding a mixed fry material of soybean meal and cottonseed meal into the dense slurry obtained by the step 2, and stirring, wherein a weight ratio of the dense slurry to the mixed fry material is 1: (1-1.5), and 4) a bagging and fermentation process comprising putting a mixed wet material obtained by the step 3 into plastic bags, carrying out heat-sealing packaging and carrying out fermentation at a normal temperature for 7 to 10 days. The technology solves the problems that the existing technology for producing dense slurry feed by a drying method has a high cost and can damage nutrients of feed.

Owner:LUOYANG MUYUAN AUTOMATIC CONTROL EQUIP

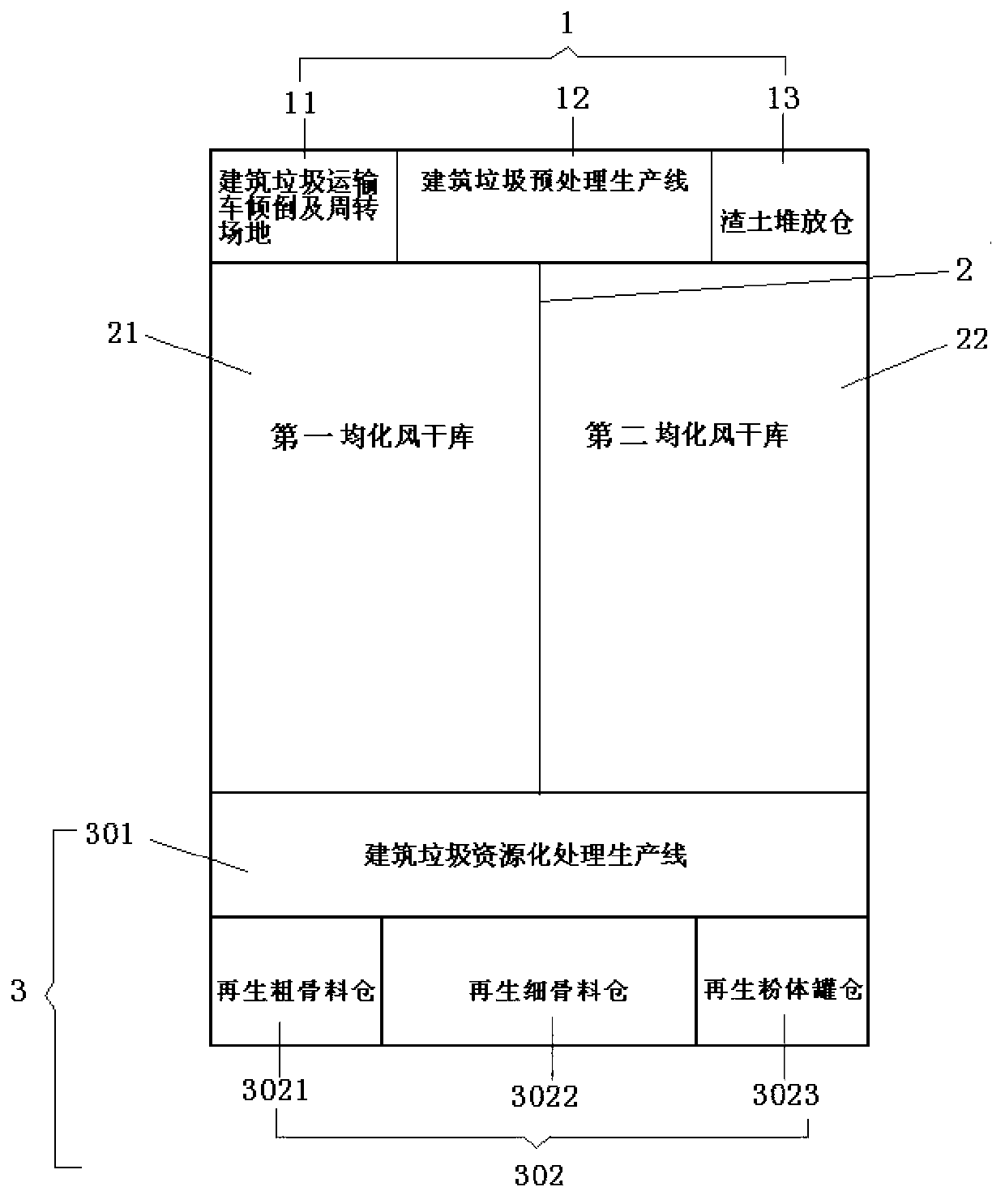

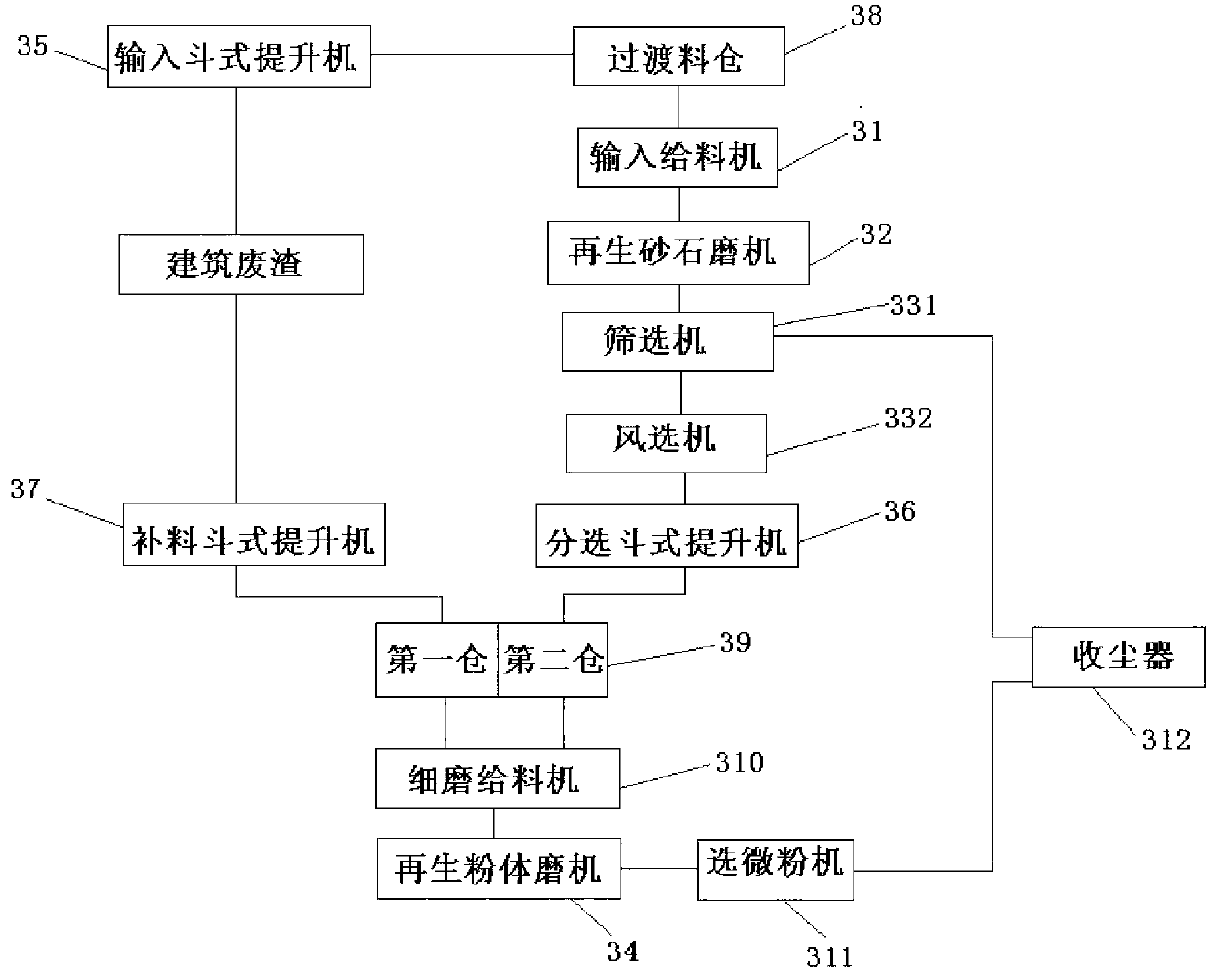

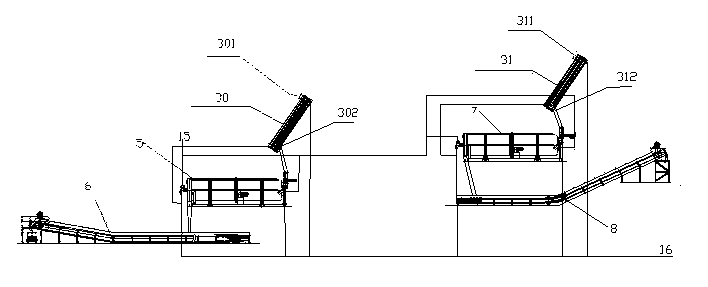

Factory type construction waste resourceful treatment system and technological process thereof

ActiveCN103128094AEasy to absorb waterIncrease moisture contentConstruction waste recoverySolid waste disposalLitterMaterials processing

The invention discloses a factory type construction waste resourceful treatment system and a technological process of the factory type construction waste resourceful treat system and belongs to the technical field of construction waste treatment. The factory type construction waste resourceful treatment system comprises a pretreatment unit, a homogenized drying unit and a recycled material processing production unit which are arranged in sequence. The layout of the technical scheme includes that no matter how the specification and the size of the components and the moisture content of the construction waste change, the normal production of three recycled materials of the construction waste resourceful treatment can not be influenced; and no matter how the three recycled materials of the construction waste resourceful treatment are adjusted, combined and changed, the normal production of the construction waste pretreatment can not be influenced. The processing and production of the recycled materials refer to breaking and grinding of the construction waste residue after harmless treatment, stripping of mishmash, homogenization and drying, the moisture content of the construction residue can be basically controlled below 6%, and therefore smooth production can be achieved.

Owner:SHANGHAI GUOTONG ENVIRONMENTAL PROTECTION EQUIP

Cordyceps militaris culture medium fermented feed and preparation method thereof

ActiveCN105028897AFor long-term storageIncrease production capacityFood processingAnimal feeding stuffBiotechnologyBacillus cereus

The invention discloses a cordyceps militaris culture medium fermented feed and a preparation method thereof. The preparation method comprises the following steps: adding corn bran, brewer's grain and candy pomace into a fresh cordyceps militaris culture medium, crushing, uniformly mixing, inoculating microorganism lactic acid bacteria and bacillus cereus during the mixing process, regulating the moisture content to be 35-45%, carrying out anaerobic fermentation, so as to obtain the cordyceps militaris culture medium fermented feed after fermentation maturity; the fermented feed can completely replace corn in concentrated feeding stuff for flocks and herds. According to the cordyceps militaris culture medium fermented feed and the preparation method thereof, provided by the invention, the fresh cordyceps militaris culture medium is subjected to anaerobic fermentation treatment, and the fermentation temperature is lower than 40 DEG C, so that high-temperature drying is avoided, function materials in the culture medium are protected, the drying process is avoided, the drying cost is avoided, besides, the fresh cordyceps militaris culture medium can be preserved for a long time under a low pH and anaerobic environment, the production performance of cattle and sheep is improved by the cordyceps militaris culture medium fermented feed after fermentation under the action of the function materials contained in the fermented feed such as cordycepic acid, probiotics, enzyme and an acidifier.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI +1

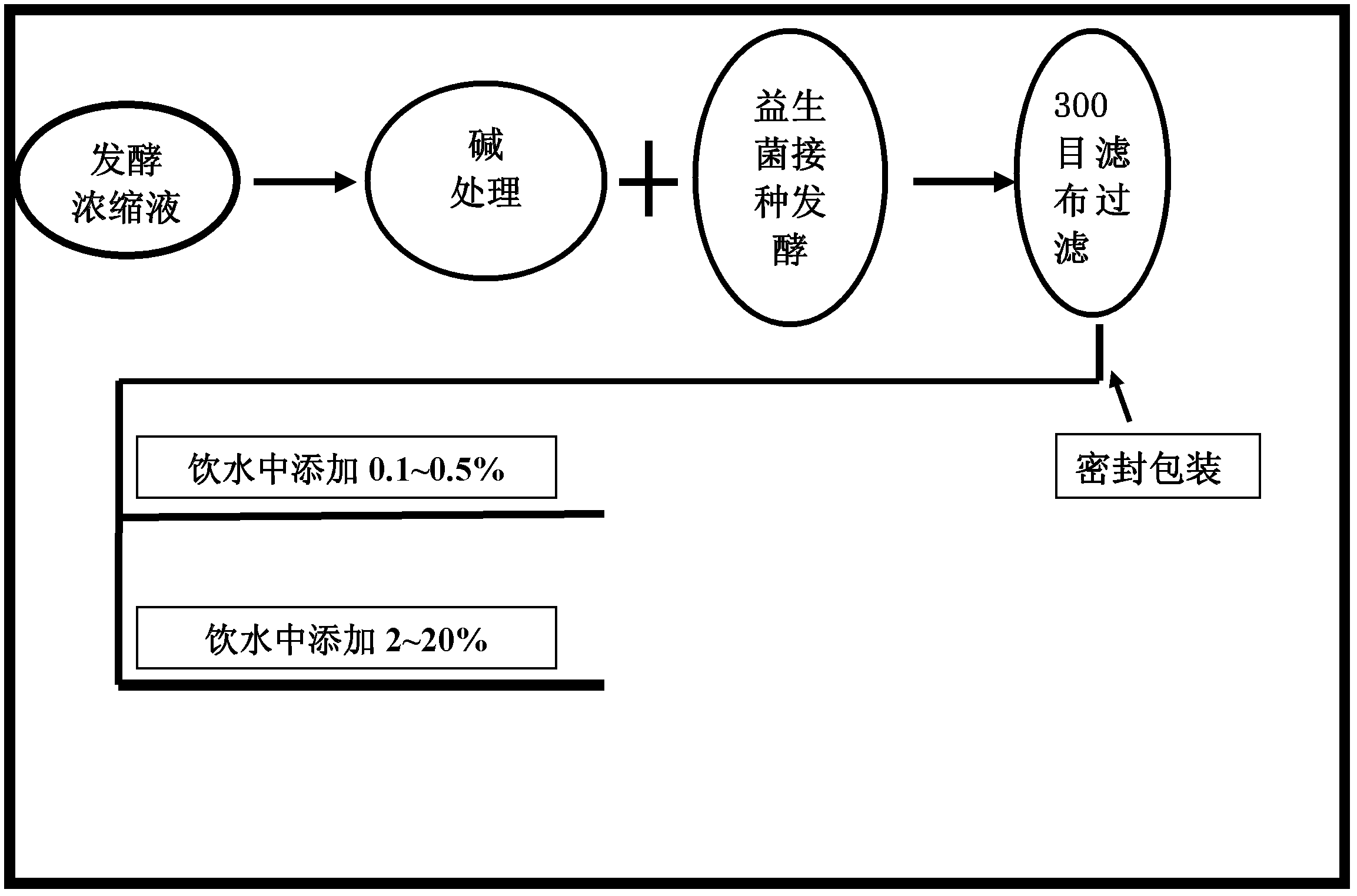

Preparation process and application method of liquid drinking-water agent prepared from concentrated fermentation waste liquid

InactiveCN103156062ASave on drying costsImprove feeding effectAnimal feeding stuffChemistryCalcium hydroxide

The invention relates to a preparation process and an application method of a liquid drinking-water agent prepared from concentrated fermentation waste liquid. The method comprises the steps that: (1) the concentrated fermentation waste liquid is subjected to alkali treatment, wherein the concentrated fermentation waste liquid purchased from a bio-fermentation plant is placed in a vessel; alkali and calcium hydroxide are added; and the pH value of the liquid is regulated to 5.5-7.2; (2) composite probiotics are added, wherein the temperature in the liquid is controlled at 37-41 DEG C, a composite probiotic strain is added into the liquid, and fermentation is carried out; liquid pH value changes are determined; when the pH value is approximately 5, the fermentation is stopped; (3) filtration is carried out by using a 300-mesh filtering cloth; and (4) the liquid is packaged into a vessel. 0.1-0.5% or 2-20% of the liquid drinking-water agent is added into drinking-water. With the invention, problems such as high cost and reduced feedstuff nutritive value of concentrated fermentation waste liquid feedstuff bake-drying treatment of prior arts are solved.

Owner:LUOYANG MUYUAN AUTOMATIC CONTROL EQUIP

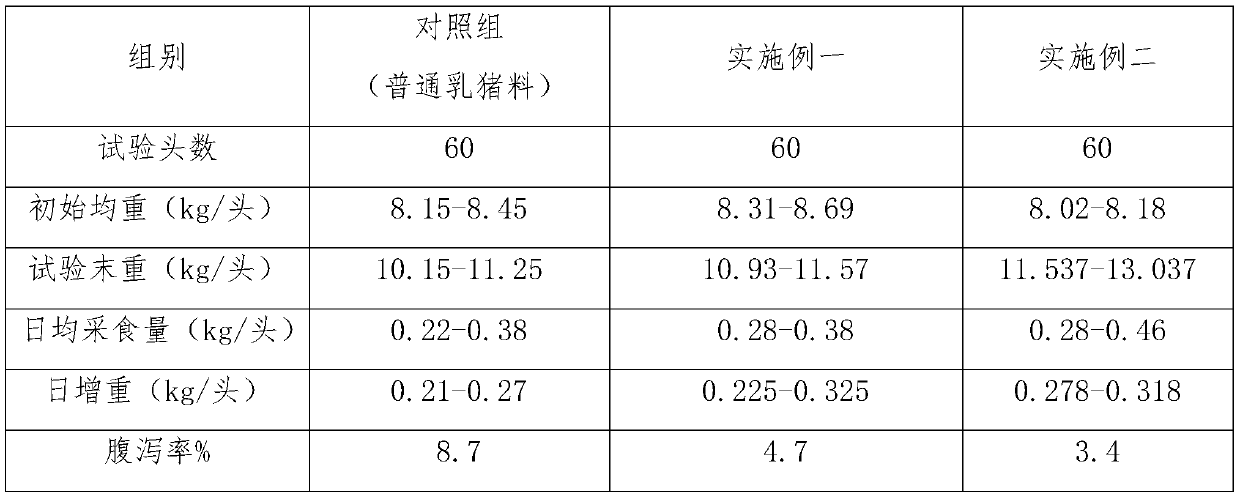

Bacterial and enzymic co-fermented traditional Chinese medicine fermented feed as well as preparation method and application thereof

PendingCN110521852AReduce stepsSave on drying costsFood processingAnimal feeding stuffPhases of clinical researchCellulase

The invention discloses bacterial and enzymic co-fermented traditional Chinese medicine fermented feed as well as a preparation method and an application thereof. The feed comprises probiotics including enterococcus faecium, bacillus subtilis, bacillus licheniformis, saccharomyces cerevisiae, candida utilis, aspergillus oryzae and sterile water, an enzymic preparation including xylanase, mannase and cellulase, traditional Chinese medicines including radix codcnopsitis pilosulas, radix astragali, flowers of poplar, smoked plums, fructus chebulae, rhizoma atractylodis, dried ginger, dried orangepeels and radix glycyrrhizae as well as raw material substrates including soybean meal, corn meal, fish meal and high-fat whey powder, the probiotics, the enzymic preparation and multiple traditionalChinese medicines are combined for co-fermentation, the efficacy is better played, and the fermented feed is added to conventional feed and can be used for preventing bacterial yellow and white scourof suckling pigs; and besides, the fermented feed contains rich natural acid metabolized by small peptides and probiotics, can help piglets digest and prevent feed diarrhea and is favorable for improving intake of the suckling pigs, particularly for preventing weight loss of weaning piglets, a good foundation is laid for later fattening stage of the piglets, and the problems caused by existing feed for the suckling pigs are solved.

Owner:辽宁爱普罗斯生物科技有限公司

Swine fermentation complete feed and production method thereof

InactiveCN102160609ASave on drying costsWell-preservedAnimal feeding stuffAccessory food factorsPlastic bagDisease

The invention discloses a swine fermentation complete feed and a production method thereof. The swine fermentation complete feed is prepared from 40 to 60 percent of thick slurry, 38 to 59 percent of drier and 1 to 2 percent of probiotics. The production method comprises the following steps of: (1) regulating the pH value of the thick slurry serving as a raw material to 6.8 to 7.2 by using alkalito obtain liquid A; (2) controlling the temperature of the liquid A to be between 37 and 41 DEG C, adding the probiotics into the liquid A for fermenting, and when the pH value of the liquid A is between 5.8 and 6.2, stopping adding the probiotics to obtain liquid B; (3) adding the drier into the liquid B, and stirring uniformly to obtain a mixture C; and (4) putting the mixture C into a plastic bag, heat-sealing, and fermenting at normal temperature for 7 to 10 days to prepare the swine fermentation complete feed. The swine fermentation complete feed has the effects of reducing cost, preventing and treating diseases and improving production performance.

Owner:HENAN UNIV OF SCI & TECH

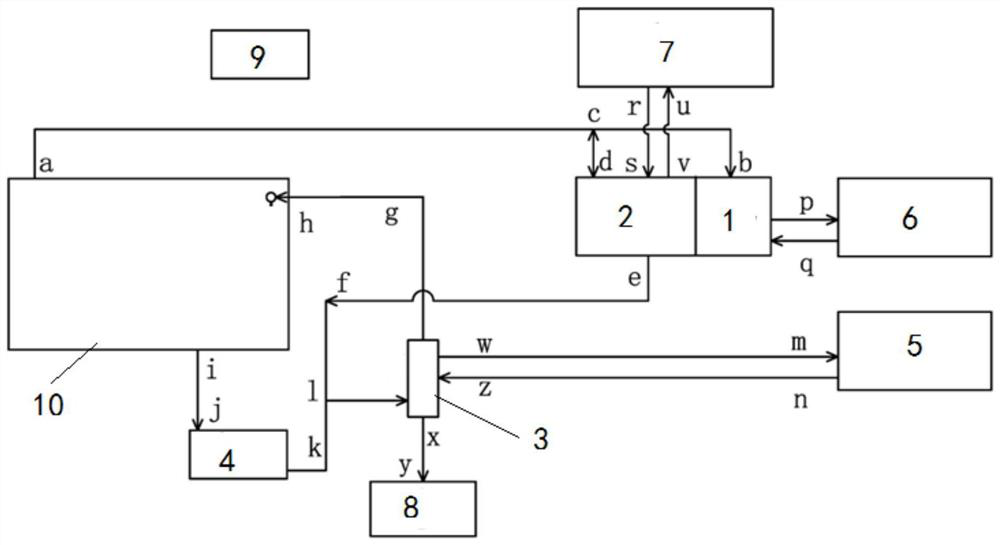

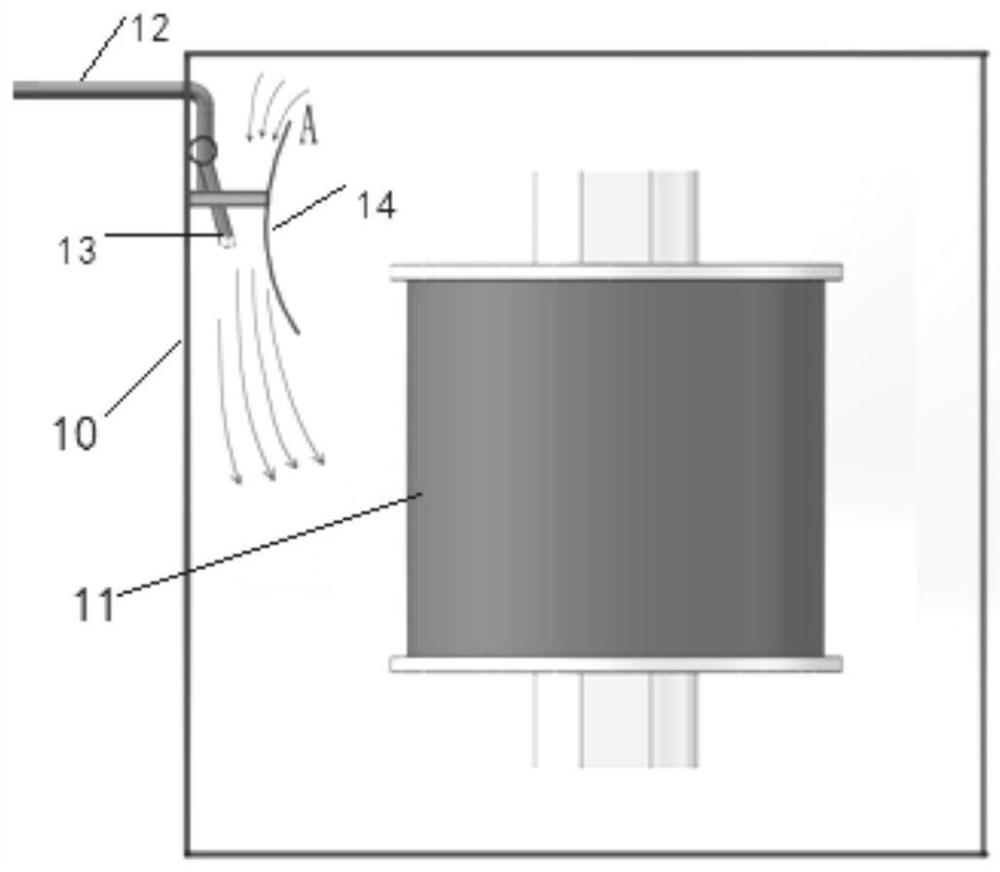

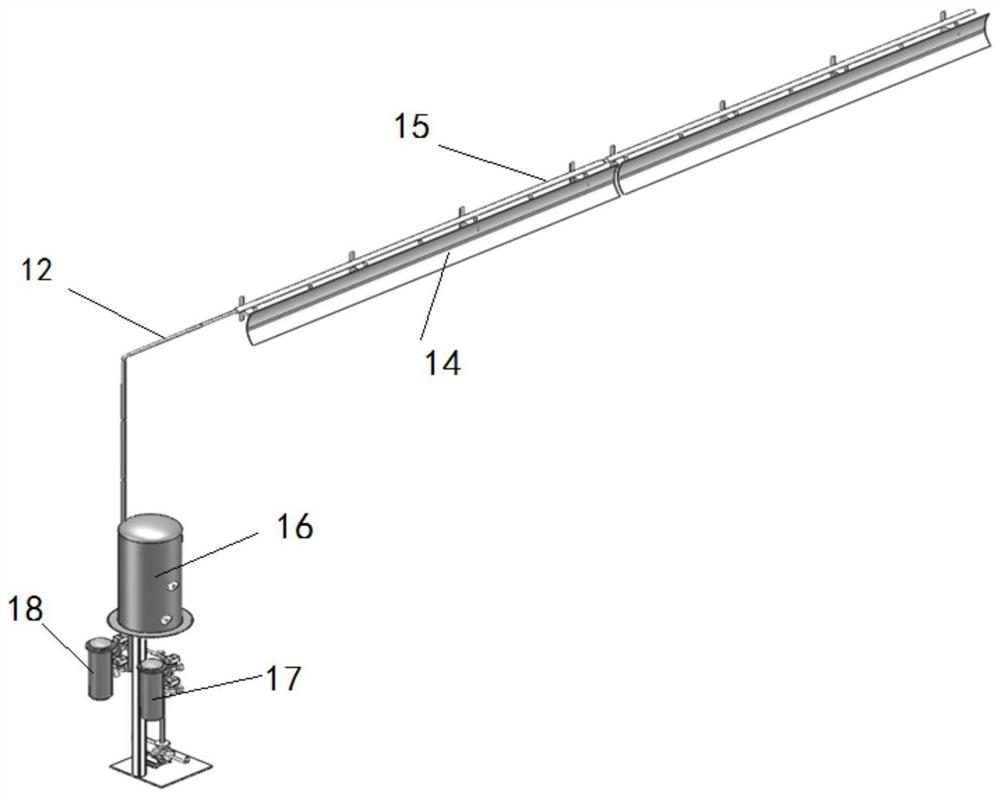

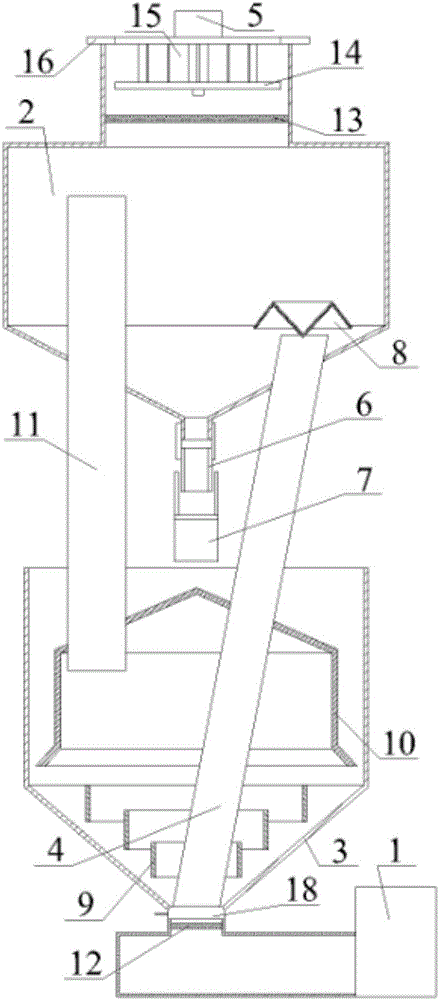

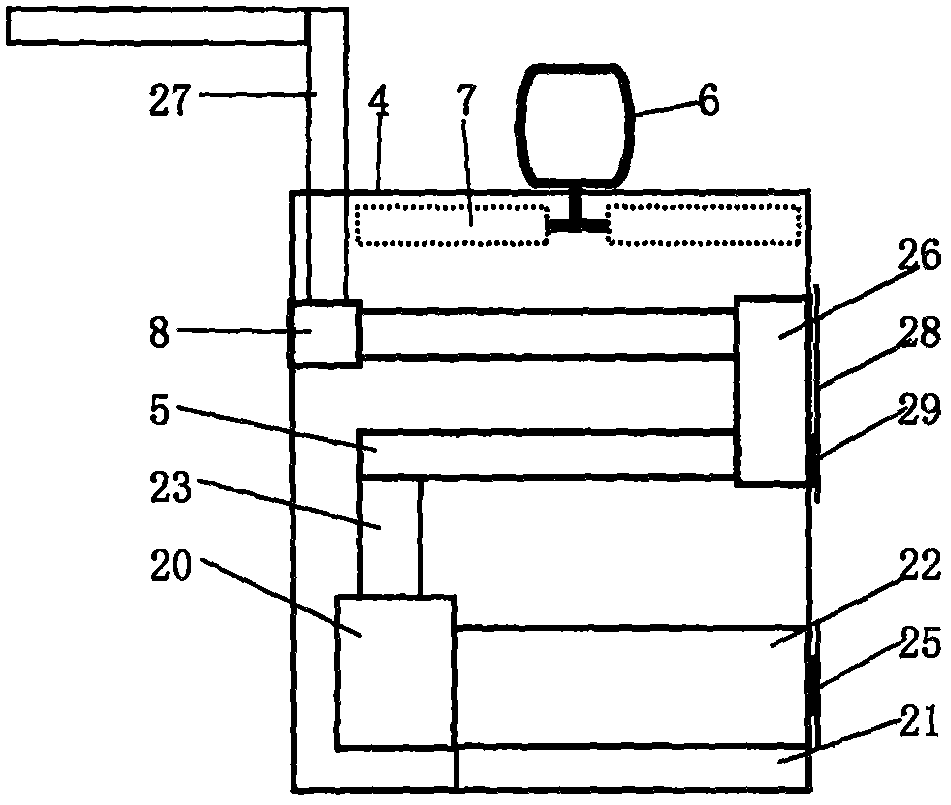

Jet evaporation vapor phase drying equipment

PendingCN111829298AImprove drying process efficiencyPrevent the core from rustingDrying solid materials without heatDrying gas arrangementsTransformerEngineering

The embodiment of the invention discloses jet evaporation vapor phase drying equipment. The jet evaporation vapor phase drying equipment comprises an evaporator module. The evaporator module is arranged outside a vacuum tank. The evaporator module adopts a plate type heat exchanger to realize heating and evaporation treatment of a liquid solvent, so that the liquid solvent reaches an over-heat supersaturated state, the liquid solvent enters the vacuum tank through a main spray pipeline and is sprayed out from a plurality of preset nozzles, jet evaporation is formed, and a transformer in the tank is heated; and venturi baffles are arranged at the front portions of the nozzles. By the adoption of the jet evaporation vapor phase drying equipment, the drying treatment efficiency of transformerproducts is improved, the drying time is shortened, the energy consumption is reduced, and meanwhile, the adopted plate type heat exchanger is small in size and higher in heating efficiency.

Owner:沈阳诚桥真空设备有限公司

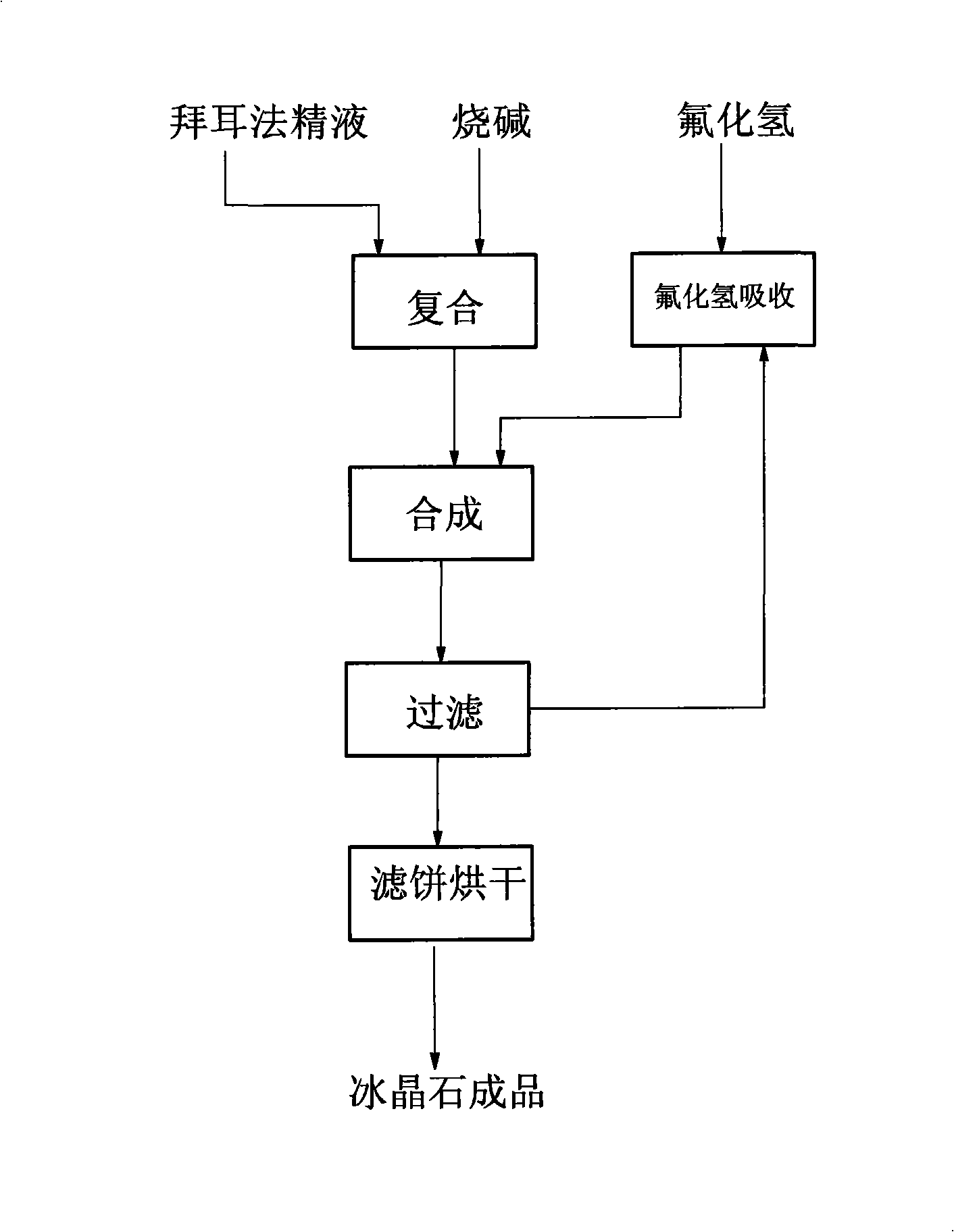

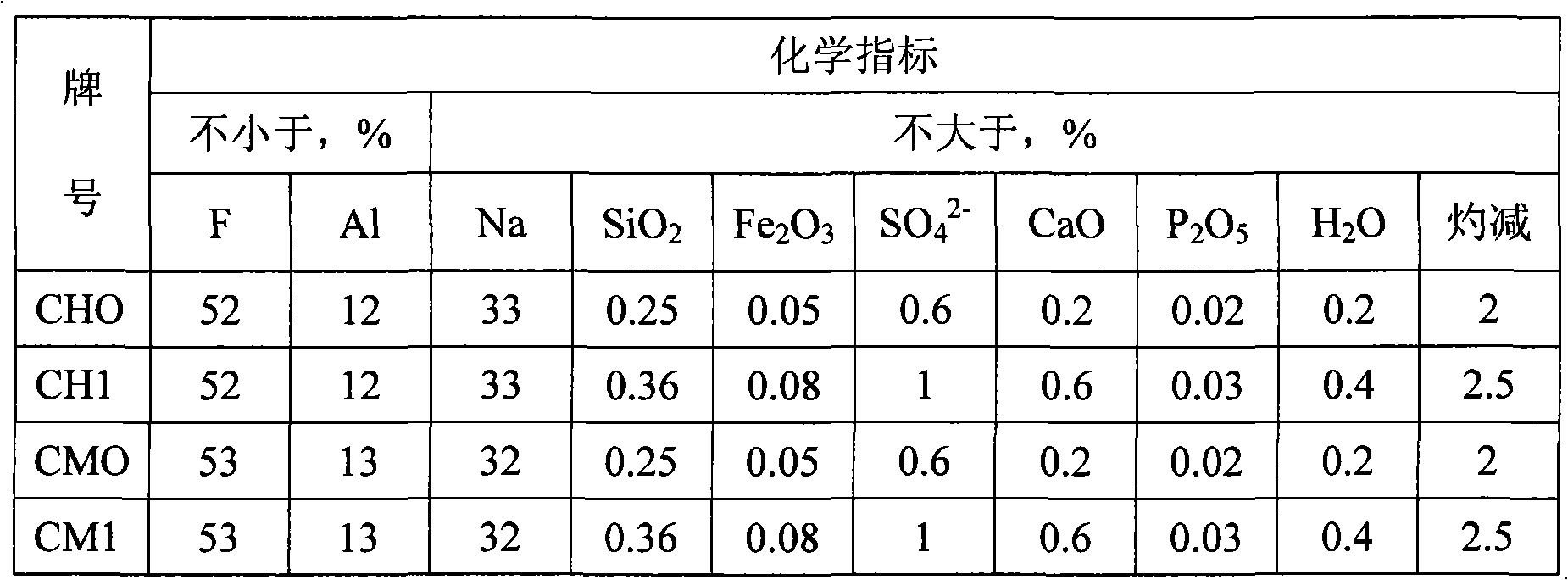

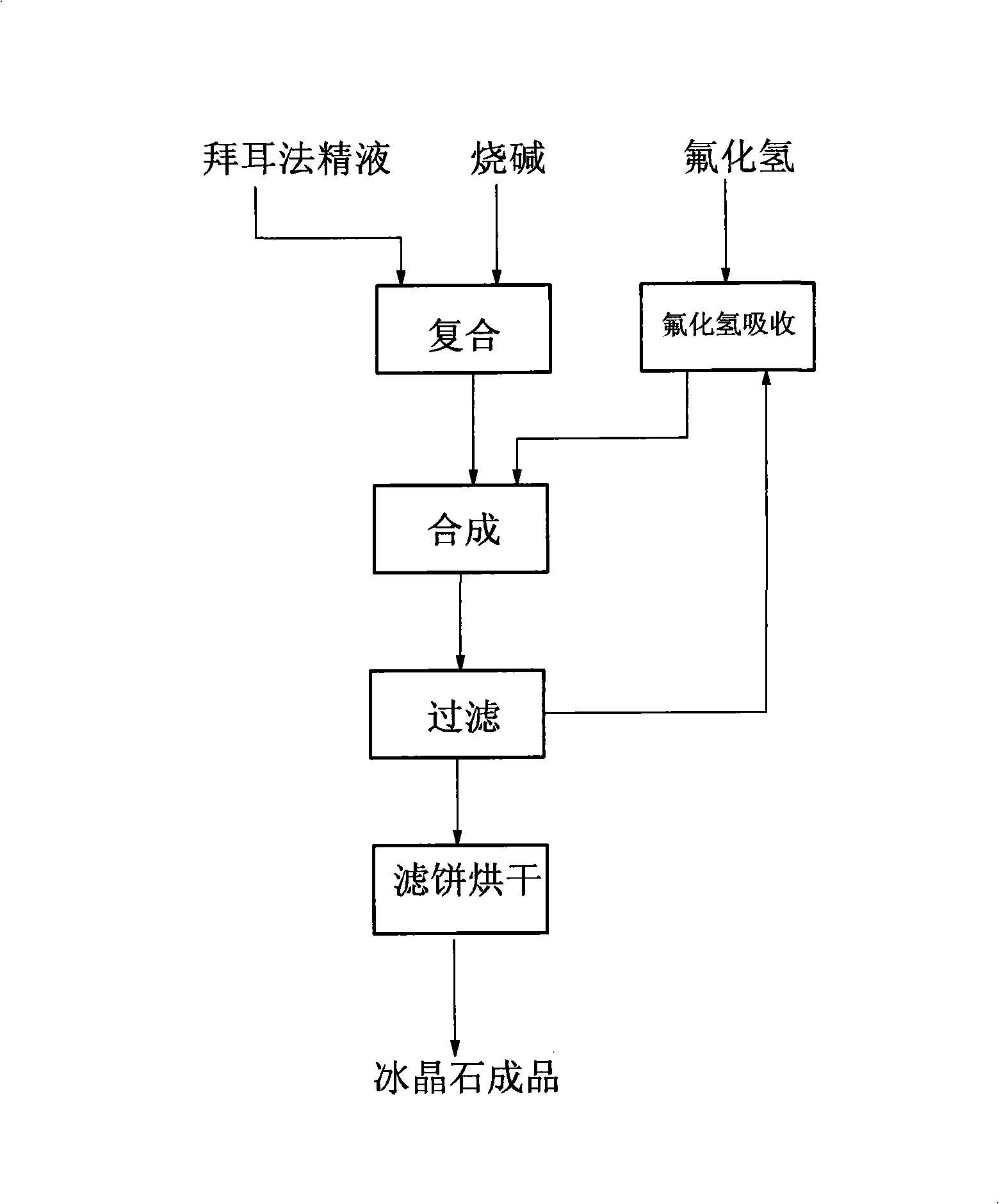

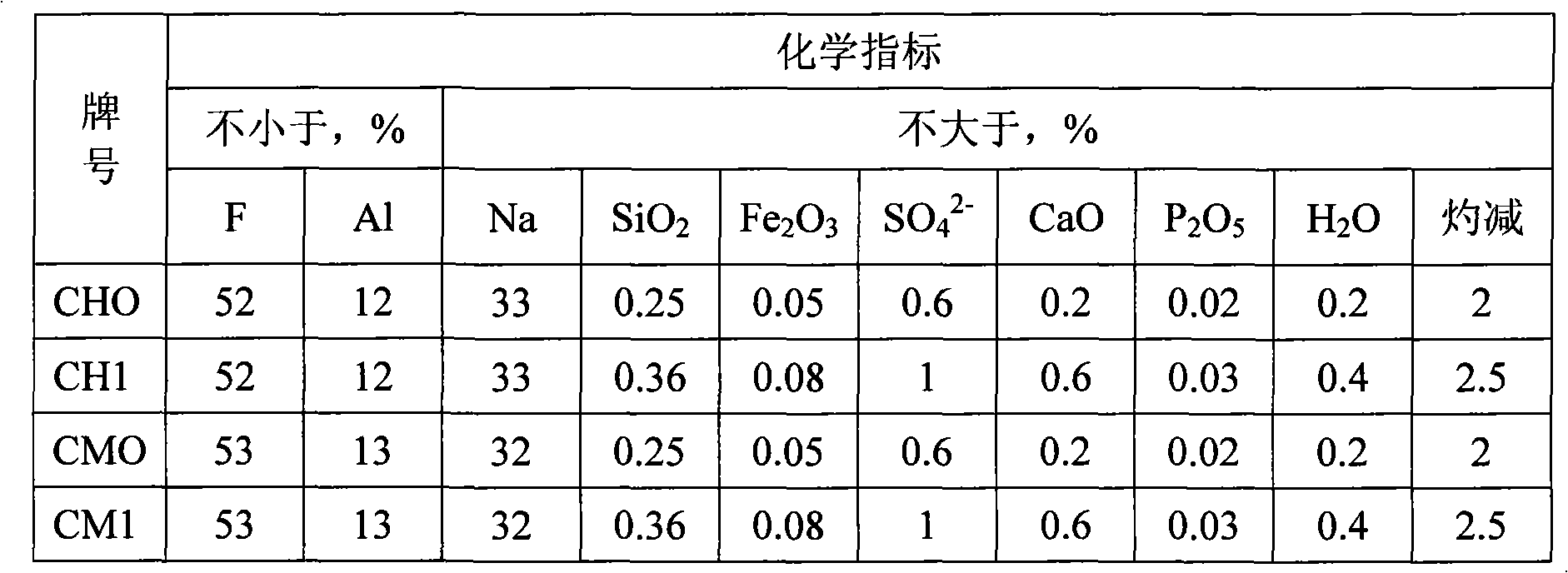

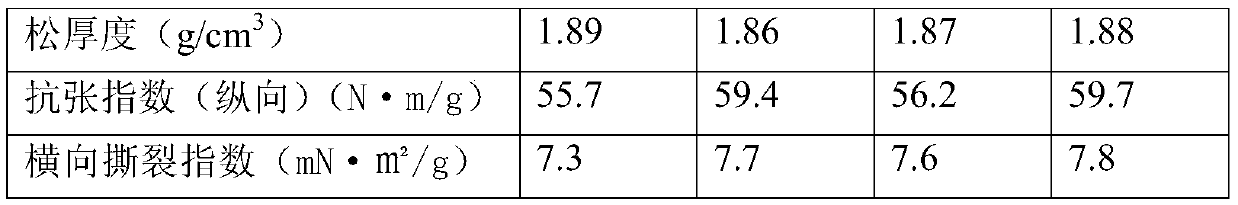

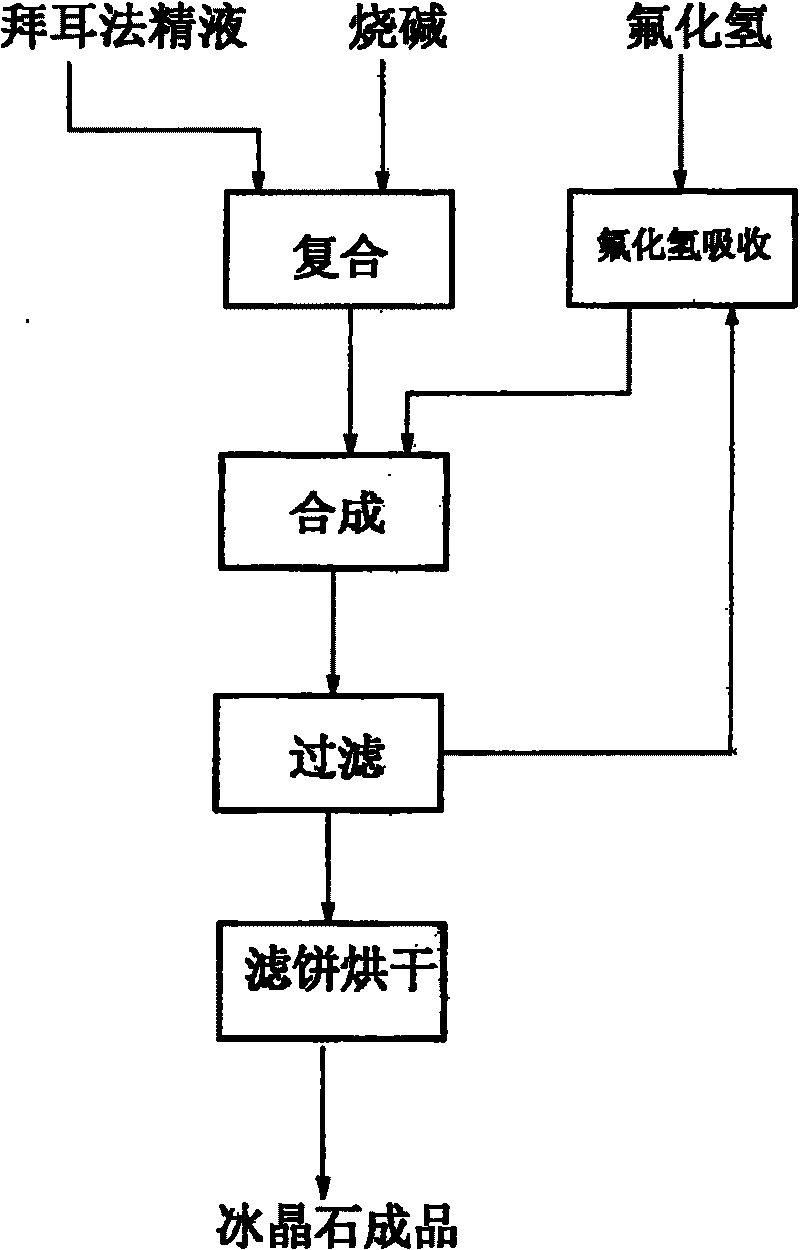

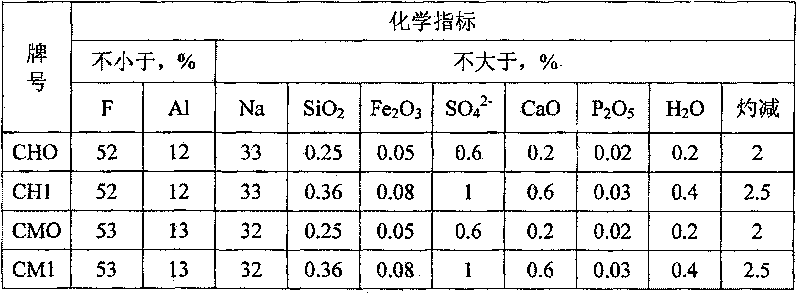

Method for producing ultra-fine cryolite

InactiveCN101264918AMolecular ratio adjustableMeet the needs of developmentAluminium fluoridesHydrofluoric acidRoom temperature

The invention discloses a production method for a super fine cryolite, which is characterized in that Bayer process concentrate solution, caustic soda, and hydrofluoric acid are used as raw materials; wherein, caustic soda is added into the Bayer process concentrate solution to obtain complex liquid, which is then added into a synthesis tank together with hydrofluoric acid for reaction, the reaction temperature is 40 to 60 DEG C, and the Ph value is larger than or equal to 10; after adding the materials, ageing is conducted for 20 to 30 minutes; subsequently, after filtering, the filter cake is dried under the temperature of 150 to 300 DEG C until the water content drops below, thus acquiring the finished cryolite. The production method has the advantages that: as the production method is carried out under normal temperature, the process is simple and easy to operate and control; and the heat source comes from heat of reaction, the need for adding a heating apparatus is obviated; by adjusting the parameter like reaction temperature, pH value and the ageing time, the product grain size D 50 is controlled within the range of 1 to 5 Mu m, and shows a desirable normal distribution; the molecular ration of NaF to AlF3 in the product is adjustable between 1.7 and 2.9; the production cost is pretty low yet with little pollution, and the treatment of three wastes, namely, wastewater, waste gas and waste residue, thus facilitating the environmental protection.

Owner:河南未来铝业(集团)有限公司

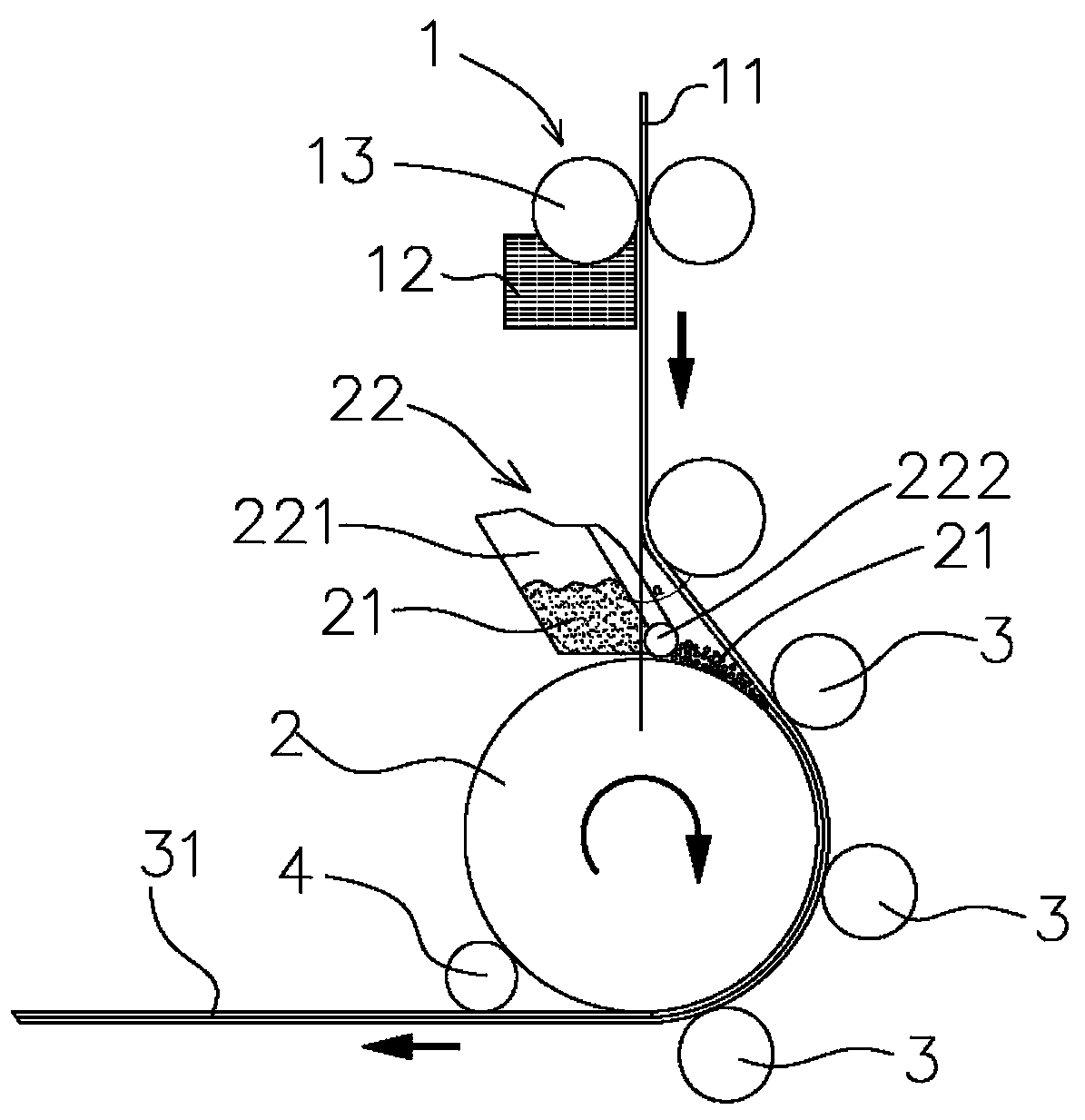

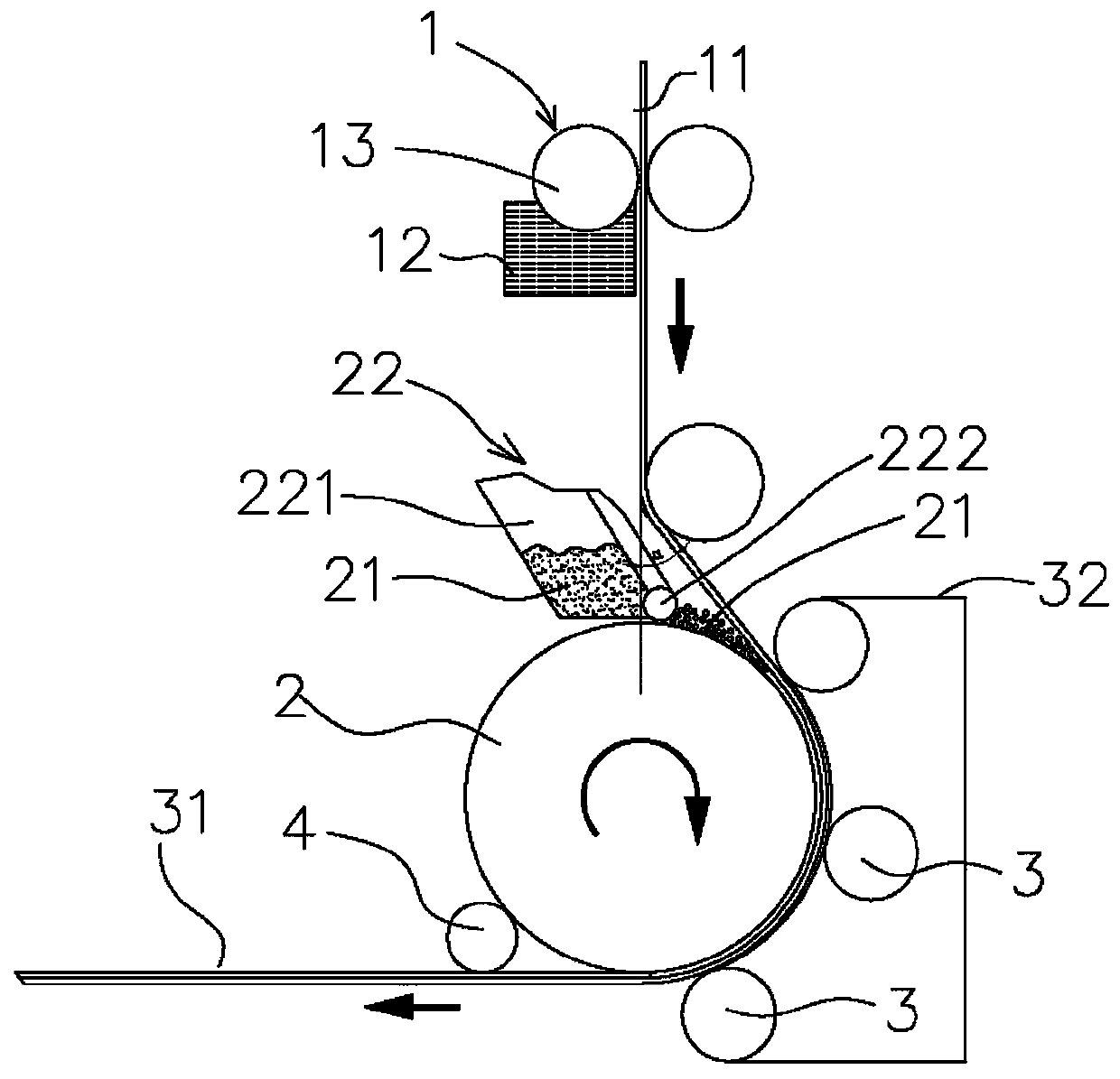

Dry powder thermal compounding transferring and coating method and system

PendingCN107681111AUniform thicknessReduce pollutionElectrode thermal treatmentElectrode collector coatingSolventCurrent collector

The invention discloses a dry powder thermal compounding transferring and coating method and system. The system comprises a powder transferring apparatus and a thermal curing apparatus, wherein a current collector partially coats the powder transferring apparatus; the powder transferring apparatus feeds mixture powder to the coating inlet of the current collector and the powder transferring apparatus; the mixture powder at least comprises a positive electrode active material or a negative electrode active material, and a viscous material; and the thermal curing apparatus is used for heating the thermal viscous material to enable the viscous material and other materials in the mixture powder to be cured into an integrated body so as to form a mixture layer on the current collector. By virtue of the dry powder thermal compounding transferring and coating method and system, the mixture powder does not scatter, so that the formed mixture layer has the advantage of uniform thickness; and meanwhile, any solvent is not needed, so that environmental pollution caused by the solvent can be avoided, the solvent is saved and cost of drying the solvent can be reduced.

Owner:SHENZHEN XINYUREN TECH

Combination preparation method for anhydrous magnesium chloride and potassium sulphate

ActiveCN101121536AStrongly corrosiveEasy to operateMagnesium chloridesAlkali metal sulfites/sulfatesOleumSulfate

The present invention provides a combined preparation method of a waterless magnesium chloride and a potassium sulfate and meanwhile produces a hydrochloride. The technic proposal is that a hexahydrated magnesium chloride (MgCl2 question mark 6H2O) is dehydrated to a dihydrated magnesium chloride. A hydrogen chloride dry gas is dried and dehydrated to a waterless magnesium chloride in a fluidized bed. The second step is that after a heat transfer, a dehydrated hydrogen chloride tail gas enters into a drying tower of a concentrated sulfuric acid and an oleum and the tail gas is dehydrated. The dried hydrogen chloride is recycled. After absorbing the water, a dilute sulfuric acid enters into a sulfate production device to absorb a sulfur trioxide again and becomes the concentrated sulfuric acid. The redundant dilute sulfuric acid enters into a Mannheim device to produce a potassium sulfate and the produced hydrogen chloride produces the hydrochloride after being cleansed. The technology producing the waterless magnesium chloride, provided by the present invention, has the advantages of low cost, good quality, high purity quotient, low energy consumption and little environmental pollution.

Owner:HANGZHOU HI TECH FINE CHEM

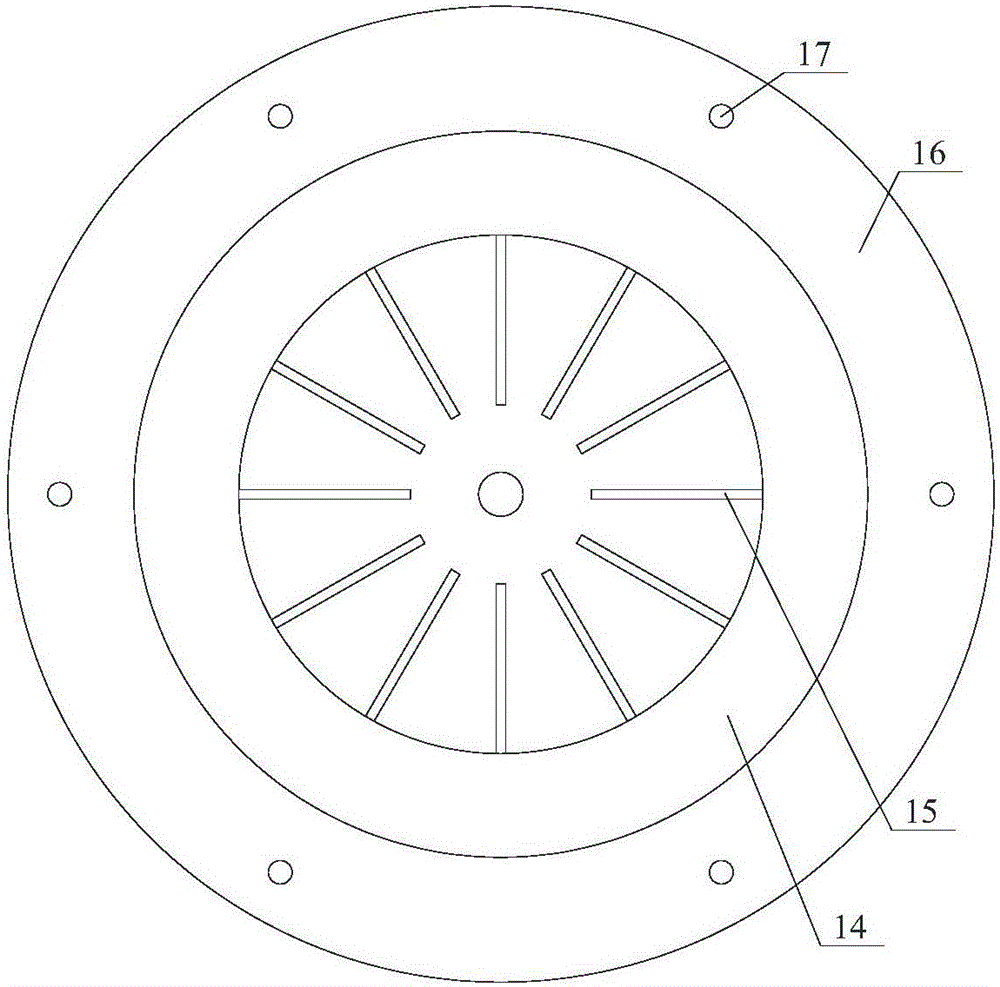

Pneumatic circulating grain drier

ActiveCN105918454APrevent mildewPrevent the situationSeed preservation by dryingFood dryingGrain storageAgricultural engineering

The invention discloses a pneumatic circulating grain drier and belongs to the technical field of drying equipment. A louver board is fixedly connected with a lower grain storage room; a hollow cavity between the louver board and a funnel-shaped structure is a distribution cavity; the hollow structure of the louver board forms an air inlet cavity which communicates with a hot air outlet of a heat source; a drying grain ascending tube passes through the air inlet cavity and reaches to the lower part of the louver board to form a feeding air inlet; the upper end of the drying grain ascending tube is located in an upper separation room; a coaxially arranged weather cap is arranged at the upper part of the drying grain ascending tube; a channel is reserved between the weather cap and the drying grain ascending tube to form a discharge air outlet; and the drying grain ascending tube forms a drying channel by virtue of a fan arranged at the top part of the upper separation room. The grain and hot air are in direct and full contact in the ascending process, so that the grain is dried; the drying effect is good by medium-free suction-type drying; the uniformity is good; the conditions of deterioration such as mildew and sprout of the grain in the links of storage, transportation, processing and the like can be effectively prevented; and the pneumatic circulating grain drier is simple in structure, convenient and fast to use, time-saving and labor-saving.

Owner:河北皓凯农业机械有限公司

Device and method for treating coking wastewater by utilizing blast furnace slag

ActiveCN106966446AReduce processing costsIncrease vitrification rateWater contaminantsWater/sewage treatmentCircular discSlag

The invention discloses a device and method for treating coking wastewater by utilizing blast furnace slag. The device comprises a first convex disc, a second convex disc, a first pipeline and a second pipeline. The first convex disc is hollow, the upper surface is provided with a plurality of coking wastewater spraying holes, the second convex disc is hollow, and the upper surface is provided with a plurality of cooling air spraying holes. The first convex disc is arranged on the second convex disc, and the first convex disc is smaller than the second convex disc in diameter. One end of the second pipeline is fixedly connected with the center of the bottom of the second convex disc, and the first pipeline penetrates through the second pipeline and the second convex disc to be fixedly connected with the center of the bottom of the first convex disc. A coking wastewater flow channel is formed in the first pipeline and is communicated with the coking wastewater spraying holes through the hollow inside of the first convex disc. A cooling air flow channel is formed between the inner surface of the second pipeline and the outer surface of the first pipeline.

Owner:SHANDONG IRON & STEEL CO LTD

Method for preparing dry powder polycarboxylate superplasticizer

The invention discloses a method for preparing a dry powder polycarboxylate superplasticizer. The method comprises the steps of 1, taking polycarboxylic acid mother solution with the solid content of 65-80%; 2, adding an additive to the polycarboxylic acid mother solution for dehydration with the extraction method; 3, conducting vacuum dehydration on the solution obtained in the step 2, so that the dry powder polycarboxylate superplasticizer is obtained. Anhydrous sodium sulphate aqueous solution separated out in the process can be recycled after concentration and drying. Dry powder polycarboxylate is dried through spraying currently, operation cost is high, however, by the adoption of the method, drying cost can be reduced by about 30% according to preliminary calculation, and energy consumption can be reduced greatly.

Owner:南京友西科技集团股份有限公司

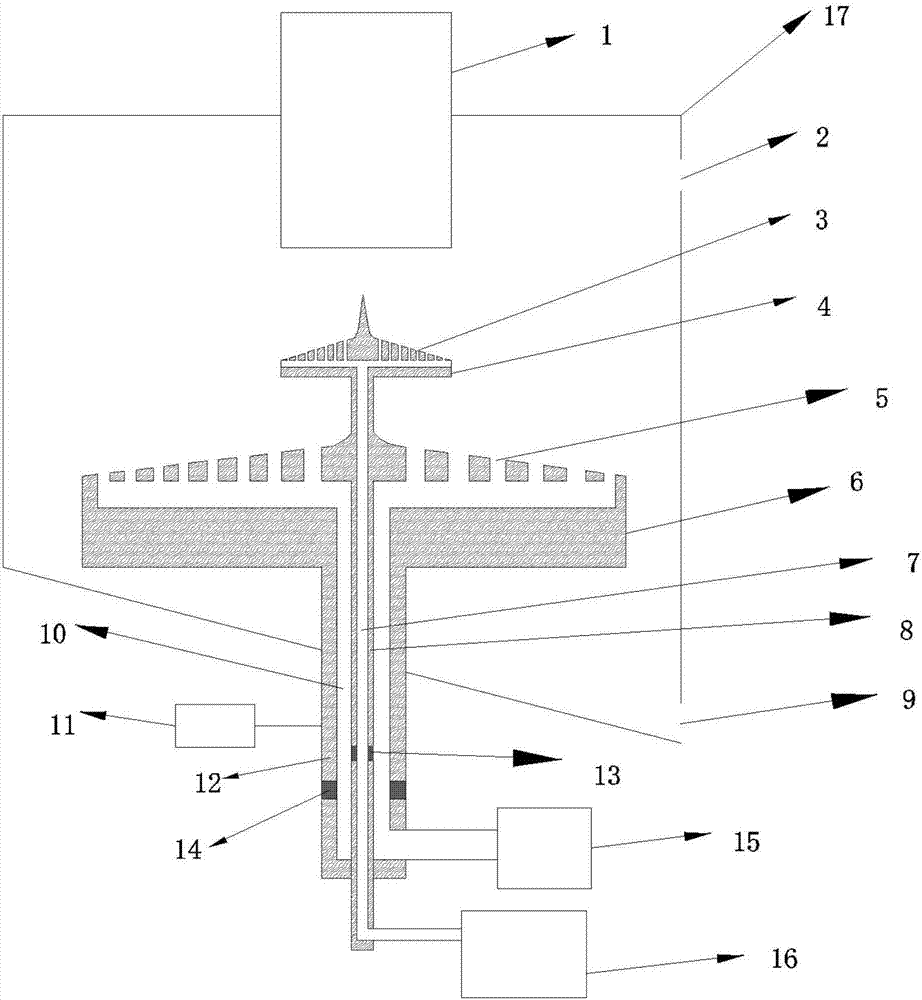

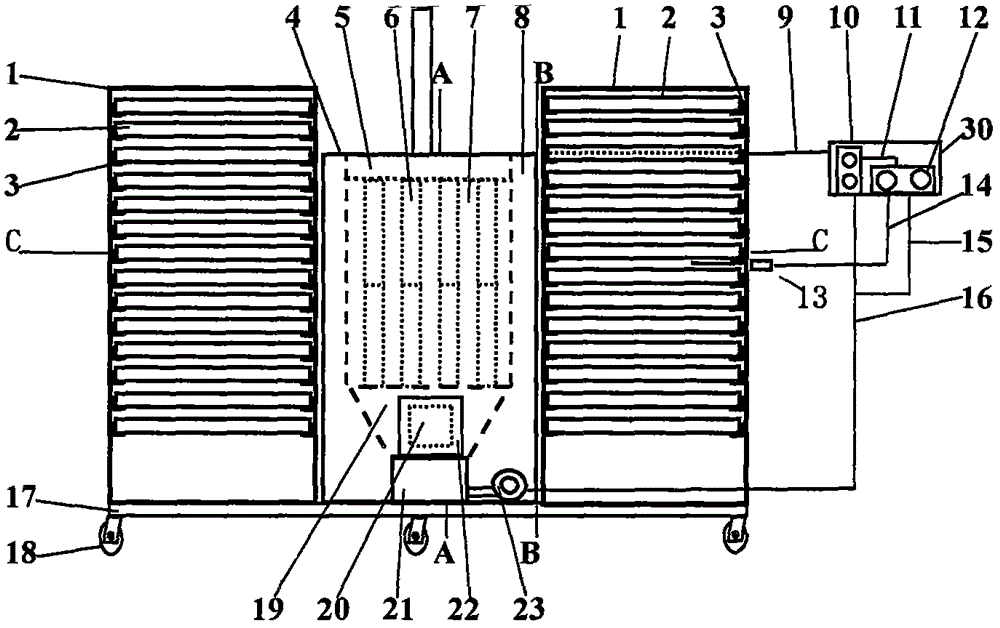

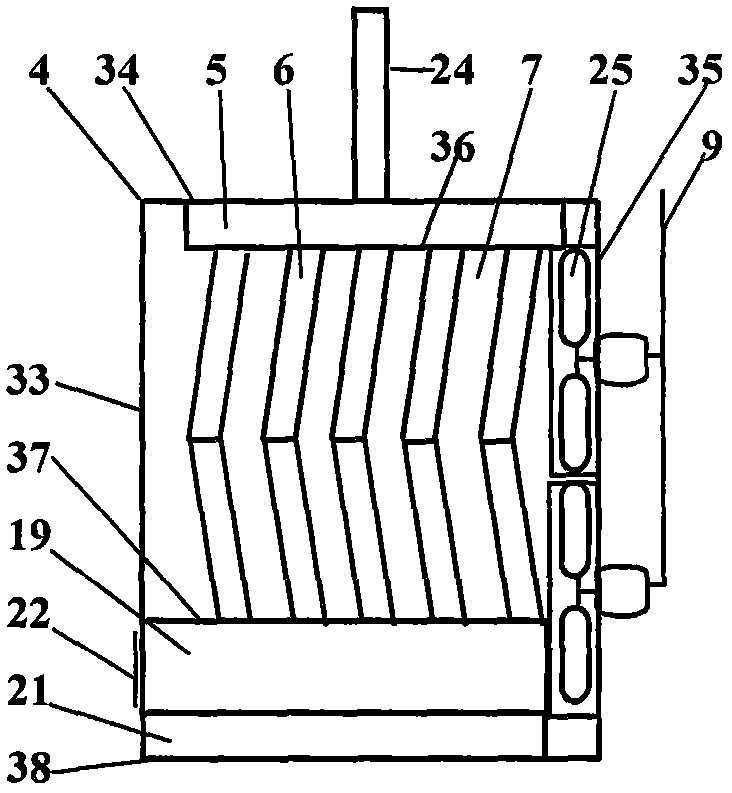

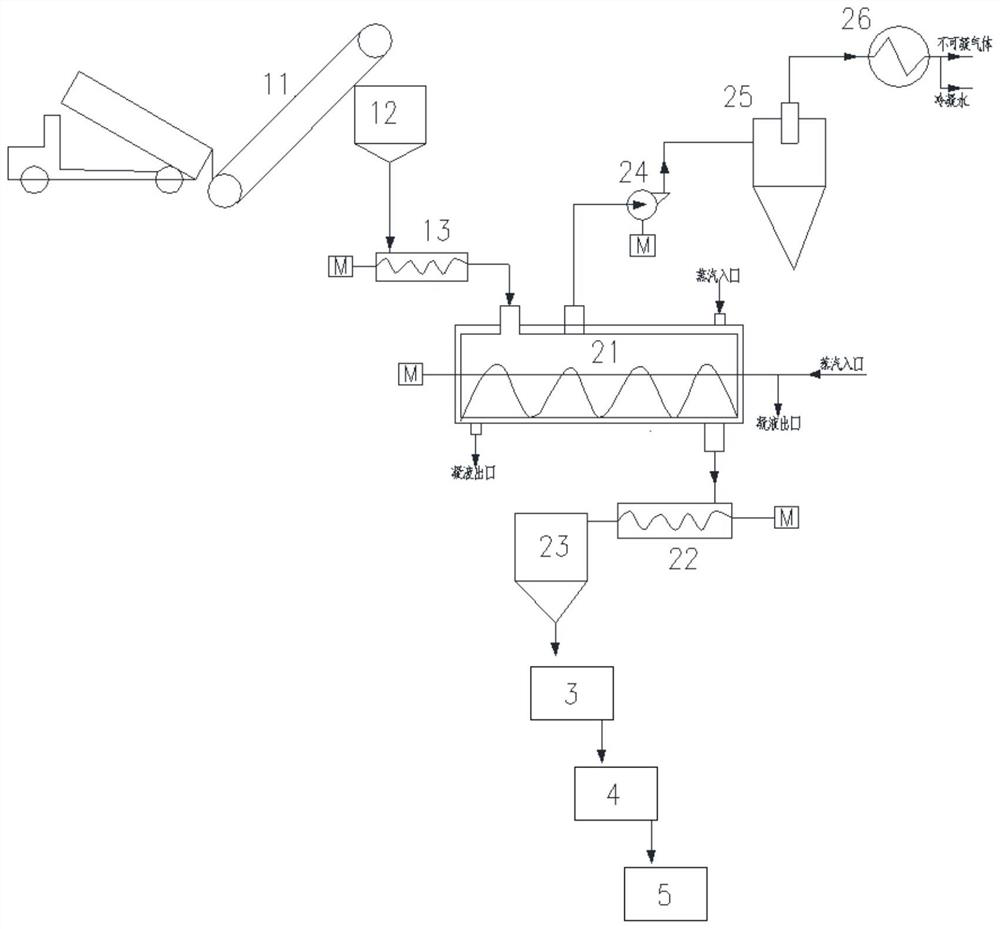

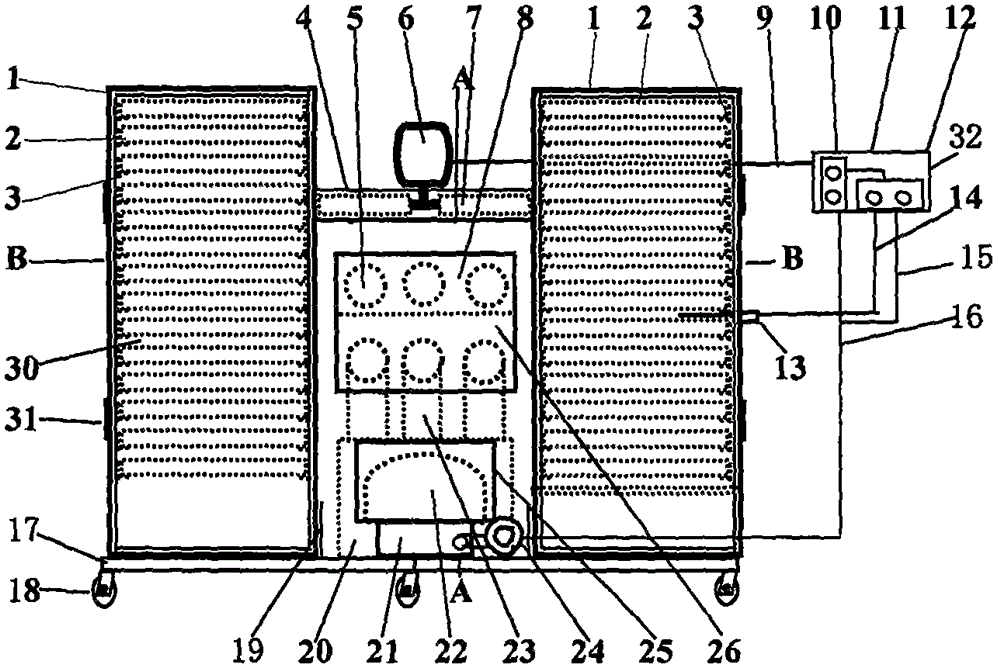

Integrated vertical cabinet type drying machine of coal firing stove with rear fan and hot blast stove

InactiveCN105865190AEasy to moveLow costDrying gas arrangementsDrying machines with local agitationTemperature controlCombustion chamber

In the present invention, a vertical cabinet dryer integrating a coal-fired stove with a fan behind and a hot blast stove is composed of five parts: a drying box, a hot blast stove, a coal heating device, an automatic temperature controller, and a movable bottom frame; the drying box consists of five parts: Drying box 1, drying box door 31 and other five parts; hot blast stove cube shape, 150 centimeters high, 100 centimeters wide on four sides, consists of hot blast stove body 4, hot blast stove hot air channel 7, hot blast stove hot blast diversion channel 26, hot blast Furnace air mixing chamber 8, hot air entering the drying box channel 27 in the air mixing chamber, left and right inner steel plates 28 of the hot blast stove, left and right outer steel plates 29 of the hot blast stove and other 15 parts; Room 19, coal-fired stove fire tube 6, blower 23, blower power cord 16 and other nine parts; the automatic temperature control device is composed of seven parts such as instrument box 30, automatic temperature controller 12; Frame 17 and steering wheel 18 form.

Owner:HANCHENG QINLONG PEPPER TECH

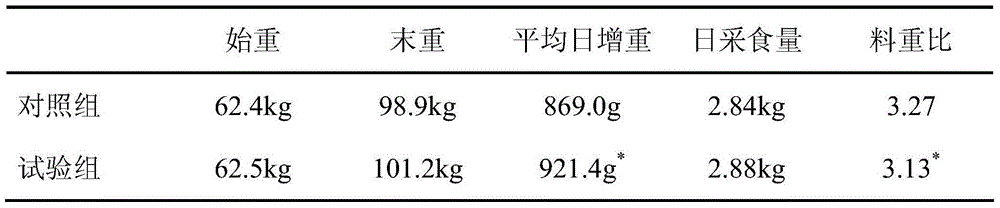

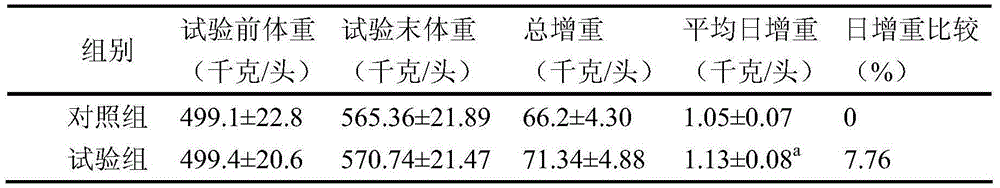

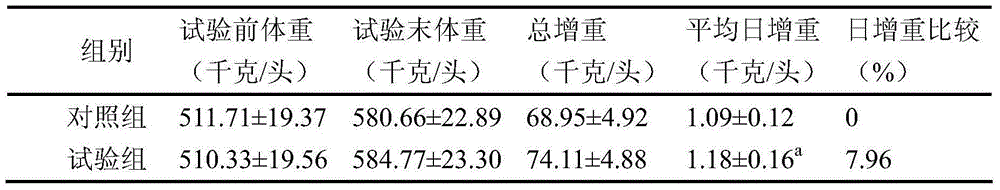

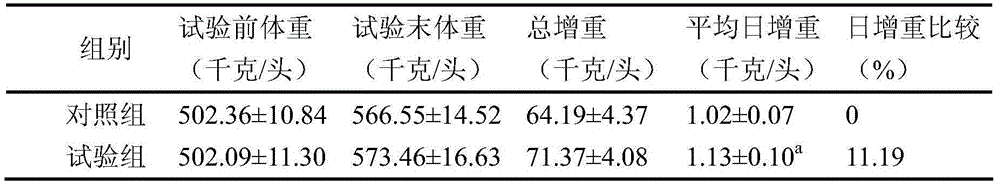

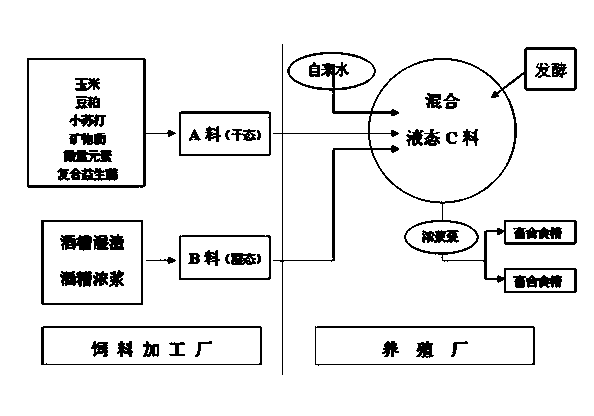

Use of wet fermented protein feed in high-efficiency mutton sheep fattening technology

InactiveCN103766619ASave on drying costsMeet low-carbon requirementsFood processingAnimal feeding stuffSodium bicarbonateVinasse

The invention relates a use of wet fermented protein feed in a high-efficiency mutton sheep fattening technology and especially relates to a production technology of the wet fermented protein feed and a use method of the wet fermented protein feed in high-efficiency mutton sheep fattening. The production technology comprises the following steps of respectively crushing corn, soybean meal, sodium bicarbonate, mineral matters, trace elements and composite probiotics, mixing the crushed materials according to a certain ratio, putting the mixture into a bag, mixing wet vinasse slag and dense vinasse slurry according to a certain ratio, carrying out seal preservation, wherein the shelf life is more than 6 months, mixing the above two materials according to a mass ratio of 1: 4, adding water into the mixture, adjusting a pH value of the mixture to 6-7, and carrying out standing fermentation for 4-8h to obtain the wet fermented protein feed. 1.5-2kg of the wet fermented protein feed is fed to the mutton sheep each day by 2 or 3 steps. In feeding, forage grass is used and then the mixed wet fermented protein feed is poured on the forage grass. The mutton sheep eats the forage grass mixture so that mutton sheep weight is increased according to a ratio of 0.4-0.5kg / d.

Owner:LUOYANG MUYUAN AUTOMATIC CONTROL EQUIP

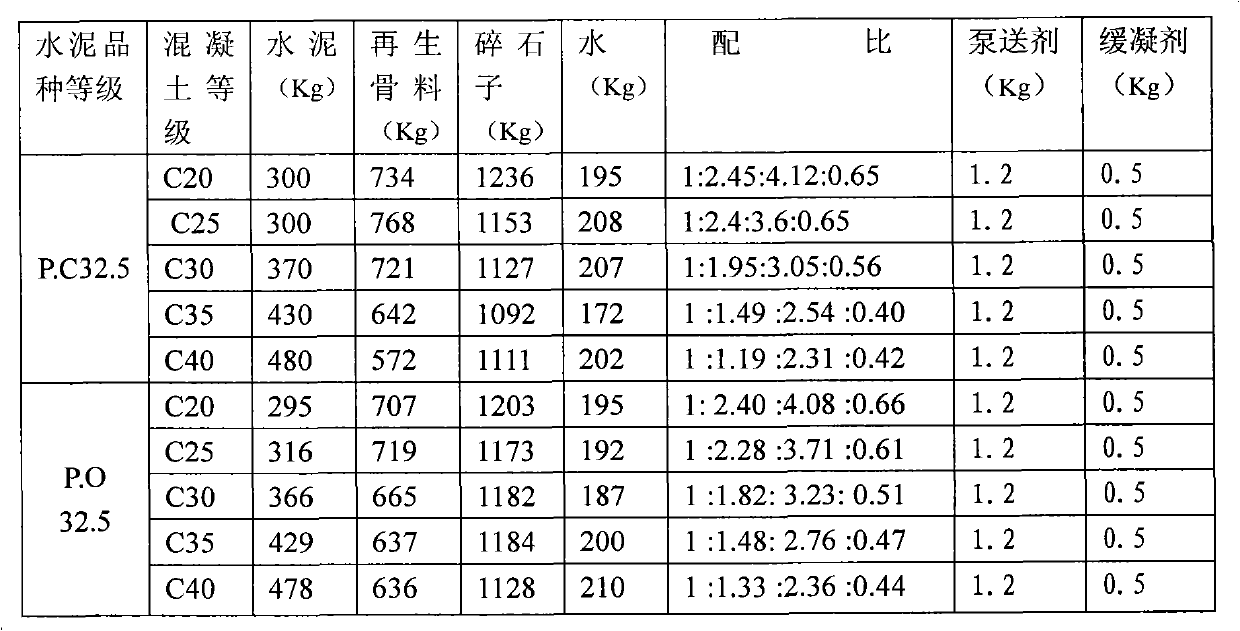

Recycled aggregate concrete preparation method

The invention discloses a recycled aggregate concrete preparation method and relates to the technical field of building raw materials. The method adopting the key technology of 'waste use' includes the steps: using building wastes such as waste concrete, waste bricks and waste lime-sand mortar which are smaller than 690mm in length as raw materials, determining the quantity of the raw materials as required, crushing and drying to enable moisture to be not more than 0.5% prior to gradational sieving, removing metal with magnets and removing wood dust, plastics and sundries according to the specific weight during gradational sieving so that recycled aggregates with the grain sizes of 0.3-0.6mm, 0.6-1.18mm, 1.18-2.36mm and 2.36-4.75mm are prepared, and then the recycled aggregates are mixed with broken stones, cement, pumping agents, retarders and water according to scientific proportion so that the recycled aggregate concrete of various grades in each recycled aggregate concrete model series is prepared. The recycled aggregate concrete is used as the building raw materials. The recycled aggregate concrete preparation method has the advantages that natural resources are protected, labor and time are saved, cost is low, wastes are turned to wealth, the requirements of low-carbon production and low-carbon life are met, and the method makes contributions to sustainable development.

Owner:伏开磊 +1

Method for producing large grain size cryolite

InactiveCN101264917AMolecular ratio adjustableMeet the needs of developmentAluminium fluoridesHydrofluoric acidReaction temperature

The invention discloses a production method for a large grain size cryolite, which is characterized in that Bayer process concentrate solution, caustic soda, and hydrofluoric acid are used as raw materials, and the proportion of raw materials is represented in the equation that Al: Na: F equals to 1:1.8-3:5-6; when compounding, the caustic soda is added into the Bayer process concentrate solution with a temperature of 90-95 DEG C, and mixed evenly to obtain the composite solution; then, the composite solution and hydrofluoric acid are gradually added into a synthesis tank, and the material feeding and agitation are carried out in the meantime, the reaction temperature is maintained between 85 and 95 DEG C, and the PH value of the reaction solution is smaller than or equal to 2; after feeding materials, the mixture undergoes an ageing process for 20 to 30 minutes; finally, the slurry is filtered, the filter cake is dried until the water content drops below 0.2%, thus acquiring the finished cryolite. The production method has the advantages that: as wet method is adopted during the production, the reaction is conducted under normal temperature, the process is simple, and easy to operate and control; the heat source is derived from the reaction heat, and the need to add a heating apparatus is avoided; by adjusting the parameters, such as the reaction temperature, PH value and ageing time, the product D50 grain size can be increased by more than 10 Mu m compared with the prior art up to 26-30 Mu m; the molecular ratio of NaF to AlF3 is adjustable, thus meeting the demands of electrolytic aluminum industry.

Owner:河南未来铝业(集团)有限公司

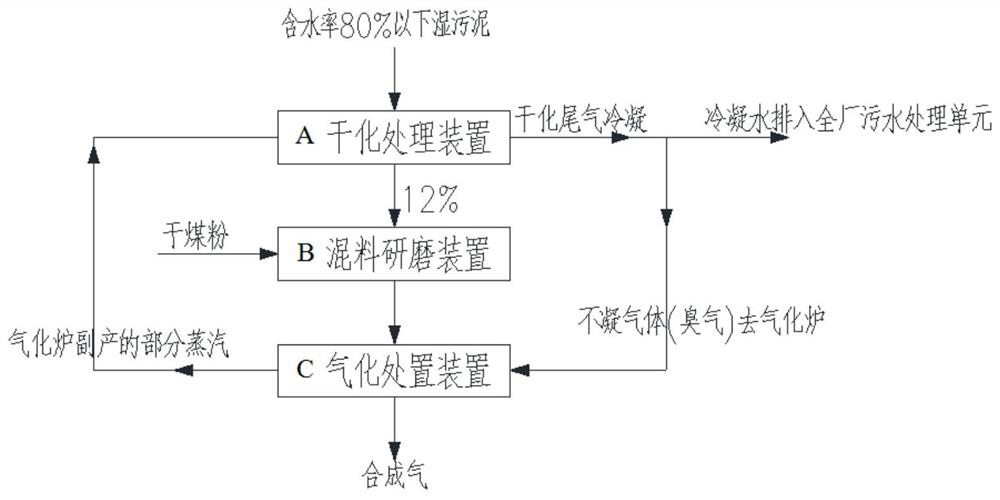

Sludge treatment system

PendingCN112723687AImprove gasification efficiencySave drying energy costsSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSyngasSludge

The invention discloses a sludge treatment system, which comprises a drying treatment device used for drying sludge, a mixed material grinding device used for mixing the dried sludge with pulverized coal to grind a mixed material, and a gasification treatment device used for gasifying the ground mixed material; the drying treatment device is provided with a discharge port, which is communicated with the feed port of the mixing and grinding device, and the discharge port of the mixing and grinding device is communicated with the inlet of the gasification treatment device. According to the system, the sludge is subjected to drying treatment to remove moisture in the sludge, so that the problem that the heat value of the sludge with high moisture content is low is solved, the sludge disposal amount of a gasification furnace is increased, the dried sludge and pulverized coal are co-gasified by utilizing a mature dry pulverized coal gasification furnace, new disposal equipment is not needed, the sludge disposal cost and the operation cost are reduced, and synthesis gas with high combustible components is generated; the sludge treatment system can be used for synthesizing chemicals or used as clean fuel gas while the gasified residues and other inorganic matters can be used for making bricks, and the resource utilization rate is high.

Owner:CHANGZHENG ENG

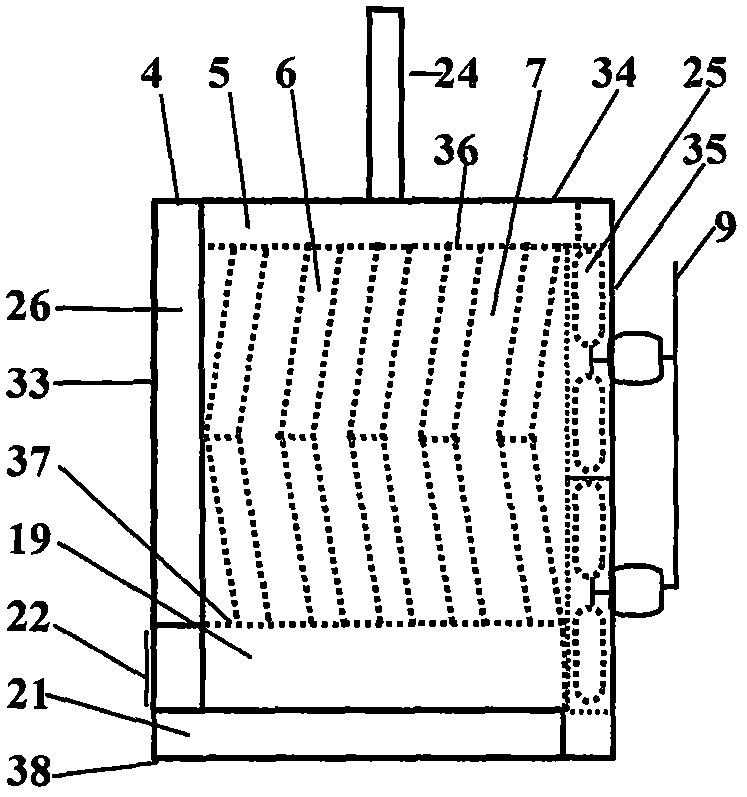

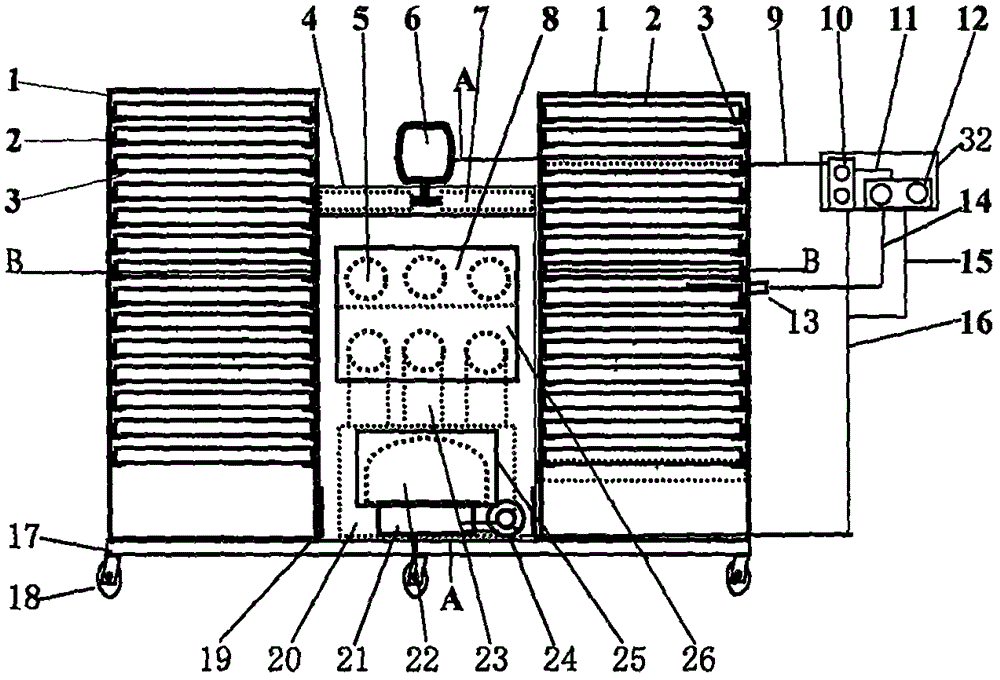

Coal burning stove and hot blast heater integral vertical cabinet type dryer with fan arranged on upper portion

InactiveCN105698501AEasy to moveLow costDrying gas arrangementsDrying machines with local agitationTemperature controlEngineering

The invention discloses a coal burning stove and hot blast heater integral vertical cabinet type dryer with a fan arranged on the upper portion. The dryer is composed of drying bakers, a hot blast heater, a coal heating device, an automatic temperature control instrument and a turnable moving bottom frame. Each drying baker is composed of a drying baker body 1, a drying baker door 3, baker door hinges 31, drying trays 2, drying tray supports 3 and the like. The hot blast heater is in a cube shape and is 150 cm high, the four sides of the hot blast heater are 90 cm wide, and the hot blast heater is composed of six parts such as a hot blast heater body 4, the electric fan 7, an electric fan power line 8, hot blast heater hot blast channels 33 and a hot blast heater blast control door 19. The coal heating device is composed of thirteen parts such as a coal burning stove burning chamber 20, a blast blower 21, a blast blower power line 16, a coal burning stove heat power distribution chamber 20, a heat power distribution chamber vertical distribution pipe 23, an upper row of heat power distribution chamber straight heat power pipes 5, a lower row of heat power distribution chamber straight heat power pipes 5 and a straight heat power pipe heat power reversing chamber 26. The automatic temperature control instrument is composed of seven parts such as an instrument box 32 and an automatic temperature control instrument body 12. The turnable moving drying baker bottom frame is composed of a bottom frame body 17 and turnable wheels 18.

Owner:HANCHENG QINLONG PEPPER TECH

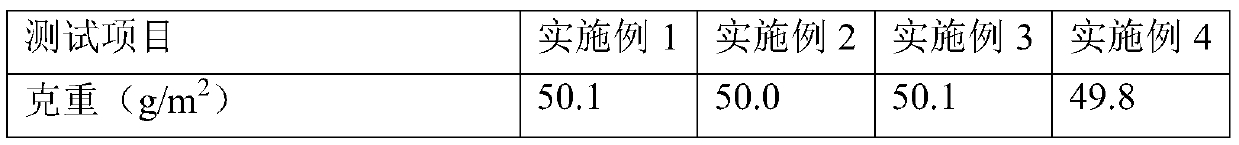

Low-gram-weight high-strength corrugated core paper and preparation process thereof

The invention relates to the field of papermaking and particularly relates to low-gram-weight high-strength corrugated core paper and a preparation process thereof. The paper is prepared from domesticwaste cardboard paper and a part of native American waste paper 8#. According to the process, the pulping process is improved, pulp residues needing to be incinerated originally are recycled, the production cost is reduced, and the low-gram-weight and high-strength corrugated core paper is obtained.

Owner:SHANDONG HUATAI PAPER

Method for producing large grain size cryolite

InactiveCN101264917BMolecular ratio adjustableMeet the needs of developmentAluminium fluoridesHydrofluoric acidRoom temperature

The invention discloses a production method for a large grain size cryolite, which is characterized in that Bayer process concentrate solution, caustic soda, and hydrofluoric acid are used as raw materials, and the proportion of raw materials is represented in the equation that Al: Na: F equals to 1:1.8-3:5-6; when compounding, the caustic soda is added into the Bayer process concentrate solutionwith a temperature of 90-95 DEG C, and mixed evenly to obtain the composite solution; then, the composite solution and hydrofluoric acid are gradually added into a synthesis tank, and the material feeding and agitation are carried out in the meantime, the reaction temperature is maintained between 85 and 95 DEG C, and the PH value of the reaction solution is smaller than or equal to 2; after feeding materials, the mixture undergoes an ageing process for 20 to 30 minutes; finally, the slurry is filtered, the filter cake is dried until the water content drops below 0.2%, thus acquiring the finished cryolite. The production method has the advantages that: as wet method is adopted during the production, the reaction is conducted under normal temperature, the process is simple, and easy to operate and control; the heat source is derived from the reaction heat, and the need to add a heating apparatus is avoided; by adjusting the parameters, such as the reaction temperature, PH value and ageing time, the product D50 grain size can be increased by more than 10 Mu m compared with the prior art up to 26-30 Mu m; the molecular ratio of NaF to AlF3 is adjustable, thus meeting the demands of electrolytic aluminum industry.

Owner:河南未来铝业(集团)有限公司

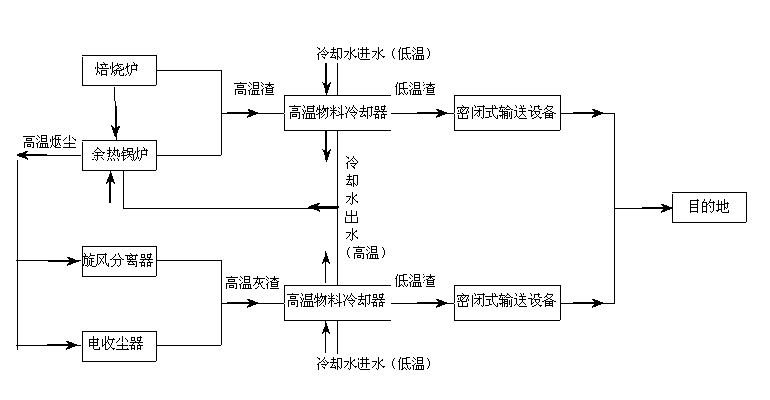

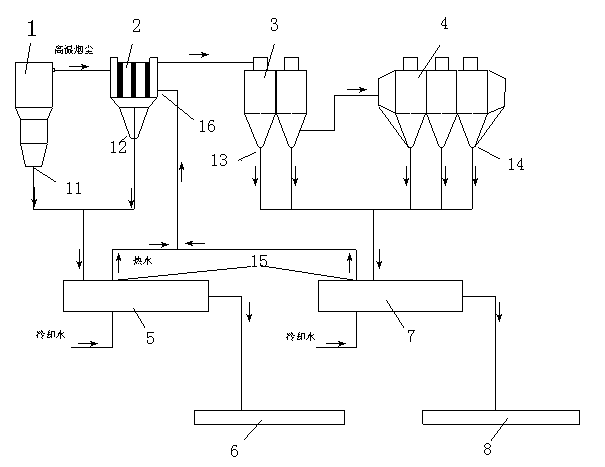

Residue discharge and heat recovery method of pyrite acid production and equipment system

ActiveCN102620574BSolving Recycling ProblemsAvoid environmental pollutionIncreasing energy efficiencyFeed-water heatersRecovery methodProcess engineering

The invention provides a residue discharge and heat recovery method of pyrite acid production and an equipment system for realizing the method. High-temperature dust-laden gas discharged from a roasting furnace is subjected to heat exchange of a waste heat boiler and dust collection and then is discharged; dust is collected through a cyclone separator and an electric dust collector in sequence; high-temperature ash residue discharged from the roasting furnace and the waste heat boiler is cooled through a first high-temperature material cooler; meanwhile, the high-temperature ash residue discharged from the cyclone separator and the electric dust collector is cooled through a second high-temperature material cooler; the cooled ash residue is conveyed to a destination by a closed conveying device to be reutilized; and meanwhile, cooling water heated by the high-temperature material coolers directly enters a deoxidation and water replenishing system of the waste heat boiler to fulfill the aim of heat recovery. According to the residue discharge and heat recovery method of pyrite acid production and the equipment system, environmental pollution produced by residue discharge treatment in a pyrite acid production process is reduced, and the residue discharge heat recovery and utilization rate can be efficiently increased.

Owner:江苏靖隆合金钢机械制造有限公司

Wet process preparation method of hydrophilic composite pigment

The invention provides a wet process preparation method of a hydrophilic composite pigment, comprising the steps: 'pigment paste' is sequentially compounded by kneading, dried, crushed and screened to obtain the products. The method saves the consumption of organic pigment, the power consumption and water loss, greatly reduces the noise, and improves the production environment of the operating workers.

Owner:SHANGHAI YIPIN PIGMENTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com