MXene/metal sulfide composite material, anode material and preparation and application

A metal sulfide, composite material technology, applied in the direction of negative electrode, active material electrode, battery electrode, etc., can solve the problems of reducing battery capacity and life, electrode material volume change, capacity reduction, etc., to improve energy density, good stability , the effect of preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Weigh 1g manganese nitrate powder and 1g Ti respectively 3 C 2 Add the powder into a beaker, then add 200ml of deionized water to dissolve, mix and stir for 5 hours, then filter and dry to obtain Ti 3 C 2 / manganese nitrate mixture;

[0046] (2) Under a nitrogen atmosphere, take 1g of the Ti prepared in step (1) 3 C 2 / manganese nitrate mixture and 1g thioacetamide were placed in a tube furnace, and the temperature was raised to 550°C at a heating rate of 2°C / min and kept for 2.5h to obtain Ti 3 C 2 / manganese sulfide composite material;

[0047] (3) get the Ti that 80g step (2) makes 3 C 2 / manganese sulfide composite material, 10g SP, 10g CMC and water are made into a slurry, coated on carbon cloth to obtain sulfur-doped MXene / metal sulfide-based composite battery negative electrode material (Ti 3 C 2 / MnS).

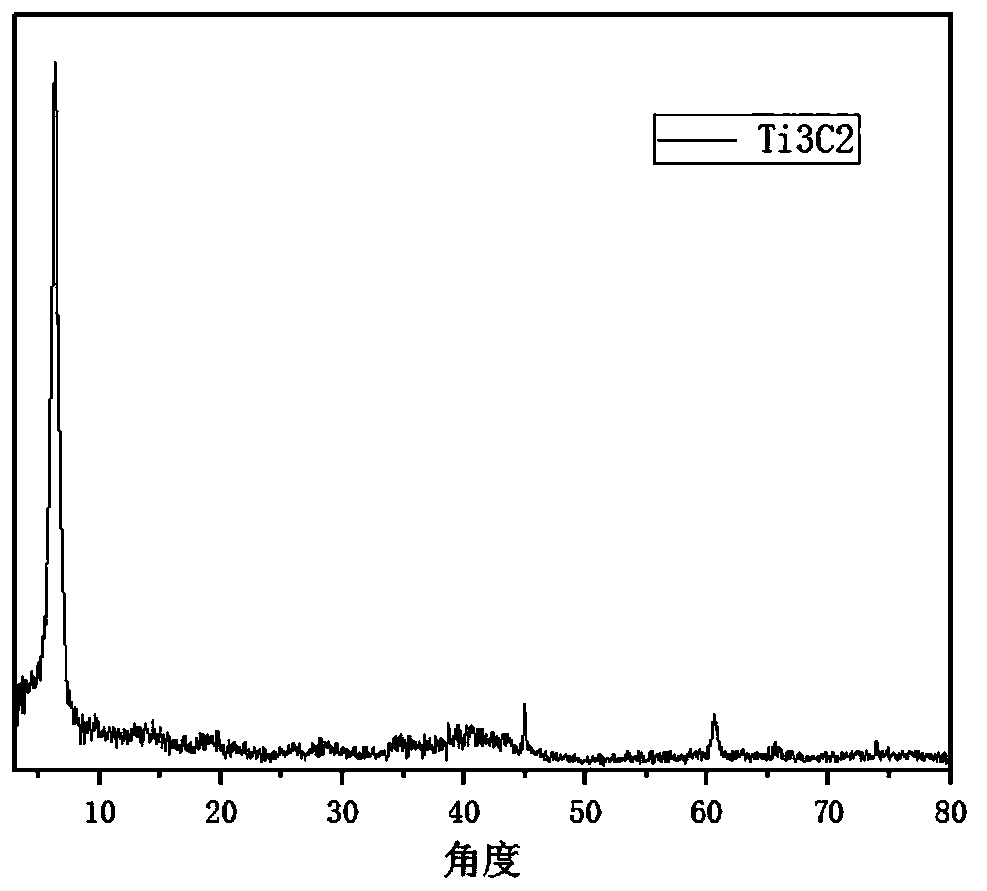

[0048] figure 1 Is the MXene material Ti in this embodiment 3 C 2 It can be seen from the X-ray diffraction pattern that MXene has an obvious...

Embodiment 2

[0050] (1) Weigh 1g cobalt sulfate powder and 0.2g Ti respectively 2 Add C powder into a beaker, then add 300ml of deionized water to dissolve, mix and stir for 12 hours, then suction filter and dry to obtain Ti 2 C / cobalt sulfate mixture;

[0051] (2) Under a nitrogen atmosphere, take 1g of the Ti prepared in step (1) 2 C / cobalt sulfate mixture and 3g ammonium persulfate are put into a tube furnace, and the temperature is raised to 400°C at a heating rate of 10°C / min and kept for 4h to obtain Ti 2 C / cobalt sulfide composite material;

[0052] (3) get the Ti that 75g step (2) makes 2 C / cobalt sulfide composite material, 15g conductive carbon black, 10g PAA and water are made into slurry, and coated on copper foil to obtain sulfur-doped MXene / metal sulfide-based composite battery negative electrode material (Ti 2 C / CoS).

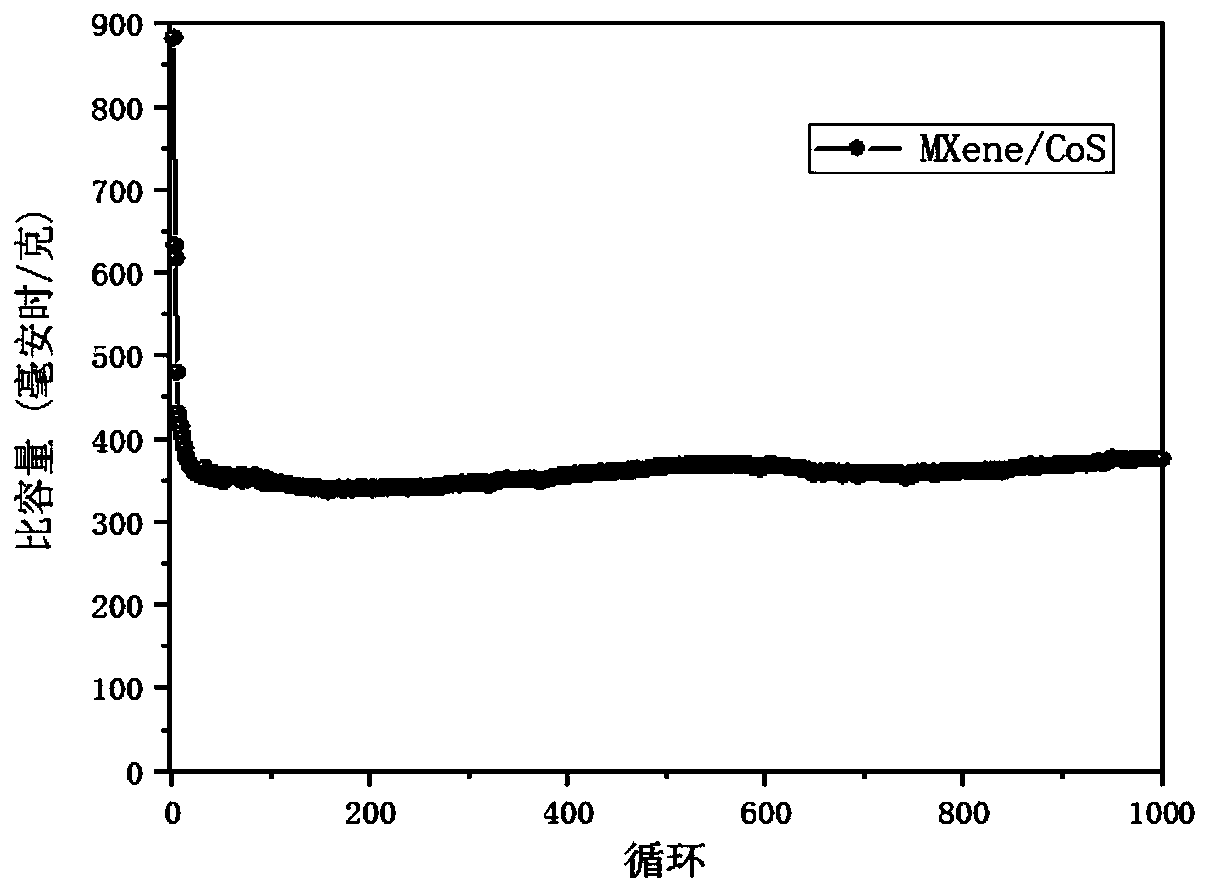

[0053] The sulfur-doped MXene / metal sulfide-based composite battery anode material prepared in step (3) was assembled into a lithium-ion half-cell wi...

Embodiment 3

[0056] (1) Weigh 1g antimony chloride powder and 0.5gV 4 C 3 Add the powder into a beaker, then add 300ml of deionized water to dissolve, mix and stir for 24 hours, filter and dry to obtain V 4 C 3 / antimony chloride mixture;

[0057] (2) Under nitrogen atmosphere, take 1g of V prepared in step (1) 4 C 3 / antimony chloride mixture and 1g cysteine were placed in a tube furnace, and the temperature was raised to 900°C at a heating rate of 20°C / min and kept for 6 hours to obtain V 4 C 3 / antimony sulfide mixture;

[0058] (3) Get 70g of V prepared in step (2) 4 C 3 / antimony sulfide mixture, 20g SP, 10g CMC and water are made into slurry, coated on the carbon-coated copper foil, obtain sulfur-doped MXene / metal sulfide-based composite battery negative electrode material (V 4 C 3 / Sb 2 S 3 ).

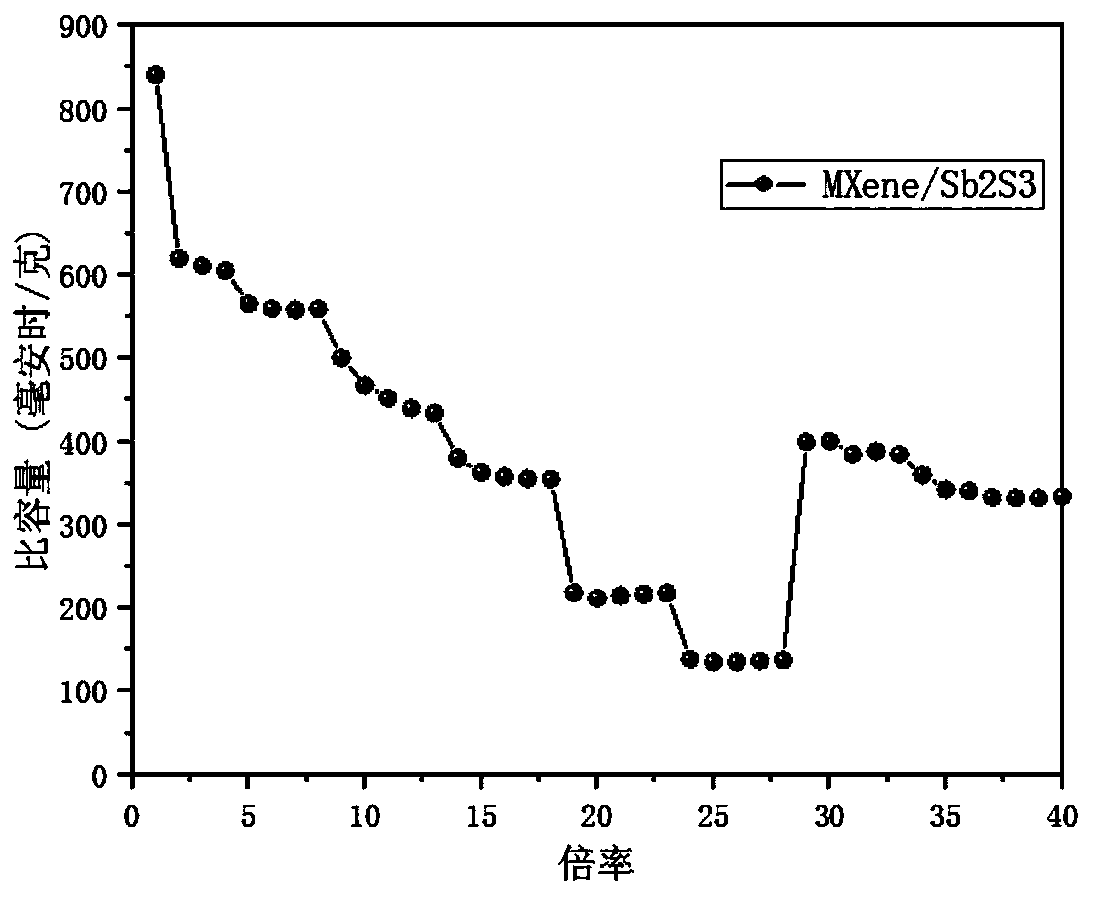

[0059] The sulfur-doped MXene / metal sulfide-based composite battery anode material prepared in step (3) was assembled into a lithium-ion half-cell with a lithium sheet, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com