Preparation method of compound powder with tubular biochar-coated SnO<2> structure and application of compound powder

A composite powder and bio-carbon technology, applied in structural parts, electrochemical generators, electrical components, etc., can solve the problems of low coulombic efficiency of materials, changes in electrode volume, large irreversible capacity, etc., and achieve uniform morphology and high purity. , the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

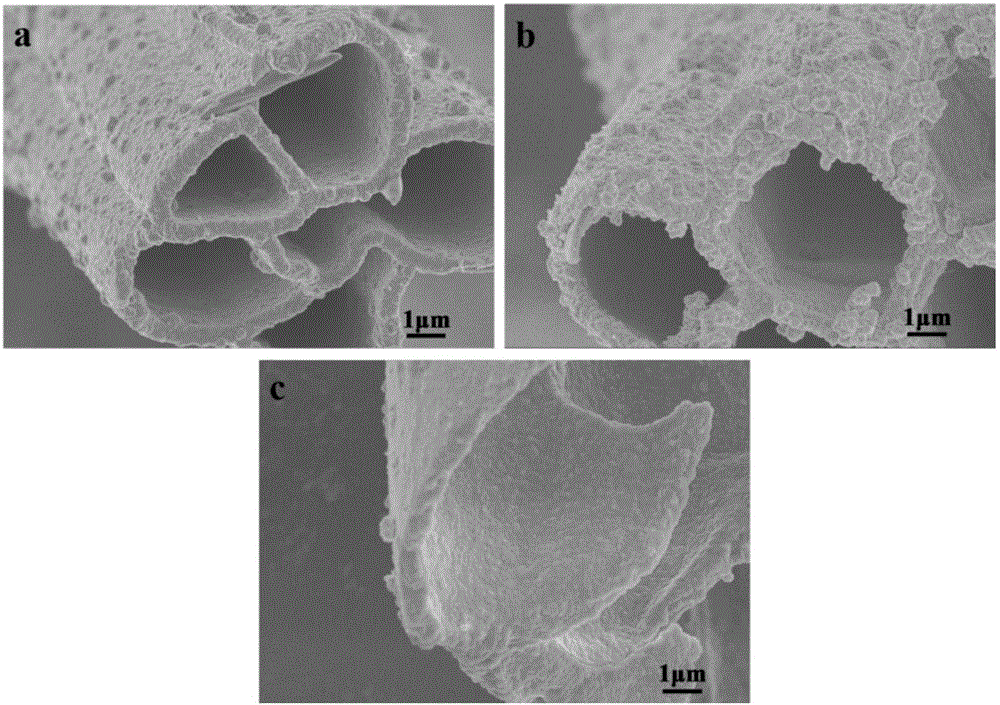

[0035] A tubular biochar-coated SnO of the present invention 2 The preparation method of structure, comprises the following steps:

[0036] (1) Deseeding, washing and drying the collected fluff plants to obtain product A;

[0037] (2) Put the product A in a white porcelain boat, put it in a tube furnace for calcination, the calcination temperature is 400-1200°C, and the heating rate is 1-10°C·min -1 , the holding time is 1~5h, the atmosphere is protected by argon, and the air flow rate is 0.1~1sccm·min -1 , to obtain product B;

[0038] (3) KOH, K 2 CO 3 、KHCO 3 Mix evenly with a mass ratio of 1:(1-2.5):(0.1-0.5) to obtain product C;

[0039] (4) Mix product B and product C uniformly at a mass ratio of 1: (0.5 to 3.5) to obtain product D;

[0040] (5) Add SnCl to substance D 2 solution, stirred evenly to obtain solution E, wherein, substance D and SnCl 2 The mass ratio of (1-5): 1; SnCl 2 The solution concentration is 0.5-3.5mol / L. Put it into a magnetic stirrer and...

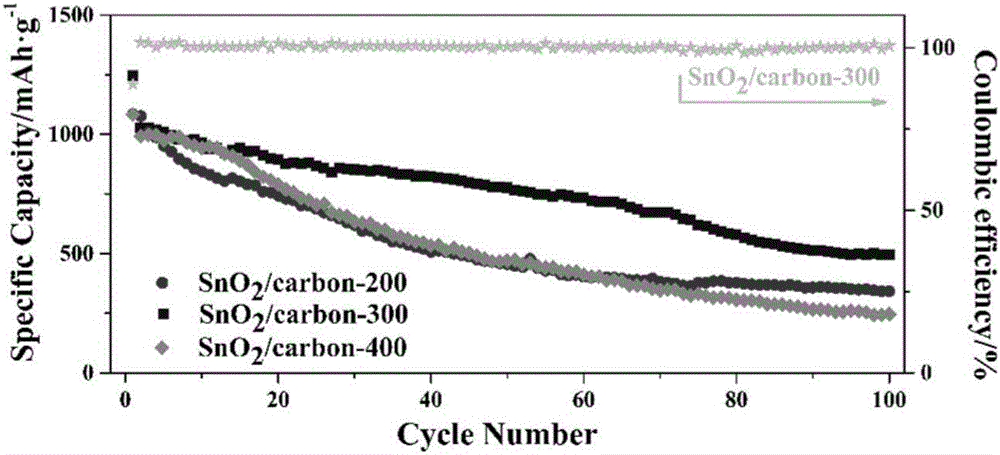

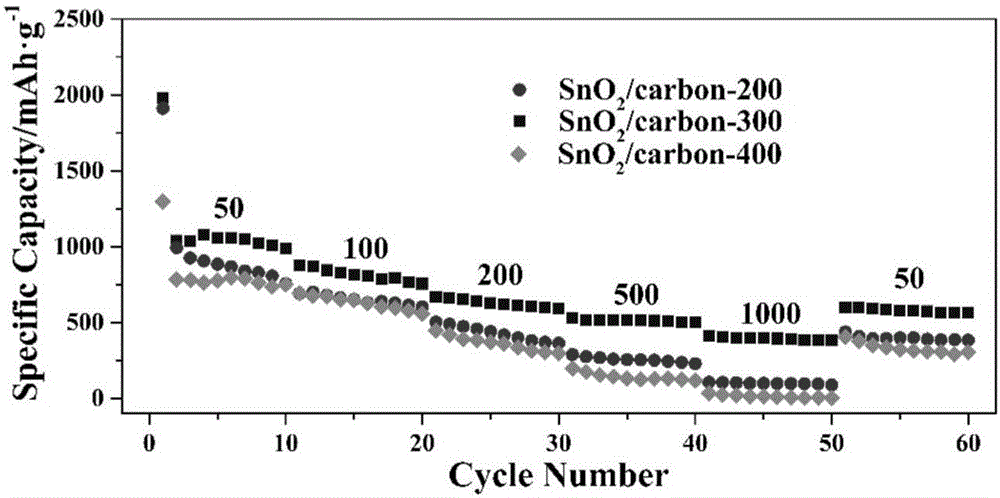

Embodiment 1

[0045] (1) Deseeding, washing and drying the collected fluff plants to obtain substance A;

[0046] (2) Put substance A in a white porcelain boat, put it in a tube furnace for calcination, the calcination temperature is 1000°C, and the heating rate is 5°C·min -1 , the holding time is 3h, the atmosphere is protected by argon, and the air flow rate is 0.5sccm·min -1 , get substance B;

[0047] (3) KOH, K 2 CO 3 、KHCO 3 Mix evenly with a mass ratio of 1:1:0.5 to obtain substance C;

[0048] (4) Mix substance B and substance C uniformly at a mass ratio of 1:1 to obtain substance D;

[0049] (5) Add SnCl to substance D 2 2H 2 0 and 50mL water, substance D and stannous chloride were added with a mass ratio of 1:1, put into a magnetic stirrer and stirred for 30min, to obtain solution E;

[0050] (6) Pour the solution E into the container, and then put the container into the microwave-ultraviolet-ultrasonic trinity synthesis extraction reaction apparatus, adopt the microwave-u...

Embodiment 2

[0053] (1) Deseeding, washing and drying the collected fluff plants to obtain substance A;

[0054] (2) Put substance A in a white porcelain boat, put it in a tube furnace for calcination, the calcination temperature is 1000°C, and the heating rate is 5°C·min -1 , the holding time is 3h, the atmosphere is protected by argon, and the air flow rate is 0.5sccm·min -1 , get substance B;

[0055] (3) KOH, K 2 CO 3 、KHCO 3 Mix evenly with a mass ratio of 1:1:0.5 to obtain substance C;

[0056] (4) Mix substance B and substance C uniformly at a mass ratio of 1:1 to obtain substance D;

[0057] (5) Add SnCl to substance D 2 2H 2 0 and 50mL water, substance D and tin protochloride were added into a magnetic stirrer with a mass ratio of 2:1 and stirred for 30min to obtain solution E;

[0058] (6) Pour the solution E into the container, and then put the container into the microwave-ultraviolet-ultrasonic trinity synthesis extraction reaction apparatus, adopt the microwave-ultravi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com