Method for processing feed through waste water microalgae

A technology for microalgae and waste water, applied in animal feed, animal feed, applications, etc., can solve problems such as no good solutions, and achieve the effects of saving drying costs, improving biological safety, and improving production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

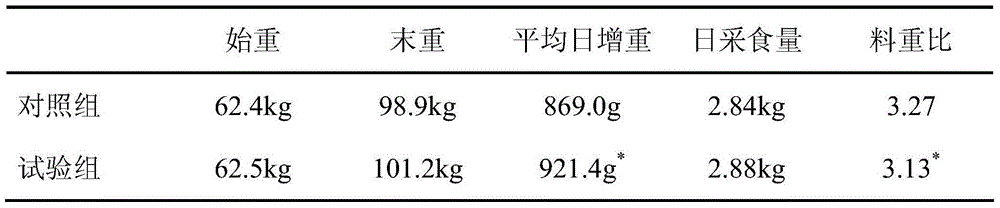

example 1

[0018] The Dunaliella is cultivated with the biogas slurry in the swine manure biogas fermentation tank of the pig farm. When the concentration of the Dunaliella is greater than 2.0 g / L, the Dunaliella begins to be collected and precipitated. The dry matter content of the Dunaliella after precipitation is 10%. Dunaliella and the maize husks crushed through a 40-mesh sieve were mixed in a weight ratio of 1:2.5, and Bacillus subtilis (1.0×10 10 cfu / g), after mixing, pile up on the ground for aerobic fermentation, the pile height is 90cm, it is conical, and the diameter of the bottom circle is 3.0m. The ambient temperature during fermentation was 15°C. On the 4th day of fermentation, when the 2 / 3 height from the ground and 20cm from the surface of the material are detected, the fermentation temperature reaches 65°C (the temperature of the material at a depth of 25cm reaches 76°C). The height is still 90cm, conical, and the diameter of the bottom circle is 3.0 meters. On the 6th...

example 2

[0027] The chlorella is cultivated by using the waste water from the pig farm, and when the concentration of the chlorella is greater than 2.0 g / L, the chlorella starts to be collected and precipitated, and the dry matter content of the chlorella after precipitation is 12%. Mix the chlorella and the corn husks crushed through a 40-mesh sieve in a weight ratio of 1:2, and add Bacillus subtilis (1.0×10 10cfu / g), after mixing, pile up on the ground for aerobic fermentation, the pile height is 80cm, trapezoidal, the bottom surface length is 2.0 meters, and the width is 1.5 meters. The ambient temperature during fermentation was 20°C. On the third day of fermentation, when the fermentation temperature reaches 62°C at a height of 2 / 3 from the ground and 20cm from the surface of the material (the temperature of the material at a depth of 25cm reaches 74°C), at this time, the material is turned from the inside out and then piled up again for fermentation. The height is still 80cm, tr...

example 3

[0030] Utilize the waste water from the pig farm to cultivate Scenedesmus, and start to collect and precipitate when the concentration of Scenedesmus is greater than 2.1g / L, and the dry matter content of the chlorella after precipitation is 15%. Mix Scenedesmus and corn bran crushed through a 40-mesh sieve in a weight ratio of 1:3, and add Bacillus subtilis (2.0×10 10 cfu / g), after mixing, pile up on the ground for aerobic fermentation, the pile height is 100cm, it is conical, and the diameter of the bottom circle is 2.0m. The ambient temperature during fermentation was 25°C. At the 60th hour of fermentation, when the fermentation temperature reaches 60°C at a depth of 2 / 3 from the ground and 20cm from the surface of the material (the temperature of the material at a depth of 25cm reaches 72°C), at this time, the material is turned from the inside out and then piled up again for fermentation. The height is still 100cm, trapezoidal, and the diameter of the bottom circle is 2.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com