Coal burning stove and hot blast heater integral vertical cabinet type dryer with fan arranged on upper portion

A technology of a hot air stove and a vertical cabinet, which is applied in the field of processing and manufacturing of an integrated vertical cabinet dryer with a coal-fired stove on the fan and a hot air stove, which can solve the problems of loss of food and economic value, economic loss, and fruit moldy, etc., to achieve The effect of low drying cost, low cost and less land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

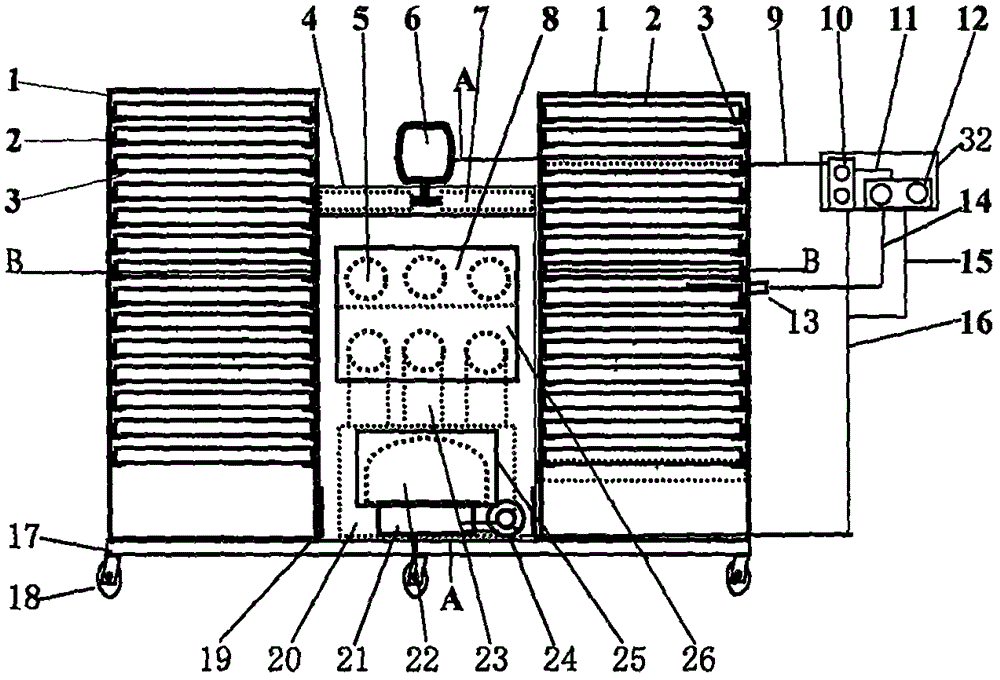

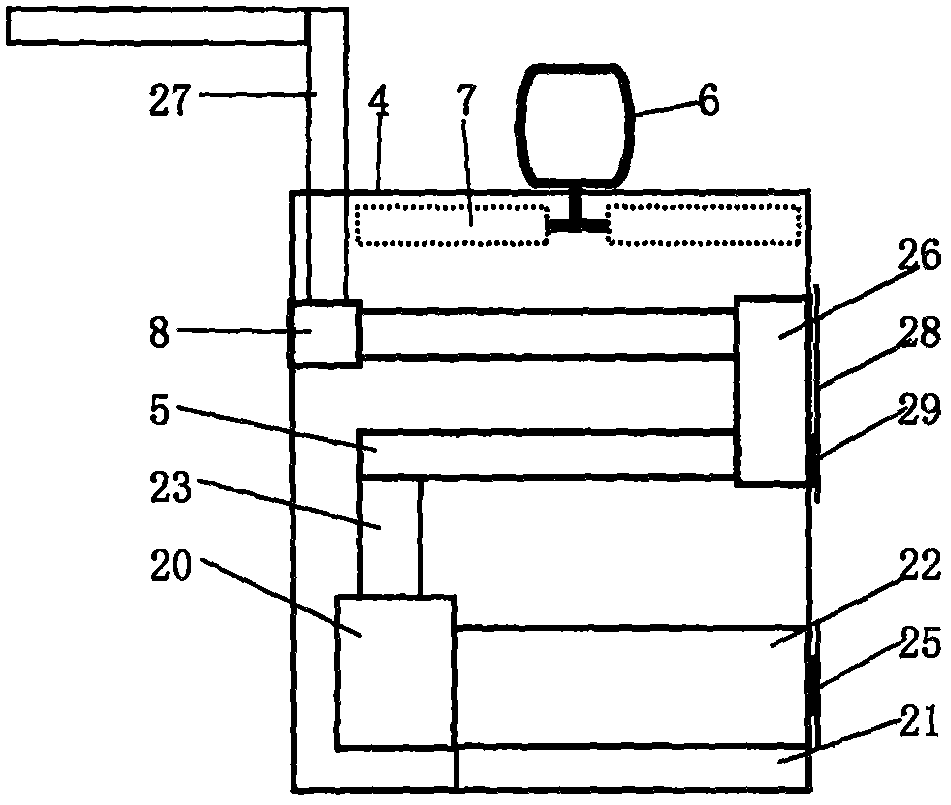

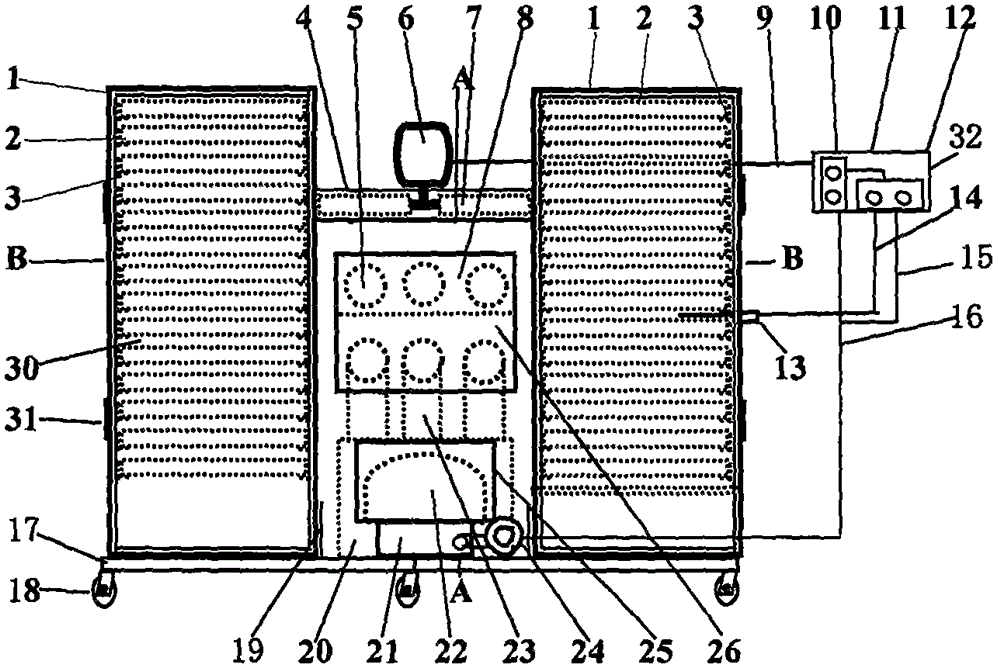

[0008] 1. A design of a vertical cabinet dryer integrating a coal-burning stove and a hot air stove with a fan above it, see the attached drawing of the manual.

[0009] 2. Purchase of raw materials

[0010] Raw materials are purchased according to the requirements of the design drawings. The finished parts mainly include: blower, power switch, automatic temperature controller, instrument box, electric fan, screws, iron nails, etc. The materials to be processed mainly include: 0.2-0.3 cm thick steel plate, diameter 10 Centimeter steel pipes, angle irons, wooden strips for drying boxes, wooden strips for drying pans, density boards, screens for drying pans, etc.

[0011] 3. Processing and installation of sub-components and devices

[0012](1) Manufacture of drying box: The drying box is composed of five parts: drying box body 1, drying box door 30, box door hinge 31, drying tray 2, and drying tray support 3; the drying box is vertical cabinet It is made of wooden strips and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com