Extraction method of aquatic collagen

An aquatic collagen and extraction method technology, applied in the field of peptide or protein preparation, can solve the problems of poor color, fishy smell, low purity, etc., and achieve the effects of short cycle, good solubility and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

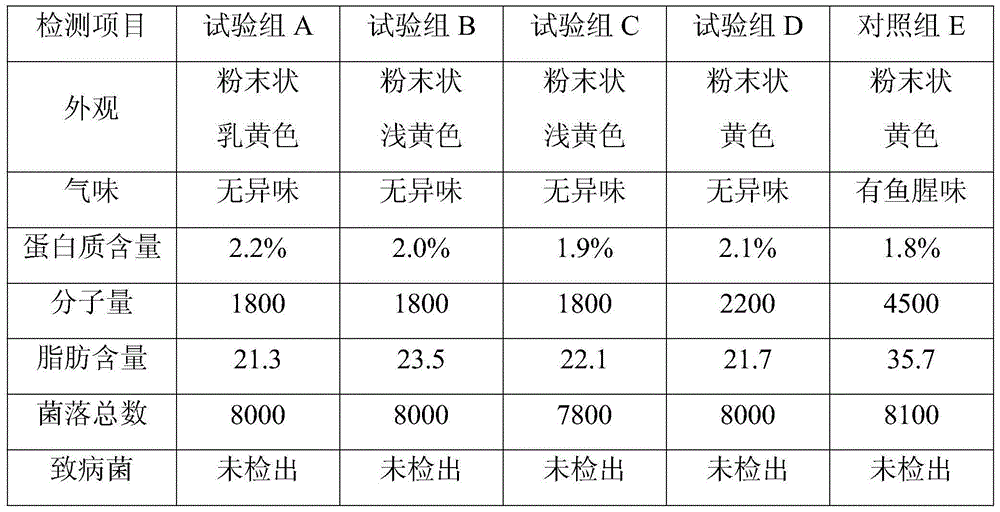

Examples

Embodiment 1

[0023] A method for extracting aquatic collagen, comprising the steps of:

[0024] a. Raw material processing: raw material cleaning, pulverization, adding 10% NaCl solution 5 times the volume of the raw material, soaking for 5 hours, centrifuging to collect the precipitate, washing the precipitate, sterilizing with damp heat at 115°C for 30 min, and obtaining the crude collagen fiber.

[0025] b. Enzymolysis treatment: adjust the crude collagen fibers to a pH of 8 with food-grade NaOH, prepare a substrate solution with a mass concentration of 50g / L, add 50PPm of compound enzyme, and perform an enzymolysis reaction at 45°C for 8 hours to obtain an enzymolysis solution liquid. The complex enzymes include cellulase, α-galactosidase, mannanase, protease and lipase.

[0026] c. Purification treatment: Enzymolysis solution was inactivated at 70°C for 15 minutes, activated carbon decolorized, the amount of activated carbon added was 3% of the raw material mass, filtered and freeze-...

Embodiment 2

[0028] A method for extracting aquatic collagen, comprising the steps of:

[0029] a. Raw material treatment: the raw material was cleaned and pulverized, added 7% NaCl solution 8 times the volume of the raw material, soaked for 12 hours, centrifuged to collect the precipitate, and sterilized by damp heat at 121°C for 20 minutes to obtain crude collagen fibers.

[0030] b. Enzymolysis treatment: adjust the crude collagen fibers to a pH of 8 with food-grade NaOH, prepare a substrate solution with a mass concentration of 100g / L, add 80PPm of compound enzyme, and perform an enzymolysis reaction at 48°C for 12 hours to obtain an enzymolysis solution liquid. The complex enzymes include cellulase, α-galactosidase, mannanase, protease and lipase.

[0031] c. Purification treatment: Enzymolysis solution was inactivated at 80°C for 12 minutes, decolorized with activated carbon, the amount of activated carbon added was 5% of the raw material mass, filtered and freeze-dried to obtain aq...

Embodiment 3

[0033] A method for extracting aquatic collagen, comprising the steps of:

[0034] a. Raw material processing: raw material cleaning, crushing, adding 10% NaCl solution 10 times the volume of the raw material, soaking for 8 hours, centrifuging to collect the precipitate, washing the precipitate, and sterilizing with damp heat at 125°C for 15 minutes to obtain crude collagen fibers.

[0035] b. Enzymolysis treatment: adjust the crude collagen fibers to a pH of 9 with food-grade NaOH, prepare a substrate solution with a mass concentration of 150g / L, add 100PPm of compound enzyme, and perform an enzymolysis reaction at 50°C for 10 hours to obtain an enzymolysis solution liquid. The complex enzymes include cellulase, α-galactosidase, mannanase, protease and lipase.

[0036] c. Purification treatment: Enzymolysis solution was inactivated at 85°C for 10 minutes, decolorized with activated carbon, and the amount of activated carbon added was 4% of the raw material mass, filtered and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com