Patents

Literature

60results about How to "Uniform purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

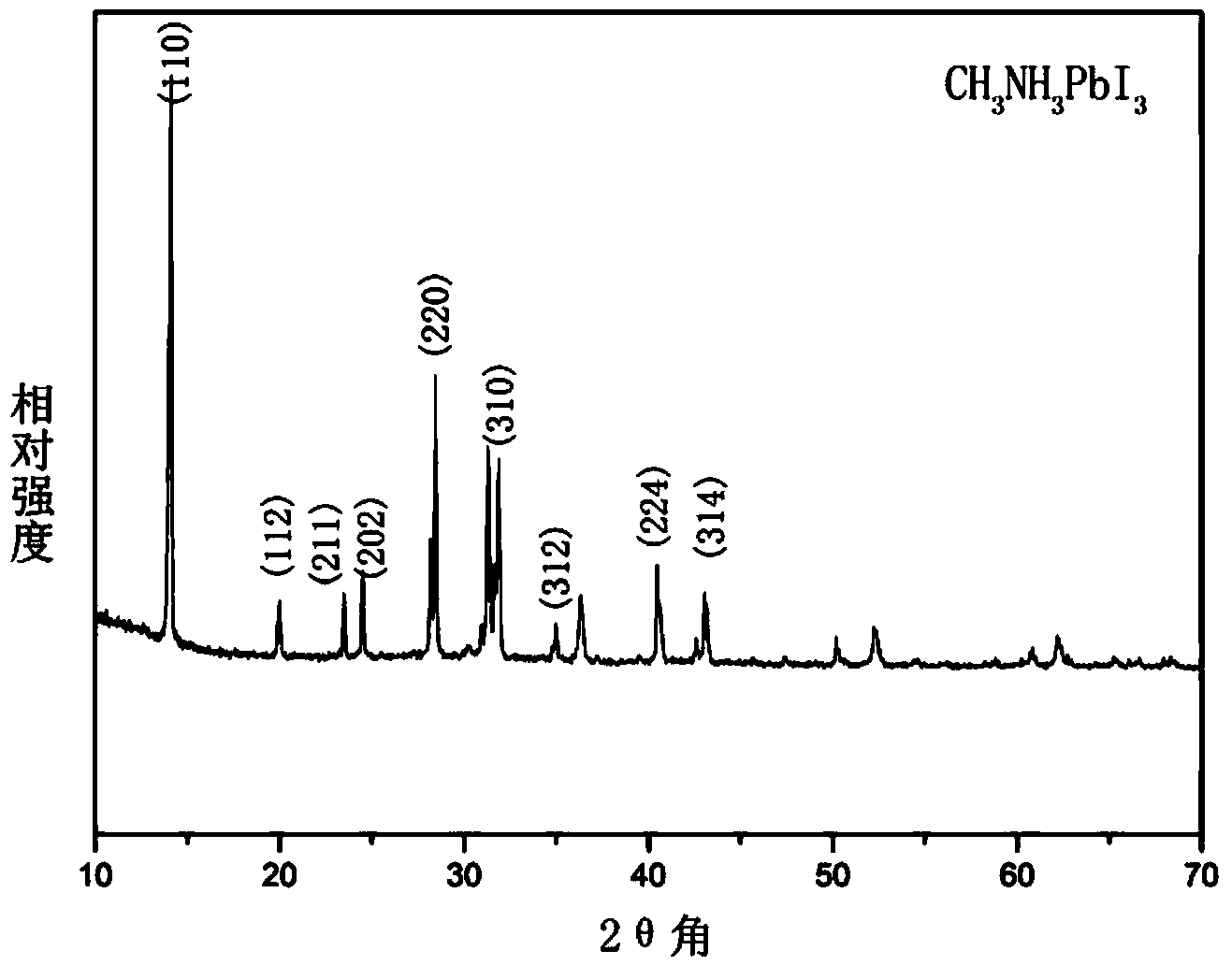

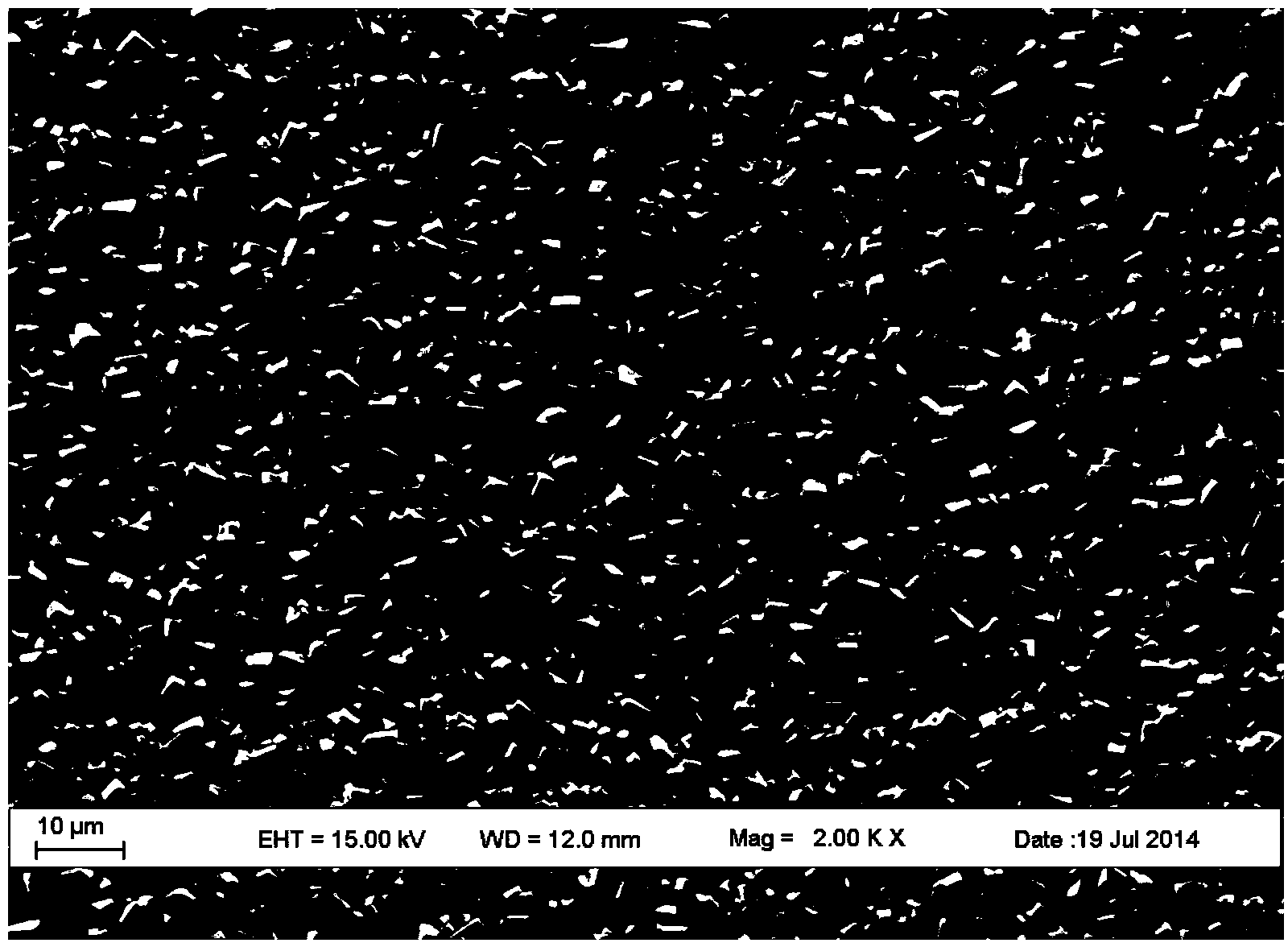

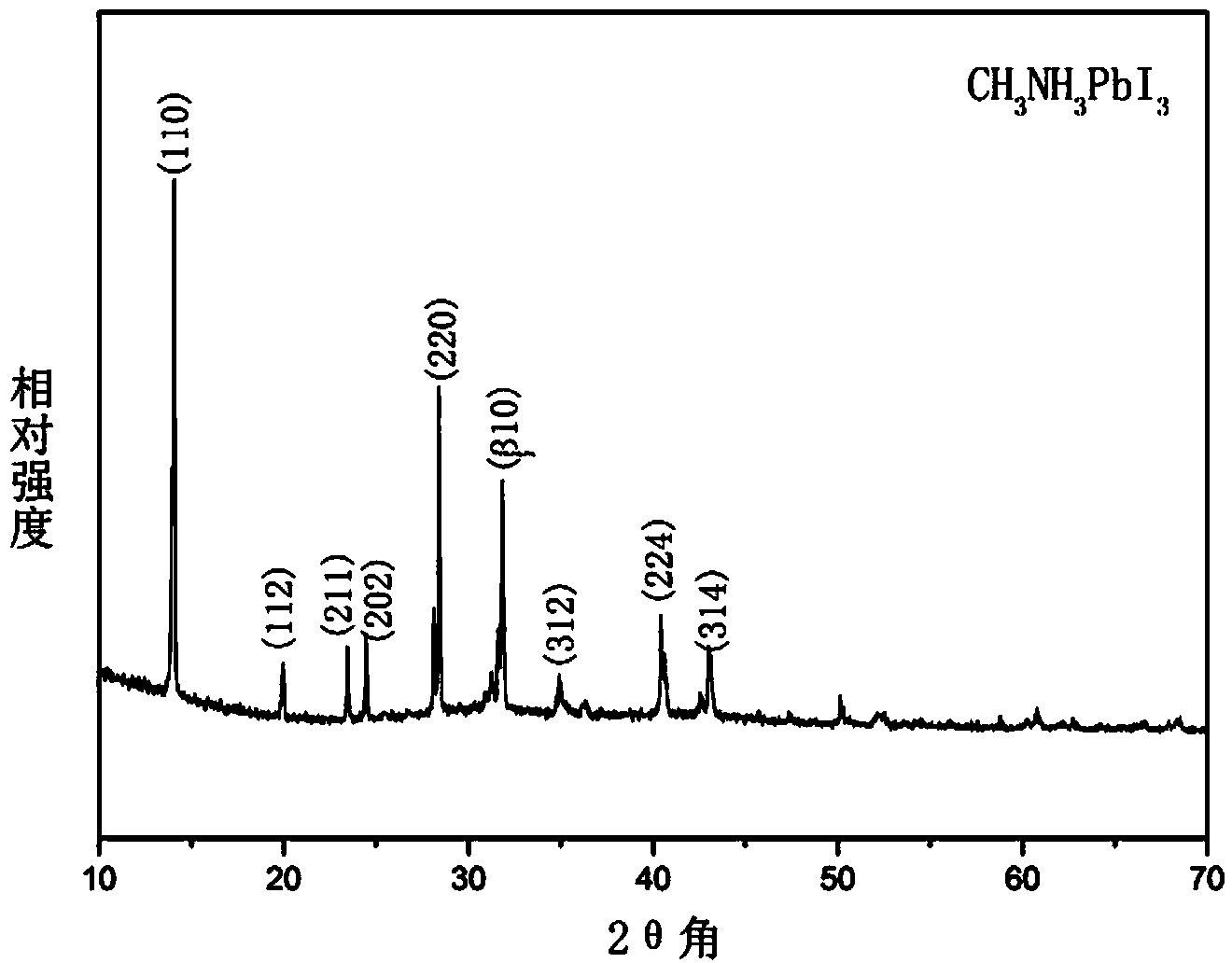

Chemical method for in-situ large-area controlled synthesis of perovskite type CH3NH3PBI3 membrane material based on lead simple-substance membrane

ActiveCN104250723AHigh purityUniform purityVacuum evaporation coatingSputtering coatingPhysical chemistryMethylamines

The invention relates to a chemical method for in-situ large-area controlled synthesis of a perovskite type CH3NH3PBI3 membrane material based on a lead simple-substance membrane. The method comprises: sputtering the lead simple-substance membrane on the surface of a substrate, then horizontally immersing the substrate material possessing the lead simple-substance membrane in an organic solution containing a simple substance iodine and iodinated methylamine, and performing a constant-temperature reaction to prepare a CH3NH3PBI3 membrane material in situ; or putting the substrate possessing the lead simple-substance membrane in a steam atmosphere of a simple substance iodine to perform iodination to generate a lead iodide membrane, then immersing in an organic solution containing iodinated methylamine, and performing a constant-temperature reaction to prepare the CH3NH3PBI3 membrane material in situ. The method is simple in operation, low in energy consumption and low in cost, and has wide industrial application prospect. The obtained CH3NH3PBI3 membrane is high in purity, uniform in membrane-surface crystal and excellent in crystallinity.

Owner:XUCHANG UNIV +1

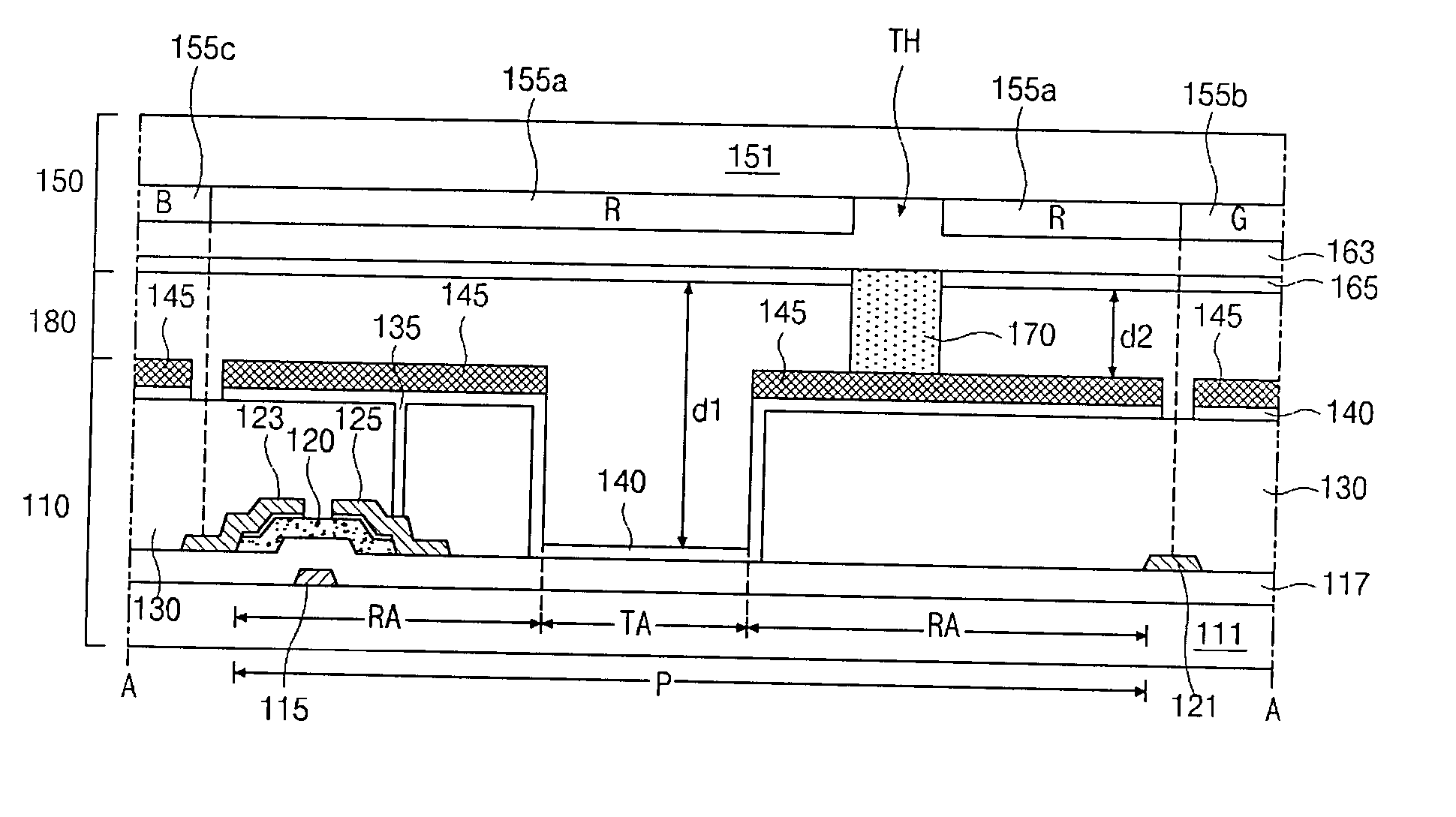

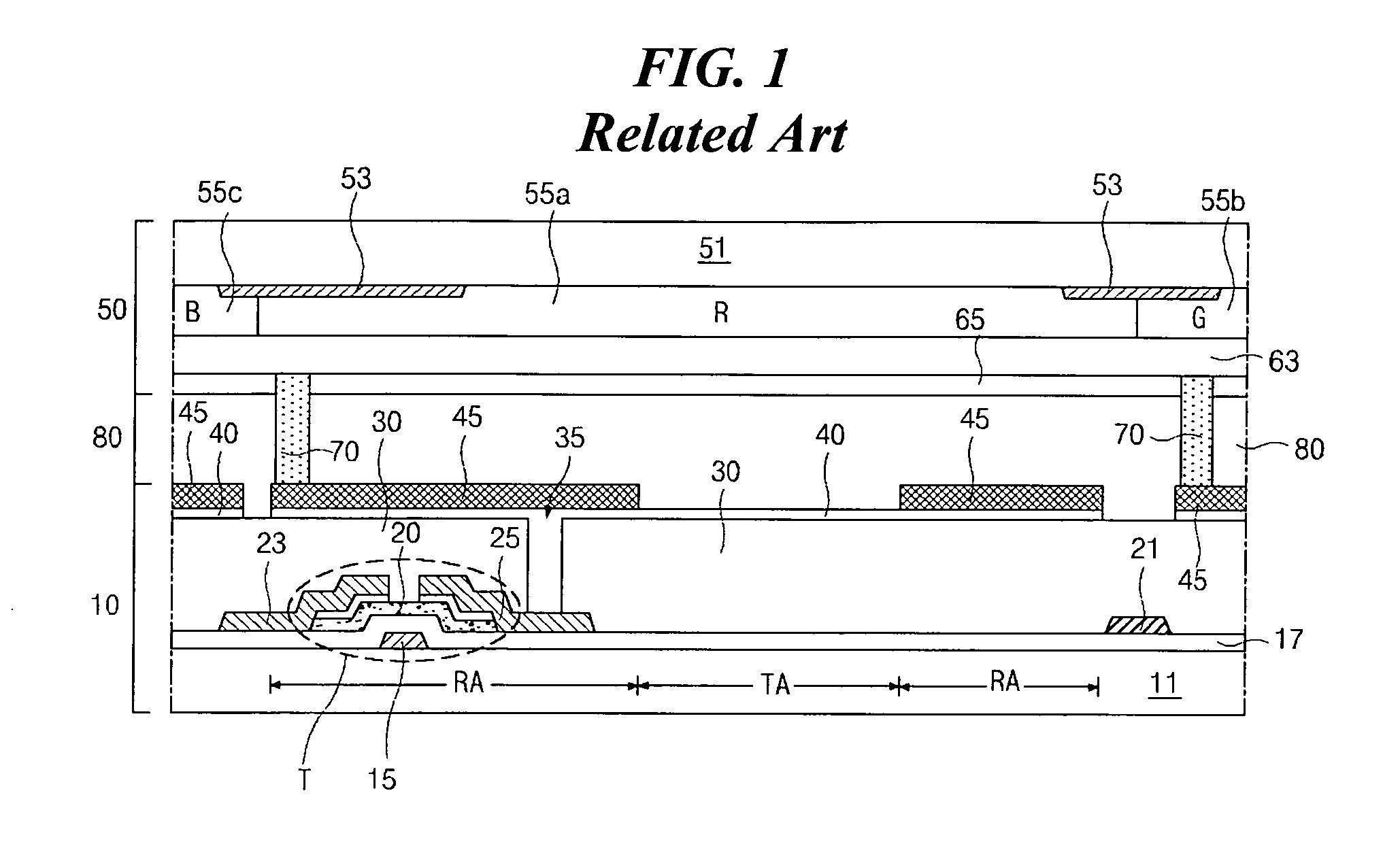

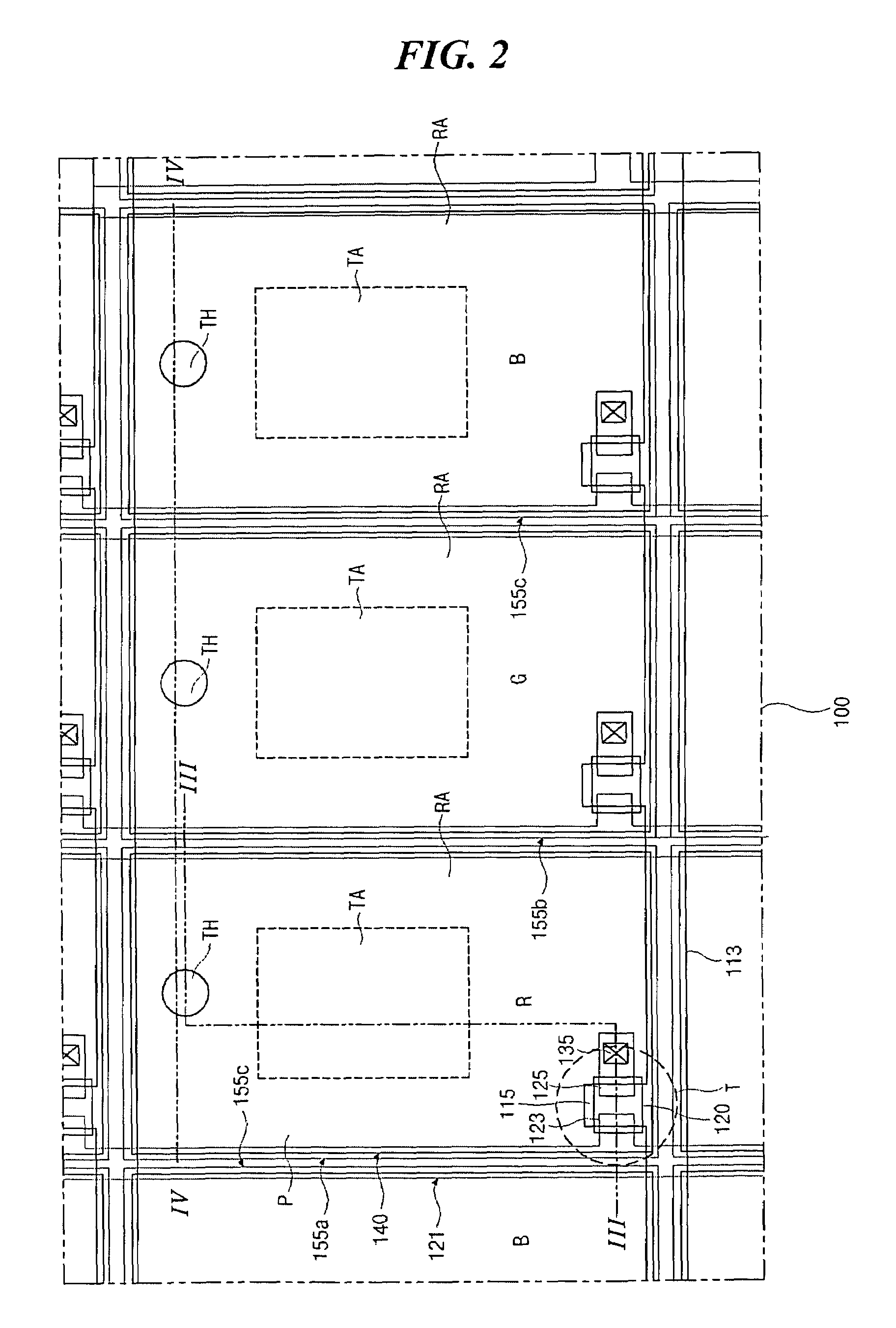

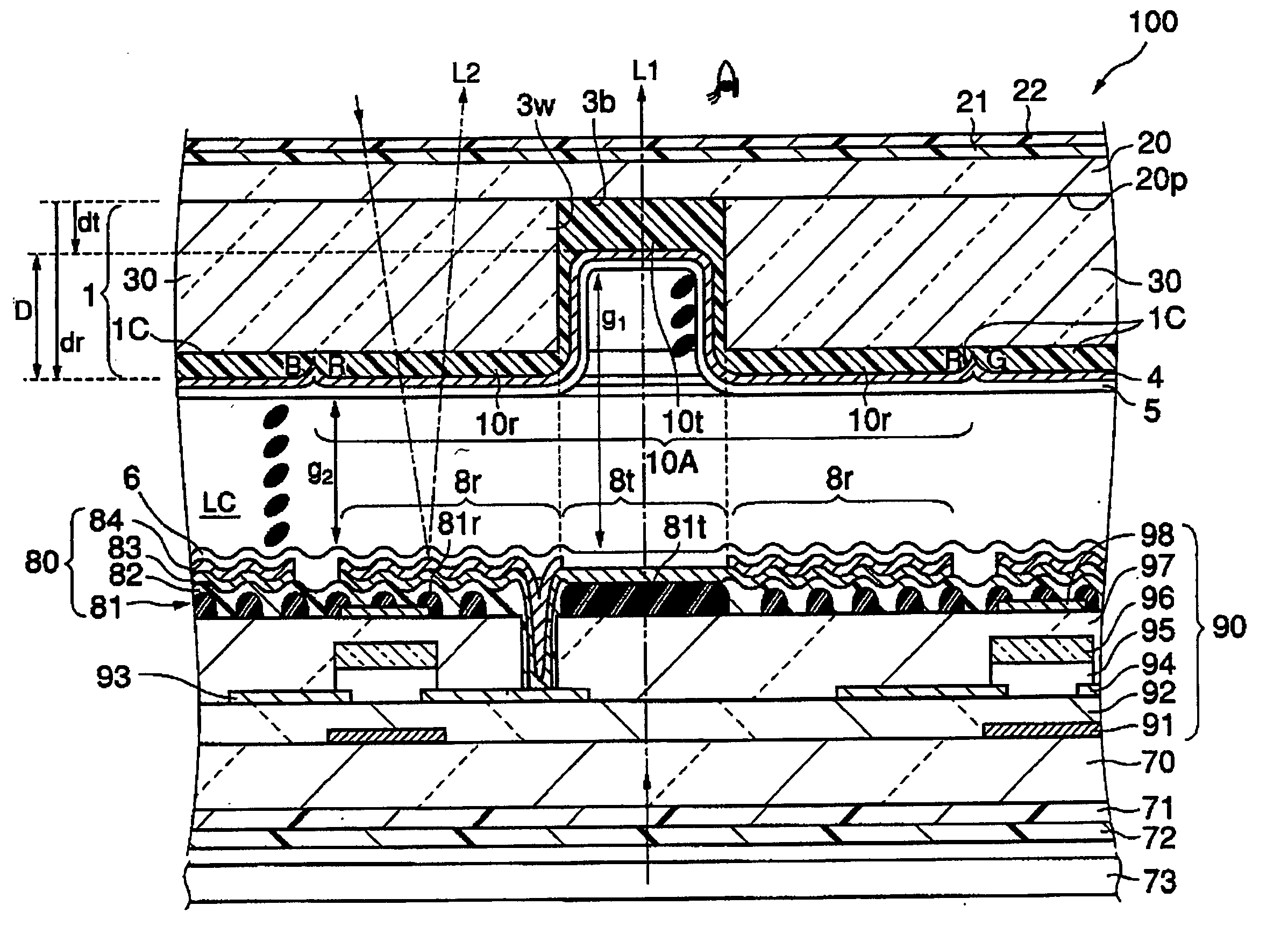

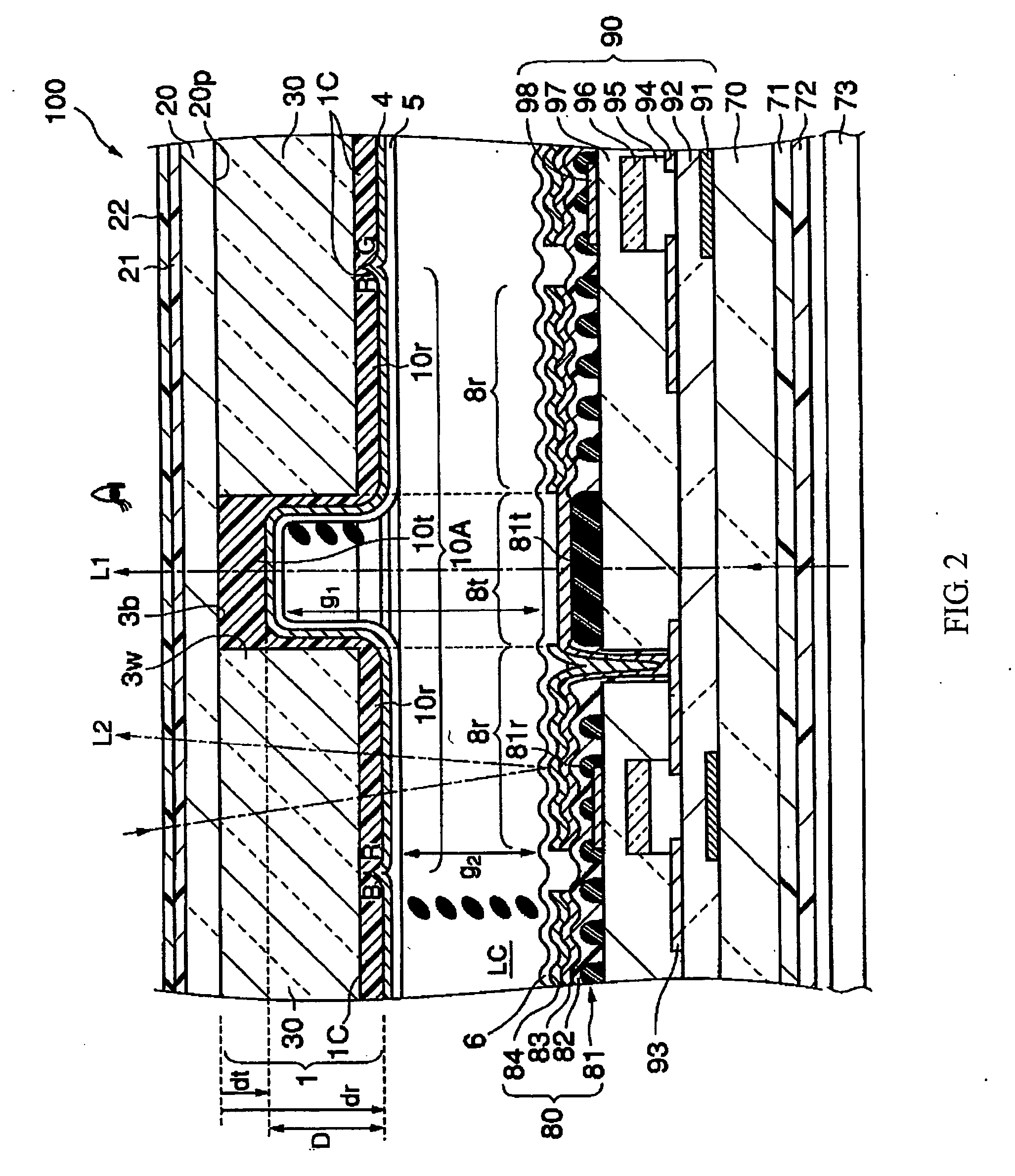

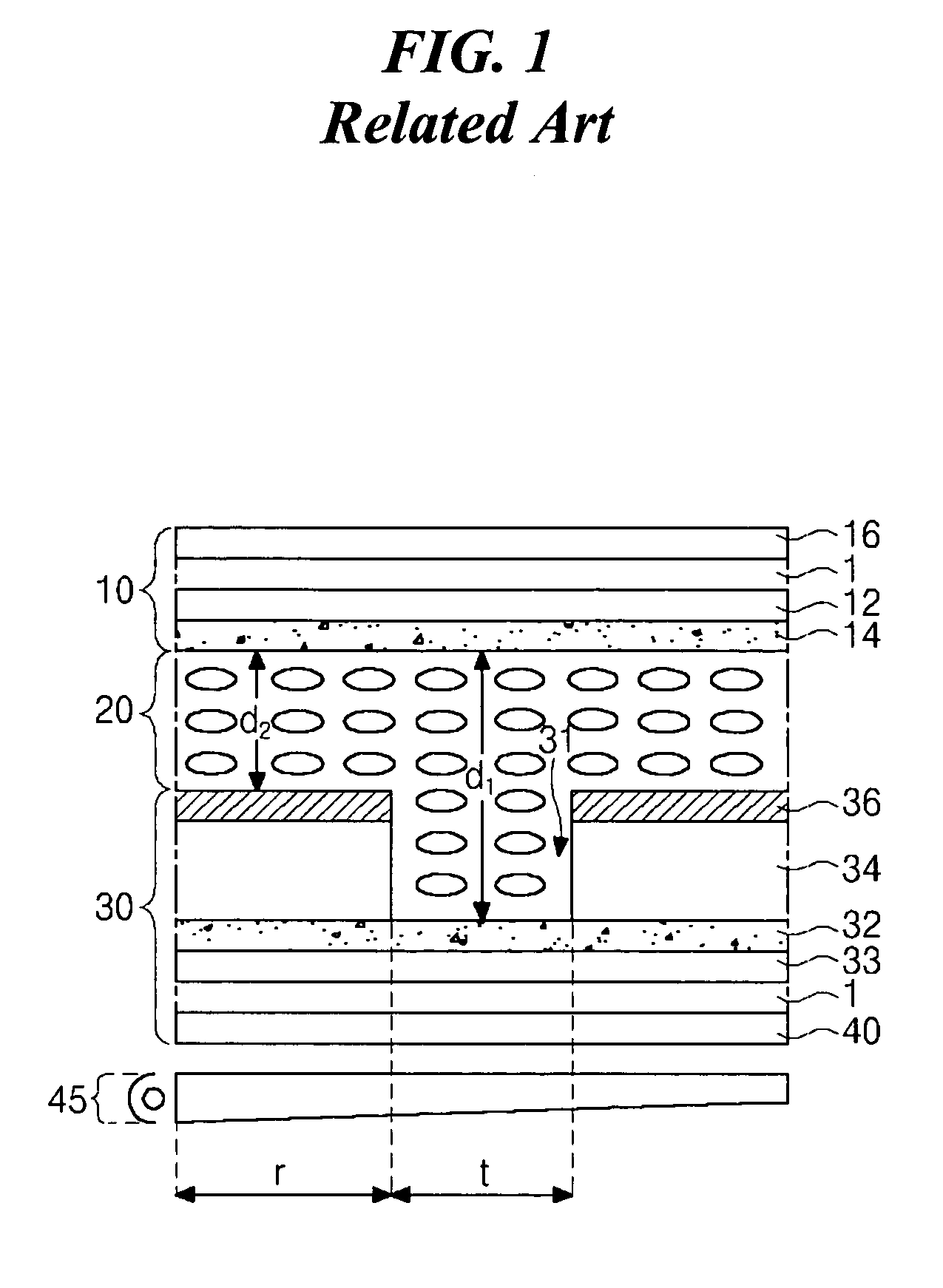

Transflective LCD device and fabrication method thereof

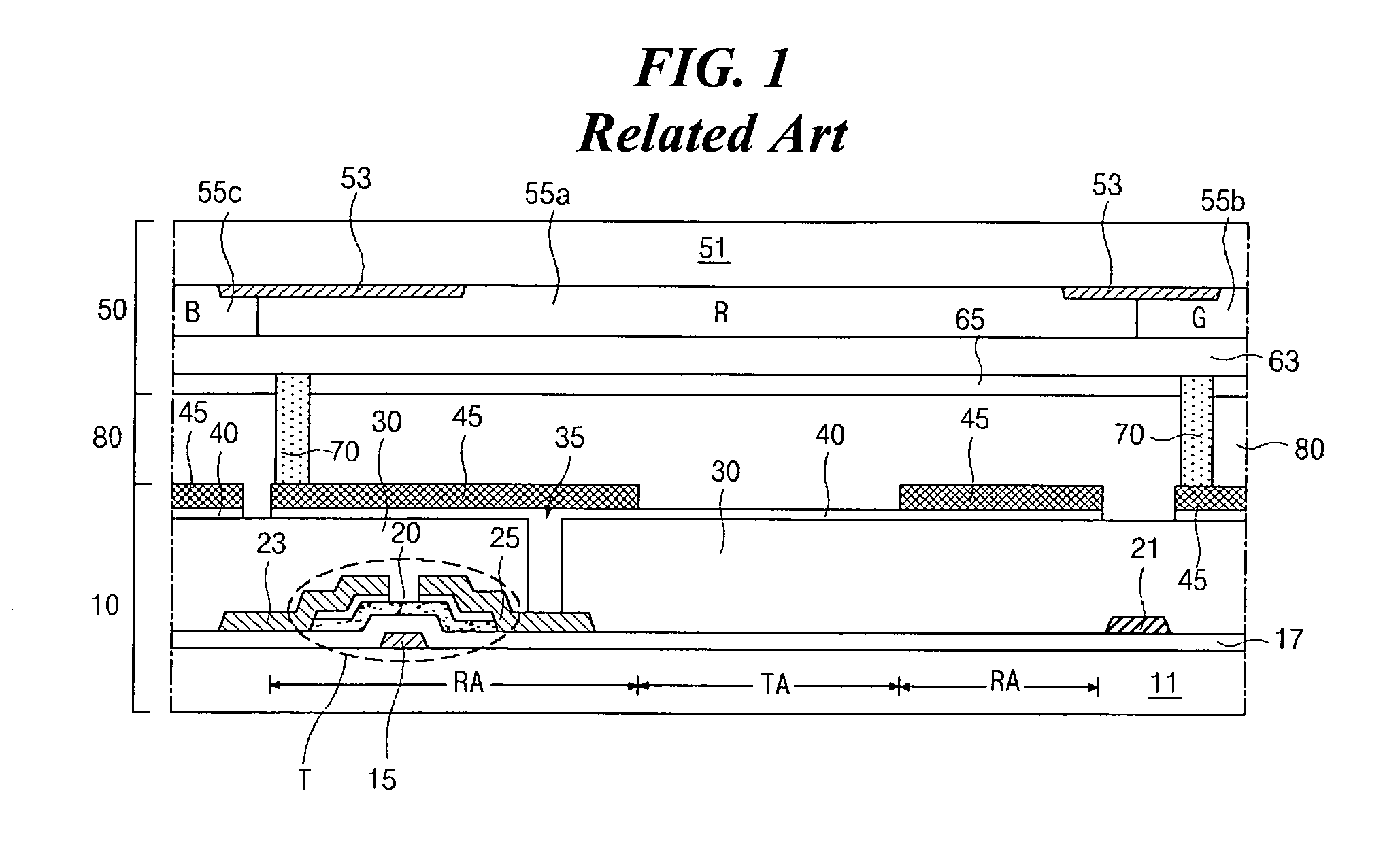

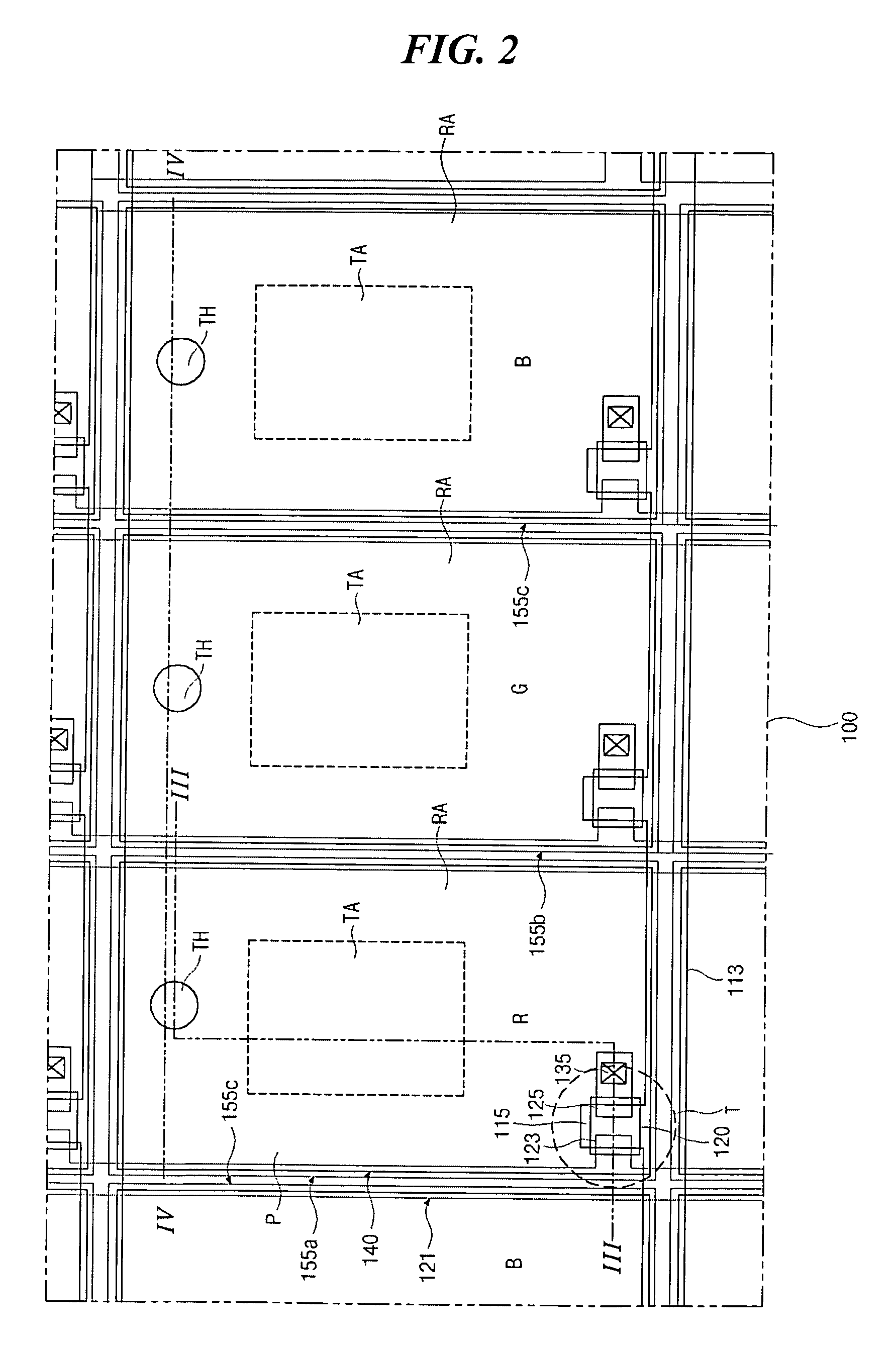

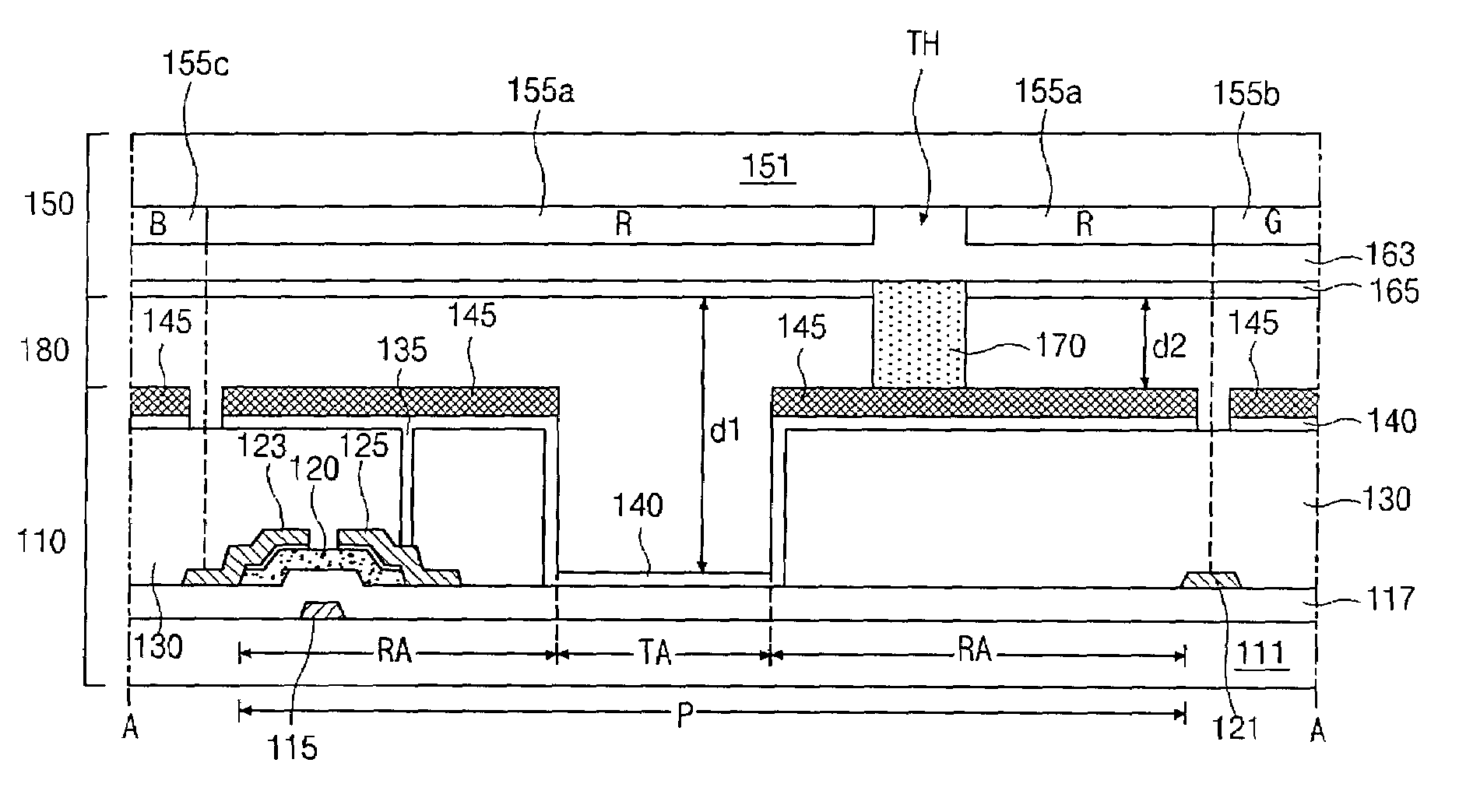

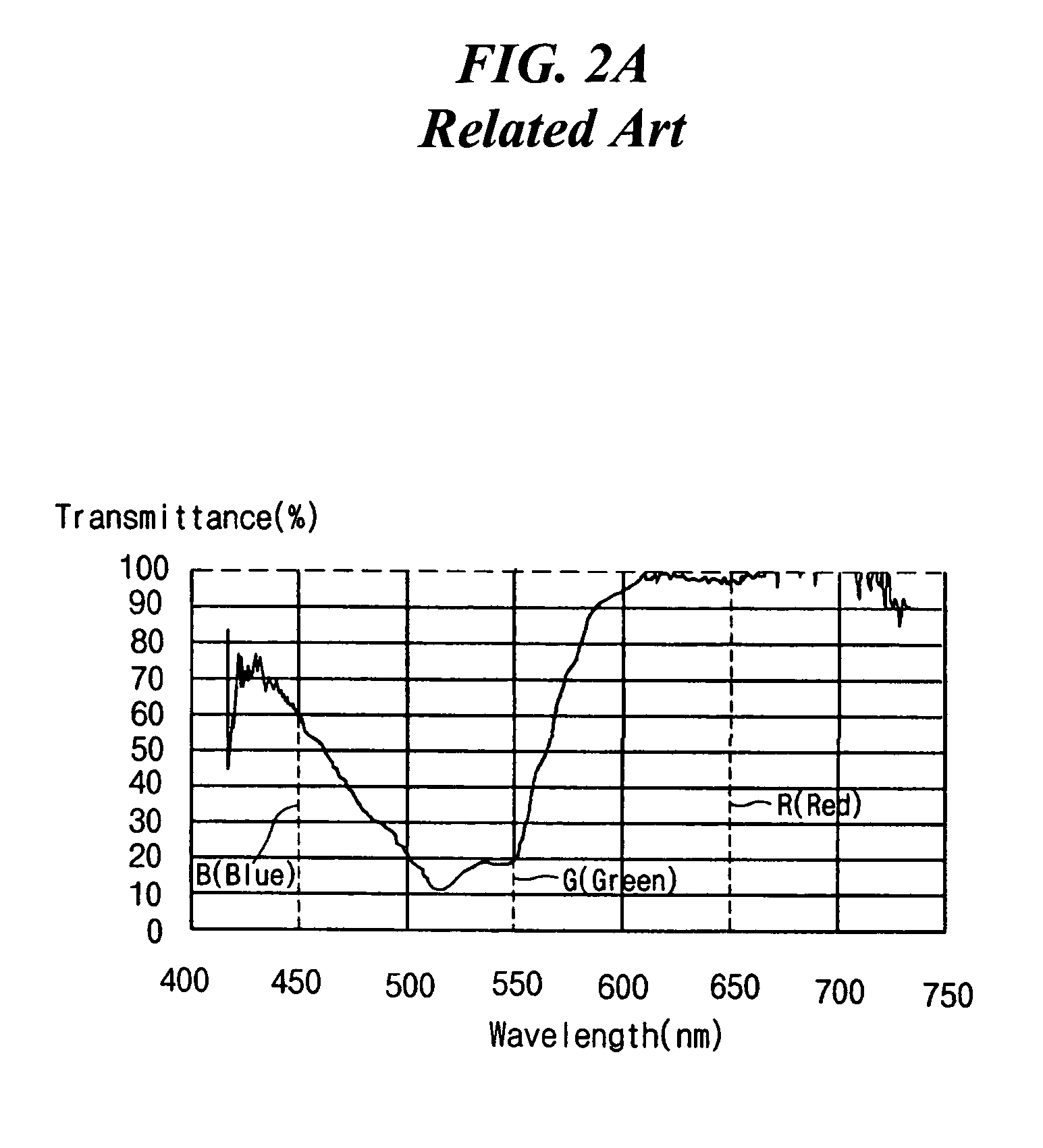

InactiveUS20040196421A1Uniform purityUniform color reproductionFoundation engineeringBridge erection/assemblyLiquid crystalTransistor

A transflective liquid crystal display device including: first and second transparent substrates facing each other with a reflective portion and a transmissive portion; gate and data lines over the first transparent substrate perpendicularly crossing each other and defining pixel regions; a thin film transistor connected to the gate and data lines in the pixel region; an insulator in the thin film transistor on the first substrate covering the gate line; a passivation layer in the reflection portion on the insulator and on the thin film transistor; a pixel electrode in the reflective and transmissive portions, wherein the pixel electrode contacts both the passivation layer in the reflective potion and the insulator in the transmissive portion; a reflector on the pixel electrode in the reflective portion; color filters on a rear surface of the second transparent substrate, the color filters having through holes; column spacers formed between the reflector and the color filters, each column spacer corresponding in position to each through hole; a common electrode under the color filters; and a liquid crystal layer interposed between the common electrode and the pixel electrode.

Owner:LG DISPLAY CO LTD

Transflective LCD device having color filters with through holes

InactiveUS7053974B2Uniform purityUniform color reproductionFoundation engineeringBridge erection/assemblyLiquid crystalTransistor

A transflective liquid crystal display device including: first and second transparent substrates facing each other with a reflective portion and a transmissive portion; gate and data lines over the first transparent substrate perpendicularly crossing each other and defining pixel regions; a thin film transistor connected to the gate and data lines in the pixel region; an insulator in the thin film transistor on the first substrate covering the gate line; a passivation layer in the reflection portion on the insulator and on the thin film transistor; a pixel electrode in the reflective and transmissive portions, wherein the pixel electrode contacts both the passivation layer in the reflective potion and the insulator in the transmissive portion; a reflector on the pixel electrode in the reflective portion; color filters on a rear surface of the second transparent substrate, the color filters having through holes; column spacers formed between the reflector and the color filters, each column spacer corresponding in position to each through hole; a common electrode under the color filters; and a liquid crystal layer interposed between the common electrode and the pixel electrode.

Owner:LG DISPLAY CO LTD

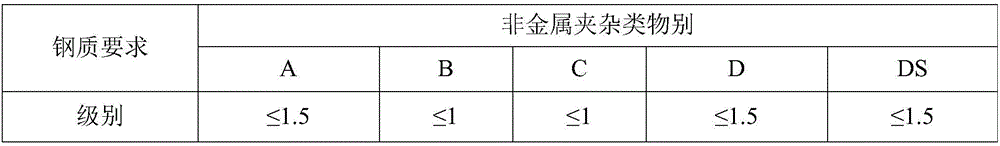

Preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming

The invention relates to a preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming, belongs to the technical field of preparation of acid-pickling steel strips, and aims at solving the technical problem of providing a low-cost preparation method of high-carbon hot-continuous-rolling acid-pickling steel strips for hot forming. According to the method, C and Mn serve as main elements, and the C content is increased; on the condition that alloy elements such as Nb, Ti, V, B, Mo, La and Cr are not added, on the premise of ensuring steel purity and chemical component uniformity of a cast blank by controlling the smelting procedure, and by means of reasonable rolling control and cooling control technological processes, hot-rolled steel plates which are moderate in strength and high in elongation rate are obtained, the hot-rolled steel plates are subjected to trimming, blanking and heating and then subjected to hot forming and hot treatment, and parts which are moderate in strength and high in ductility and toughness are obtained finally. The steel strips are widely applied to automotive structural parts and can replace part of hot-rolled and cold-rolled continuous annealing steel plates and steel strips which are high in alloy content and product cost and are used for high-strength automobile structures.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

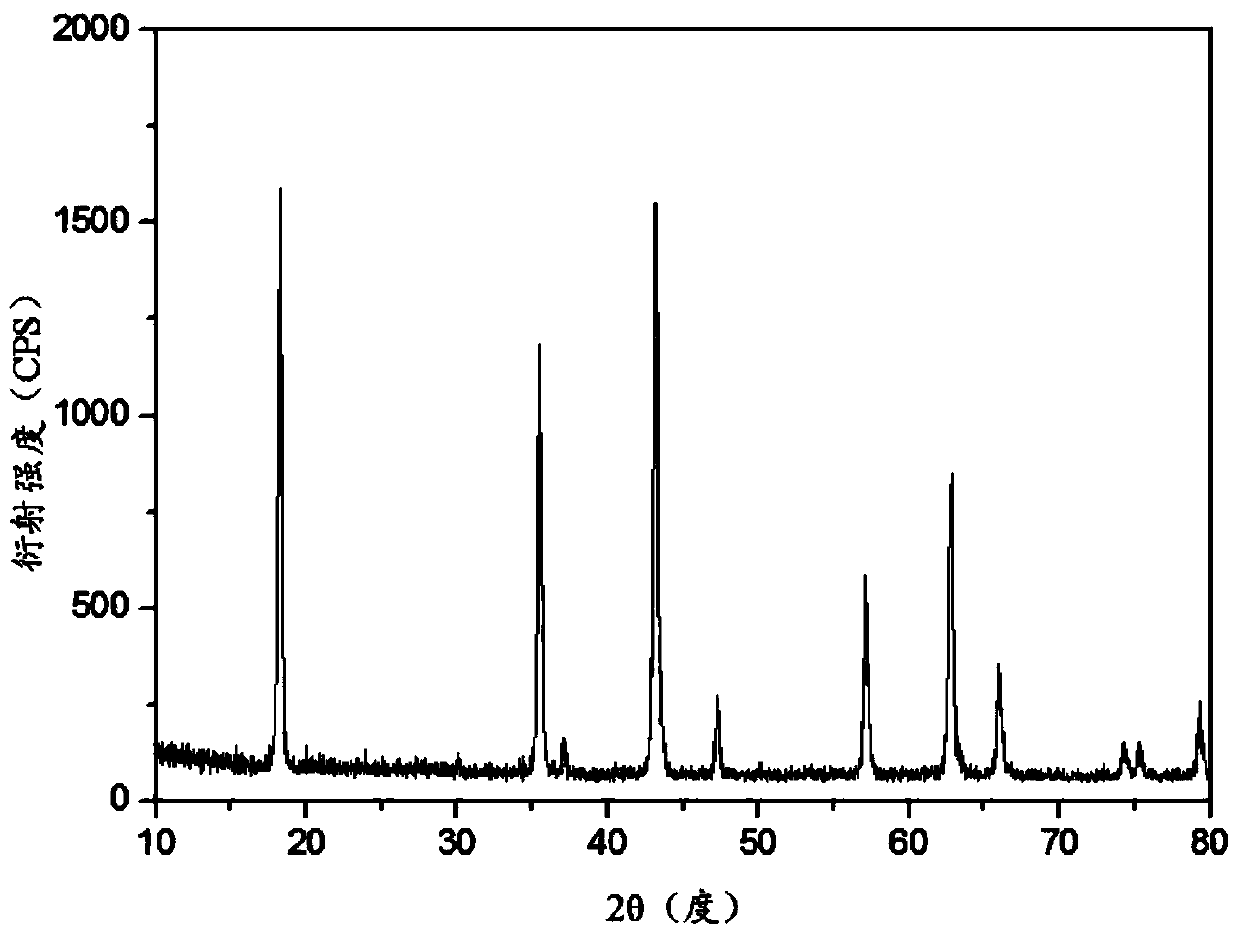

Preparation method of lithium titanate-nickel oxide nanofiber composite material for lithium battery

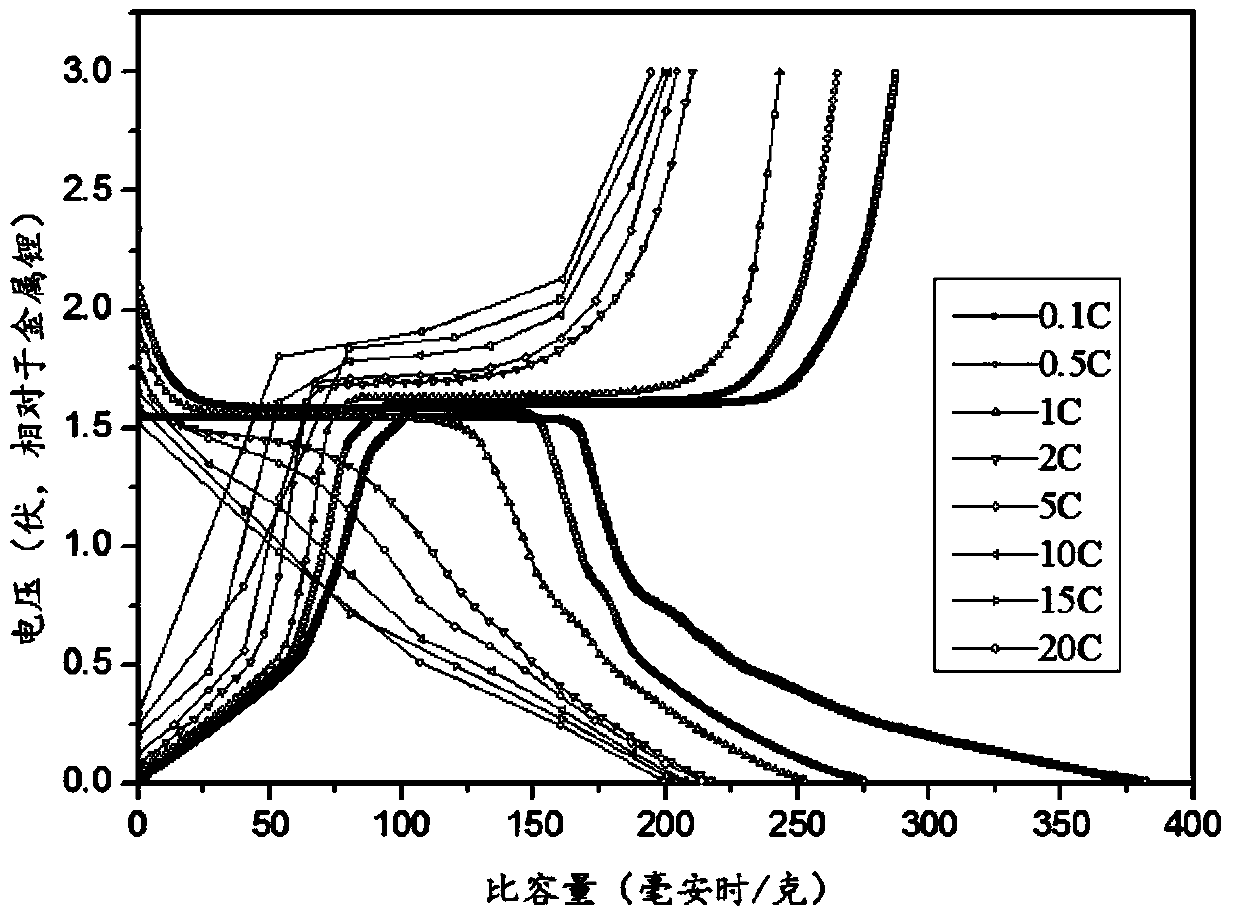

ActiveCN104201341AHigh crystallinityHigh specific capacityMaterial nanotechnologyCell electrodesSolventPolymer

The invention relates to a preparation method of a lithium titanate-nickel oxide nanofiber composite material for a lithium battery. The preparation method comprises the steps: firstly, dissolving a high-molecular polymer carrier and a surfactant in a solvent, and stirring to obtain a carrier solution; respectively adding a lithium source and a nickel source into water; after constant-temperature mixing to obtain a mixture, adding hydrogen peroxide into the mixture; after uniformly mixing, adding a titanium source and regulating pH by using ammonium hydroxide; after constant-temperature mixing to obtain a solution, adding the solution into the carrier solution, mixing to form a precursor solution; then performing electrostatic spinning on the precursor solution to obtain a nanofiber precursor; and finally after pre-decomposing and sintering the nanofiber precursor, quenching in liquid nitrogen or water to obtain the lithium titanate-nickel oxide nanofiber composite material for the lithium battery. The nanofiber composite material disclosed by the invention is uniform in distribution, controllable in particle size, and excellent in electrochemical performance, and can be widely applied to the field of lithium ion batteries.

Owner:JIANGSU UNIV OF SCI & TECH

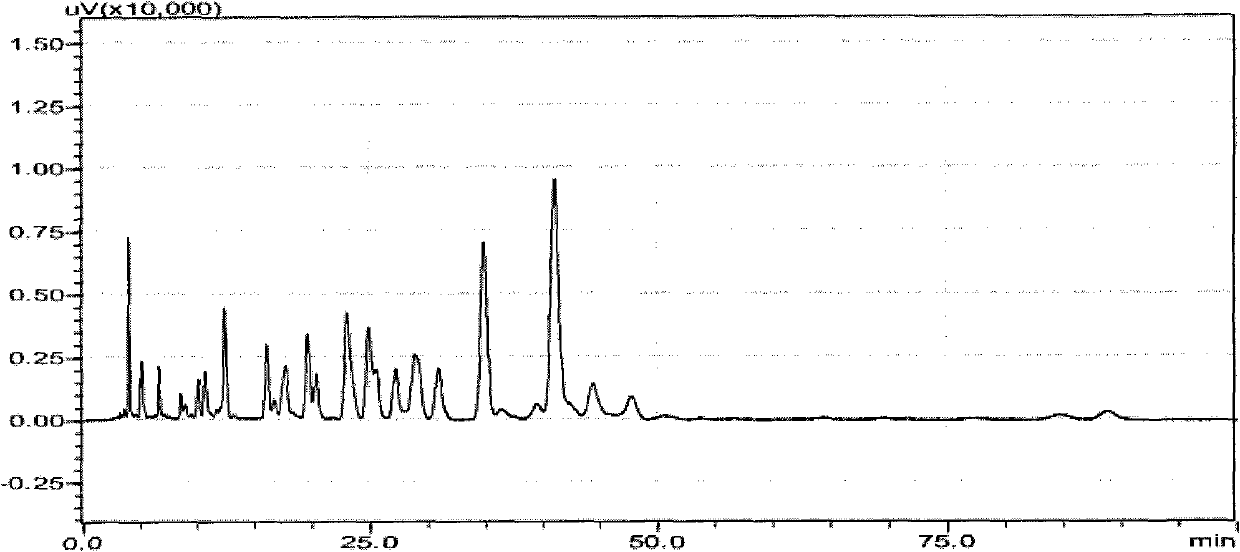

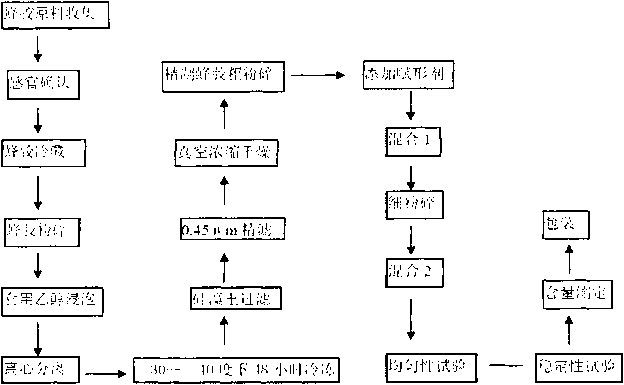

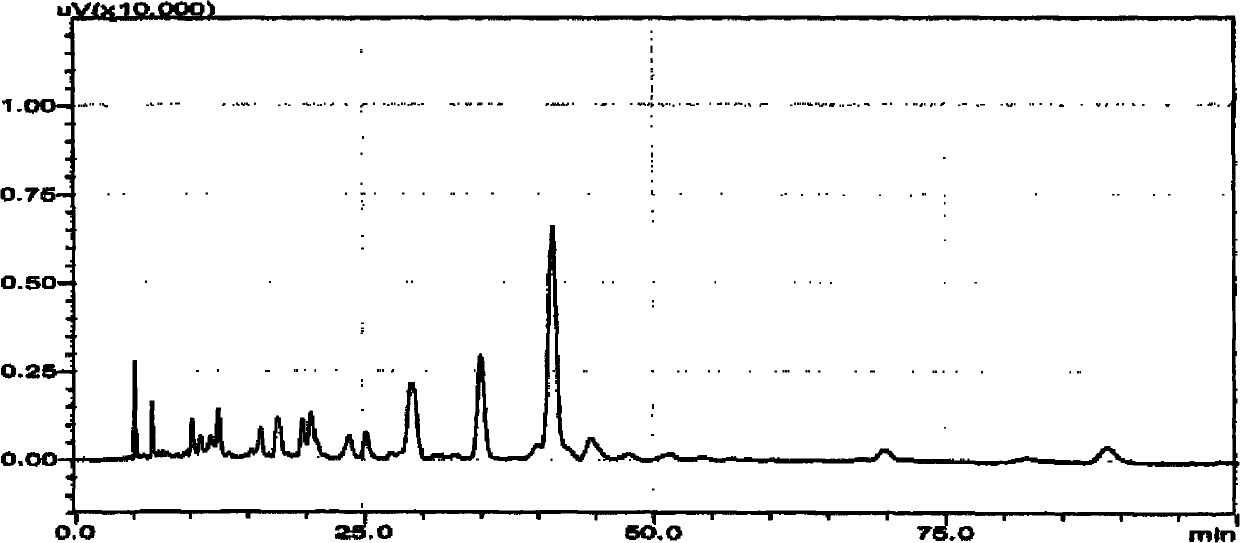

Method for preparing real substance sample for authentication of propolis liquid phase fingerprint

ActiveCN101957349AAnalysis method is simpleQuality improvementComponent separationWater bathsPropolis

The invention relates to a method for preparing a real substance sample for authentication of a propolis liquid phase fingerprint. At present, the mature method for authenticating poplar gum and propolis is unavailable. The method comprises the processes of preparing a propolis substance sample and a poplar gum substance sample. The process of preparing the propolis substance sample comprises thefollowing steps of: soaking the propolis in 95 percent edible ethanol; drying the refined propolis liquid in vacuum in a water bath at the temperature of 80 to 95 DEG C; and mixing the crushed refined propolis and an excipient, and sieving the mixture with an 80-mesh sieve to obtain the propolis substance sample. The process of preparing the poplar gum substance sample comprises the following steps of: heating polar-water mixed liquid to over 90 DEG C; pressing the liquid to obtain a polar liquid; after cooking the polar liquid, soaking the polar liquid in the 95 percent edible ethanol; drying the refined polar gum liquid in vacuum in the water bath at the temperature of 80 to 95 DEG C; and mixing the crushed refined polar gum liquid and the excipient, and sieving the mixture with the 80-mesh sieve to obtain the poplar gum substance sample. The method has the advantages of reasonable and scientific preparation, strong operability and application to effective authentication of the false propolis prepared from polar sprouts.

Owner:杭州蜂之语蜂业股份有限公司

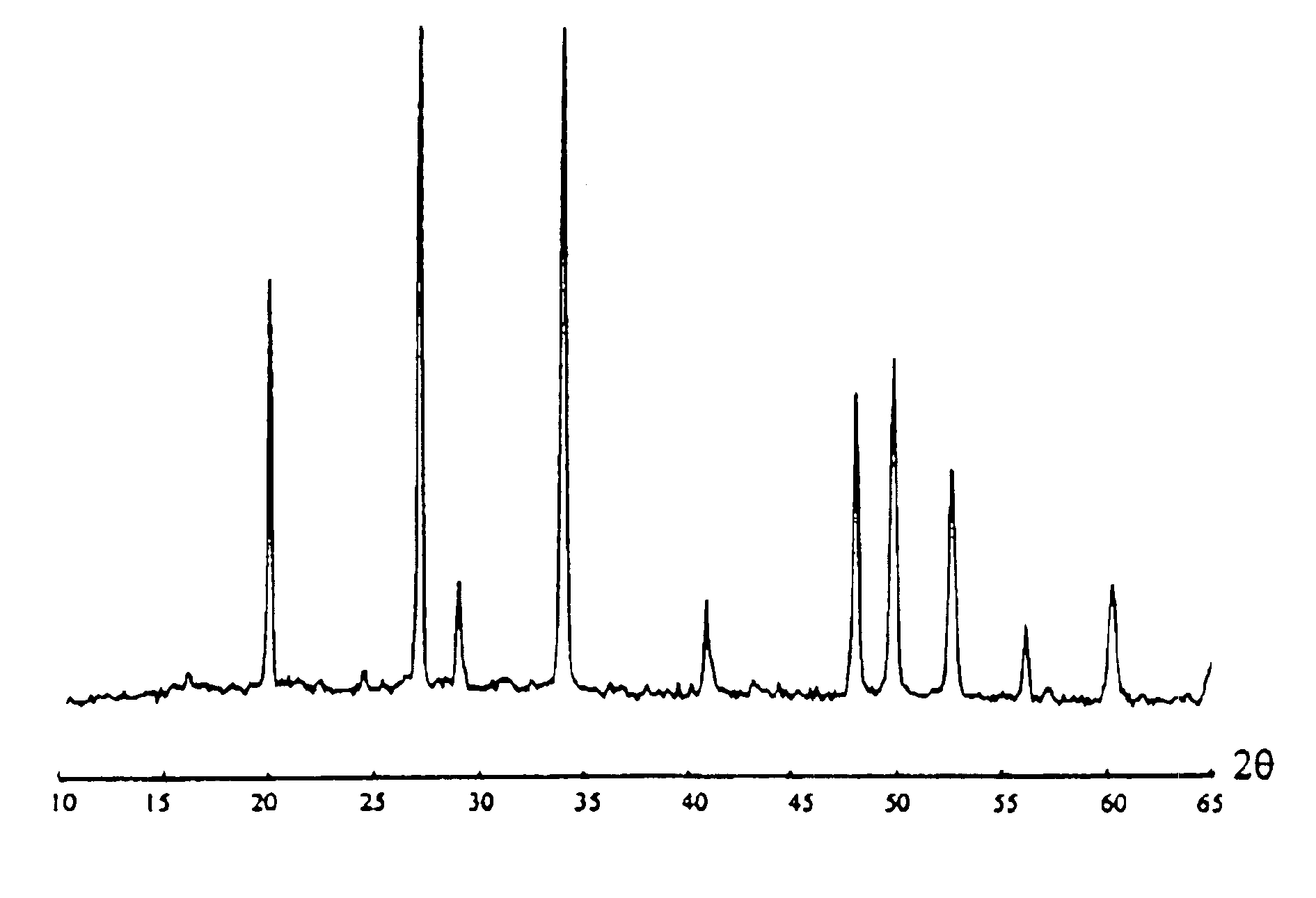

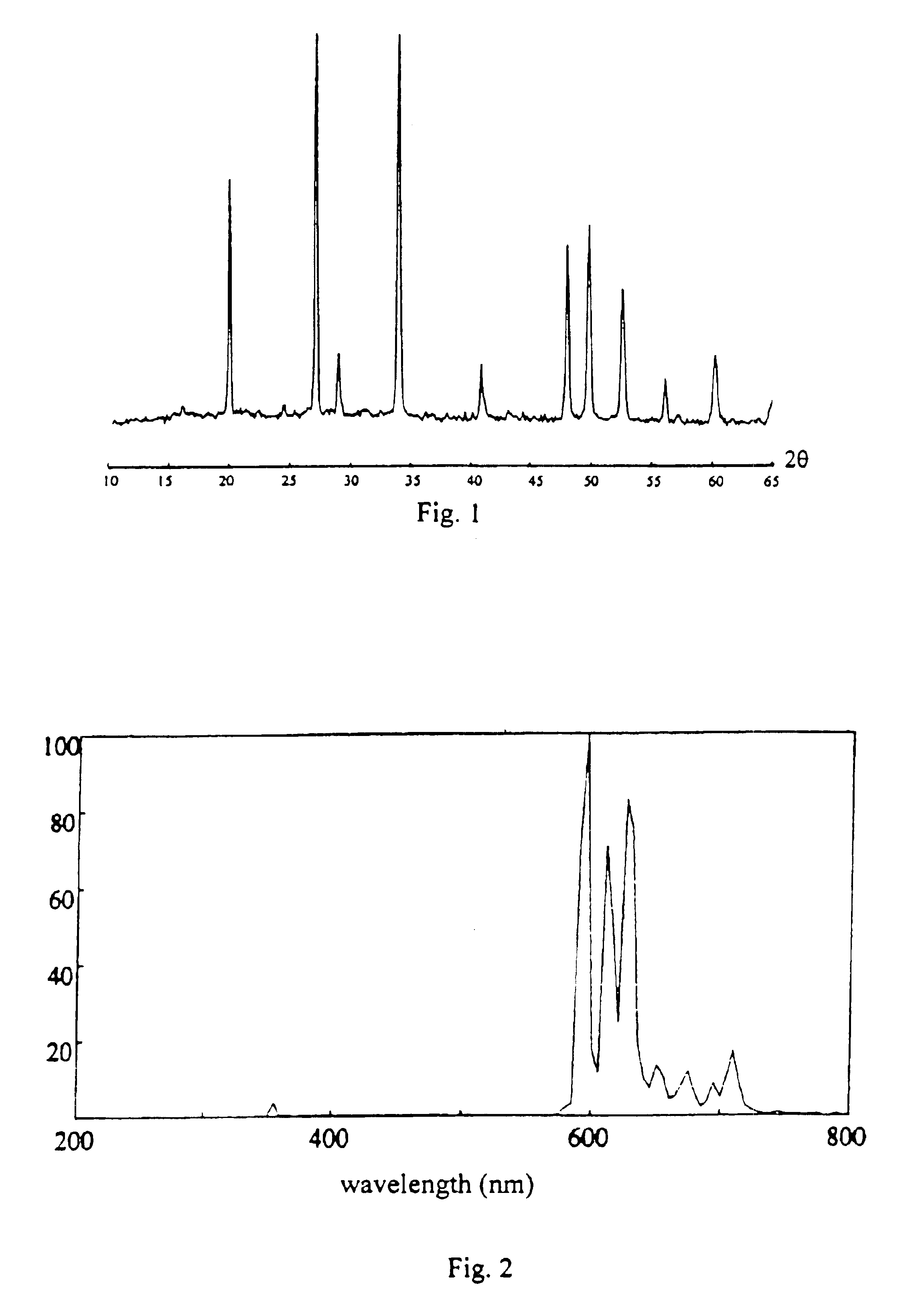

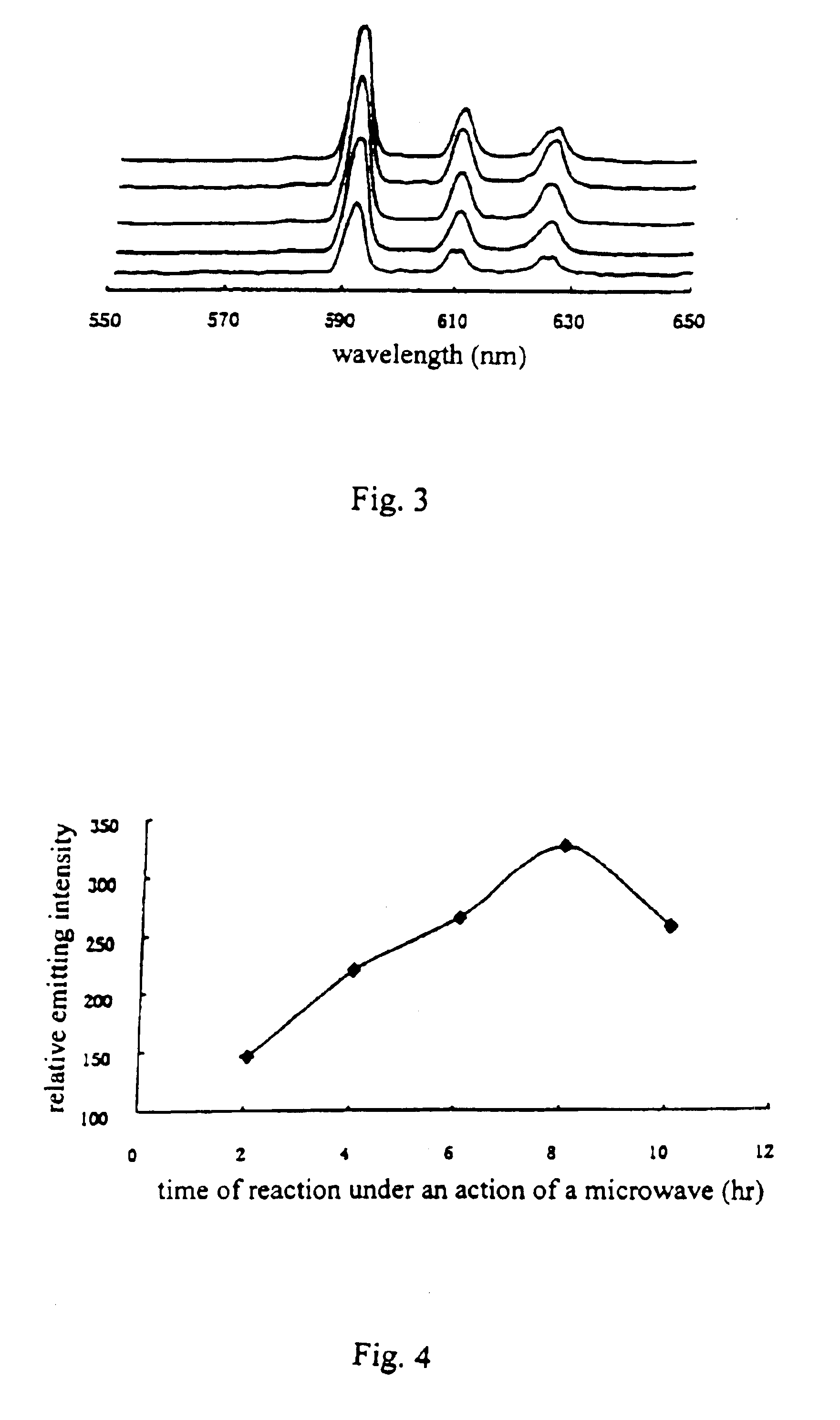

Method for the production of europium activated yttrium gadolinium borate phosphor particles

InactiveUS6905636B2Short periodUniformity and purity and particle sizeLuminescent compositionsYttriumAqueous solution

The present invention relates to a method for producing europium activated yttrium gadolinium borate phosphors and a product produced by the method. The chemical formula of said phosphors is (Y1-x-y-zEuxGdyMz)BO3, wherein: 0.01≦x≦0.01, 0≦y≦0.5, M=Ca, Sr, Ba or Mg, 0≦z≦0.1. The method comprises: mixing a yttrium source, an europium source, a gadolinium source, a boron source and an M source to produce an aqueous solution in a microwave system; placing the aqueous solution into a microwave system, and making the solution reacting under the condition of condensation cycling and stirring to produce a sol; heating the sol in a microwave system to produce a gel; drying, baking, washing and collecting the gel to produce the product. The method of the present invention can greatly short the production period and improve the production efficiency. The europium activated yttrium gadolinium borate phosphor particles is of a particle size as fine as 80 nm and has good uniformity and emitting performance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

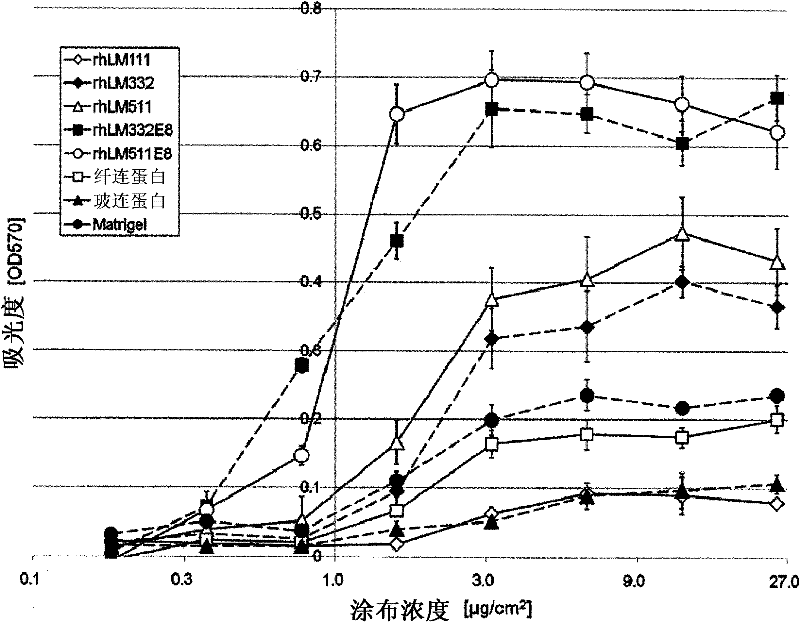

Culture substratum for human pluripotent stem cells, and use thereof

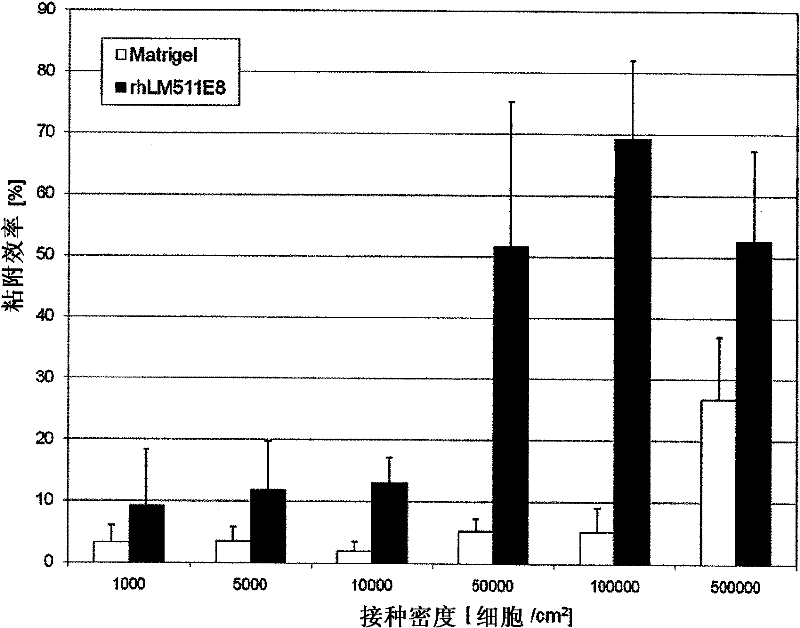

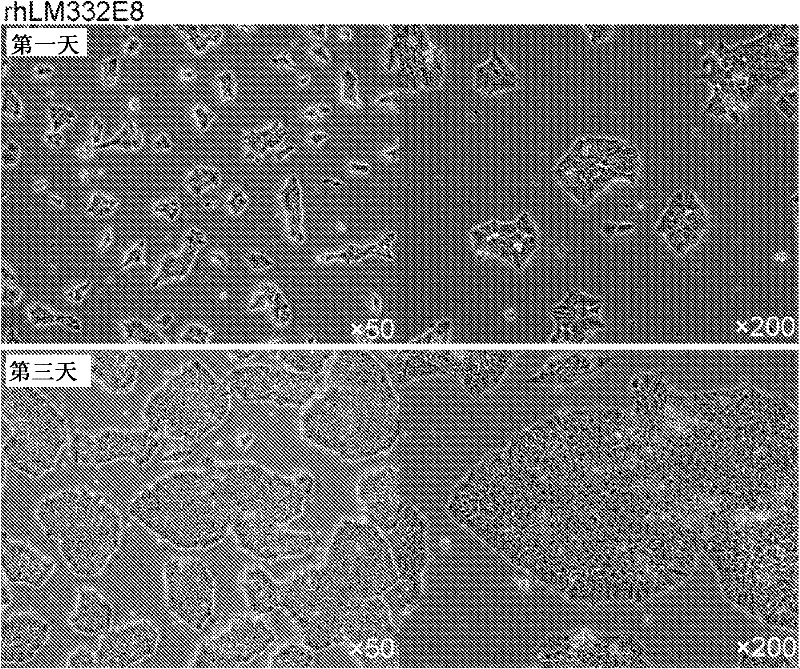

ActiveCN102597217AImprove securityRapid expansionCell culture supports/coatingArtificially induced pluripotent cellsCulture environmentMultipotent cell

Disclosed are: a culture substratum which can retain and culture human pluripotent stem cells under a feeder-free culture environment while maintaining the pluripotency of the stem cells; and a method for culturing human pluripotent stem cells using the culture substratum. Human pluripotent stem cells which are dispersed in the form of single cells are seeded onto a culture substratum at a density of 4*104 to 10*104 cells / cm<2>, wherein the culture substratum is one intended to be used for culturing human pluripotent stem cells and has been coated with an E8 fragment of human laminin [alpha]5[beta]1[gamma]1 or an E8 fragment of human laminin [alpha]3[beta]3[gamma]2 preferably at a concentration of 0.5 to 25 [mu]g / cm<2>. In this manner, human pluripotent stem cells can be expanded rapidly while maintaining the pluripotency of the stem cells.

Owner:OSAKA UNIV +1

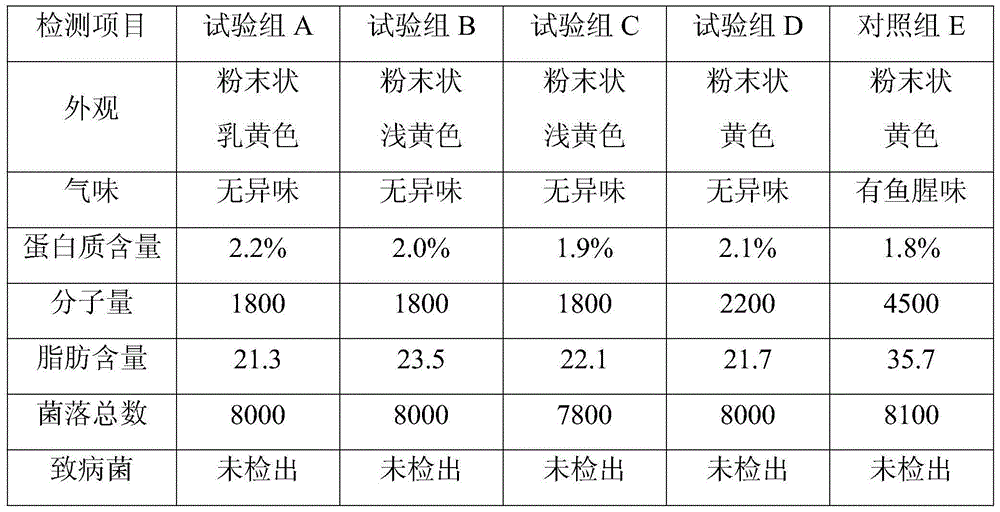

Extraction method of aquatic collagen

The invention relates to a preparation method of a peptide or a protein, and discloses an extraction method of an aquatic collagen. The method comprises the following steps: raw material treatment, enzymolysis and purification treatment. The aquatic collagen is obtained by the following specific steps: washing and crushing the raw materials; soaking by sodium chloride liquor and centrifugalizing the raw materials; carrying out enzymolysis by virtue of a compound enzyme for 8-15 hours at 45-50 DEG C; inactivating, filtering, freezing and drying an enzymatic hydrolysate. The collagen product prepared by the method provided by the invention is low in molecular weight and good in solubleness, and can be used for overcoming the technical problems of peculiar smell and fishy smell of conventional aquatic collagens, low purity, poor color and luster and the like. The collagen product is high in purity, uniform in color and luster, free from peculiar smell, simple and convenient in production and shorter in period, and can be widely applied to industries such as foods, health-care products and cosmetics.

Owner:NINGBO XINUOYA MARINE BIOTECH CO LTD

Hollow heat-retaining putty

InactiveCN101555366ALow water absorptionReduce coefficient of frictionFilling pastesFiberCrack resistance

The invention relates to hollow heat-retaining putty which is prepared by the following steps: mineral fiber, heat-response powder and base material gluing auxiliary powder are evenly mixed with a weight proportion of 1.0-2.0:0.2-0.8:89.5-137.3 to prepare the putty, ant the putty is weighted and packaged by bags. The putty overcomes the defects that the prior product has large blocking force, is easy to sag and can not ensure the blow thickness of a coat when being used in construction, the grains of the product are easy to smash when being stirred and blown, and the adhesive force is unsteady. The invention has fire resistance, heat insulation, heat preservation, sound insulation, crack resistance and yellowing resistance, steady structure, long quality guarantee period and low cost, thereby being particularly suitable for the actual need of energy saving in construction engineering.

Owner:胡建中

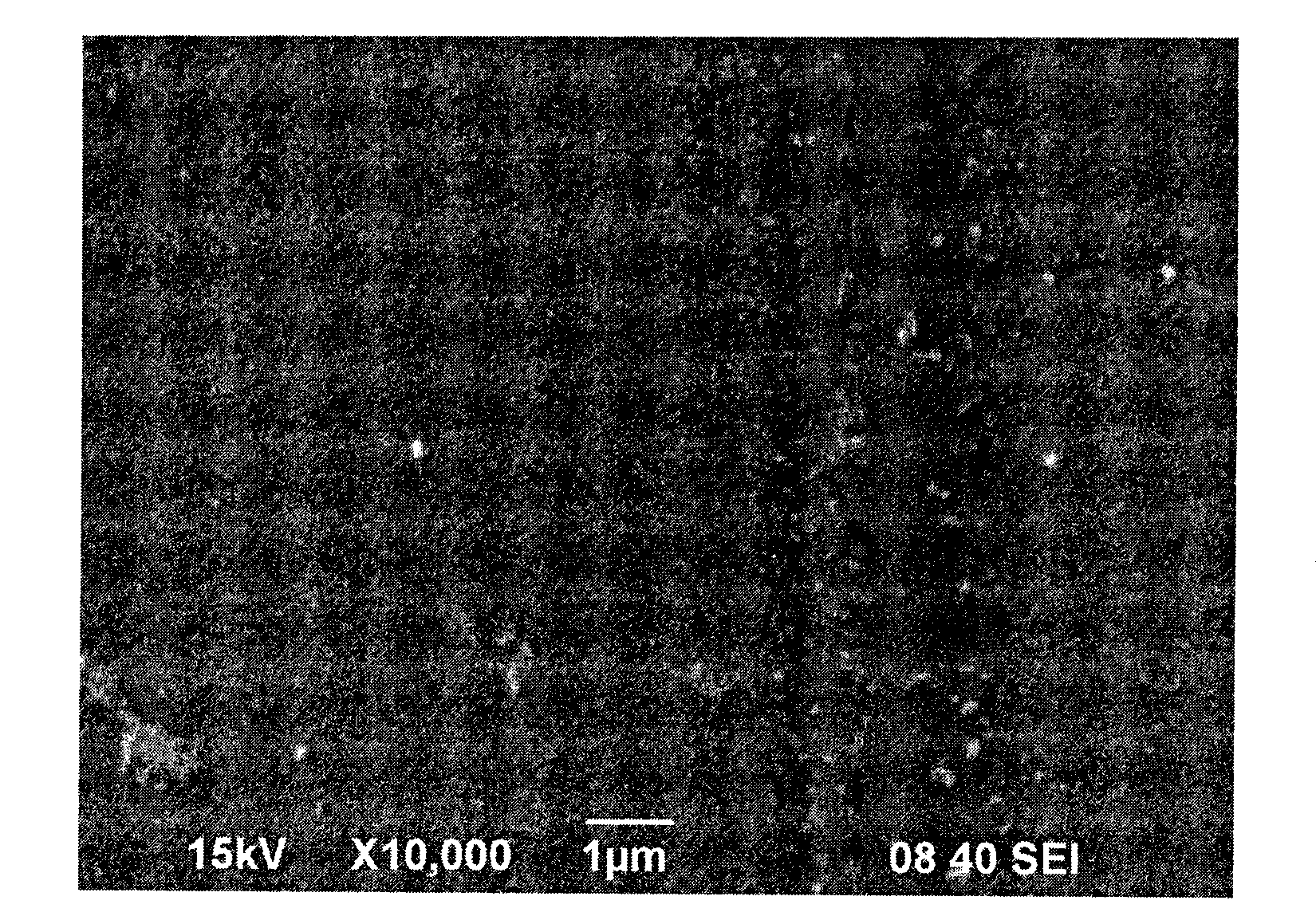

Simple method for preparing polyimide film surface modified nano-hydroxyapatite coating

The invention relates to a simple method for preparing a polyimide film surface modified nano-hydroxyapatite coating. The method comprises the following steps: firstly, soaking a polyimide film in a strong alkali aqueous solution for 4-12 hours; secondly, adding a (Ca<2+>)-containing aqueous solution to react for 4-6 hours; and finally, adding a (PO4<3->)-containing aqueous solution to react for 24-72 hours so as to prepare the polyimide film surface modified nano-hydroxyapatite coating. The molar ratio of the (Ca<2+>) to (PO4<3->) which are added in a reaction system is 1.5-2. The reaction is carried out under mild conditions that the pressure is one atmospheric pressure, the temperature is 10-40 DEG C and the pH value is 8-14. The polyimide film surface modified nano-hydroxyapatite coating prepared by the invention has the characteristics of high purity, uniform dispersion and the like. The method provided by the invention has the advantages of low energy consumption, mild conditions and simple equipment in the whole preparation process, is easy to realize, is suitable for large-scale industrial production, and is wide in application prospect.

Owner:HENAN NORMAL UNIV

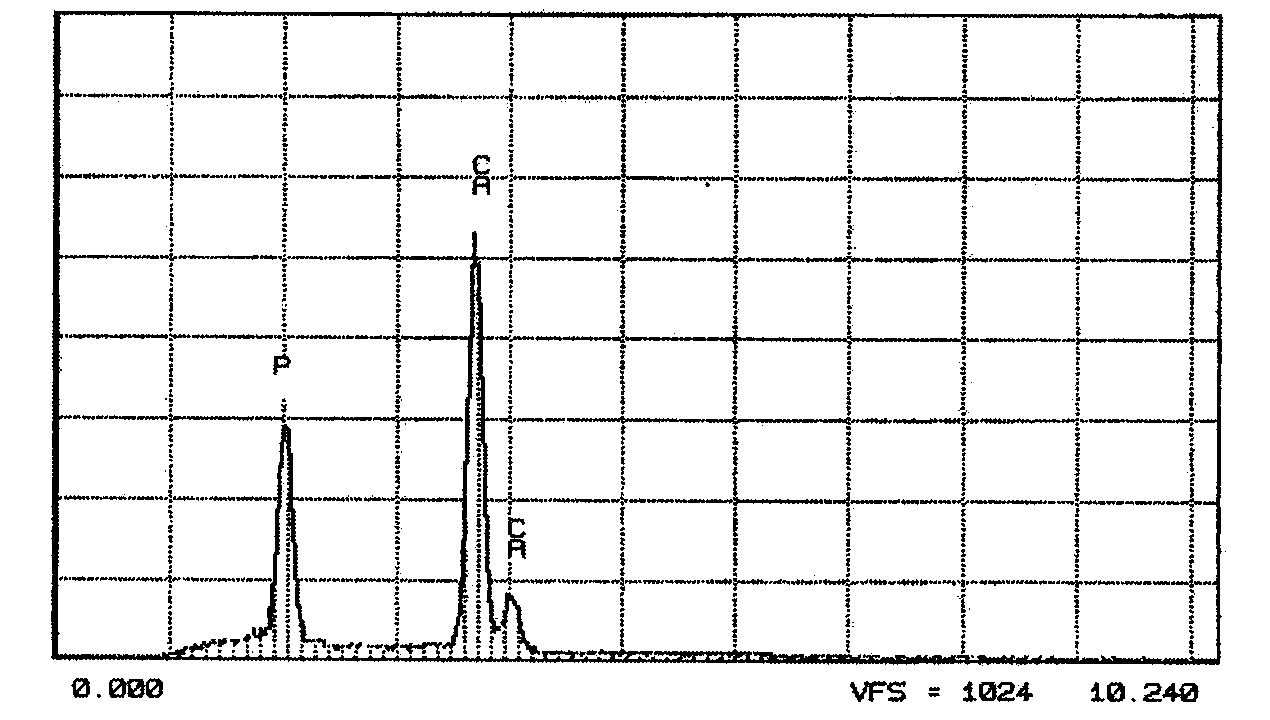

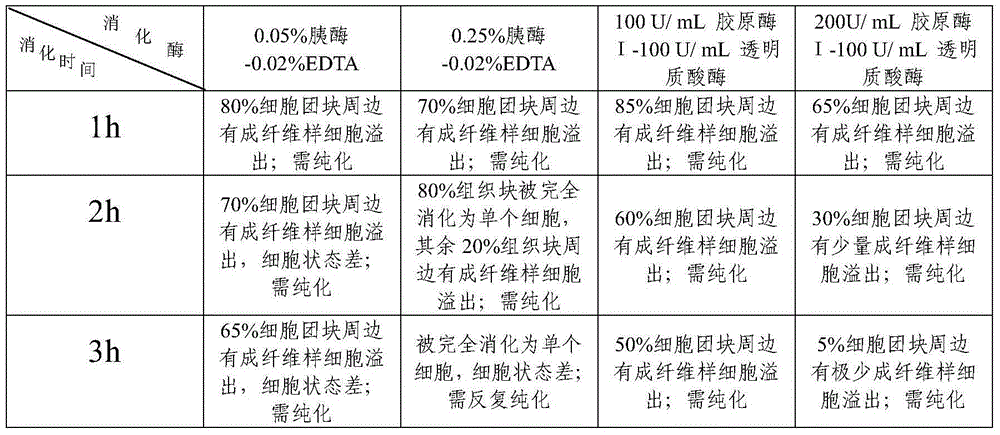

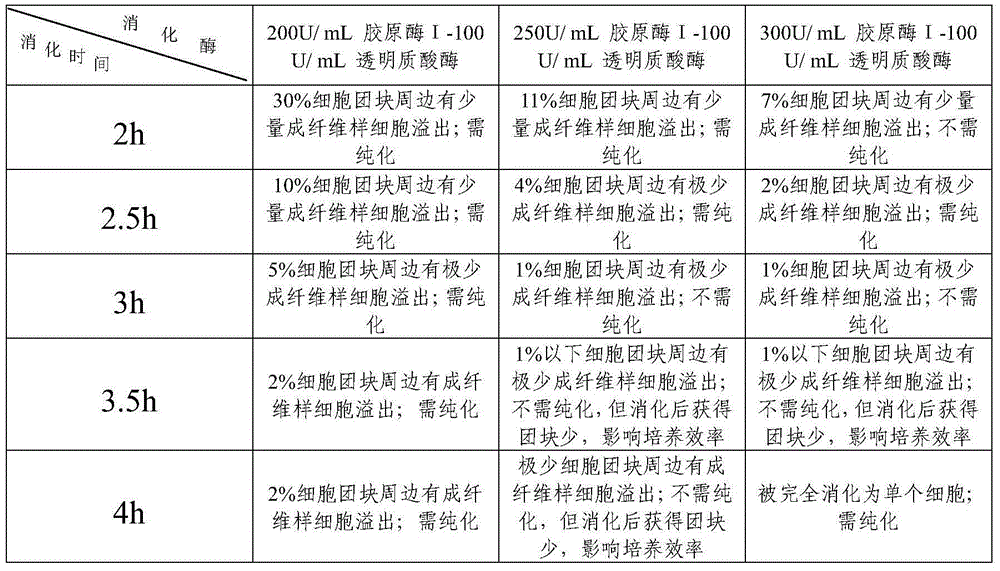

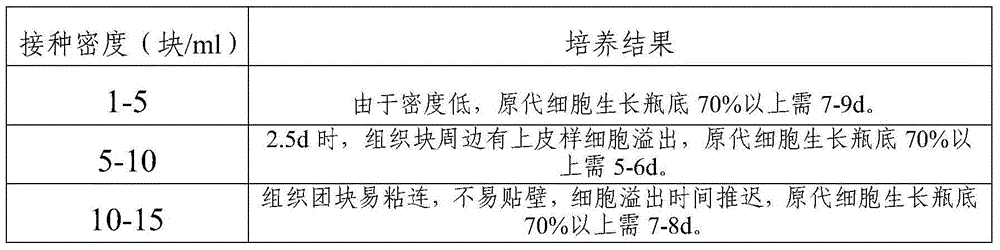

Method for efficiently separating and purifying mammary epithelial cells

InactiveCN105316279AReduce incubation timeImprove cultivation efficiencyArtificial cell constructsVertebrate cellsDiseaseGestation

The invention discloses a method for efficiently separating and purifying mammary epithelial cells. The method is suitable for a plurality of mammals. The mammary tissues of adult mammals, which are in the middle and later periods of gestation or in the lactation period, are collected through aseptic operation. According to the provided method, the separation and purification can be achieved in one step, the whole experiment is simple and efficient; the purification, which comprises repeated differential digestion and differential attachment, in the conventional method is eliminated, the purity of mammary epithelial cells obtained by the provided method can reach 98% or more, the obtained mammary epithelial cells can be continuously cultured in-vitro and passed down for 40 generations, and the lactating function of mammary epithelial cells is not affected. The obtained mammary epithelial cells can be applied to the researches on growth of mammary gland, lactating mechanism, mammary bioreactor, transgenic animals, mammary diseases, and the like.

Owner:北京大北农科技集团股份有限公司动物医学研究中心 +3

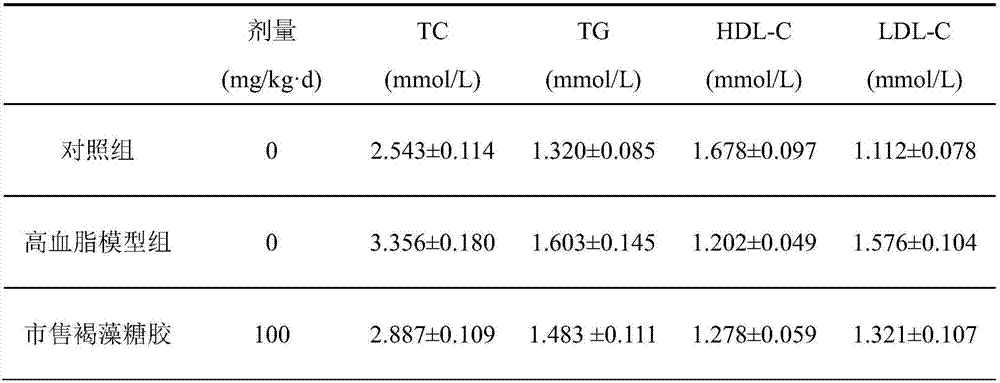

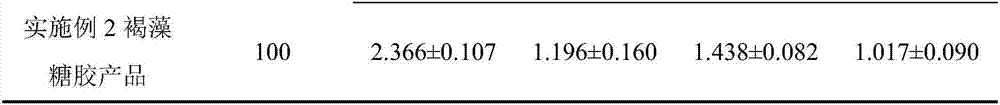

A method of preparing fucoidan having an efficiently customized molecular weight and applications of the fucoidan

ActiveCN106866834AUniform purityUniform structureOrganic active ingredientsMetabolism disorderMicrowaveFucoidan

A method of preparing fucoidan having an efficiently customized molecular weight and applications of the fucoidan are disclosed. The method includes subjecting kelp fucoidan that is adopted as a raw material to microwave dissolution and ultrasonic degradation to obtain a fucoidan degraded solution; grading the fucoidan degraded solution by utilizing high-flow-speed agarose gel chromatography; collecting a solution of low-molecular-weight fucoidan having the target molecular weight; subjecting the solution of fucoidan having other molecular weights to ultrasonic degradation again, performing grading by utilizing the high-flow-speed agarose gel chromatography, and collecting a solution of low-molecular-weight fucoidan having the target molecular weight; combining all target fucoidan solutions; filtering the obtained target fucoidan solution by utilizing a nanofiltration membrane; subjecting a filtration product to desalting and concentration; diluting the fucoidan concentrate again; then subjecting the diluted fucoidan concentrate to nanofiltration, concentration and desalting again; precipitating the fucoidan with an ethanol solution, and washing and drying the fucoidan to obtain a fucoidan product having the low molecular weight. The method keeps active components of the fucoidan to the utmost. The purity of a target product that is a fucoidan product having high purity and a uniform low molecular weight is as high as 95% or above.

Owner:点滴(南京)生物科技有限公司

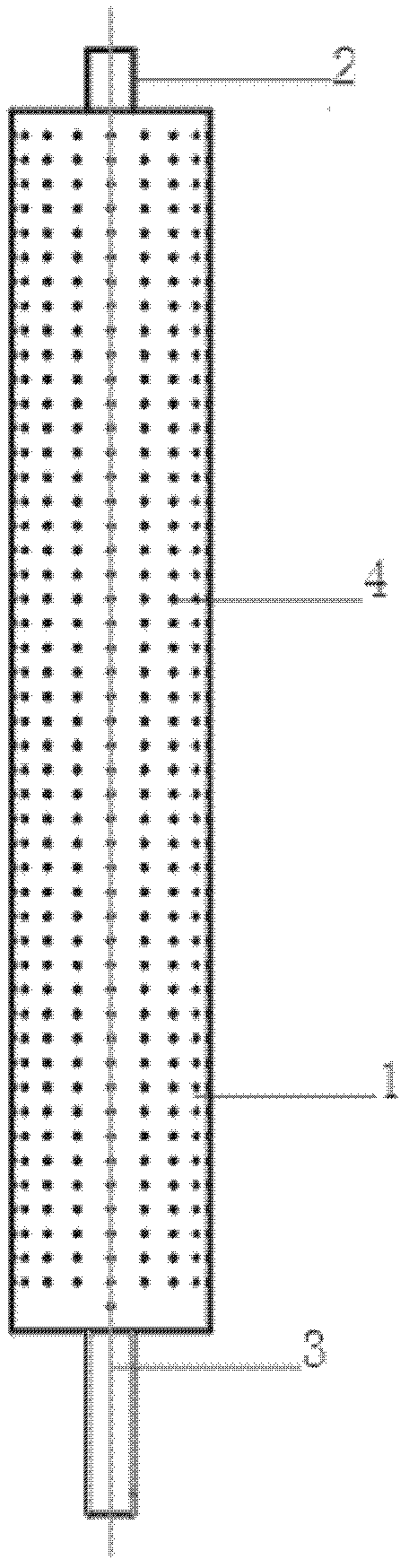

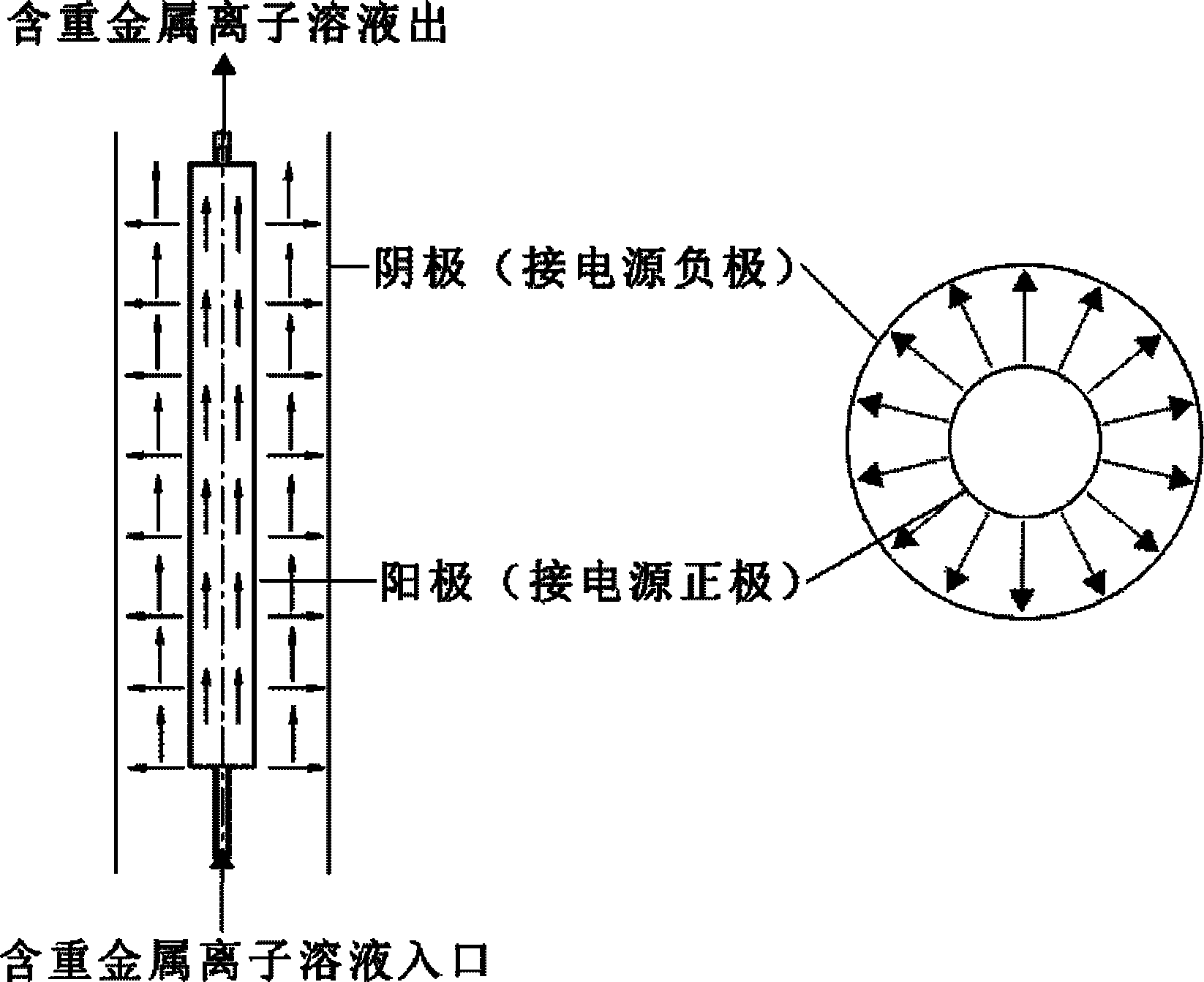

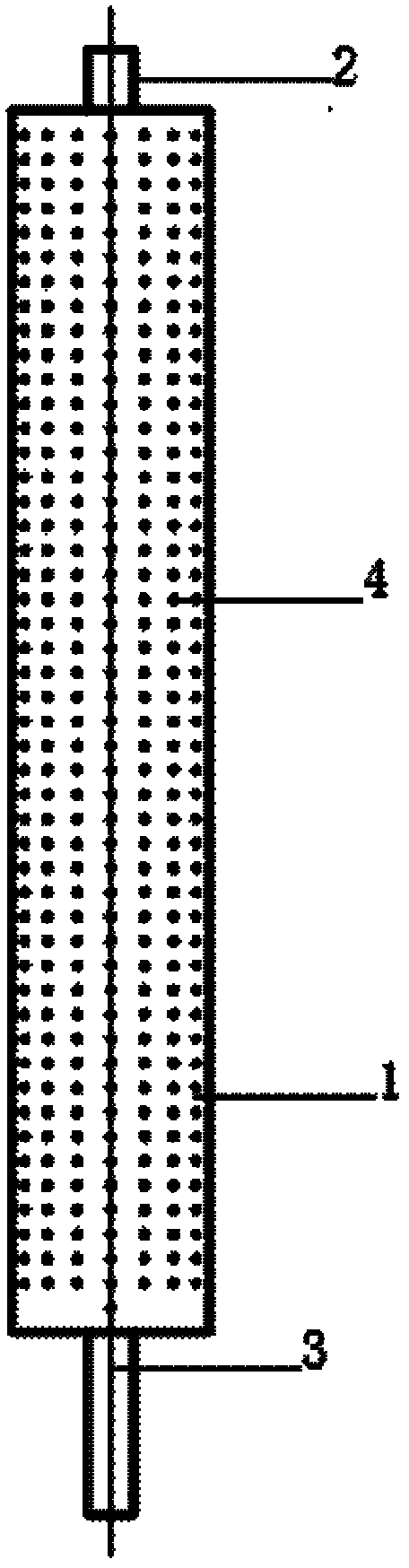

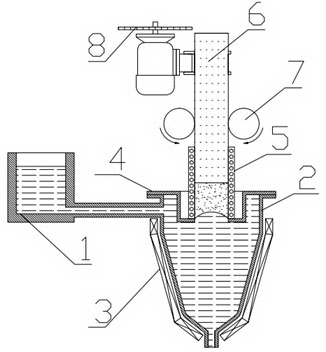

Anode for cylindrical jet-state direct electrodeposition devices

The invention discloses an anode for cylindrical jet-state direct electrodeposition devices, which comprises an anode tube, an upper coaxial positioning column and a lower coaxial positioning column, wherein the anode tube is a hollow cylinder, jet holes are uniformly distributed on the outer edge surface of the anode tube, and the lower coaxial positioning column is a hollow tube; one end of the anode tube is connected with the upper coaxial positioning column, and the other end of the anode tube is connected with the lower coaxial positioning column; the anode tube, the upper coaxial positioning column and the lower coaxial positioning column are coaxially arranged, and an inner-cylinder cavity of the anode tube is communicated with a hollow tube in the lower coaxial positioning column. The invention relates to one of core components of a cylindrical jet-state electrodeposition device, and the cylindrical jet-state electrodeposition device disclosed by the invention can effectively overcome the concentration polarization of a cathode surface, so that metal ions are successfully reduced and deposited on the cathode surface of a cathode. Therefore, compared with metal raw materials produced in previous modes, a metal raw material produced by the anode is more uniform in purity and better in surface effect.

Owner:工信华鑫科技有限公司

Production method of low-hydroxyl rosy rare-earth-doped quartz tube

ActiveCN103387328AUniform penetrationGood colorGlass shaping apparatusHydrofluoric acidManufacturing technology

The invention discloses a production method of a low-hydroxyl rosy rare-earth-doped quartz tube. The invention belongs to the technical field of quartz tube production. The method comprises the steps that: (1) raw materials are selected, wherein high-purity quartz is selected; (2) stirring is carried out, wherein various rare earth nitrating agents such as samarium nitrate are added into the raw material, and mixing and stirring are carried out; (3) dilution is carried out, wherein strong hydrofluoric acid is added, and a dilution reaction is carried out; (4) doping is carried out, wherein the material is doped with a high-purity quartz powder material; and the mixture is placed into a high-temperature-resistant quartz tube; (5) bake-drying is carried out, wherein high-temperature continuous bake-drying is carried out, such that the various rare earth nitrating agents completely penetrating into the quartz powder material; (6) melting is carried out, wherein the material is molten in a continuous melting furnace; through tube-drawing machine drawing, an integrally colored rosy quartz tube is obtained; and (7) decarboxylation is carried out, wherein the rosy quartz tube is subjected to high-temperature decarboxylation in a vacuum decarboxylation furnace. The method is mainly used in the aspect of quartz tube manufacturing.

Owner:连云港龙立石英制品有限公司

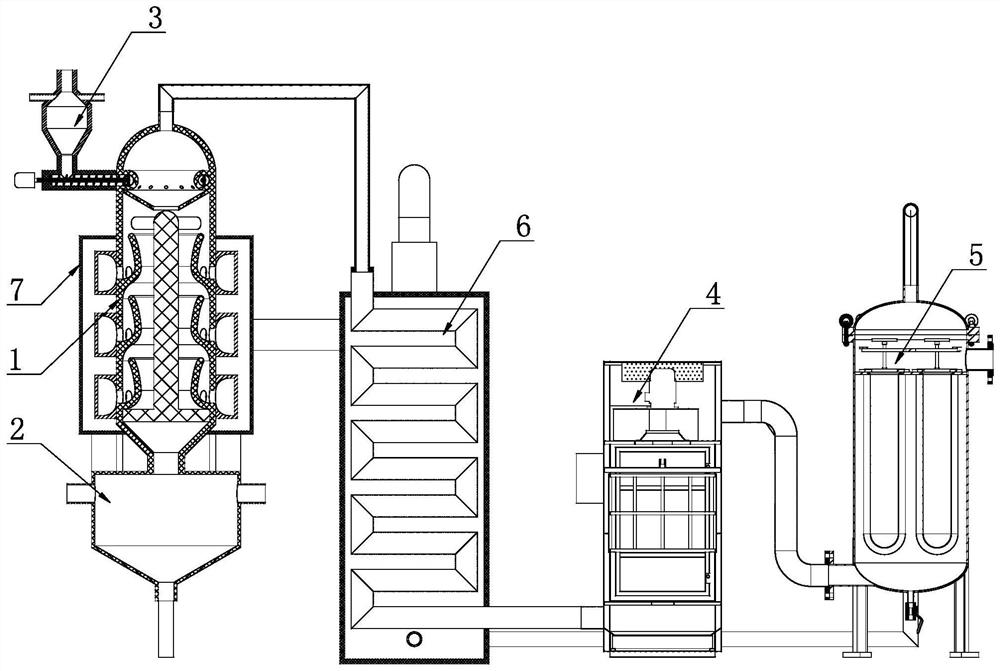

High-purity aluminum continuous purifying device

The invention provides a high-purity aluminum continuous purifying device which purifies molten aluminum by utilizing a hydrocyclone structure consisting of a crucible, a crucible cover and a crystallizer. On the one hand, due to normal segregation, pure aluminum crystals are obtained on a solid-liquid interface in the crystallizer and impurities are diffused to molten aluminum from the solid-liquid interface, so that density of adjacent molten aluminum is enlarged due to increase of content of the impurities, and on the other hand, due to gravity segregation under the centrifugal effect, the molten aluminum with high content of the impurities is centrifugalized to the crucible wall and gradually moves to a bottom flow port, and the molten aluminum with low content of the impurities is extruded to the solid-liquid interface due to small density. Under the effect of normal segregation and gravity segregation, the purifying efficiency is greatly improved. The device provided by the invention can produce continuously, is energy-saving and efficient, simple in structure and safe and reliable, and can be combined to use through various modes.

Owner:李霞

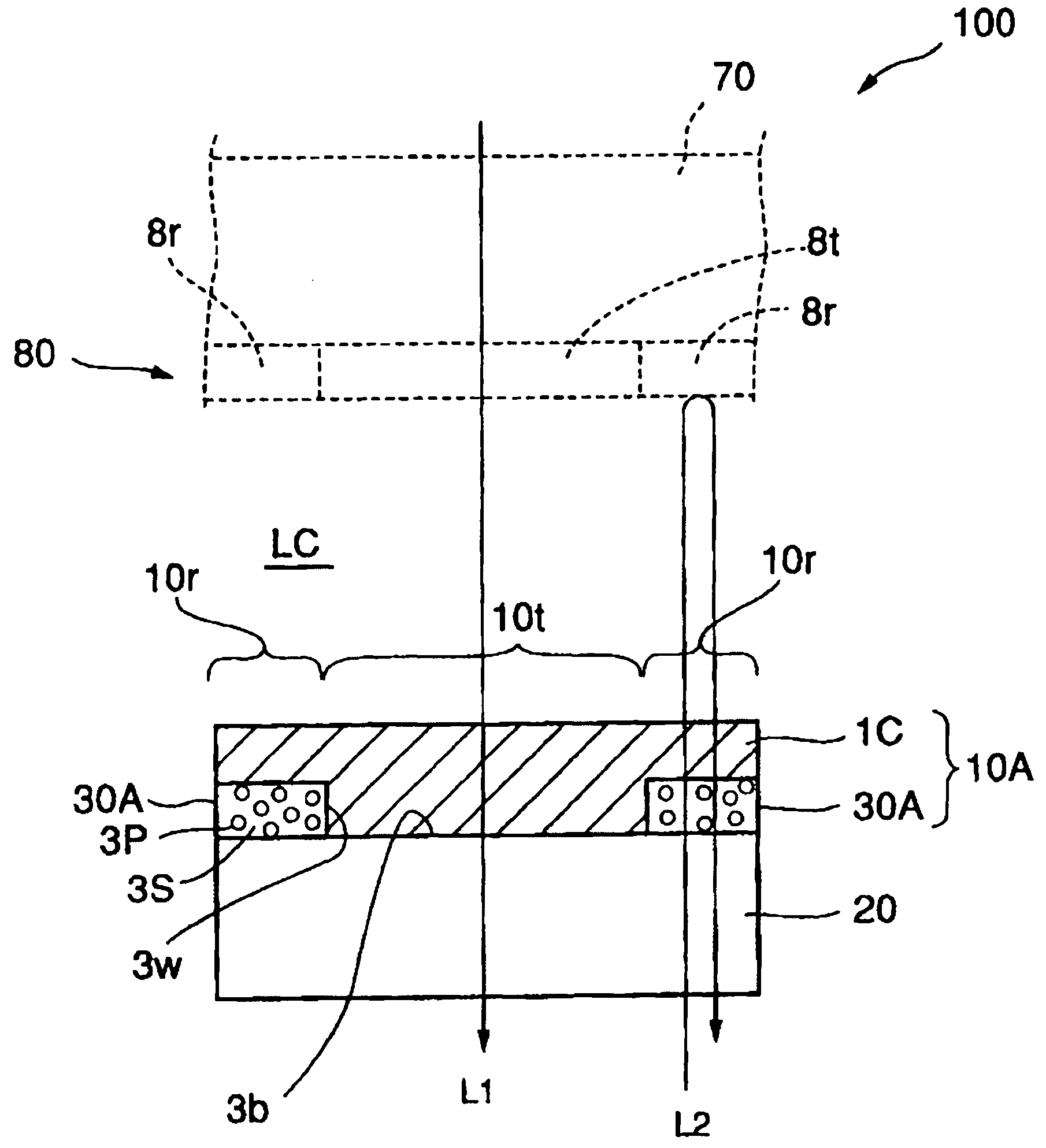

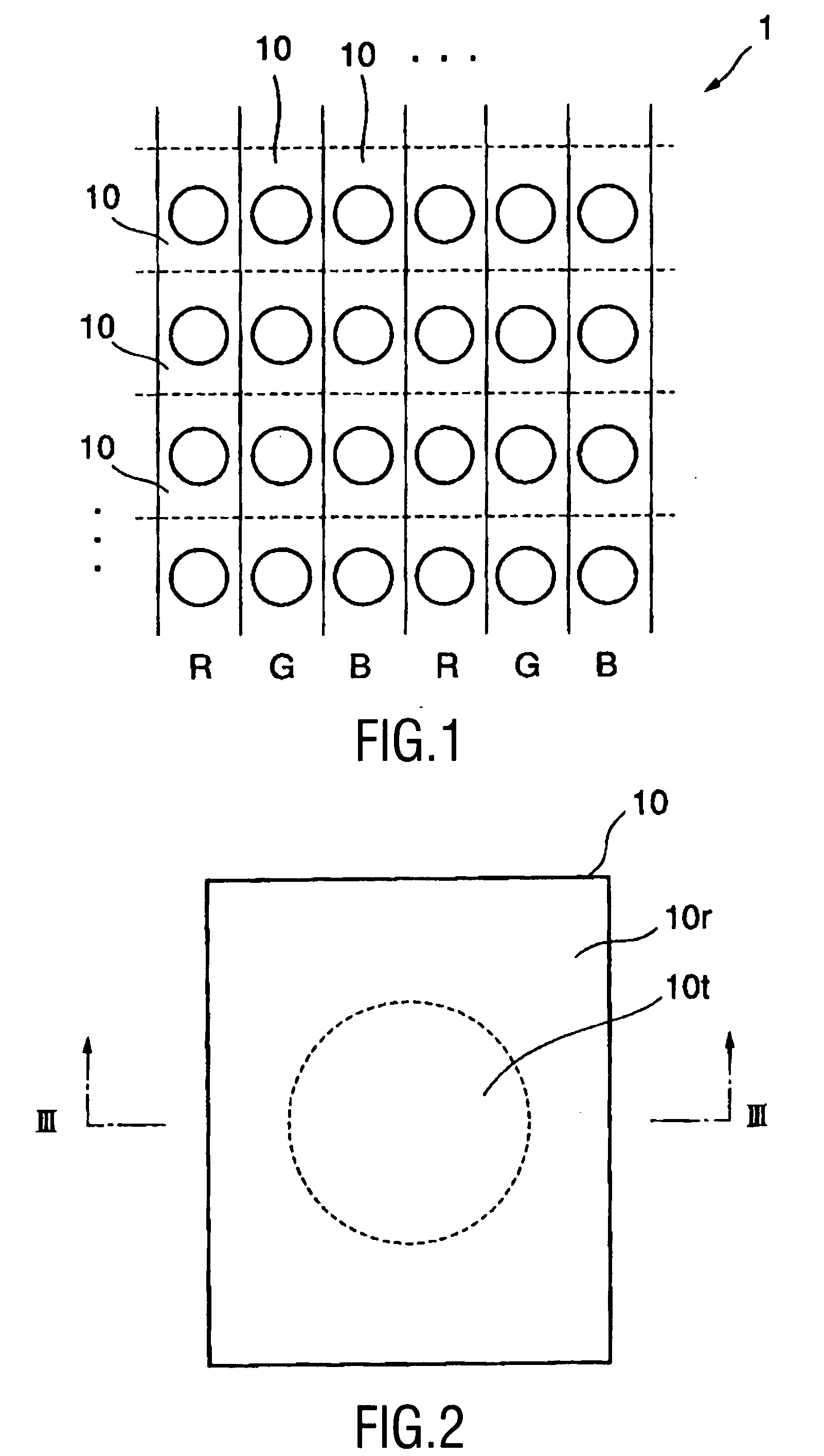

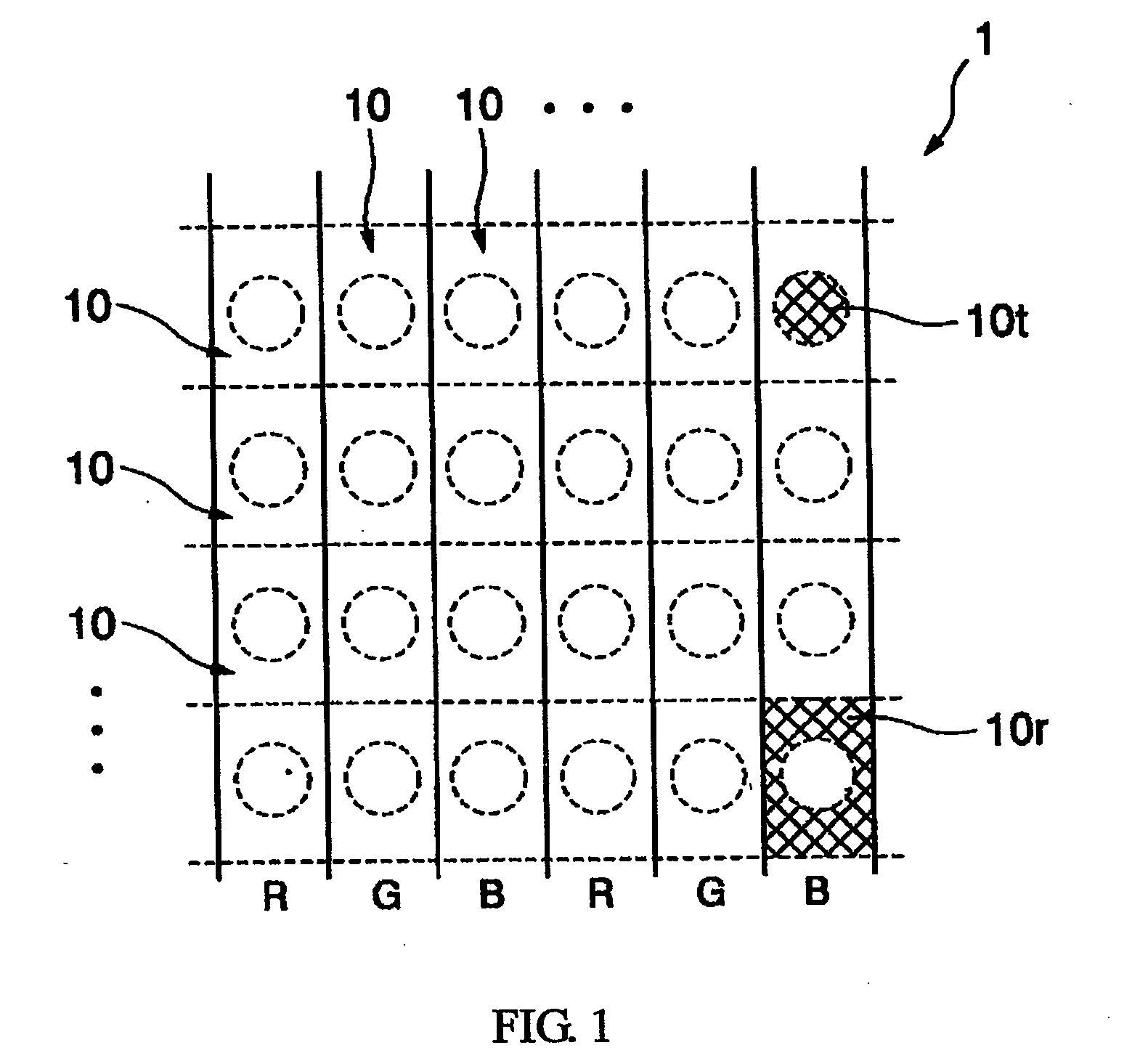

Color filter and liquid crystal display device using it, and manufacturing method thereof

InactiveUS20040169796A1Uniform puritySuppress light leakageMirrorsDiffusing elementsLiquid-crystal displayColor filter array

An object of the invention is to provide a color filter and a liquid crystal display device using it, which can acquire uniform color purity within a pixel. A color filter for coloring the first light ray L1 having a unidirectional optical path and the second light ray L2 having a bidirectional optical path for each pixel. This filter comprises: a step-forming layer of optically transmissive material, which can be supported by a base layer 20, and which is patterned for a pixel to form at least one recess-shaped portion having a bottom face 3b of a predetermined shape corresponding to an area wherein the first light ray L1 is caused to be transmitted and a wall face 3w of a predetermined height; and a coloring layer 1C deposited on the step-forming layer 30 and the recess-shaped portion for coloring the first and second light rays.

Owner:TPO HONG KONG HLDG

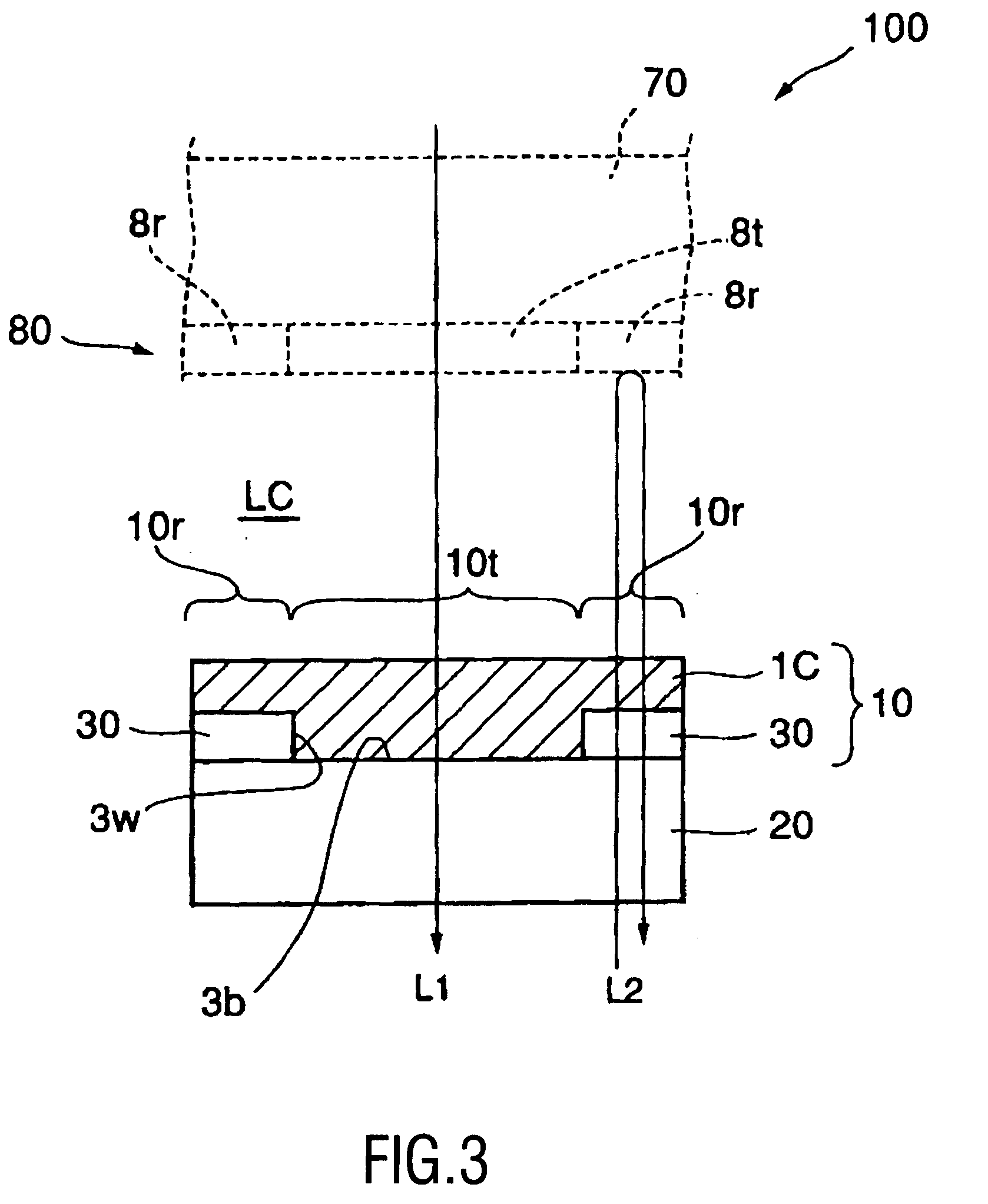

Color filter and liquid crystal display device using it, and their manufacturing methods

InactiveUS20060072055A1Easy handling and other processingEasy to manufactureOptical filtersNon-linear opticsOptical pathColor gel

An object of the invention is to acquire uniform color purity within a pixel to make a good color reproduction and to easily manufacture it with few constraints. A color filter for coloring a first light ray L1 having a unidirectional optical path and a second light ray L2 having a bidirectional optical path for each pixel (10). The color filter comprises: a first coloring portion 10t for coloring the first light ray L1 and a second coloring portion L2 for coloring the second light ray L2, the first coloring portion 10t having a greater thickness than the second coloring portion 10r, the first coloring portion 10t being formed in subsidence with respect to the second coloring portion 10r with a principal plane of the first coloring portion 10t being different in height from a principal plane of the second coloring portion 10r by a predetermined value D.

Owner:TPO HONG KONG HLDG

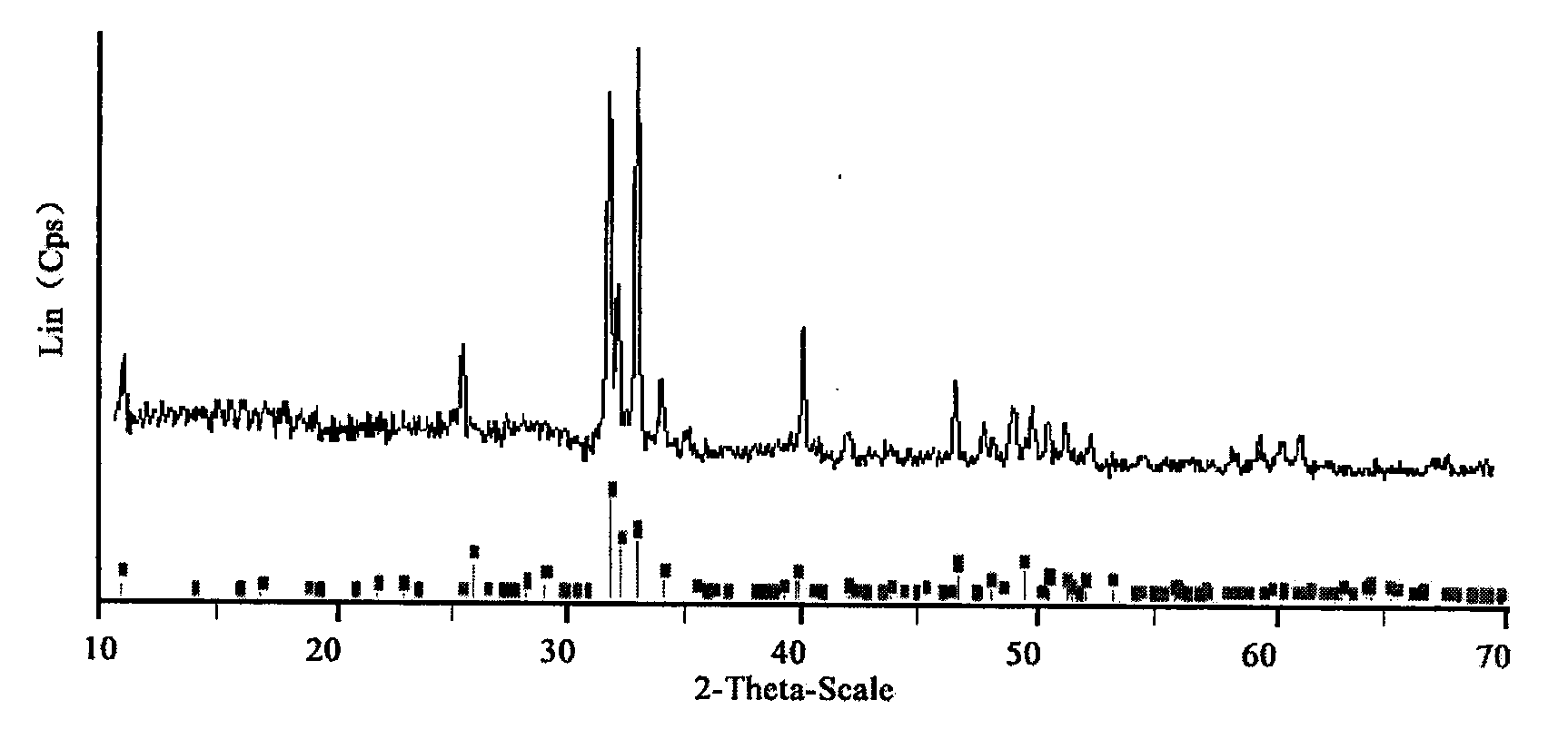

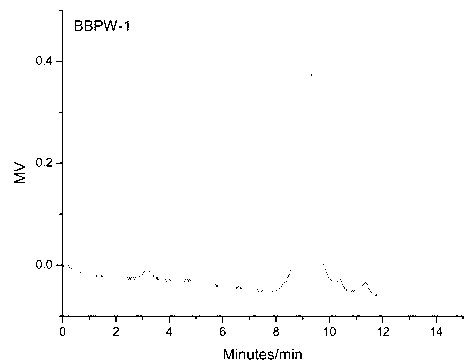

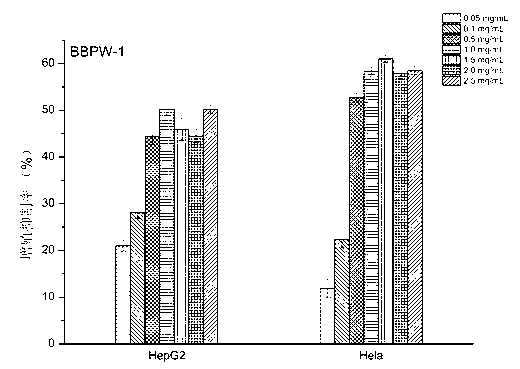

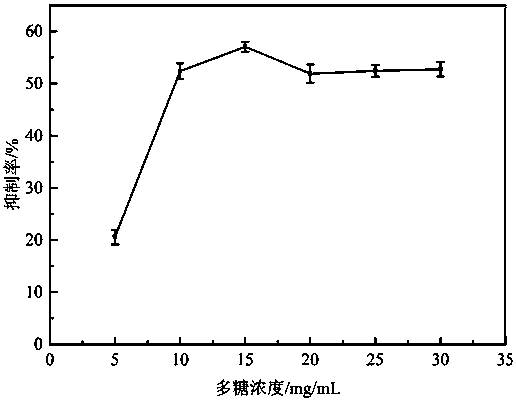

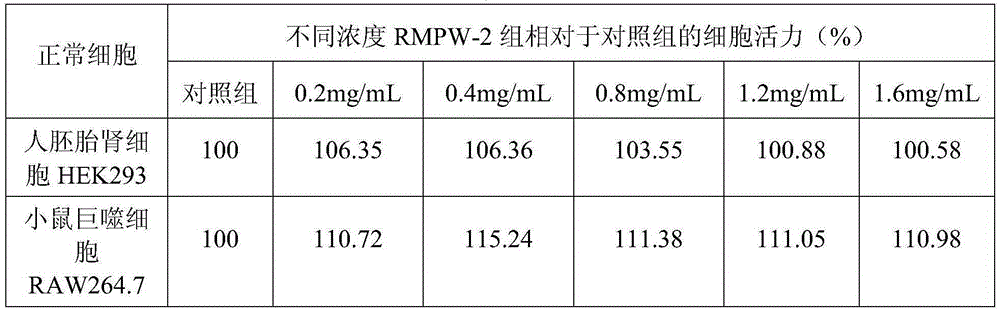

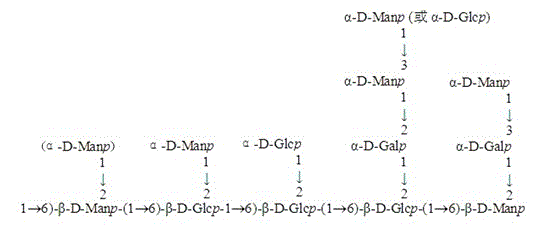

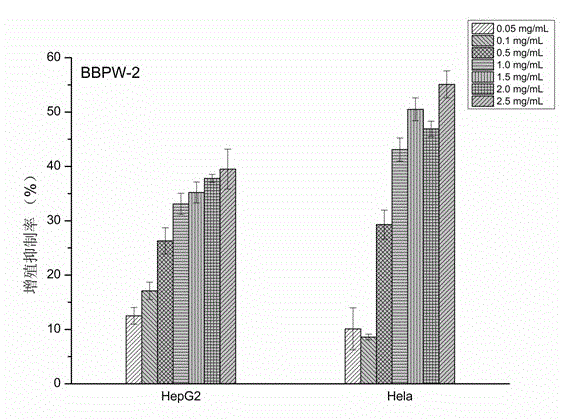

Separating and purifying method for preparing white muscardine silkworm anticancer-activity polysaccharide BBPW-1

InactiveCN103265643AHigh medicinal valueUniform purityAntineoplastic agentsFreeze-dryingIon exchange

The invention relates to a separating and purifying method for preparing white muscardine silkworm anticancer-activity polysaccharide BBPW-1, which comprises the following steps: degreasing white muscardine silkworm powder under reflux of acetone-petroleum ether and 80% ethanol to remove glycosides and alkaloids, and extracting with distilled water at 80-100 DEG C to obtain crude polysaccharide; and after removing proteins from the crude polysaccharide by a Sevag process, separating out the neutral polysaccharide component by DEAE (diethylaminoethanol) sepharose ion-exchange chromatography, carrying out propylene dextrangel S-300 chromatography, taking the first eluting peak, concentrating under reduced pressure, carrying out propylene dextrangel S-500 chromatography for further purification, and carrying out freeze-drying to obtain the white muscardine silkworm anticancer-activity polysaccharide BBPW-1. The product prepared by the method provided by the invention has uniform purity, and the molecular weight is 3.67*10<6>Da; and the product has an inhibiting action on growth of human cervical cancer cells Hela and human liver cancer cells HepG2, does not have any adverse effect on growth of normal human embryo kidney cells HEK293 and mouse macrophages RAW264.7, and can be used for developing anticancer products.

Owner:ZHEJIANG UNIV

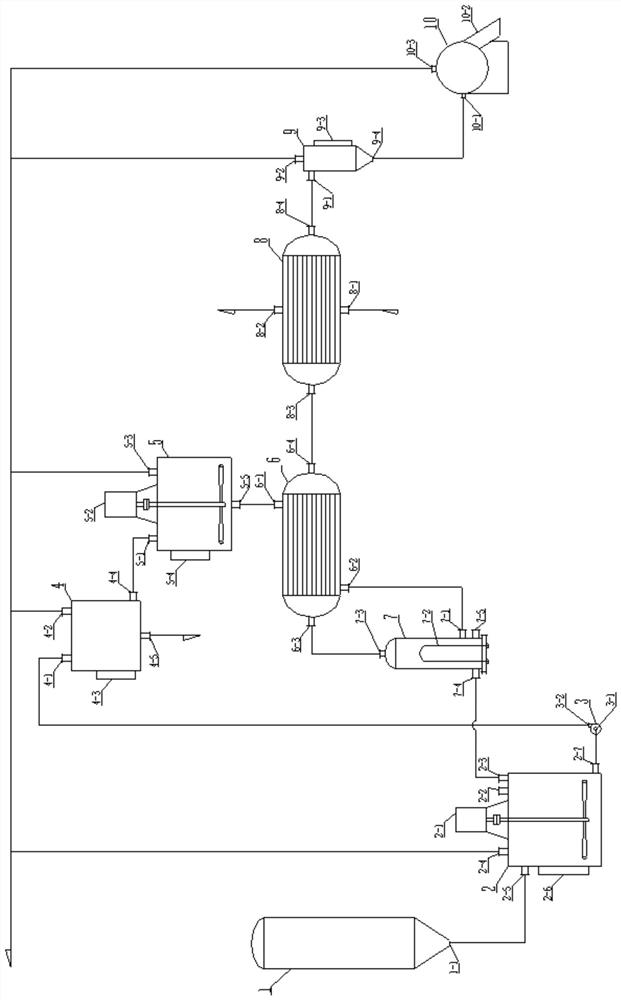

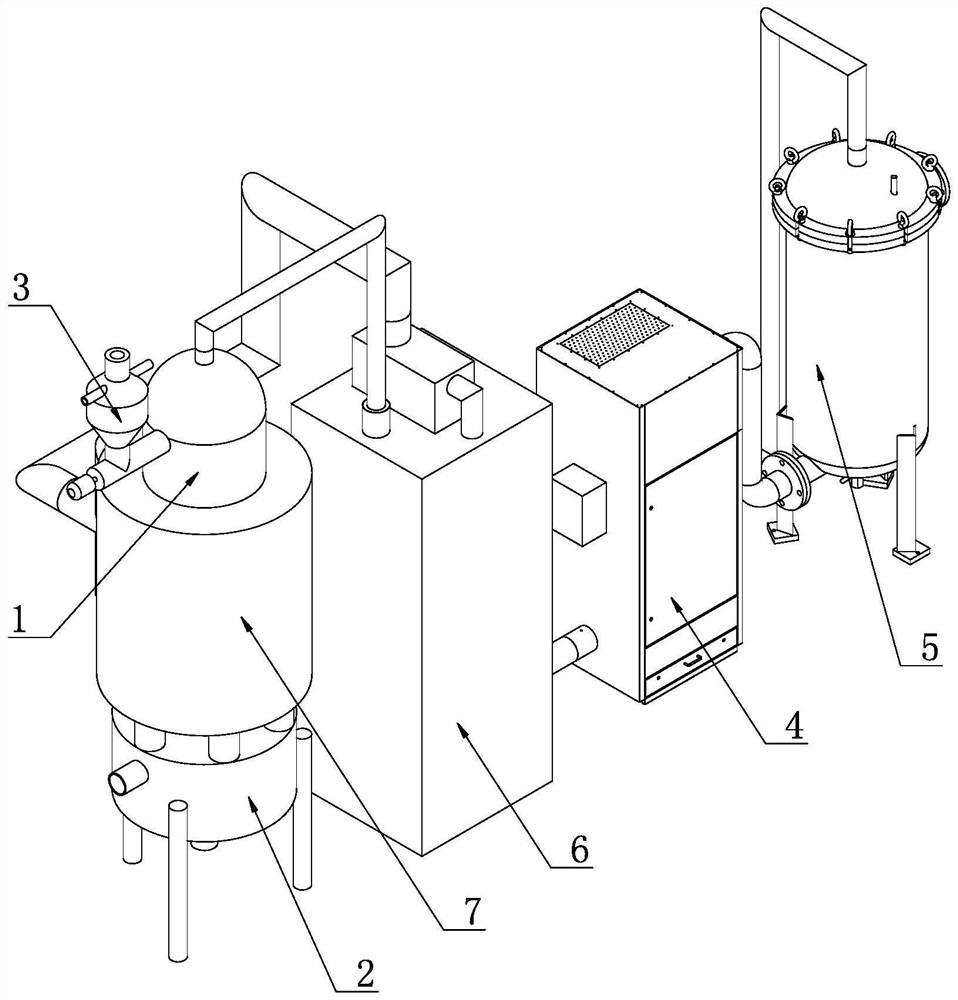

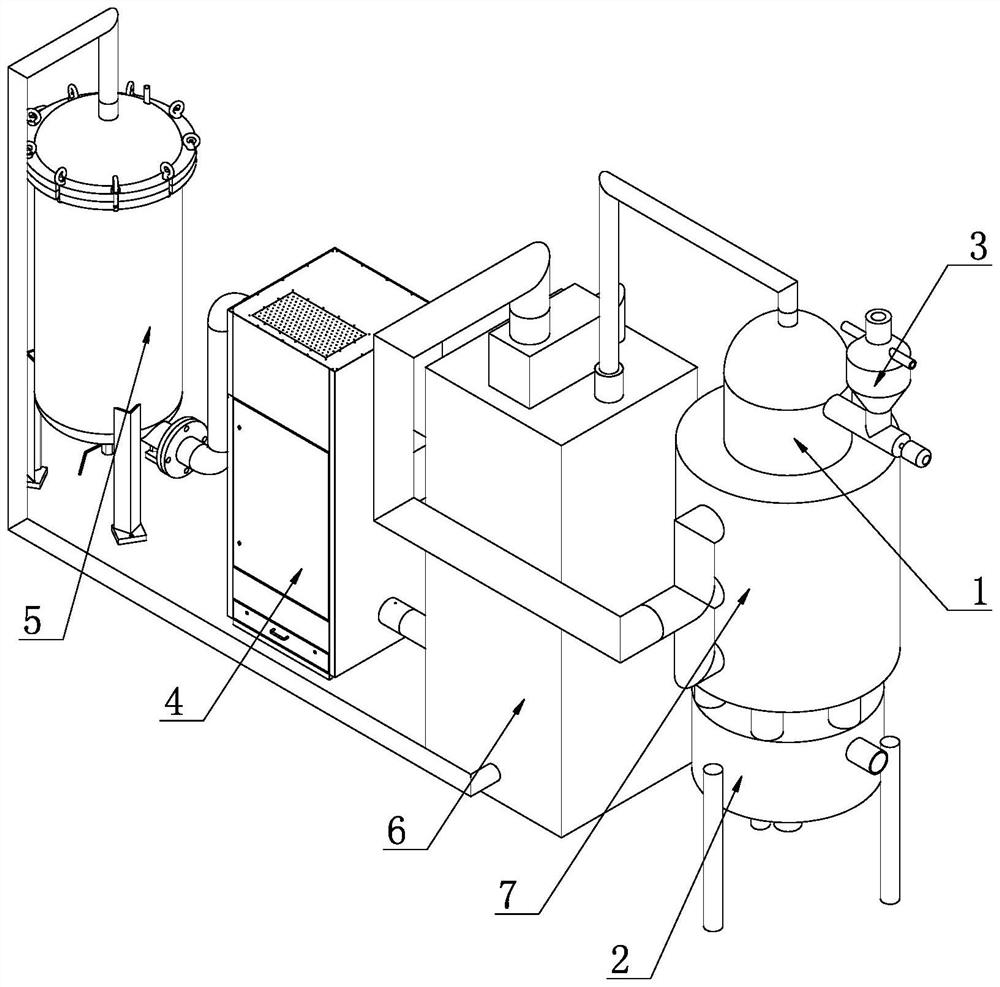

Sulfur purification system and purification process thereof

PendingCN112794289ASimple processImprove efficiencySulfur preparation/purificationChemistryProcess engineering

The invention discloses a sulfur purification system and a sulfur purification process, and belongs to the technical field of sulfur purification. Liquid crude sulfur melted by the sulfur melting kettle is discharged into the stirring tank and pumped by the liquid sulfur pump to be conveyed to the separation device, the crude sulfur after solid impurities are separated enters the decomposition tank to be heated, liquid sulfur discharged from the decomposition tank enters the outside of a pipe of the gas-liquid heat exchanger to exchange heat with gaseous sulfur in the pipe, and the liquid sulfur is discharged out of the gas-liquid heat exchanger to enter the heater; liquid sulfur in the heater is heated to the boiling point temperature to be gasified, gaseous sulfur enters a pipe of a gas-liquid heat exchanger from the heater and exchanges heat with liquid sulfur outside the pipe, and gas-liquid mixed sulfur after gas-liquid heat exchanger enters a pipe of a cooler and exchanges heat with a medium outside the pipe; and the sulfur discharged from the cooler is in a liquid state and enters a slicing machine through a separator to prepare refined sulfur slices. The method not only has better safety, but also is high in efficiency, and the adopted purification process is simple.

Owner:王占华

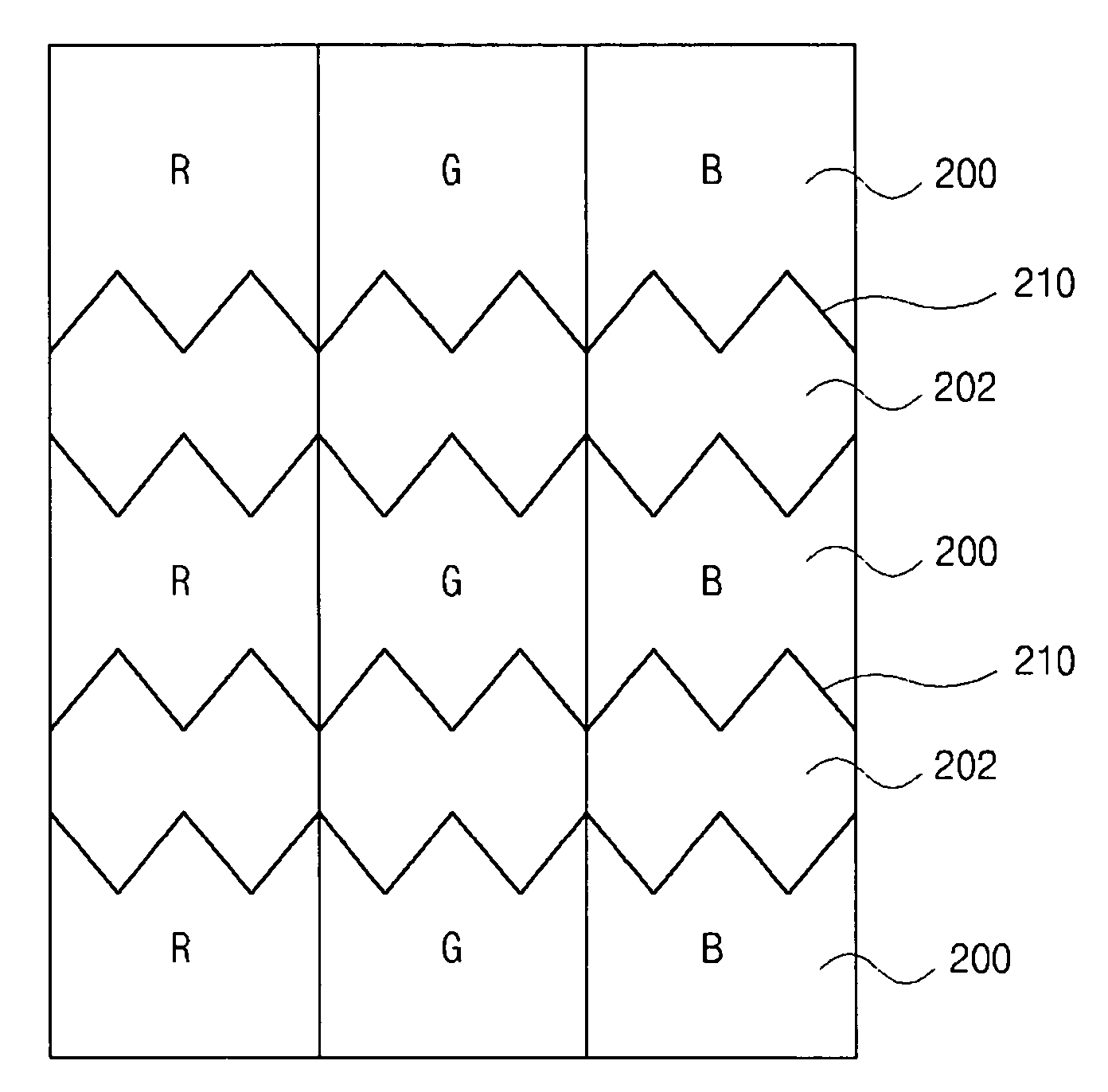

Transflective LCD device having dual thickness color filter

InactiveUS7119864B2Uniform color purityUniform color reproductionStatic indicating devicesNon-linear opticsLiquid crystalElectrode

A transflective LCD device includes first and second transparent substrates spaced apart from each other and having a reflective portion and a transmissive portion, an insulator on the first transparent substrate, a passivation layer on the insulator within the reflective portion, a reflector on the passivation layer, a transparent pixel electrode disposed over the insulator covering the reflector and the passivation layer, a buffer pattern disposed on a rear surface of the second substrate, the buffer pattern having a saw-tooth shape corresponding to the reflective portion, a color filter on the rear surface of the second substrate covering the buffer pattern, the color filter having a first thickness in the transmissive portion and a second thickness in the reflective portion, a transparent common electrode on a rear surface of the color filter, and a liquid crystal layer between the transparent pixel electrode and the transparent common electrode.

Owner:LG DISPLAY CO LTD

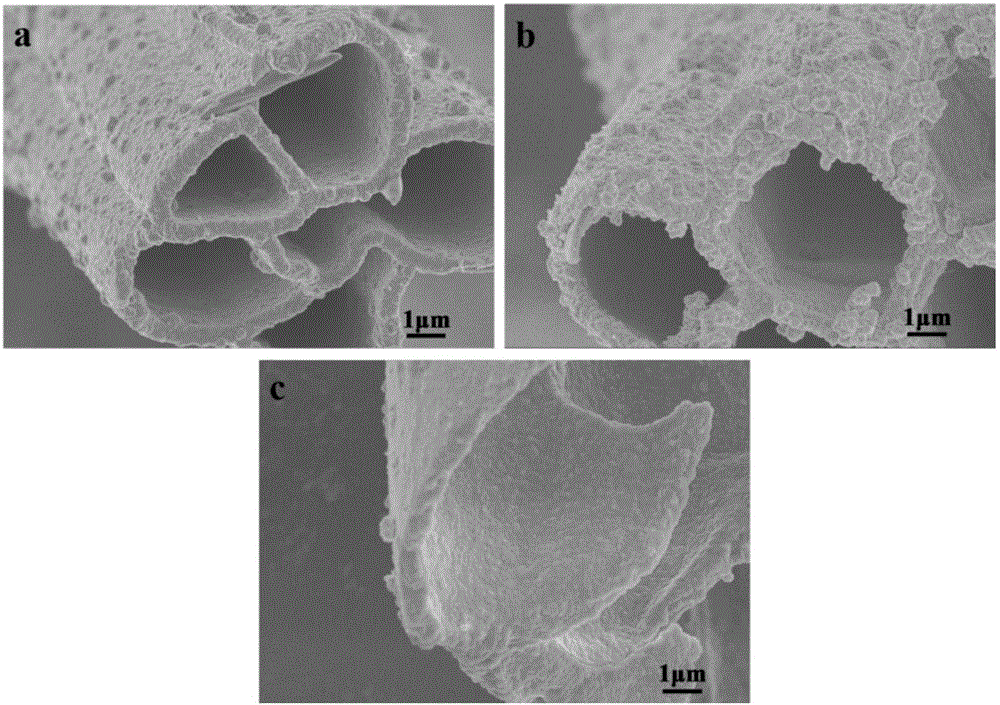

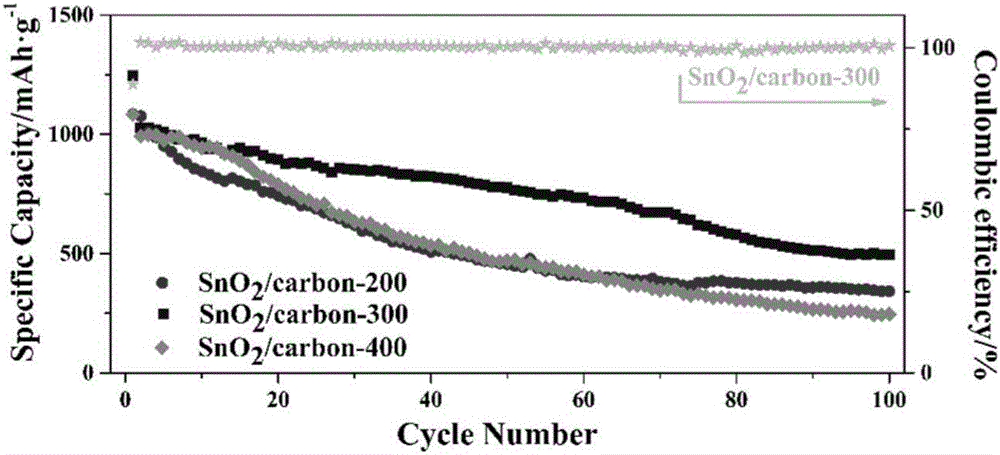

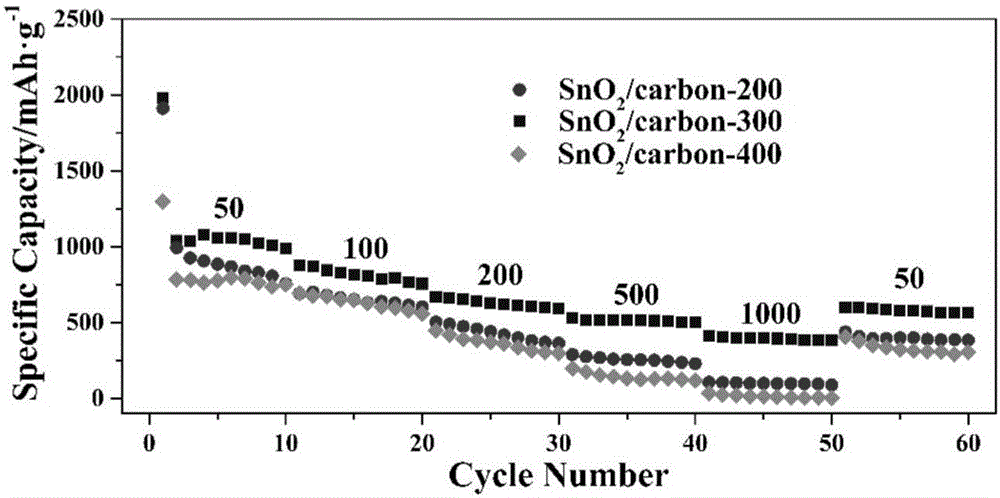

Preparation method of compound powder with tubular biochar-coated SnO<2> structure and application of compound powder

ActiveCN106602035AAlleviate volume expansionImprove adsorption capacityCell electrodesSecondary cellsMicrowaveProcess equipment

The invention relates to a preparation method of compound powder with a tubular biochar-coated SnO<2> structure and an application of the compound powder. According to the preparation method, villus plants such as dandelion are subjected to earlier-stage alkali activation treatment at an earlier stage, so that a large quantity of oxygen-containing functional groups similar to hydroxyl and carboxyl exist inside a carbon tube. A microwave-ultraviolet-ultrasound synthetic mode is adopted, so that the adsorption of SnO<2> particles by a carbon framework can be facilitated; the problem of volume expansion of the SnO<2> in charging and discharging processes is effectively solved; and the tubular biochar-coated SnO<2> structure is obtained finally. The preparation method is simple, low in reaction temperature, short in reaction period, simple in process equipment, environmentally friendly and suitable for large-scale production, and does not need subsequent treatment.

Owner:SHAANXI UNIV OF SCI & TECH

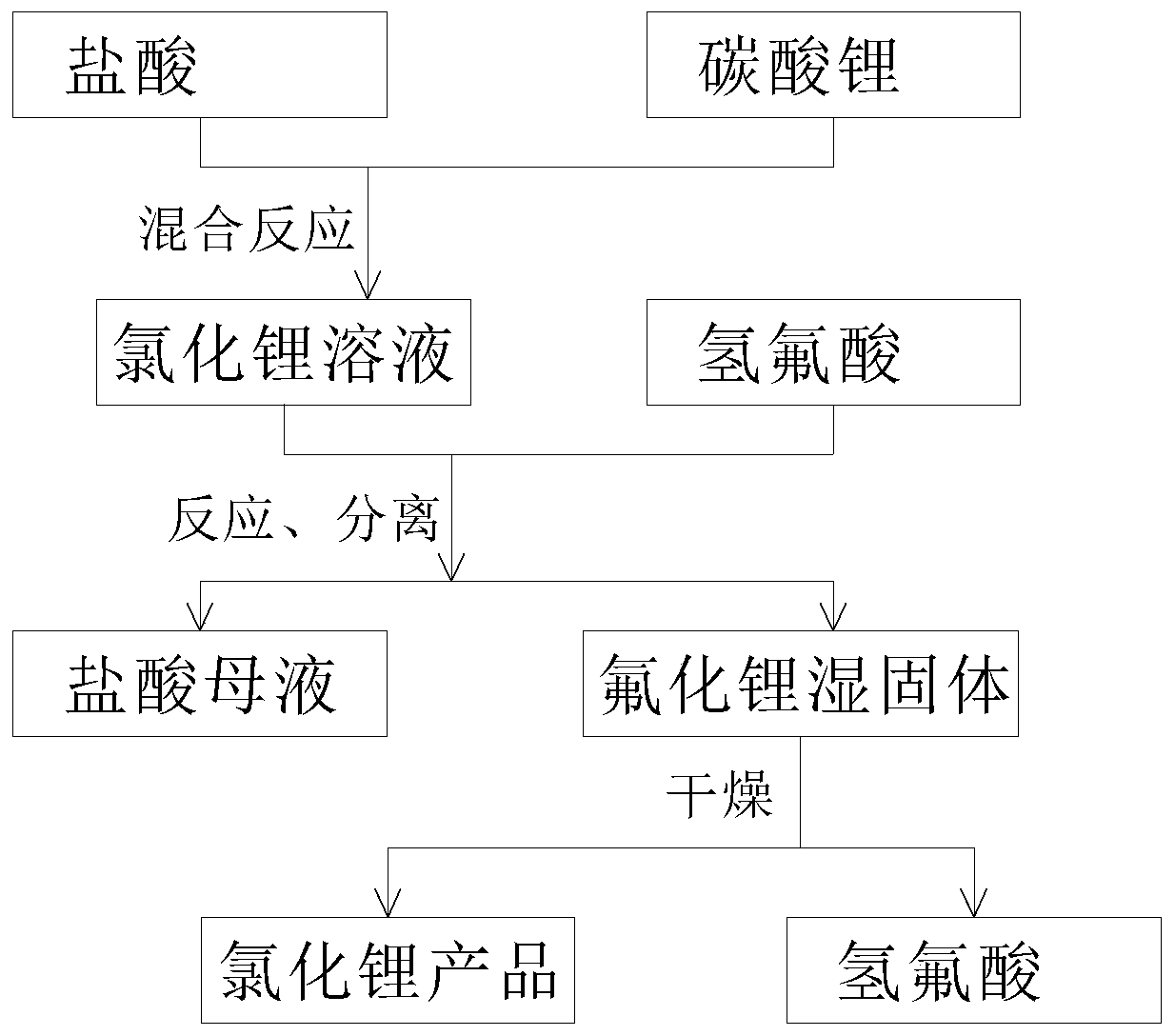

Method for preparing high-purity lithium fluoride

The invention discloses a method for preparing high-purity lithium fluoride, comprising the following steps of 1) sufficiently mixing lithium carbonate powder and hydrochloric acid for reaction to obtain a lithium chloride solution with the pH value of 6 to 7; 2) adding excessive hydrofluoric acid solutin into the lithium chloride solution obtained in the step 1) for sufficient mixing, and reacting to obtain a mixed solution containing lithium fluoride precipitate; 3) standing the mixed solution obtained in the step 2) and filtering to obtain a lithium fluoride wet solid and hydrochloric acidmother liquor; 4) washing and performing vacuum drying on the lithium fluoride wet solid obtained in the step 3) to obtain the high-purity lithium fluoride solid. According to the method provided by the invention, cheap and available hydrochloric acid is taken as an intermediate raw material for preparing lithium fluoride, lithium chloride with good water solubility is firstly prepared using hydrochloric acid and lithium carbonate, then lithium chloride is reacted with hydrogen fluoride to obtain lithium fluoride and the hydrochloric acid mother liquor, and the hydrochloric acid solution withlithium fluoride separated out is recycled to be reacted with lithium carbonate; the method has the advantages that the raw material cost is low, the process is simple, and the product conversion rateis high.

Owner:GUIZHOU INST OF TECH +1

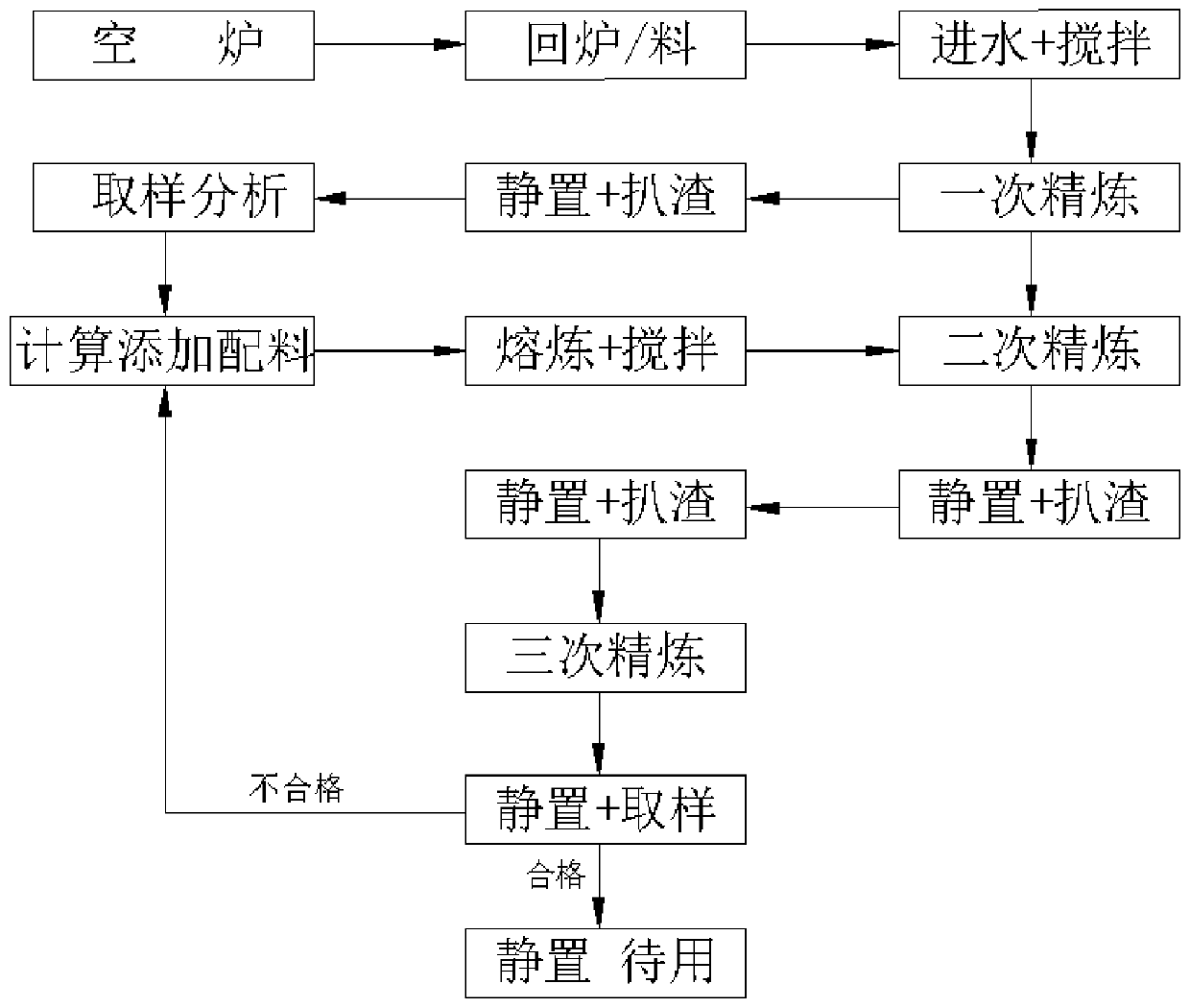

Stokehole production process of electrician round aluminum rod

InactiveCN111041254AIncrease the number of refinementsReduce the impurity content of aluminum waterManufacturing engineeringMaterials science

The invention discloses a stokehole production process of an electrician round aluminum rod, and relates to the field of electrician round aluminum rod production. The stokehole production process comprises the following steps that a raw material and a returned material are added into a smelting furnace; a refining agent is sprayed into molten aluminum by using high-purity argon to carry out primary refining treatment; an intermediate alloy raw material is added into the smelting furnace, and stirring is carried out for 20-40 minutes; the refining agent is sprayed into an alloy solution by using the high-purity argon for secondary refining treatment; and the refining agent is sprayed into the alloy solution subjected to standing by using the high-purity argon for tertiary refining treatment, and if the alloy solution reaches the production standard, the alloy solution flows into a launder and then stands for standby application. According to the stokehole production process of the electrician round aluminum rod, the permanent magnet stirring time is prolonged to be combined with manual stirring, the refining temperature is strictly controlled, the refining frequency is increased, so that the uniformity and stability of molten aluminum components are ensured; and the molten aluminum temperature in the whole launder is monitored in real time by additionally arranging a launder heating cover plate, so that the molten aluminum temperature stability is ensured, then the uniformity of the casting temperature is ensured, and components and tissues of a cast ingot are kept uniformas much as possible.

Owner:宝胜(宁夏)线缆科技有限公司

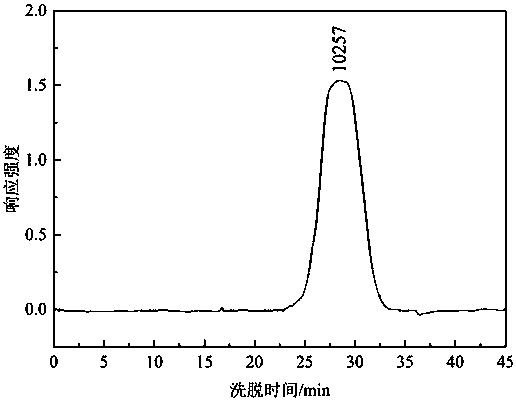

Extraction method of hericium erinaceus anti-allergic active polysaccharide

InactiveCN107686527AUniform purityEnhanced inhibitory effectImmunological disordersIon exchangeChemistry

The invention discloses an extraction method of a hericium erinaceus anti-allergic active polysaccharide. According to the extraction method, the hericium erinaceus anti-allergic active polysaccharideis obtained by adopting a technology comprising hot water extraction and DEAE (Diethyl Aminoethanol) Sepharose Fast Flow ion exchange chromatography purification. After the hericium erinaceus anti-allergic active polysaccharide obtained by the extraction method is subjected to high performance gel permeation chromatography detection, the hericium erinaceus anti-allergic active polysaccharide hasa single symmetrical peak and uniform purity; the molecular weight calculated relative to a standard curve is 10kDa; the hericium erinaceus anti-allergic active polysaccharide has an obvious inhibition effect on hyaluronidase and has anti-allergic activity.

Owner:SOUTH CHINA UNIV OF TECH

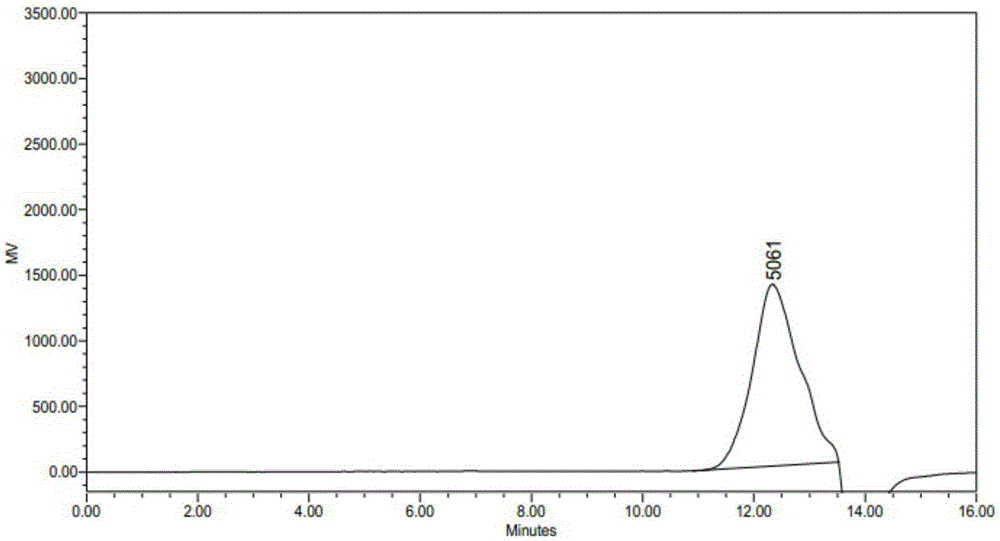

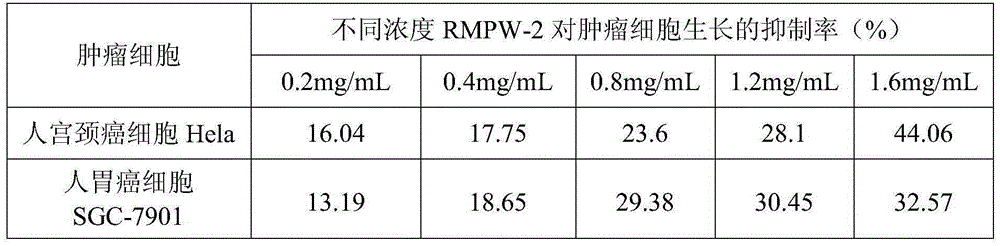

Preparation method of mulberry twig antineoplastic activity polysaccharide RMPW-2

InactiveCN105294879AUniform purityHigh medicinal valueAntineoplastic agentsDEAE-SepharoseIon exchange

The invention discloses a preparation method of mulberry twig antineoplastic activity polysaccharide RMPW-2. The method comprises the steps of removing small molecular substances such as glycoside and alkaloid of mulberry twig powder by performing backflow and degreasing on petroleum ether and backflow of ethyl alcohol, then extracting crude polysaccharide by double distilled water, removing protein by the Sevag method, precipitating with ethyl alcohol twice in sequence, separating an acid polysaccharide component by DEAE sepharose gel ion-exchange column chromatography, desalting by propylene sephadex S-100 chromatography, collecting eluant corresponding to the second eluting peak through propylene sephadex S-300 chromatographic purification, concentrating under reduced pressure, and freezing and drying in vacuum to obtain the product. The product prepared in the invention is uniform in purity, has a molecular weight of 5.06*10<3>Da, has an obvious inhibition effect on the growth of human cervical carcinoma cells Hela and human gastric carcinoma cells SGC-7901, has no adverse influence on the growth of human embryo nephrocyte HEK293 and mouse macrophage RAW264.7, and can be used for the development of antitumor products.

Owner:ZHEJIANG UNIV

A kind of production method of rose-colored rare earth doped quartz tube with low hydroxyl

ActiveCN103387328BUniform penetrationGood colorGlass shaping apparatusHydrofluoric acidManufacturing technology

The invention discloses a production method of a low-hydroxyl rosy rare-earth-doped quartz tube. The invention belongs to the technical field of quartz tube production. The method comprises the steps that: (1) raw materials are selected, wherein high-purity quartz is selected; (2) stirring is carried out, wherein various rare earth nitrating agents such as samarium nitrate are added into the raw material, and mixing and stirring are carried out; (3) dilution is carried out, wherein strong hydrofluoric acid is added, and a dilution reaction is carried out; (4) doping is carried out, wherein the material is doped with a high-purity quartz powder material; and the mixture is placed into a high-temperature-resistant quartz tube; (5) bake-drying is carried out, wherein high-temperature continuous bake-drying is carried out, such that the various rare earth nitrating agents completely penetrating into the quartz powder material; (6) melting is carried out, wherein the material is molten in a continuous melting furnace; through tube-drawing machine drawing, an integrally colored rosy quartz tube is obtained; and (7) decarboxylation is carried out, wherein the rosy quartz tube is subjected to high-temperature decarboxylation in a vacuum decarboxylation furnace. The method is mainly used in the aspect of quartz tube manufacturing.

Owner:连云港龙立石英制品有限公司

Preparation method of white muscardine silkworm anticancer-activity polysaccharide BBPW-2

InactiveCN103265644BHigh medicinal valueUniform purityAntineoplastic agentsFreeze-dryingIon exchange

Owner:ZHEJIANG UNIV

Preparing method of moxibustion patch with graphene skeleton

ActiveCN107334633AIncrease surface lubricityExcellent essential properties skin-friendlyDevices for heating/cooling reflex pointsFiberCarbon fibers

The invention relates to a preparing method of a moxibustion patch with a graphene skeleton. The method particularly includes the steps that carbon fibers serve as raw materials, and through three stages of preliminary oxidation, concentrated-sulfuric-acid and potassium-permanganate oxidation and hydrogen-peroxide final oxidation and the like, fully oxidized graphite oxide is obtained; then, through a strong reductant vitamin C, the harmless graphene skeleton with a healthcare effect is obtained; finally, the moxibustion patch is obtained by filling the graphene skeleton with quick lime and aged argy-wormwood-leaf dust, wherein heat is generated when the quick lime makes contact with water, and the aged argy-wormwood-leaf dust which is stocked for 3-5 years has the optimal thermal moxibustion effect. The moxibustion patch with the graphene skeleton is good in skin affinity, convenient to use, long in duration, significant in effect and capable of being recycled.

Owner:青岛卓护医疗用品有限公司

High-purity graphite purification system

PendingCN114291815AControl the falling speedLong enough to heatCarbon compoundsHigh energyEngineering

The invention relates to a high-purity graphite purification system, the high-purity graphite purification system comprises a purification furnace, the purification furnace is in a vertically arranged cylindrical shape, the purification furnace comprises a furnace body, an air guide ring, an air inlet ring and a heating column, the furnace body is a cylindrical shell, the upper end and the lower end of the furnace body are respectively provided with an air outlet and a discharge port, the upper part of the furnace body is provided with a feed port, and the upper part of the furnace body is provided with a discharge port; the air guide ring and the air inlet ring are correspondingly arranged on the inner side and the outer side of the circumference of the furnace body respectively, the lower end of the air guide ring is fixedly connected with the furnace body in a sealed mode, a gap is reserved between the upper end of the air guide ring and the inner wall of the circumference of the furnace body, and an opening of the section of the air inlet ring is fixedly connected with the outer side of the circumference of the furnace body in a sealed mode. The air inlet ring communicates with the air outlet end of an inert gas source, and the heating column is coaxially and fixedly arranged in the furnace body. The invention aims to solve or at least alleviate the problems of high energy consumption and non-uniform heating during purification of the existing graphite high-temperature purification equipment, and provides the high-purity graphite purification system.

Owner:FIVE STAR NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com