Antibacterial polylactic acid master batch and application thereof

A technology of lactic acid masterbatch and polylactic acid, applied in the field of biological materials, can solve the problems of unstable physical and chemical properties, limited application scope, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

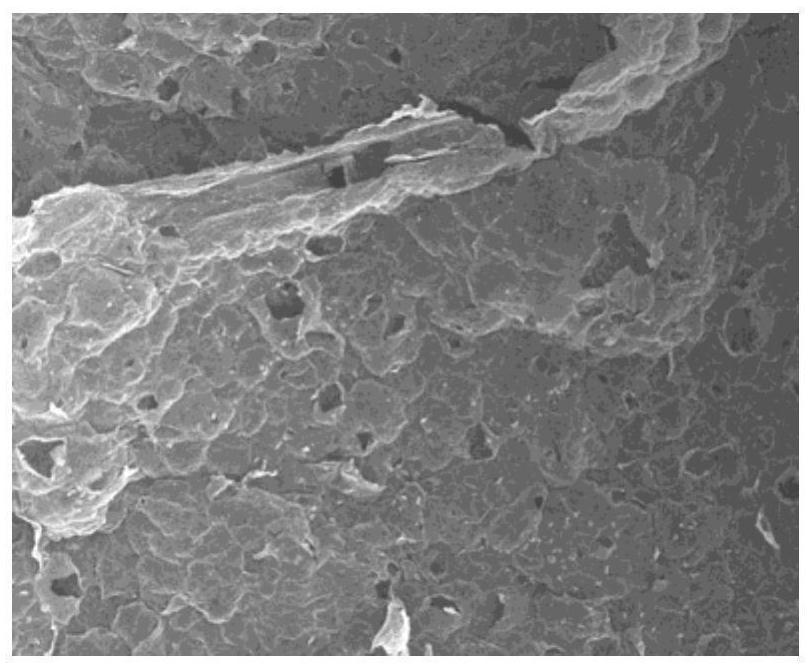

Image

Examples

Embodiment approach

[0047] According to other embodiments of the present invention, the step B includes:

[0048] Step S1, the polylactic acid masterbatch is crushed into granules, dried at 80-200°C for 10 hours, and mixed with antibacterial powder to obtain a polylactic acid-antibacterial powder mixture; in the polylactic acid-antibacterial powder mixture Wherein, the antibacterial powder accounts for 1%-20% of the mass of the polylactic acid nibs;

[0049] Step S2: Put the polylactic acid-antibacterial powder mixture into a double-cone screw extruder for melt blending. During the melt blending process, the temperature is controlled at 180-250°C. After the extrusion is cooled, it is pelletized. Obtain antibacterial polylactic acid masterbatch.

[0050] In some specific embodiments of the present invention, using the method of the present invention to prepare antibacterial polylactic acid masterbatch includes the following steps:

[0051] (1) Preparation of antibacterial powder: the copper oxide (CuO) a...

Embodiment 1

[0087] 1. Preparation of antibacterial polylactic acid masterbatch:

[0088] (1) Weigh 0.795gCuO, 14.310g Cu 2 O (the molar ratio of copper oxide to cuprous oxide is 0.1:1) and 3.021g of graphene oxide (the mass ratio of graphene oxide to copper oxide and cuprous oxide mixed powder is 0.2:1) in a flask, shake and stir Evenly, and dispersed in 400mL deionized water, fully stirred for 12h under 80℃ oil bath conditions, centrifuged at 3000rpm for 10min, rinsed with deionized water and freeze-dried. The obtained solid powder is placed in the center of the tubular reactor, and the system is evacuated to 300 Pa with an argon flow. The sample was heated to 400°C at a heating rate of 5°C / min, and kept at this temperature for 4 hours, and then taken out after cooling to obtain nano-copper oxide and cuprous oxide containing a carbonized layer, namely antibacterial powder.

[0089] (2) Grind the commercially available polylactic acid masterbatch with a grinder into granules, and dry them at ...

Embodiment 2

[0095] 1. Preparation of antibacterial polylactic acid masterbatch:

[0096] (1) Weigh 1.36g CuO, 4.77g Cu 2 O (the molar ratio of copper oxide to cuprous oxide is 0.5:1) and 1.23g starch (the mass ratio of starch, copper oxide and cuprous oxide mixed powder is 0.2:1) in a flask, shake and stir evenly, and disperse In 400mL deionized water, fully stirred for 12h under 80℃ oil bath, centrifuged at 3000rpm for 10min, rinsed with deionized water, and freeze-dried. The obtained solid powder is placed in the center of the tubular reactor, and the system is evacuated to 250 Pa with an argon flow. The sample is heated to 500°C at a heating rate of 8°C / min, kept at this temperature for 2h, and taken out after cooling to obtain nano-copper oxide and cuprous oxide containing a carbonized layer, namely antibacterial powder.

[0097] (2) Grind the commercially available polylactic acid masterbatch with a grinder into granules, and dry them at 150°C for 10 hours. Weigh 100g of the ground poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com