Method for preparing dry powder polycarboxylate superplasticizer

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of preparation of dry powder polycarboxylic acid water reducing agent, can solve problems such as performance reduction, and achieve the effects of low cost, convenient source and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

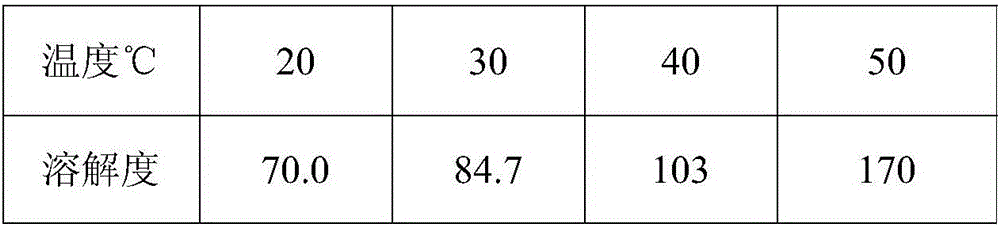

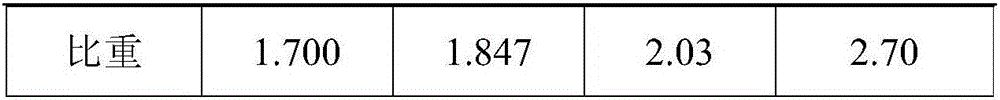

Embodiment 1

[0032] 8 tons of polycarboxylate mother liquor, the solid content is 65%, the temperature is 50 ℃, add 950Kg of sodium sulfate, stir to accelerate the dissolution of sodium sulfate, after standing, the system is layered, the upper layer is polycarboxylic acid, and the lower layer is aqueous solution of sodium sulfate , pump the upper layer of polycarboxylic acid into the vacuum drying system, the vacuum degree is 0.04-0.09MPa, and the moisture content of polycarboxylic acid particles is 0.8%. Reuse. Yuanming powder aqueous solution can also be used to compound early-strength superplasticizer products.

Embodiment 2

[0034] Synthesize 8 tons of polycarboxylic acid mother liquors, solid content is 75%, temperature is 40 ℃, add 750 kilograms of sodium sulfate, after stirring and standing, the system is layered, the upper layer is polycarboxylic acid, and the lower floor is aqueous solution of sodium sulfate, and then The upper layer of polycarboxylic acid is pumped into the vacuum drying system with a vacuum degree of 0.04-0.09MPa to obtain polycarboxylic acid particles with a moisture content of 0.7%. The polycarboxylic acid particles enter the crushing system for granulation. use.

Embodiment 3

[0036] Synthesize 6 tons of polycarboxylic acid mother liquor, the solid content is 75%, the temperature is 40 ℃, add 1.2 tons of sodium bicarbonate, after stirring and standing, the system is layered, the upper layer is polycarboxylic acid, the lower layer is sodium bicarbonate aqueous solution, and then the upper layer polycarboxylate The acid is pumped into a vacuum drying system with a vacuum degree of 0.04-0.09 MPa to obtain polycarboxylic acid particles with a water content of 0.75%. The polycarboxylic acid particles enter the crushing system for granulation, and the sodium bicarbonate solution enters the evaporation system for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com