Cannabidiol-containing composition and preparation method thereof

A cannabidiol and preparation technology, which is applied in the field of cannabidiol-containing compositions and its preparation, can solve the problems of cannabidiol instability and low bioavailability, and achieve good appearance, good stability, and preparation conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

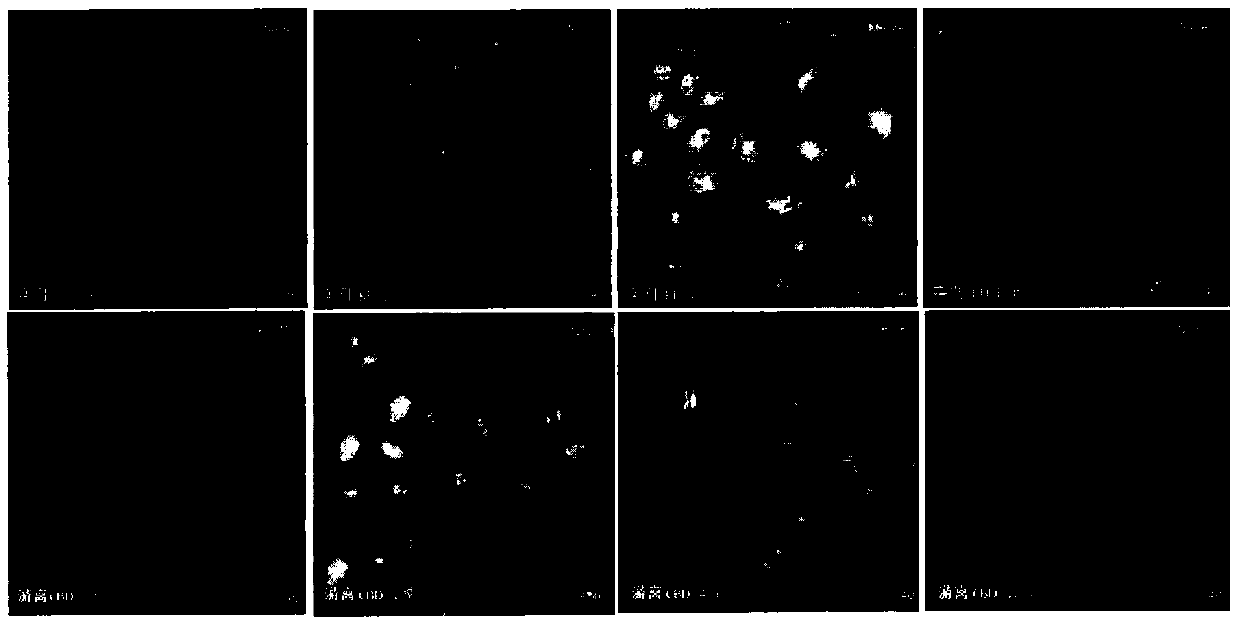

Image

Examples

Embodiment 1

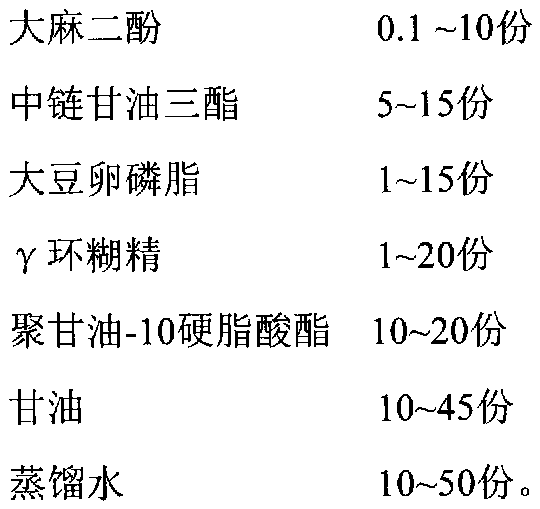

[0036]

[0037] The preparation method includes the following steps:

[0038] S1. Mix soybean lecithin, polyglyceryl-10 stearate and medium-chain triglycerides, stir and heat at 65°C and 500 rpm for 1 hour to obtain a light yellow oily liquid, which is the first mixed oil phase;

[0039] S2. Add cannabidiol to the first mixed oil phase, continue to stir and heat at 65° C. and 500 rpm for 15 minutes, and fully mix under the protection of nitrogen to obtain an oily liquid, which is the second mixed oil phase;

[0040] S3. Weigh gamma cyclodextrin, glycerin and distilled water in a weight ratio, and then mix them thoroughly at 40°C and 500 rpm to obtain a clear aqueous solution, which is the water phase;

[0041] S4. Disperse the second mixed oil phase dropwise into the water phase until the dispersion is complete, and then use high shear to obtain a light yellow opaque emulsion, which is a cannabidiol crude emulsion;

[0042] S5. The crude cannabidiol emulsion was homogenized under high p...

Embodiment 2

[0045]

[0046] The preparation method includes the following steps:

[0047] S1. Mix soybean lecithin, polyglyceryl-10 stearate and medium chain triglycerides (MCT), stir and heat for 1 hour at 65°C and 1000 rpm to obtain a light yellow oily liquid, which is the first mixed oil phase;

[0048] S2. Add cannabidiol to the first mixed oil phase, continue to stir and heat at 65° C. and 1000 rpm for 15 minutes, and fully mix under the protection of nitrogen to obtain an oily liquid, which is the second mixed oil phase;

[0049] S3. Weigh gamma cyclodextrin, glycerin and distilled water in a weight ratio, and then mix them thoroughly at 40°C and 1000 rpm to obtain a clear aqueous solution, which is the water phase;

[0050] S4. Disperse the second mixed oil phase dropwise into the water phase until the dispersion is complete, and then use high shear to obtain a light yellow opaque emulsion, which is a cannabidiol crude emulsion;

[0051] S5. The cannabidiol crude emulsion was homogenized und...

Embodiment 3

[0053]

[0054] The preparation method includes the following steps:

[0055] S1. Mix soybean lecithin, polyglyceryl-10 stearate and medium chain triglycerides (MCT), stir and heat for 1 hour at 65°C and 1000 rpm to obtain a light yellow oily liquid, which is the first mixed oil phase;

[0056] S2. Add cannabidiol to the first mixed oil phase, continue to stir and heat at 65° C. and 1000 rpm for 15 minutes, and fully mix under the protection of nitrogen to obtain an oily liquid, which is the second mixed oil phase;

[0057] S3. Weigh gamma cyclodextrin, glycerin and distilled water in a weight ratio, and then mix them thoroughly at 40°C and 1000 rpm to obtain a clear aqueous solution, which is the water phase;

[0058] S4. Disperse the second mixed oil phase dropwise into the water phase until the dispersion is complete, and then use high shear to obtain a light yellow opaque emulsion, which is a cannabidiol crude emulsion;

[0059] S5. The crude cannabidiol emulsion is homogenized unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com