High-purity graphite purification system

A high-purity graphite and furnace body technology, applied in the direction of inorganic chemistry, non-metallic elements, carbon compounds, etc., can solve the problems of uneven heating and high energy consumption, and achieve the effects of uniform purity, uniform heating, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

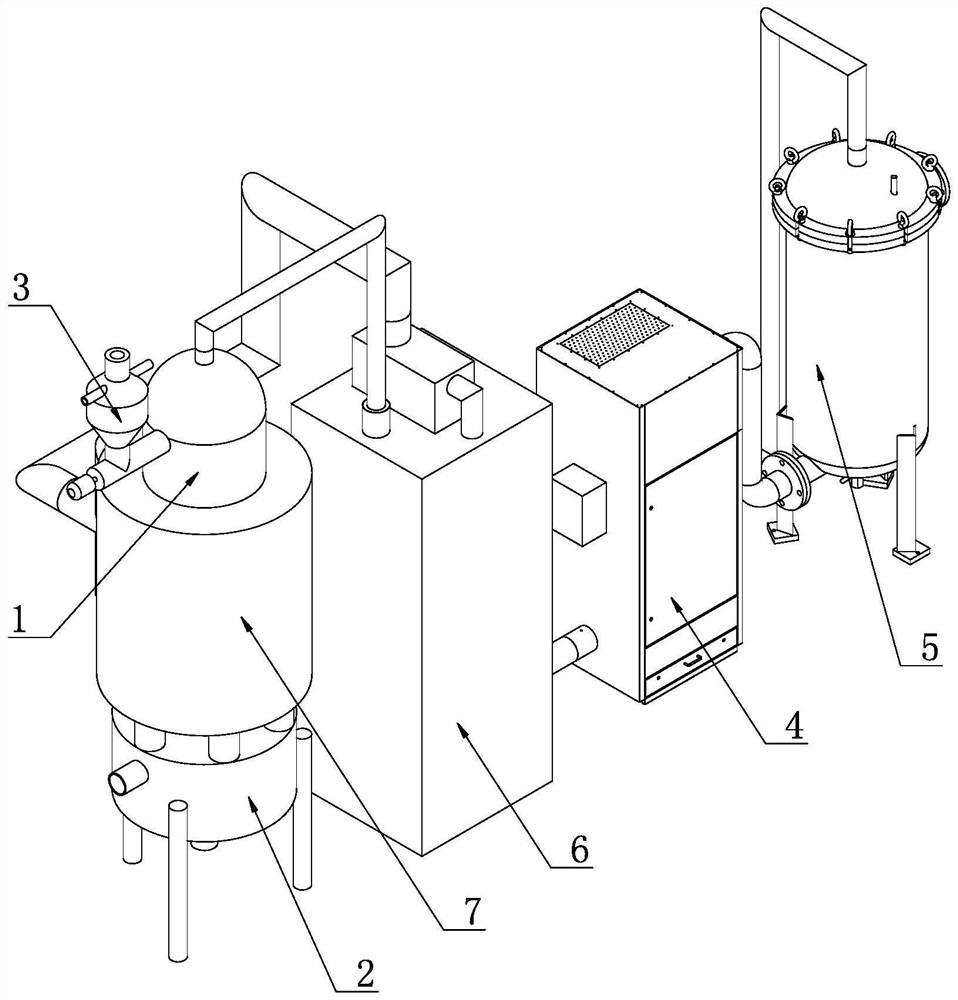

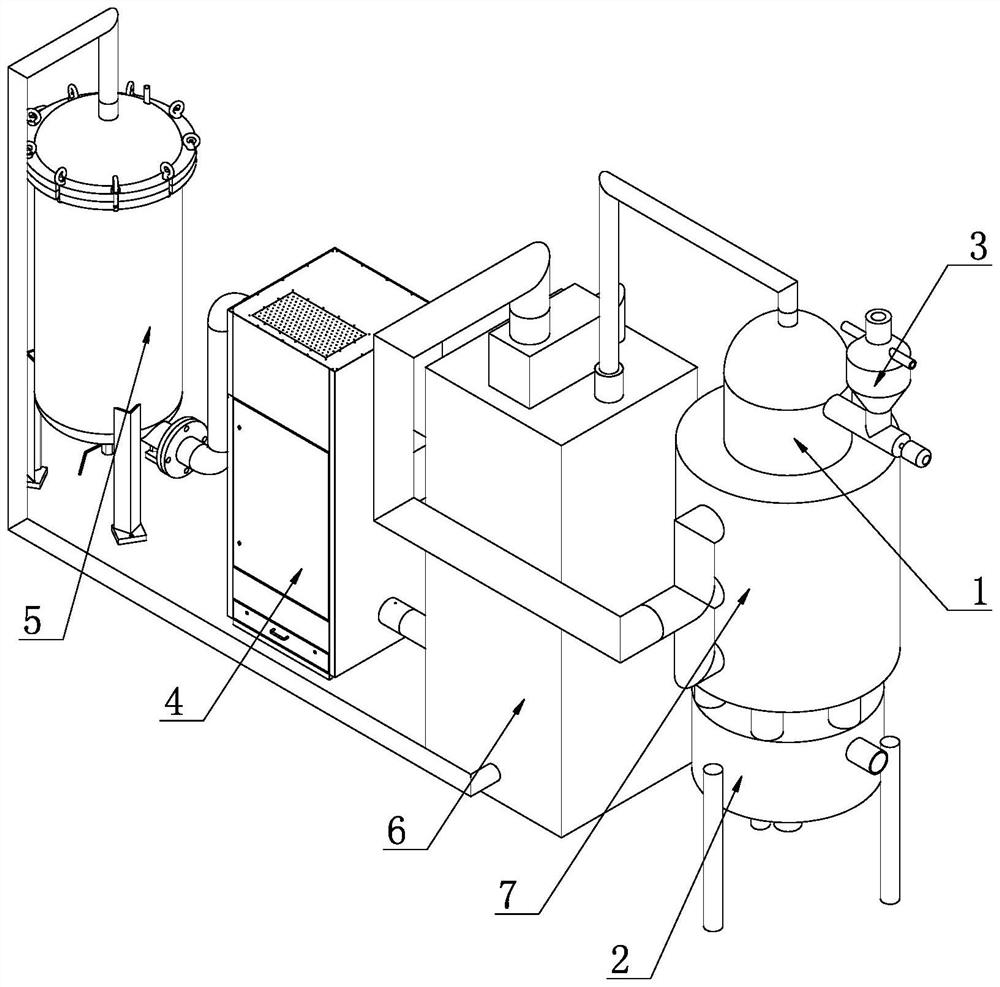

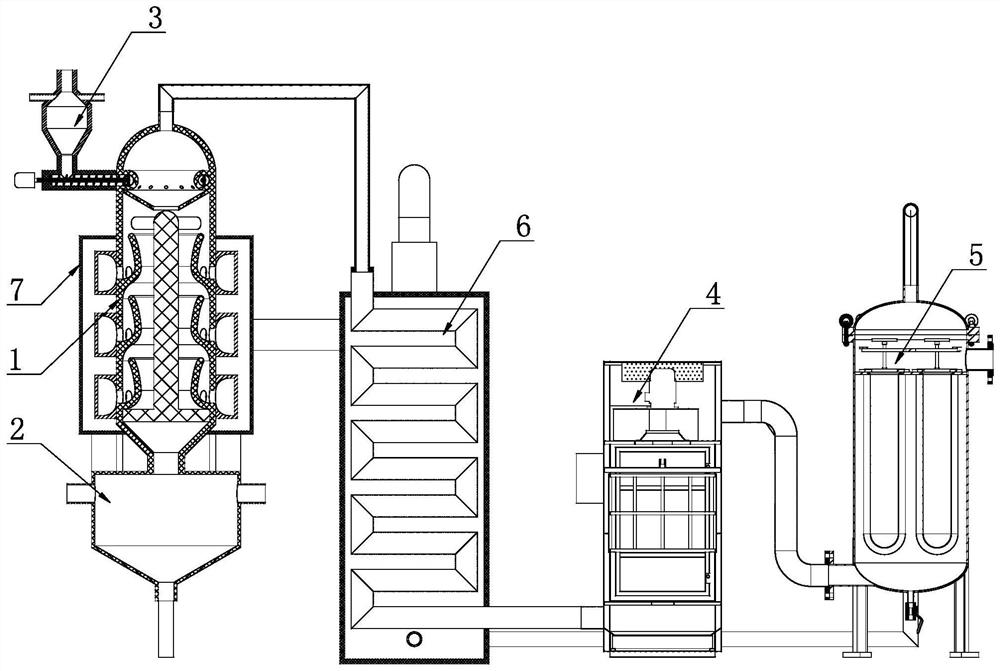

[0046] Such as Figure 1-12 As shown, a high-purity graphite purification system, the high-purity graphite purification system includes a purification furnace 1, the purification furnace 1 is a vertically arranged cylindrical shape, and the purification furnace 1 includes a furnace body 101, an air guiding ring 102, an air inlet ring 103 and The heating column 104, the furnace body 101 is a cylindrical shell, the upper and lower ends of the furnace body 101 are respectively provided with an air outlet and a material outlet, the upper part of the furnace body 101 is provided with a feed port, and the air guide ring 102 and the air inlet ring 103 correspond to It is arranged on both sides inside and outside the circumference of the furnace body 101. The air guide ring 102 is in the shape of a dumbbell-shaped tube. It is circular and its cross-section is C-shaped. The opening of the cross-section of the air inlet ring 103 is sealed and fixedly connected with the outer circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com