Stokehole production process of electrician round aluminum rod

A production process, the technology of round aluminum rods, which is applied in the field of furnace production process of electrical round aluminum rods, can solve the problems of affecting the composition of ingots and aluminum rods, insufficient stirring of molten aluminum at the corner of the furnace, uneven composition of molten aluminum, etc. , to achieve the effect of ensuring the casting temperature, ensuring uniform purity, and increasing the number of refining times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

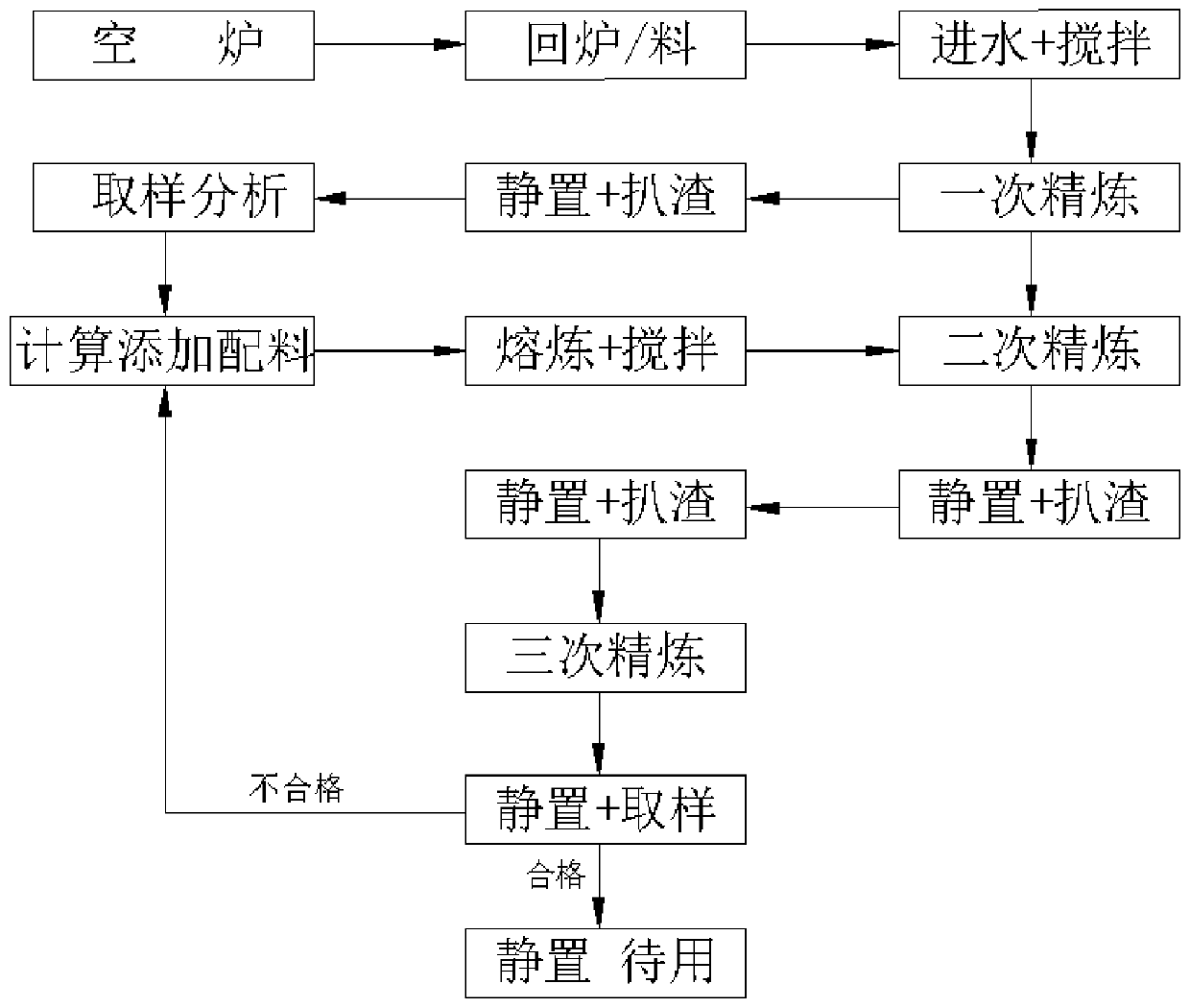

[0020] see figure 1 , a pre-furnace production process for electrical round aluminum rods, comprising the following steps:

[0021] Step 1: Add raw materials and recycled materials into the smelting furnace, control the temperature in the furnace, add aluminum water and stir for 20-40 minutes to obtain aluminum liquid;

[0022] Step 2: Use high-purity argon to spray the refining agent into the molten aluminum for a refining treatment, remove slag after refining, and take samples for analysis after standing;

[0023] Step 3: Add the calculated intermediate alloy raw materials into the melting furnace, stir for 20-40 minutes, and control the temperature of the melting furnace to 750-800°C to obtain the alloy melt;

[0024] Step 4: Use high-purity argon to spray the refining agent into the alloy solution for secondary refining treatment, remove the slag and let it stand after refining;

[0025] Step 5: Use high-purity argon to spray the refining agent into the alloy solution af...

Embodiment 2

[0028] As a preferred embodiment of the present invention, the recycled aluminum ingot weight in step 1 is calculated according to parameters such as the actual molten aluminum temperature, the temperature of the recycled aluminum ingot, and the temperature absorption of recycled aluminum ingot per ton of aluminum.

[0029] In this embodiment: by calculating the weight of the returned aluminum ingot, the increase of the intermediate alloy raw material is determined, and the melting temperature is strictly ensured to be within the optimum processing temperature range.

Embodiment 3

[0031] As a preferred embodiment of the present invention, the stirring in step 1 and step 3 adopts the combination of permanent magnetic stirring and manual stirring.

[0032] In this embodiment: by using a combination of permanent magnetic stirring and manual stirring, it is ensured that the molten aluminum in any part of the furnace is fully stirred evenly in step 1, the uniformity of the intermediate alloy addition in step 3 is ensured, and the aluminum liquid at the corner of the furnace is avoided. If the stirring is not in place, the composition of the molten aluminum will be uneven during the casting process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com