Patents

Literature

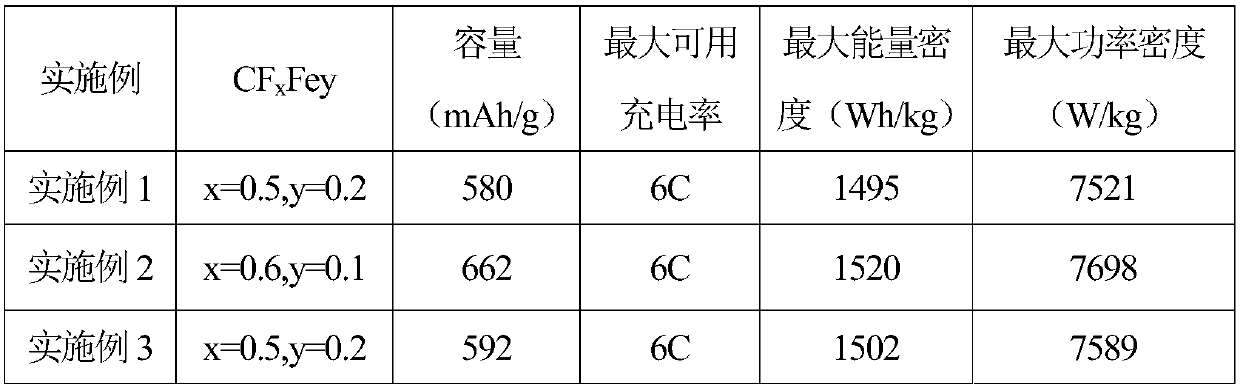

120results about How to "High theoretical specific capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

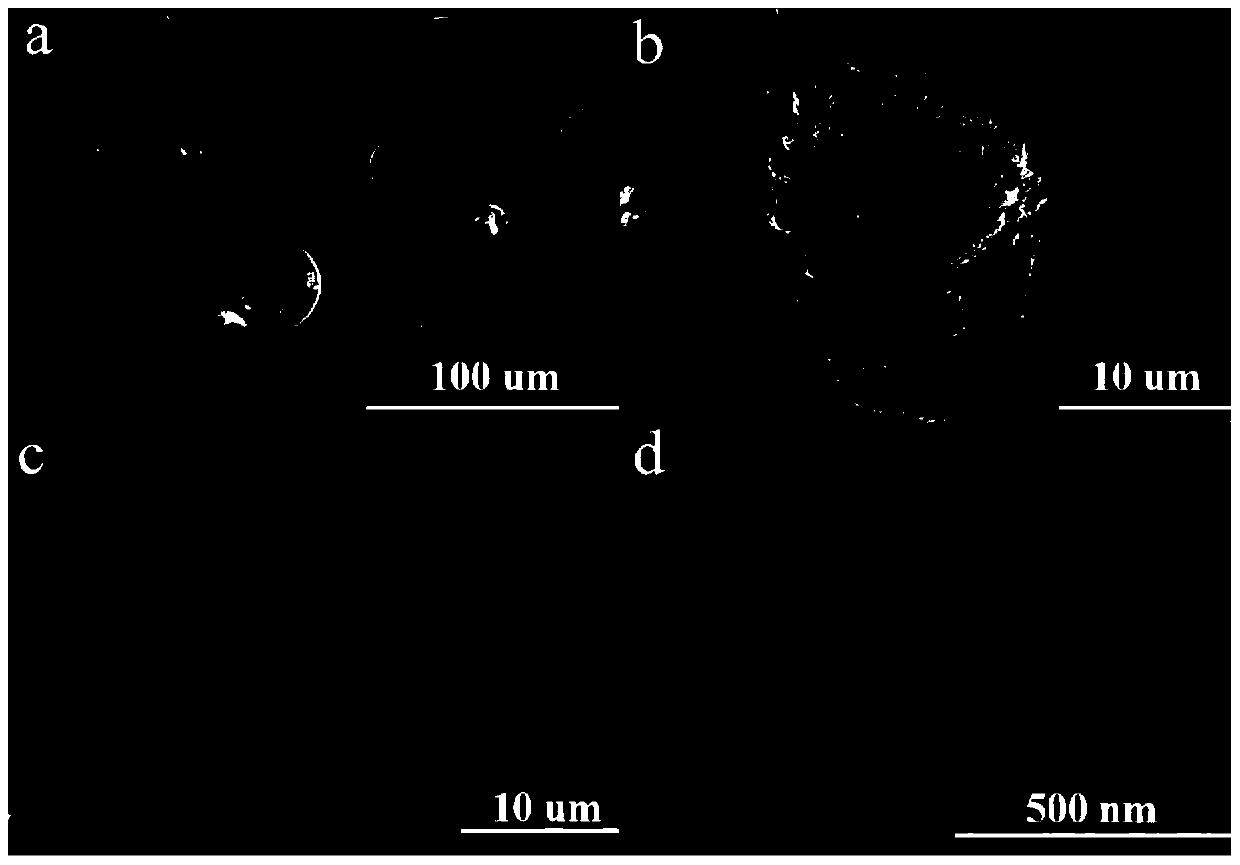

Nitrogen-doped carbon-coated manganese monoxide composite material with one-dimensional porous core-shell structure and preparation method of nitrogen-doped carbon-coated manganese monoxide composite material

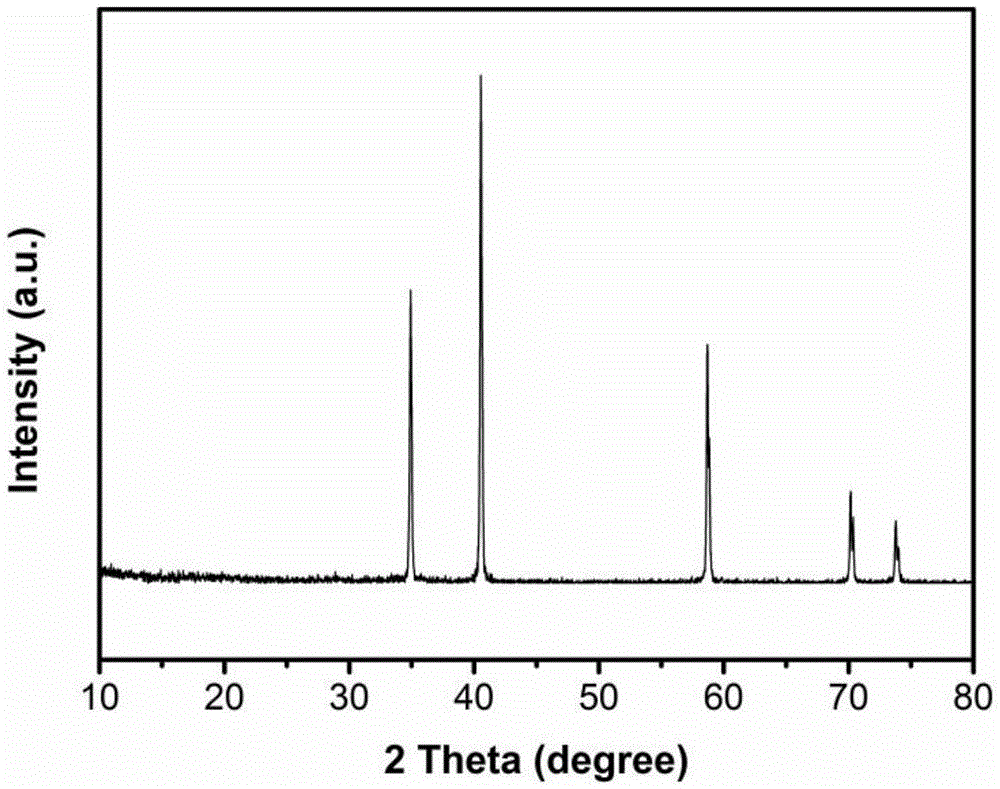

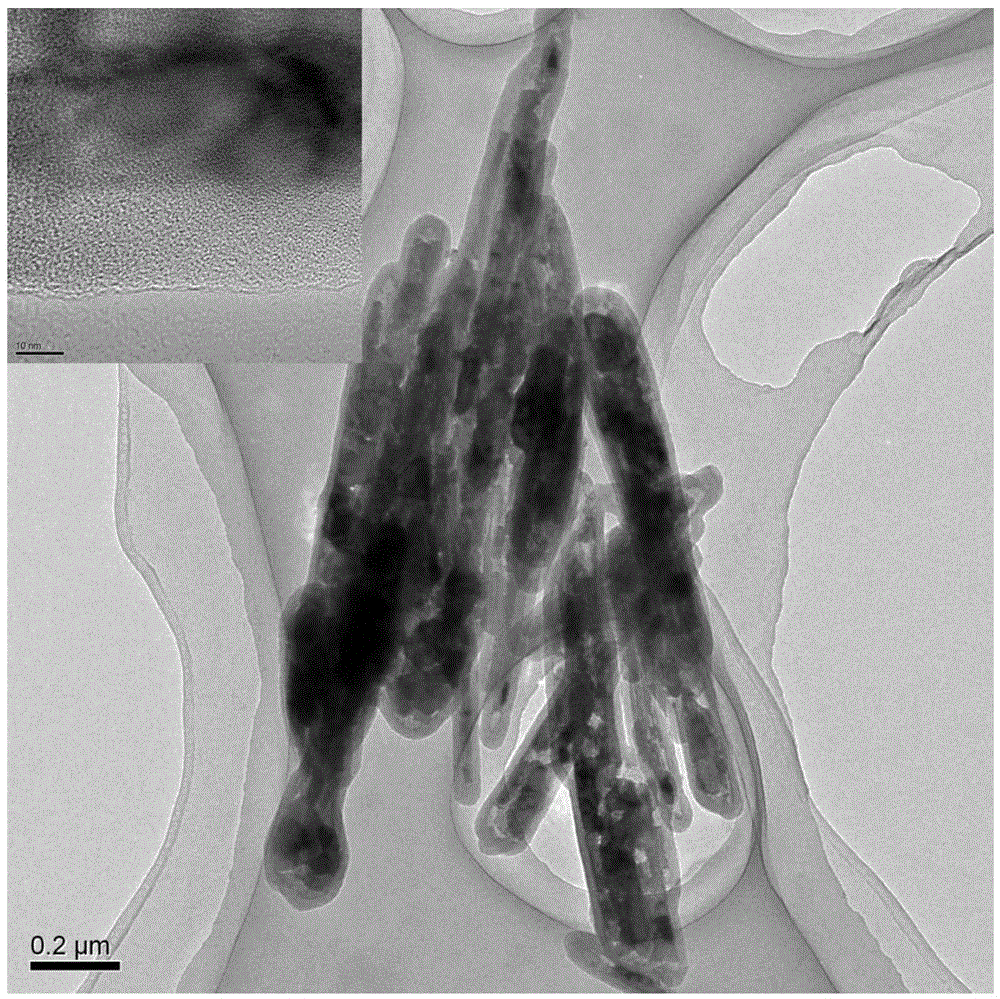

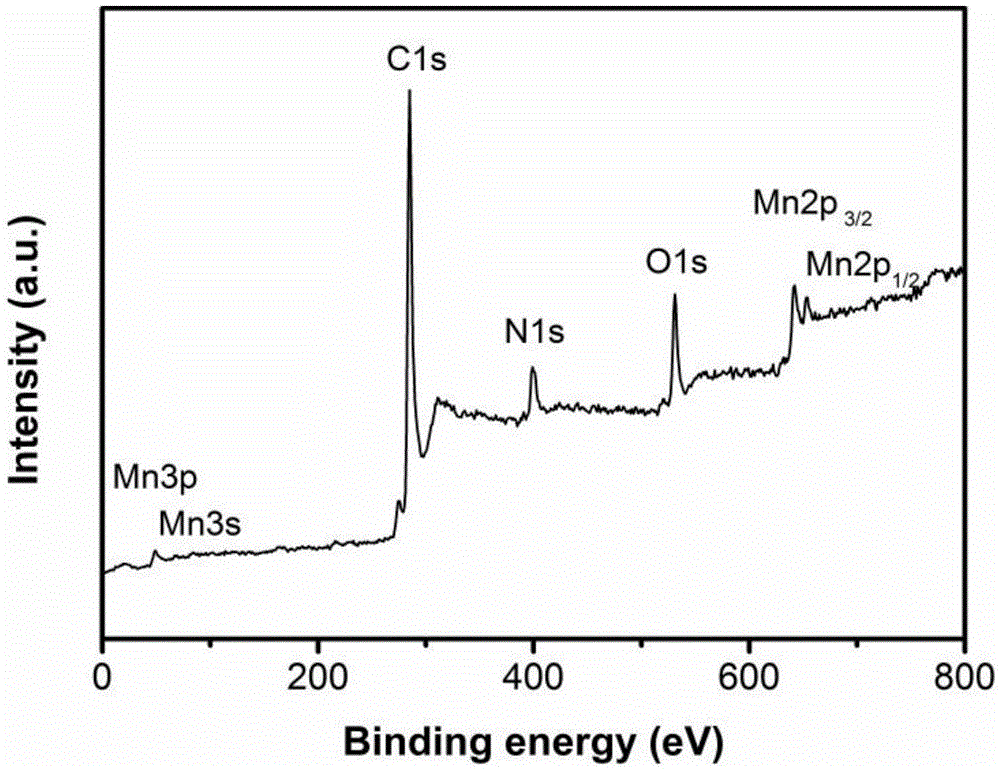

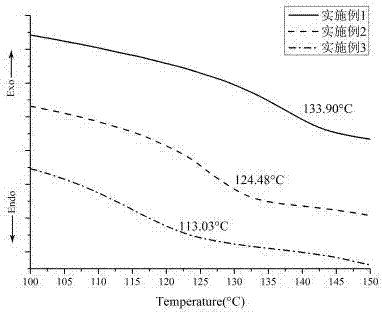

InactiveCN105470481AImprove conductivityOvercoming the problem of rapid capacity fadingMaterial nanotechnologyCell electrodesCarbon layerIn situ polymerization

The invention relates to a nitrogen-doped carbon-coated manganese monoxide composite material with a one-dimensional porous core-shell structure and a preparation method of the nitrogen-doped carbon-coated manganese monoxide composite material. The composite material is doped with nitrogen, is in a one-dimensional porous carbon-coated manganese monoxide core-shell structure; manganese monoxide is in a nano rodlike structure; and an outer layer of a manganese monoxide nanorod is coated with an amorphous carbon layer. The nitrogen-doped carbon-coated manganese monoxide composite material is obtained by an in-situ polymer coating method accompanied by burning. The preparation method of the composite material is simple and novel, and high in adjustability; and meanwhile, nitrogen-doped carbon can store lithium ions. Due to the ingenious design, the specific capacity of the composite material exceeds the theoretical specific capacity of the manganese monoxide; furthermore, according to the composite material, the problems of low capacity and fast attenuation caused by poor conductivity and high volumetric strain of a pure manganese monoxide material are solved; and the composite material has excellent electrochemical properties, cycle lifetime and structural stability.

Owner:WUHAN UNIV OF TECH

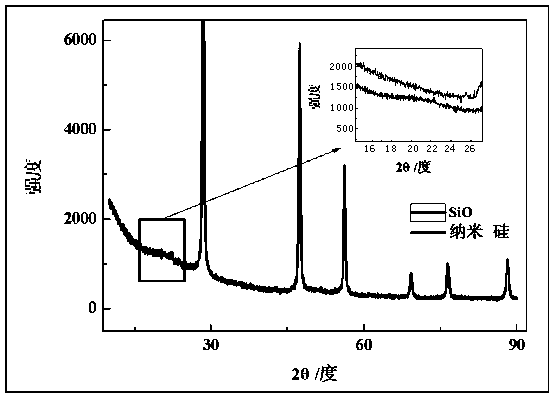

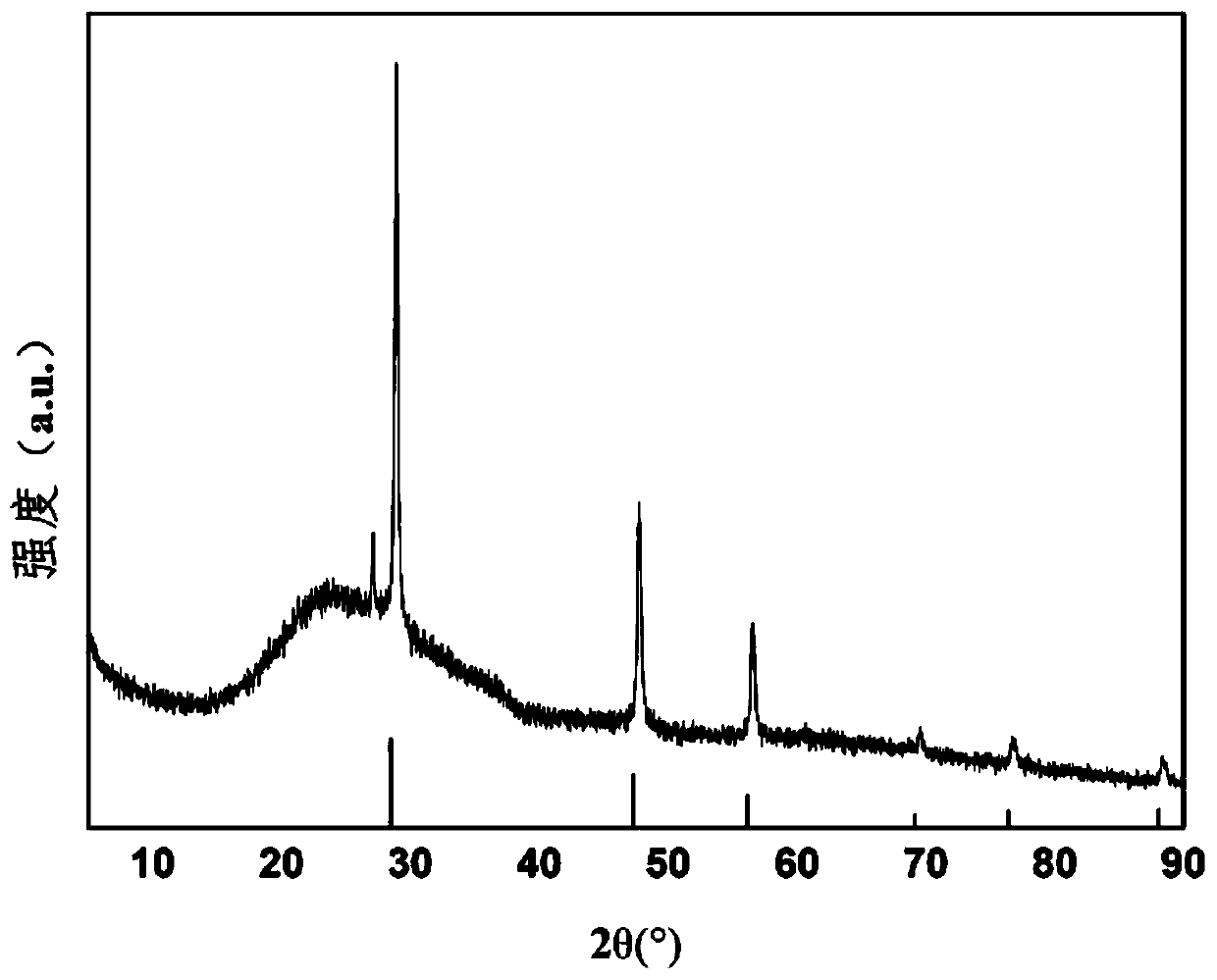

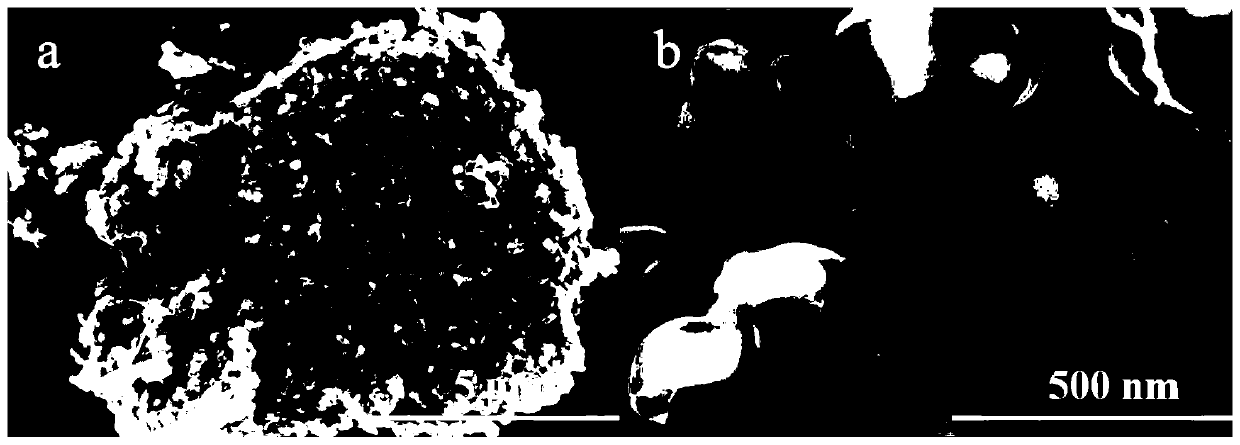

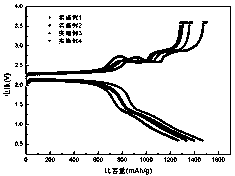

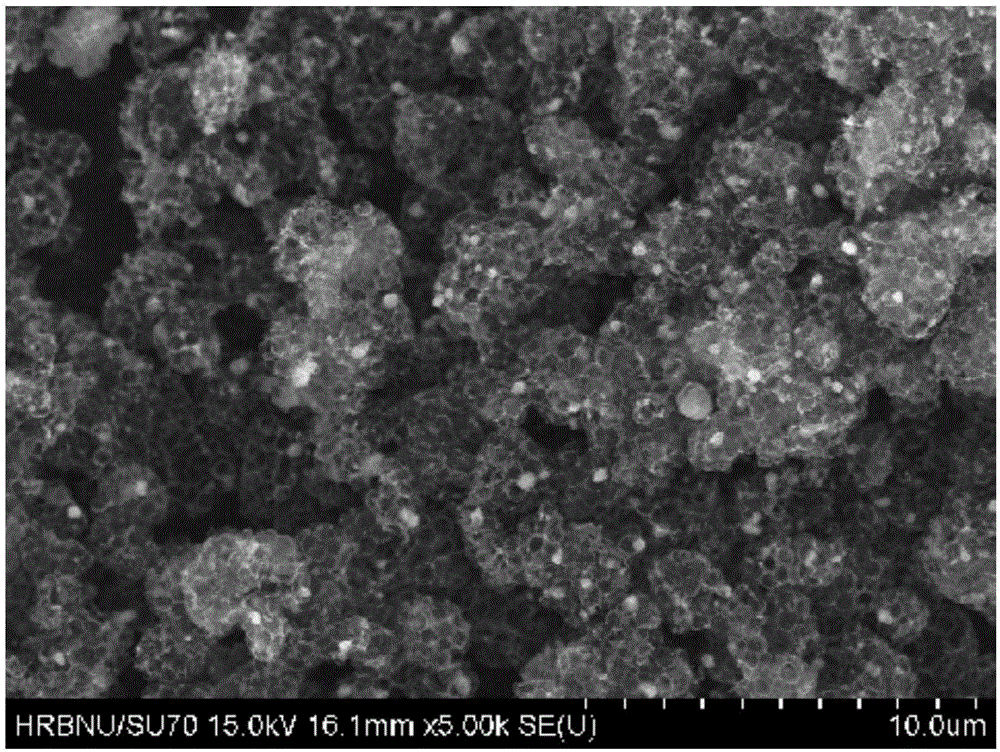

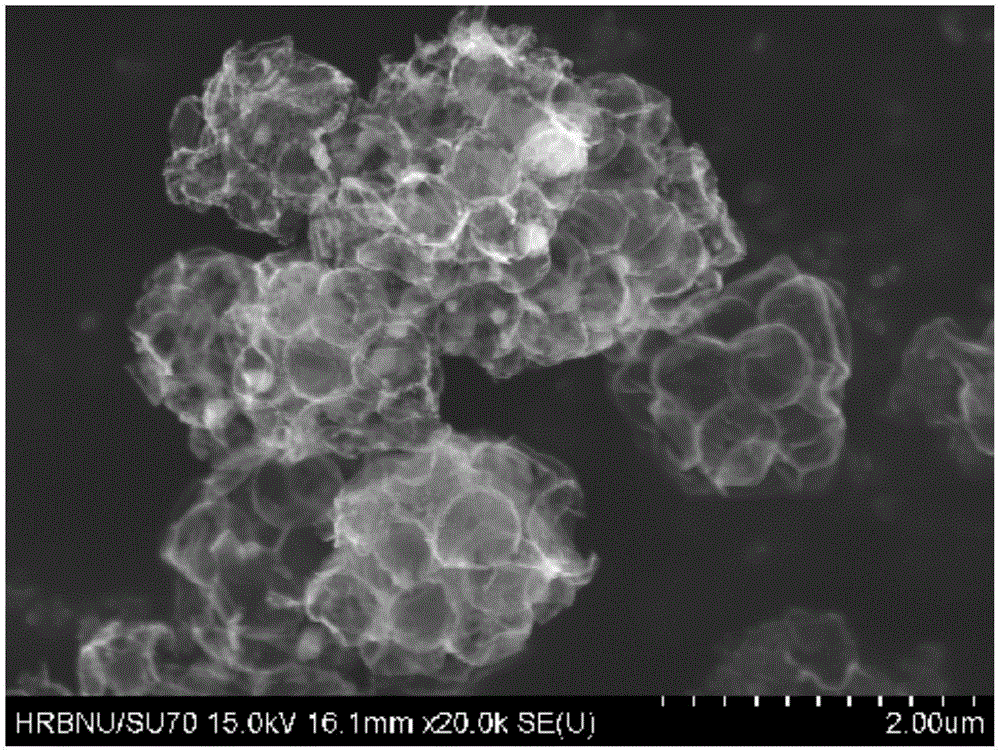

Porous silicon material, and preparation method and application thereof

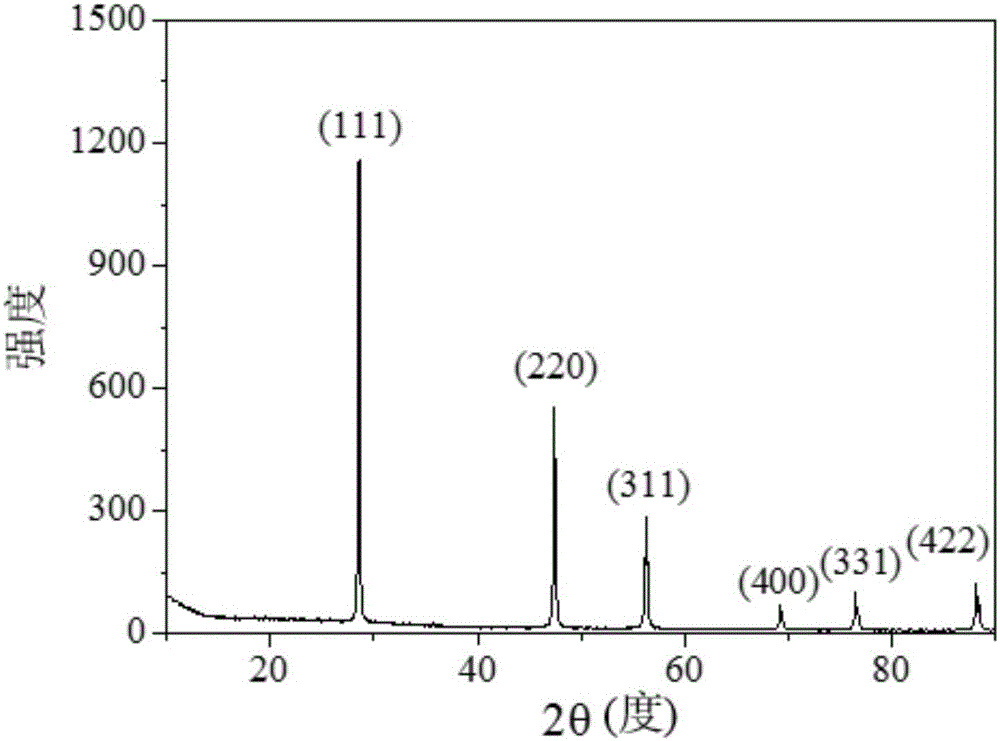

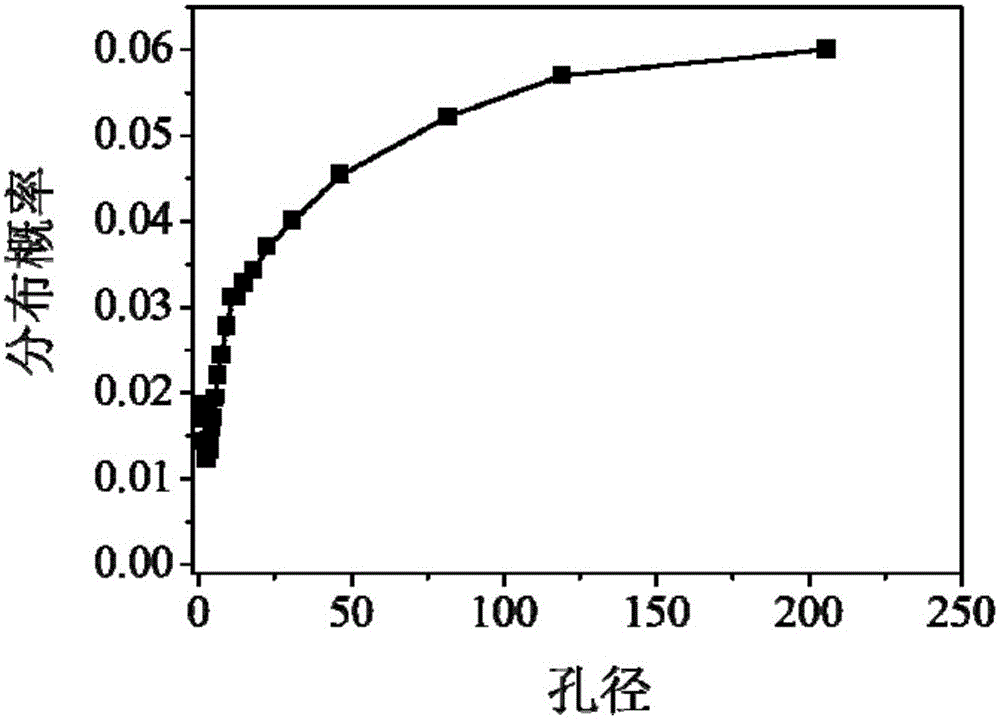

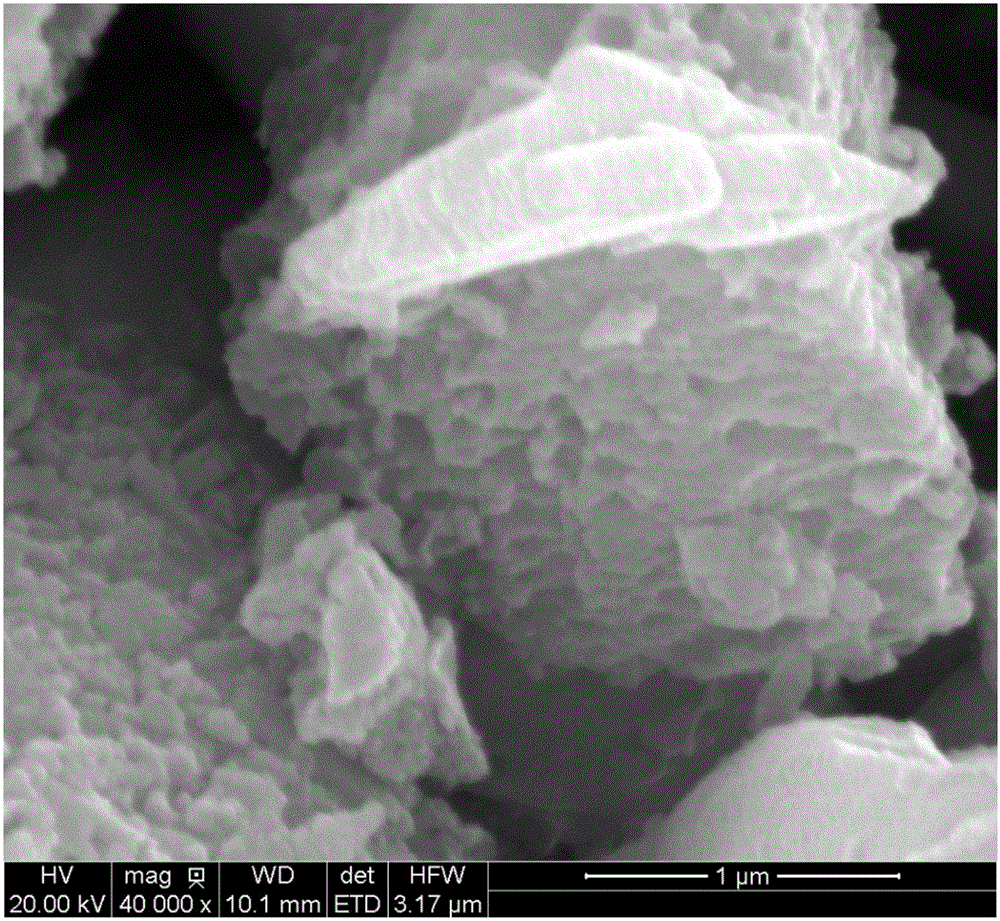

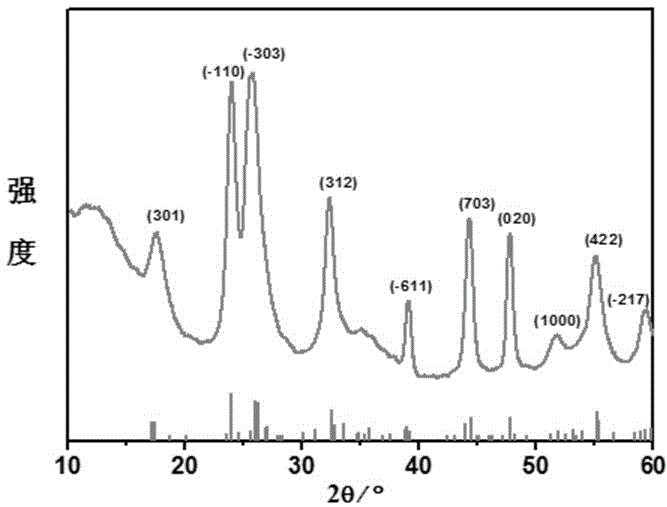

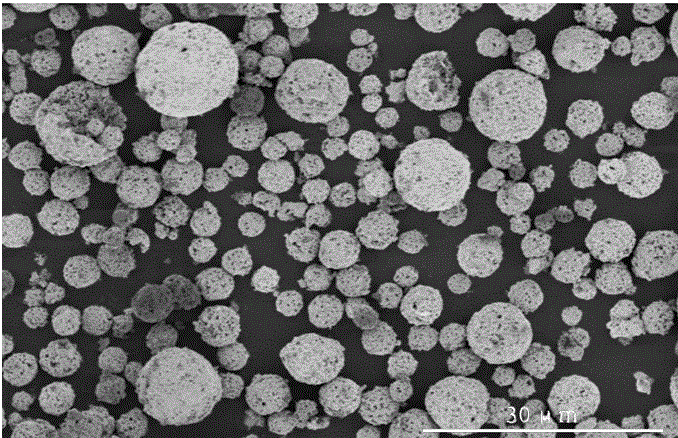

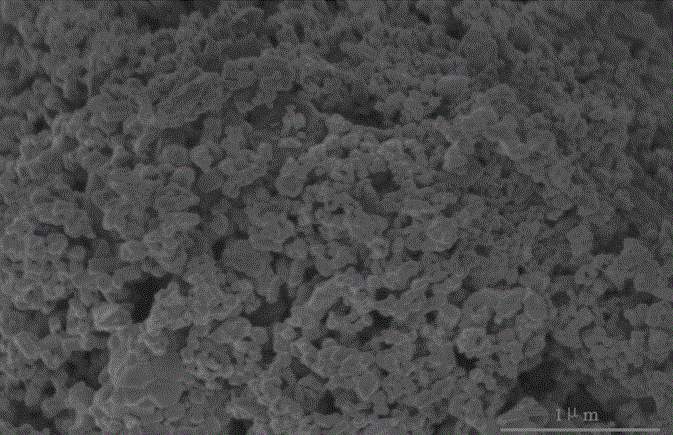

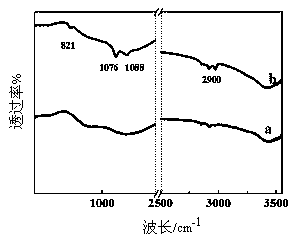

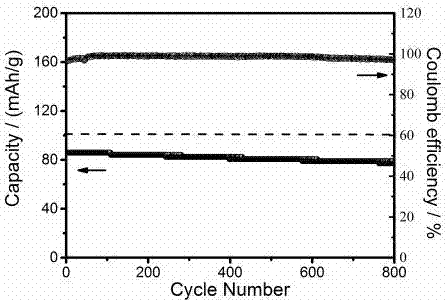

ActiveCN105047892AImprove cycle stabilityImprove the first Coulombic efficiencyCell electrodesSecondary cellsAcid etchingSpace group

The invention discloses a porous silicon material, and a preparation method and an application thereof. The porous silicon material is mainly prepared by mechanical milling and acid etching of metallurgical iron-silicon alloy as a raw material; the dimension of the porous silicon material is in micron / submicron level; the porous silicon material has a diamond structure, belongs to an Fd-3m (227) space group, and has a reaction phase which can react with lithium (Li); a large number of hierarchical porous structures with different dimensions are evenly distributed in the surface and the inside of the porous silicon material; the porous silicon material can be used as a lithium ion battery anode active material, and shows the characteristics of high (first) coulombic efficiency, high capacity, excellent cycling stability and the like when applied to a lithium ion battery; meanwhile, the preparation technology of the porous silicon material is simple, and can be carried out only by conventional equipment; the used raw materials are cheap and available; the technological process is easy to control; and the porous silicon material is good in repeatability, high in productivity, stable in product quality and suitable for large-scale production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

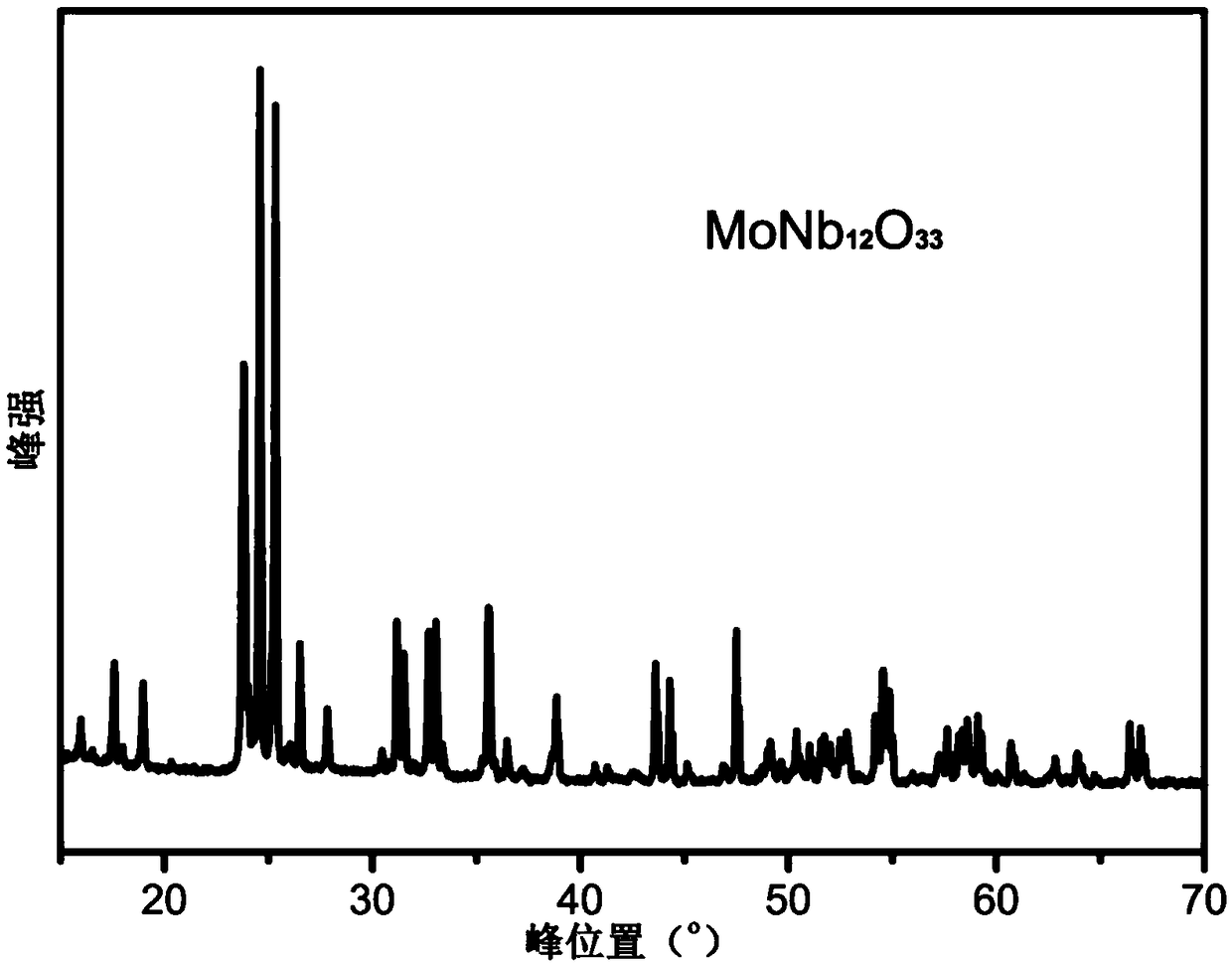

Lithium ion battery cathode material and non-aqueous electrolyte batterie

InactiveCN109244443AHigh theoretical specific capacityImprove securityNegative electrodesElectrode collector coatingNiobiumPhysical chemistry

Owner:AAC TECH NANJING

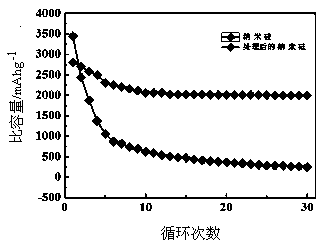

Nanometer silicon/graphene lithium ion battery cathode material and preparation method thereof

ActiveCN103400970AImprove cycle performanceGranularity controllableCell electrodesSolventLithium-ion battery

The invention relates to a nanometer silicon / graphene lithium ion battery cathode material and a preparation method thereof. The cathode material comprises nanometer silicon and graphene, wherein the granularity of nanometer silicon granules is 10-100nm, and the mass ratio of nanometer silicon to graphene is 1:(5-10). The preparation method of the nanometer silicon / graphene lithium ion battery cathode material comprises the following steps of: preparing an electron solution; reducing a silicon tetrachloride liquid phase into nanometer silicon; preparing a graphene oxide glue sample solution; loading the graphene oxide glue sample solution on nanometer silicon; and drying and sintering the semi-finished product of the composite electrode material. According to the preparation method, after the nanometer silicon granules the granularity of which can be controlled are obtained through a liquid phase reducing method; in a mode that a glue body is separated out through replacing a solvent graphene is reduced and a glue layer is formed at the same time, and moreover the glue layer is adsorbed on an existing nanometer silicon glue nucleus; the obtained nanometer silicon has a better size and a better structure, can combine graphene and nanometer silicon efficiently in the term of molecule size; the obtained silicon carbon material has stable circulation performance and excellent electric conducting performance.

Owner:湖北高地石墨烯科技有限公司

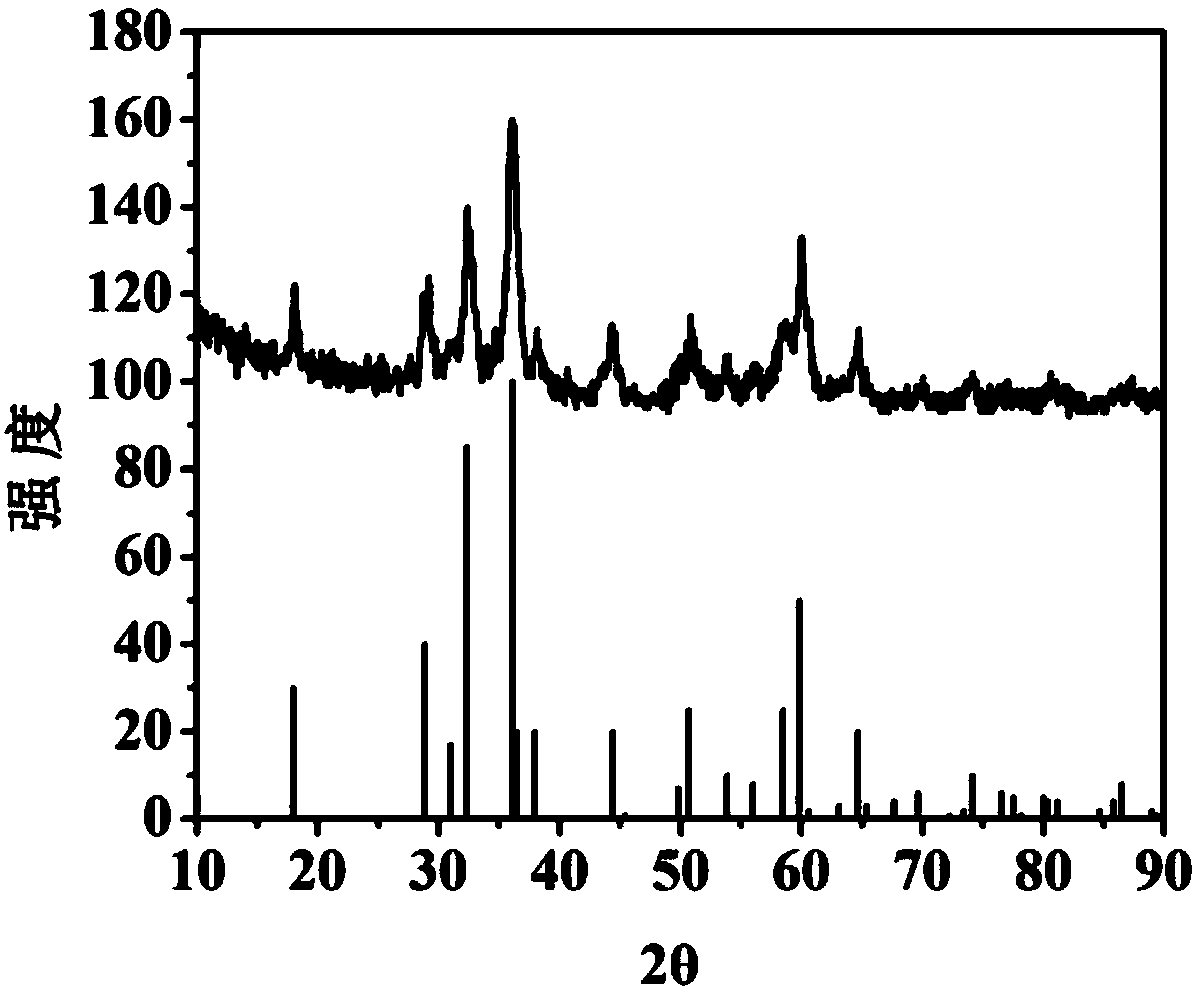

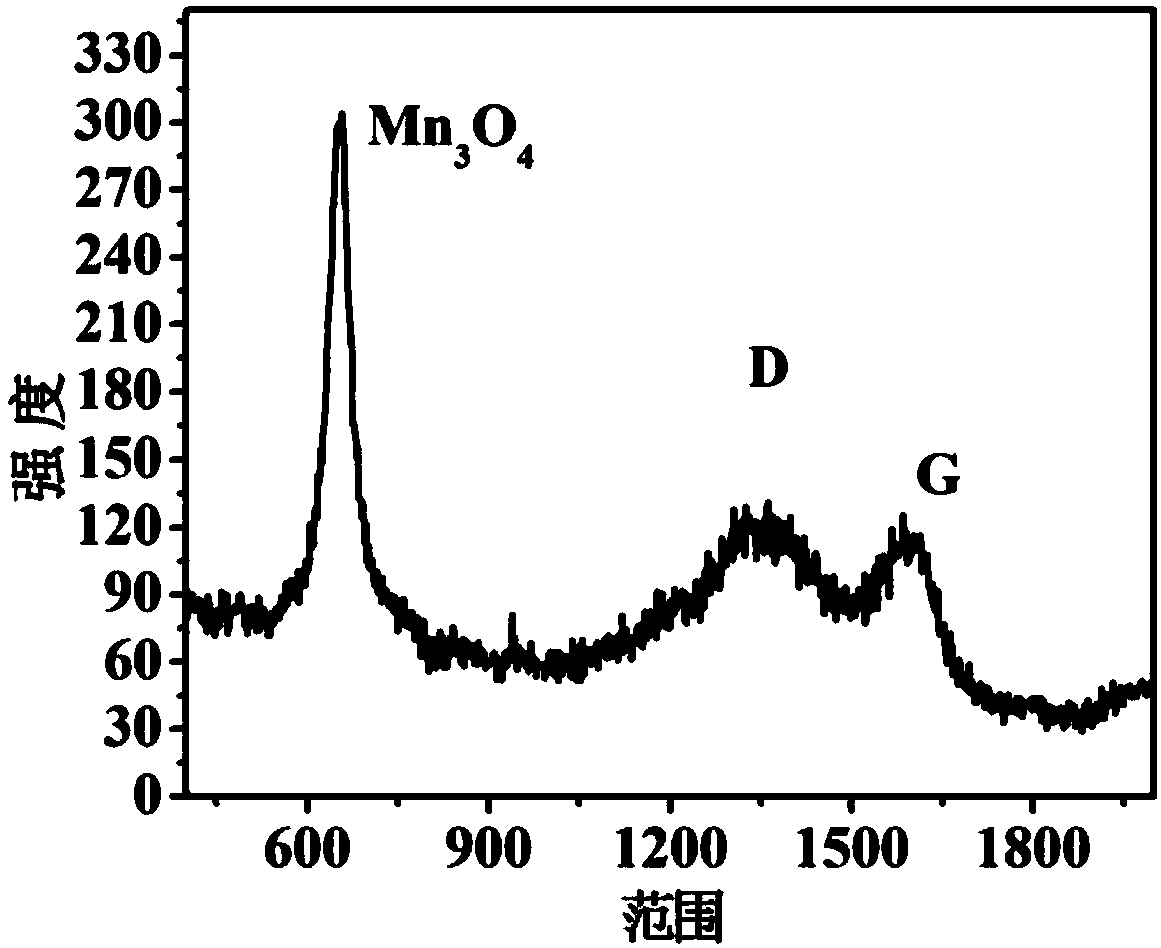

Nitrogen-doped carbon-coated manganous-manganic oxide composite material, as well as preparation method and application thereof

InactiveCN108520944AImprove stabilityImprove conductivityCell electrodesSecondary cellsMANGANESE ACETATEManganous-manganic oxide

The invention belongs to the field of materials for lithium ion batteries, and discloses a nitrogen-doped carbon-coated manganous-manganic oxide composite material, as well as a preparation method andapplication thereof. The preparation method comprises the steps of dissolving manganese acetate and ammonium bicarbonate into ethylene glycol, carrying out solvent heat treatment at the temperature of 180 to 220 DEG C, and obtaining manganese carbonate; reacting with dopamine hydrochloride, and obtaining a manganese carbonate / polydopamine composite material; then calcining under an inert atmosphere, and finally oxidizing in a muffle furnace to obtain the nitrogen-doped carbon-coated manganous-manganic oxide composite material. The preparation method provided by the invention is simple and lowin cost; the prepared nitrogen-doped carbon-coated manganous-manganic oxide composite material is stable in structure and good in electrical conductivity, and has excellent rate performance and cyclic stability when being used as a lithium ion battery cathode material.

Owner:SOUTH CHINA UNIV OF TECH

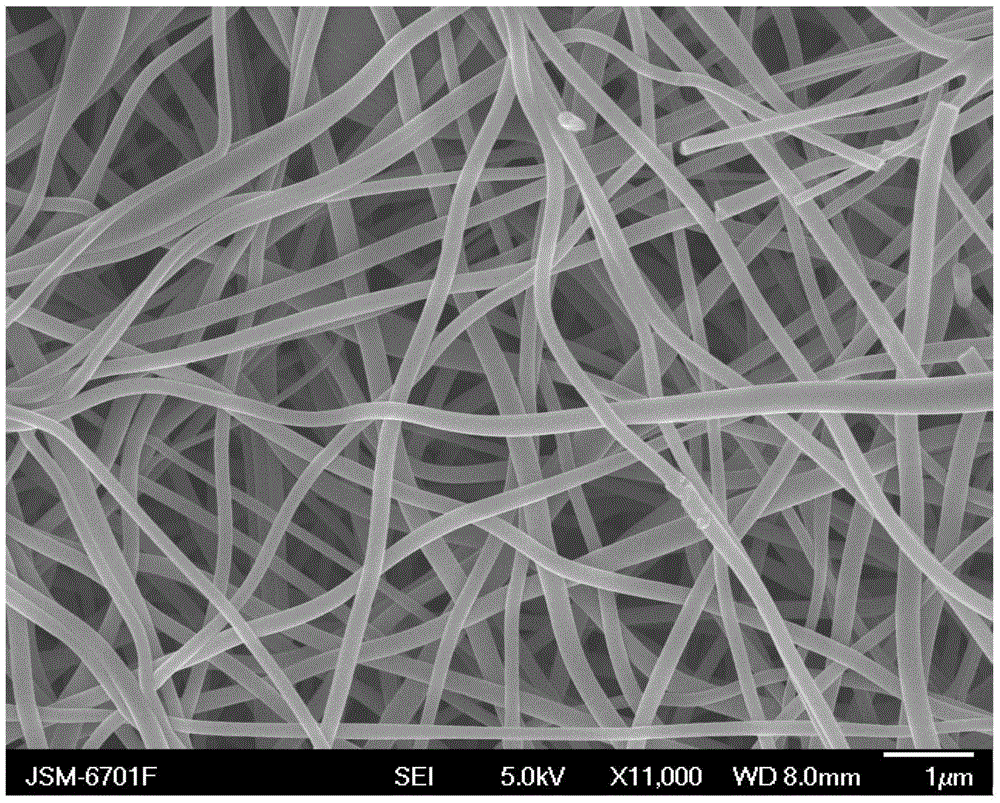

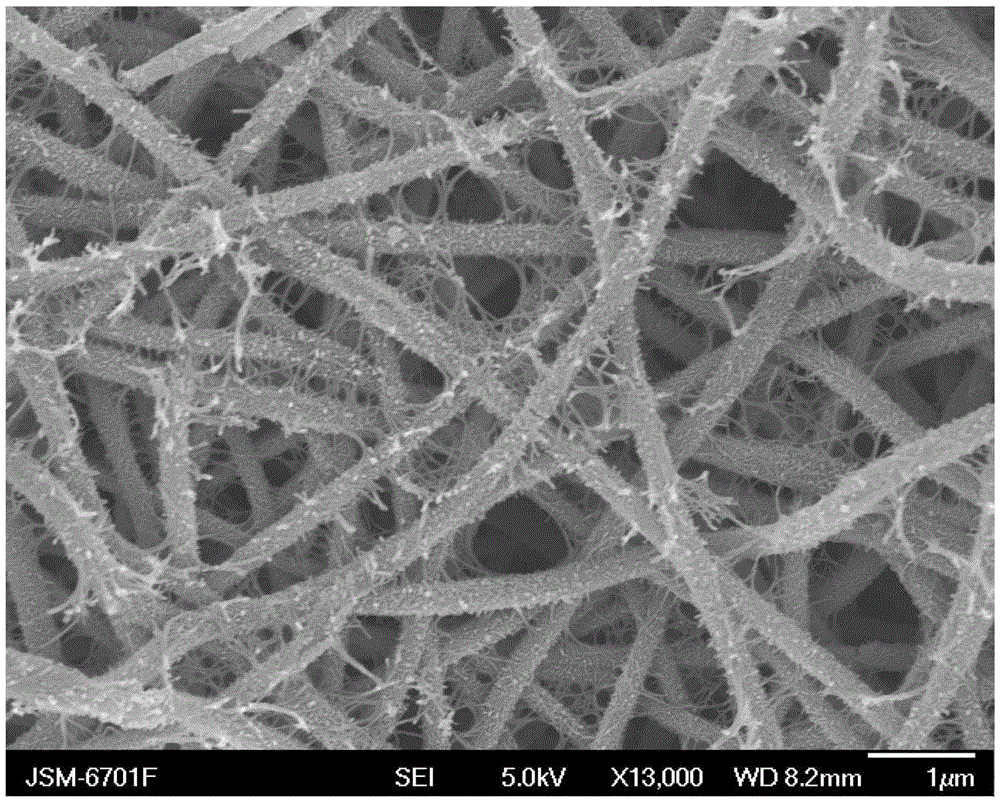

Flexible negative electrode with MnO2 attached onto carbon fiber of lithium ion battery and preparation method of flexible negative electrode

InactiveCN105552342ALithium extraction and extraction potential is lowImprove cycle performanceCell electrodesSecondary cellsFiberCarbon fibers

The invention relates to a flexible negative electrode with MnO2 attached onto carbon fibers of a lithium ion battery and a preparation method of the flexible negative electrode. A metal oxide in the prior art is wrapped inside the carbon nanofibers, and thus, the contact of the metal oxide serving as an active substance with an electrode and the de-intercalation process of the metal oxide with lithium ions are not promoted; and further, the metal oxide is Fe2O3, Fe3O4, Co3O4 and the like, and such metal oxide has a defect of relatively high de-intercalation lithium potential. The preparation method is characterized by comprising the following steps of firstly, preparing a flexible carbon nanofiber net, which comprises electrostatic spinning, pre-oxidation of a polymer nanofiber net and high-temperature calcination; secondly, preparing a flexible composite fiber thin film with an MnO2 nanowire attached onto the surfaces of the carbon nanofibers, placing the flexible carbon nanofiber net in a KMnO4 solution, and completing high-temperature reaction under process conditions of a reaction temperature of 150-200 DEG C and reaction time of 30-60 minutes; and finally, cutting the flexible carbon nanofiber net into the flexible negative electrode with MnO2 attached onto the carbon fibers of the lithium ion battery.

Owner:CHANGCHUN UNIV OF SCI & TECH

Mesopore vanadium oxide/carbon composite nano material and preparation method thereof

InactiveCN104167303AHigh theoretical specific capacityImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureCarbon compositesActive agent

The invention discloses a mesopore vanadium oxide / carbon composite nano material and a preparation method thereof. The mesopore vanadium oxide / carbon composite nano material is of a meso-structure. According to calculation by an atom percentage, the content of a vanadium element is 20% to 60%, and the balance being carbon. A pore diameter is distributed from 1.98 nm to 2.3 nm, a specific surface area is about 759.39 m<2> / g to 800.65 m<2> / g, and a pore volume is 0.65 cm<3> / g to 1.33 cm<3> / g. The preparation method involves preparing the mesopore vanadium oxide / carbon composite nano material with the large specific surface area, the large pore volume and the large pore diameter through an evaporation induction self-assembling method by taking a non-ionic surface active agent as a template agent and ammonium metavanadate as a vanadium source. The mesopore vanadium oxide / carbon composite nano material serves as an electrode material for manufacturing a supercapacitor.

Owner:SHANGHAI INST OF TECH

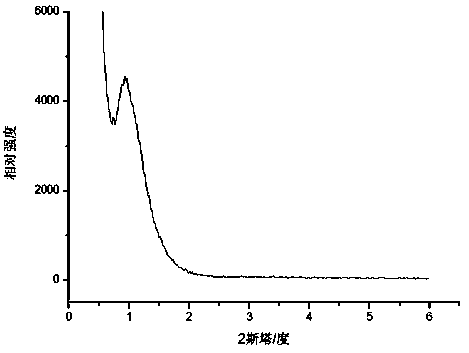

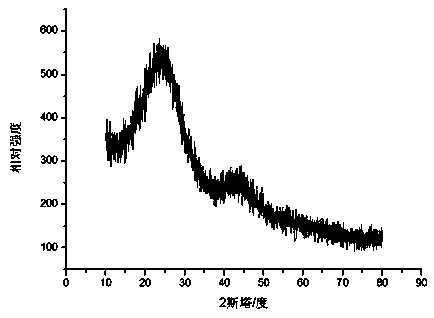

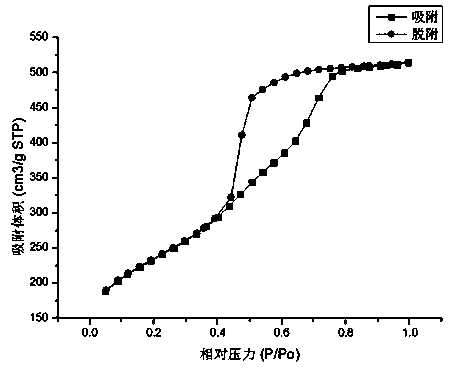

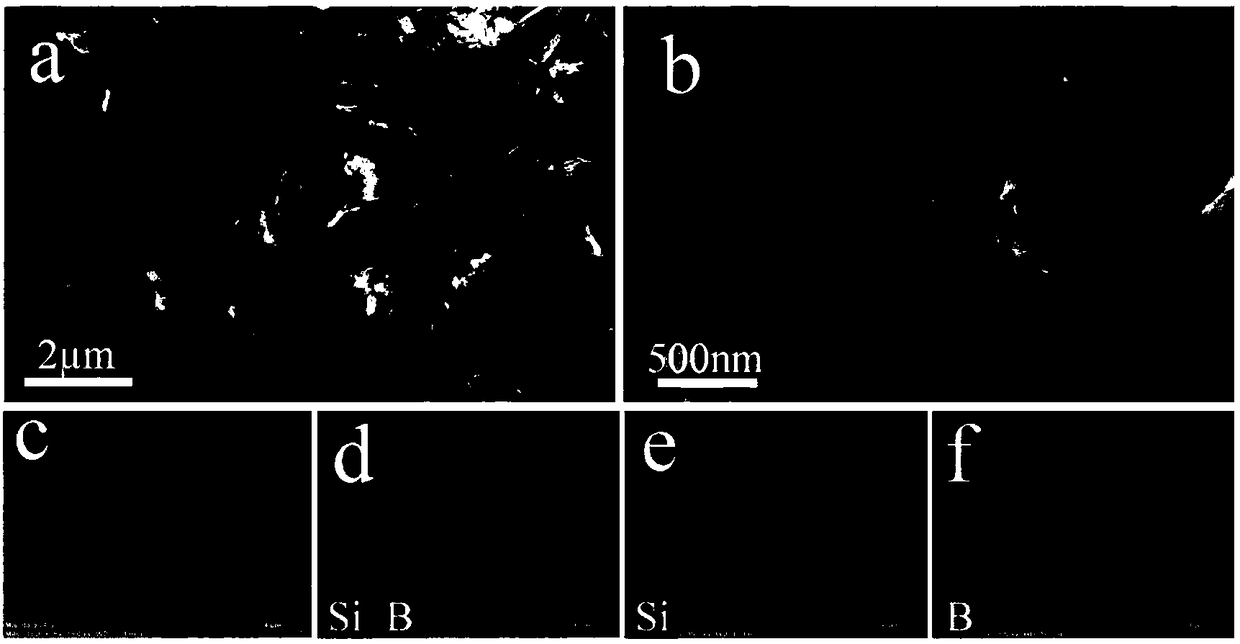

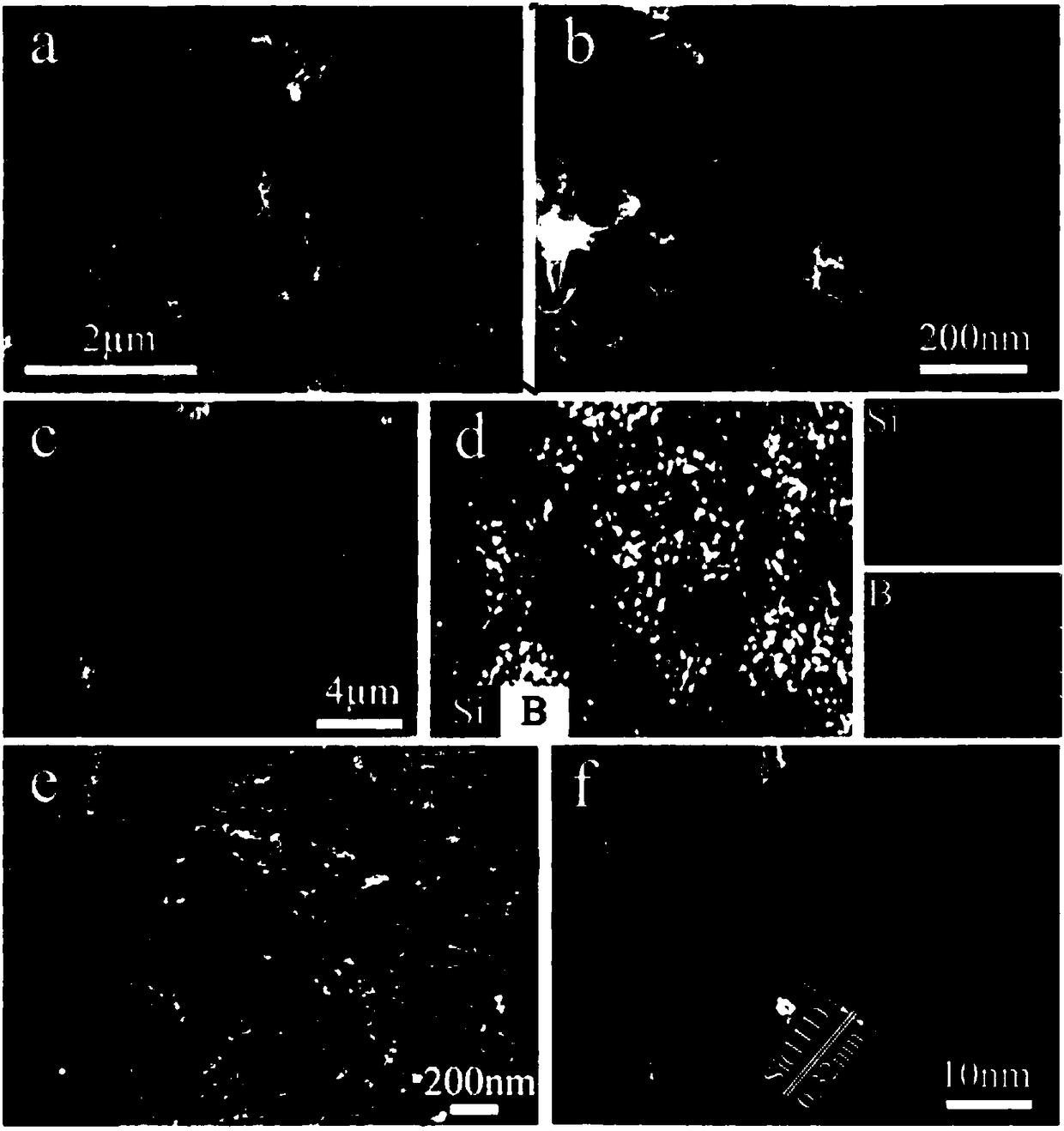

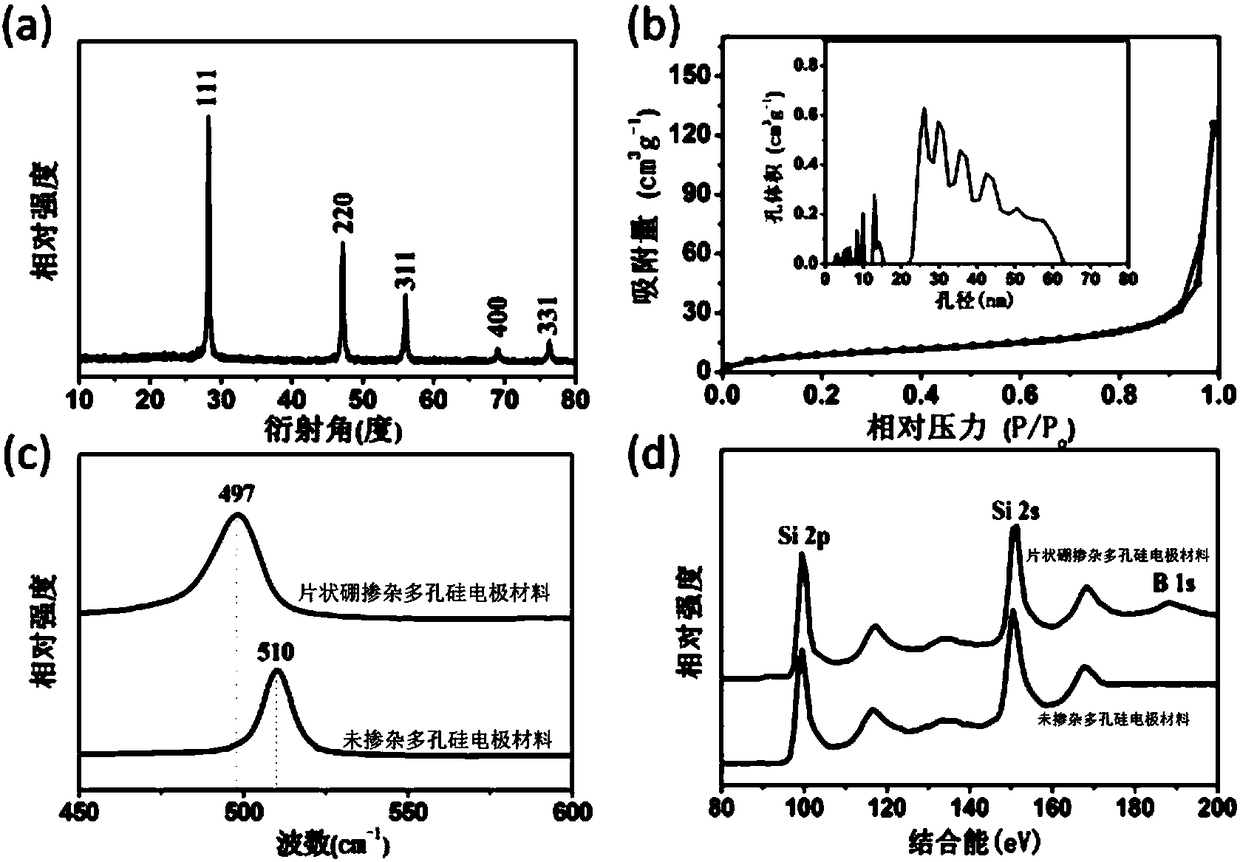

Sheet-shaped boron-doped porous silicon electrode material and preparation method thereof

ActiveCN108390053AImprove conductivityMeet the needs of conductionSiliconCell electrodesMixed materialsP type silicon

The invention discloses a preparation method of a sheet-shaped boron-doped porous silicon electrode material. The preparation method comprises the steps of (1) immersing boron-doped P-type silicon debris with an inorganic acid for 6-24 hours, and performing washing and drying to obtain boron-doped silicon powder; (2) uniformly mixing the boron-doped silicon powder and magnesium powder according toa mole ratio being 1:(1-2.5) to obtain a mixed material, and performing thermal processing on the mixed material under inert atmosphere to generate Mg2Si powder; (3) oxidizing the Mg2Si powder undera high temperature of 400-850 DEG C to obtain a reaction product, immersing the reaction product with the inorganic acid, cleaning and washing the reaction product with an HF solution, and obtaining the sheet-shaped boron-doped porous silicon electrode material after drying. The grain size of the prepared sheet-shaped boron-doped porous silicon electrode material is 0.2-5 micrometers, the specificarea is (10-100) m<2> / g, and the pore diameter is 20-70 nanometers. The sheet-shaped boron-doped porous silicon electrode material has favorable cycle stability and high specific capacity.

Owner:中国平煤神马控股集团有限公司 +2

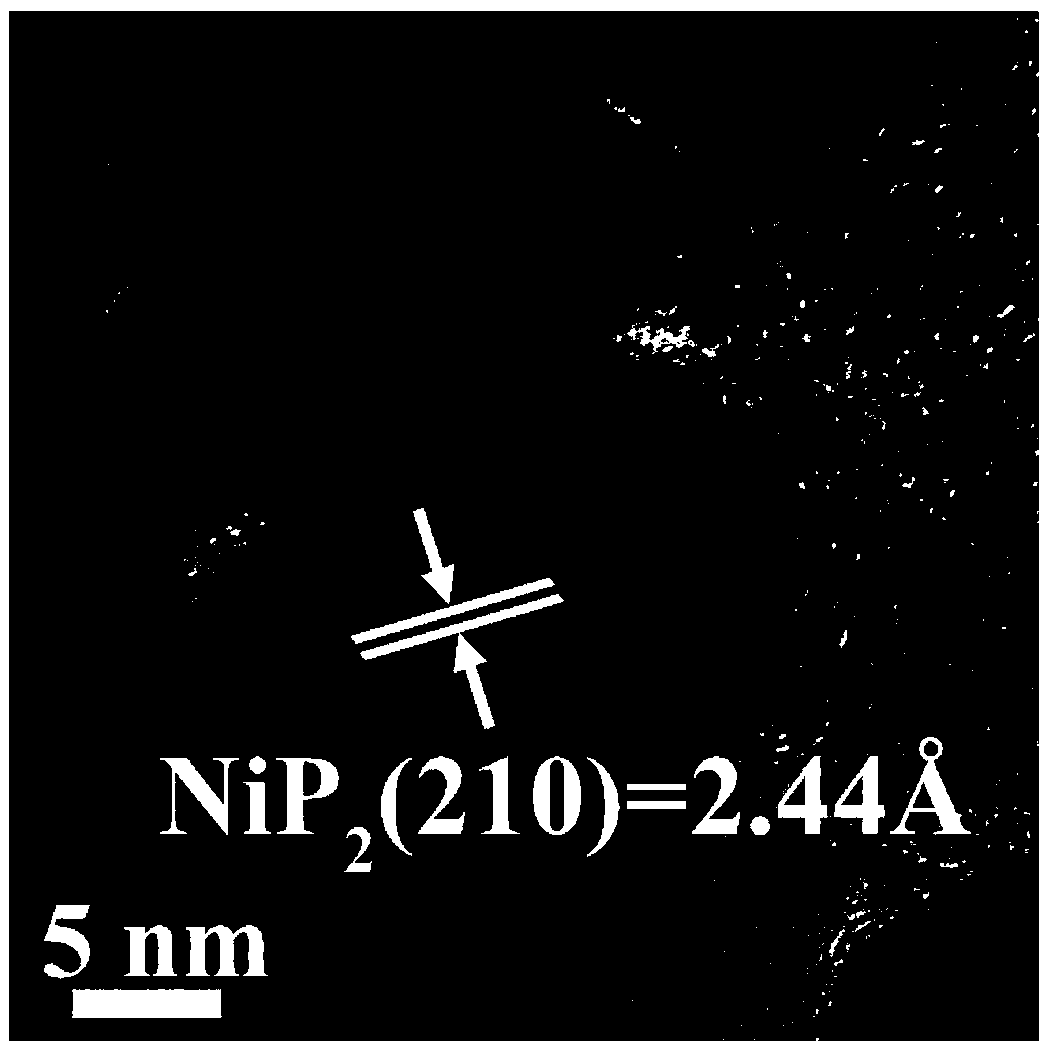

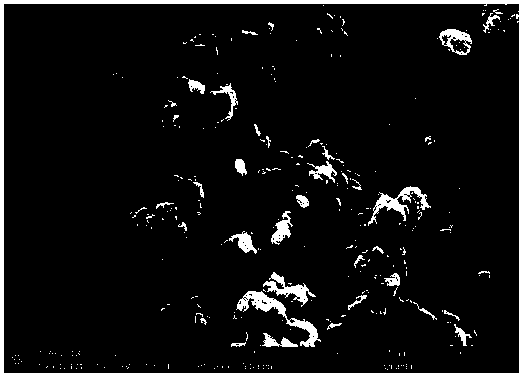

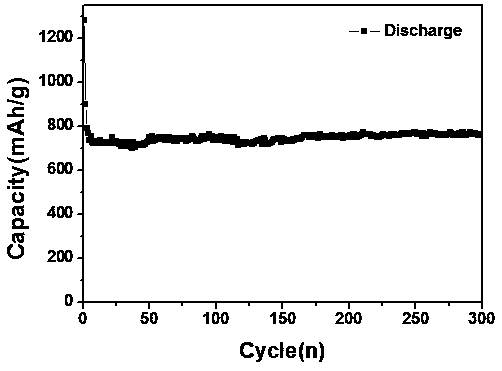

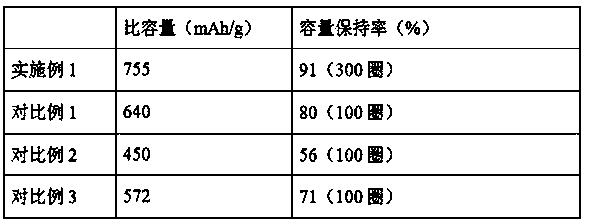

Carbon-coated NiPx nanometer composite electrode material with monodisperse structure characteristic, and preparation method thereof

ActiveCN108172770AShorten the transmission pathHigh mechanical strengthMaterial nanotechnologyCell electrodesComposite electrodeNanoparticle

The invention relates to a carbon-coated NiPx nanometer composite electrode material with monodisperse structure characteristic, and a preparation method thereof, wherein the carbon-coated NiPx nanometer composite electrode material comprises an electric conduction carbon material matrix and carbon-coated NiPx nanoparticles uniformly dispersed and distributed in the electric conduction carbon material matrix in a monodispersed state. According to the present invention, the carbon-coated NiPx nanoparticles are dispersed in the electric conduction carbon material matrix in the monodispersed state, such that the electron and lithium ion transmission path can be substantially shortened through the unique composition and the structure form, the mechanical strength of the composite material canbe improved, and the stress strain generated during the conversion reaction of the active material can be relieved so as to ensure the structural integrity of the electrode material.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

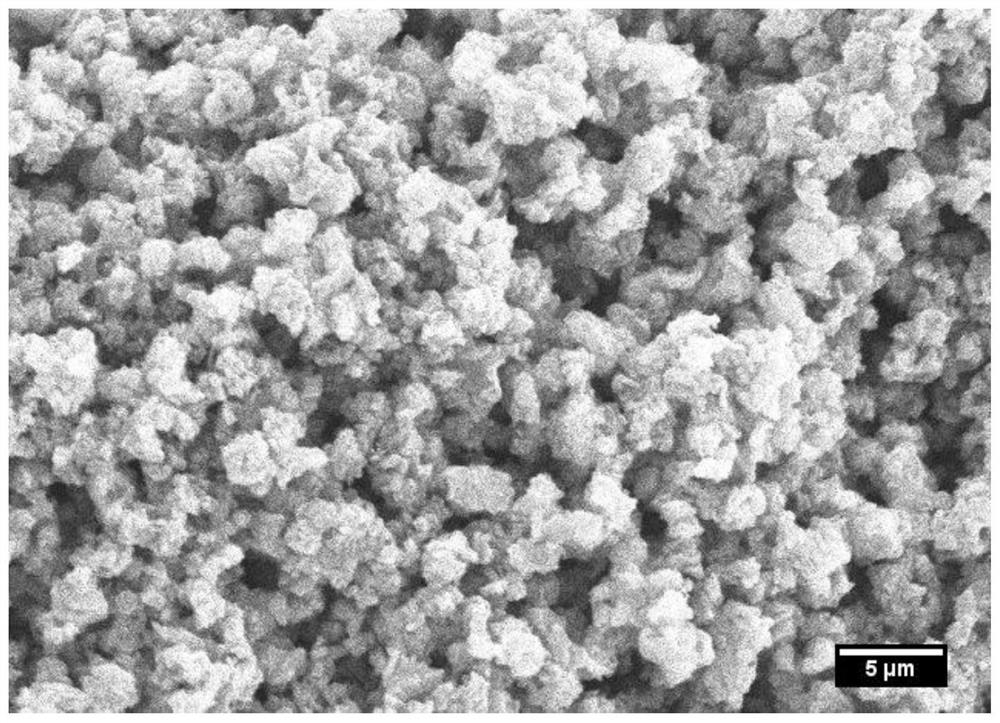

Silicon monoxide-based anode material for lithium ion battery and method for preparing same

ActiveCN109713294AGood carbon coating effectInhibition of volume expansionCell electrodesCarbon sourceSol-gel

The invention discloses a method for preparing a silicon monoxide-based anode material for a lithium ion battery, and belongs to the fields of new materials and electrochemistry. The method comprisesusing organic silicon as a silicon source and organic carbon as a carbon source; obtaining a silica / carbon precursor by a sol-gel method; and preparinga SiOx / C composite material having double interfaces by a carbon thermal reduction reaction occurring during a high-temperature heat treatment process. The method controls the colloidalization process of the organic silicon source to uniformly disperse the silicon source and the carbon source, enhances the ability of the carbon thermal reduction reaction in the heat treatment process, and obtains the silicon monoxide-based anode material with agood pyrolytic carbon coating effect. In addition, by adding a loosening agent, the method solves problem that the material is easily densified during the heat treatment. The anode material has high specific capacity and good cycle stability. The method is easy to operate and low in cost. The preparation process does not relate to acid washing and centrifugation. The method has a good applicationprospect.

Owner:郑州中科新兴产业技术研究院 +1

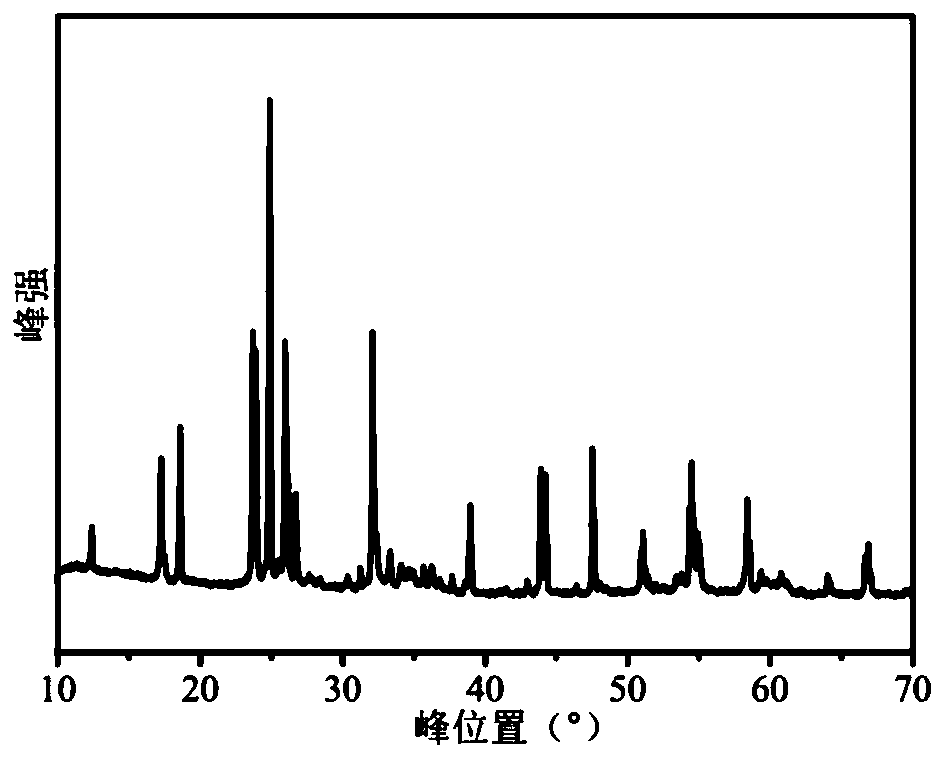

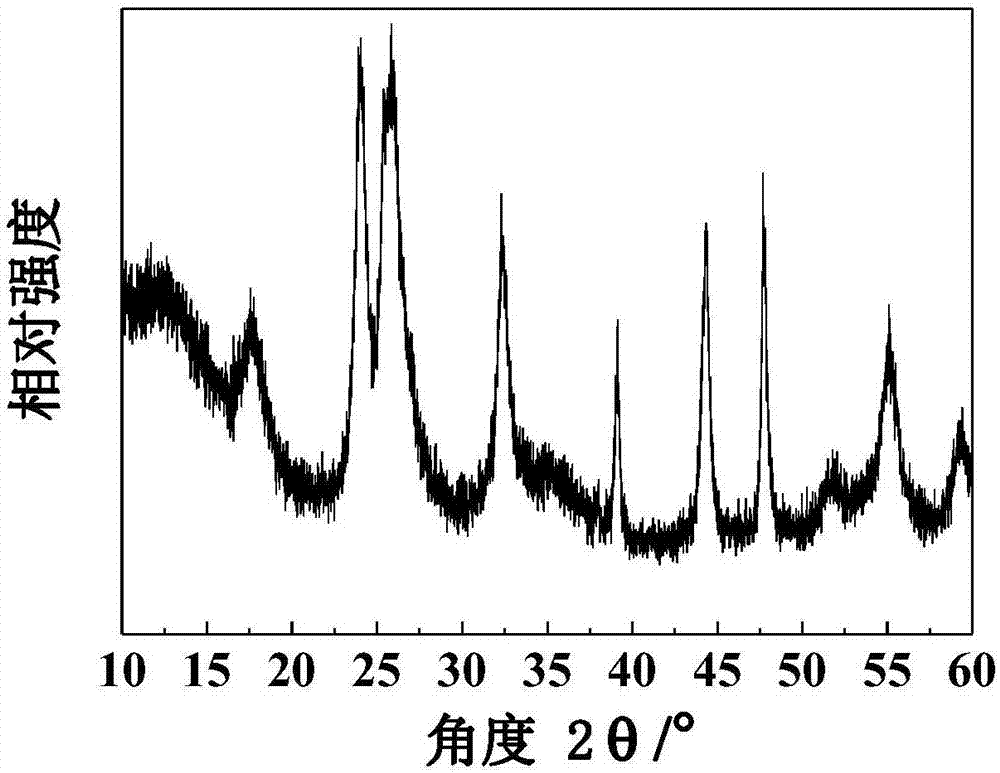

Preparation method of porous titanium/carbon niobate composite microsphere

InactiveCN106169569ASimple methodShort preparation cycleCell electrodesSecondary cellsMicrosphereSolvent

The invention belongs to the technical field of synthesis of nanometer materials, and specifically discloses a preparation method of a porous titanium / carbon niobate composite microsphere. The preparation method is used for successfully preparing the porous titanium / carbon niobate composite microsphere with a multilevel structure by selecting titanium dioxide as a titamium source, selecting niobium pentoxide as a niobium source, selecting saccharose as a carbon source, selecting deionized water as a solvent and carrying out processes such as ball milling, spray drying and heat treatment in sequence. Having a relatively high theoretical specific capacity (388 mA.h / g) and a relatively large specific surface area, the porous titanium / carbon niobate composite microsphere is expected to replace lithium titanate to serve as a lithium ion battery cathode material. In addition, the preparation method has the advantages of being simple in preparation process and relatively short in preparation period, is very suitable for industrial large-scale production and has a wide application prospect.

Owner:FUDAN UNIV

Preparing method and application of silicon-based negative electrode material with SiO2 coating layer

InactiveCN105514382AAvoid chalkingImprove cycle lifeCell electrodesSecondary cellsSilanesLithium-ion battery

The invention discloses a preparing method and application of a silicon-based negative electrode material with a SiO2 coating layer. The method includes the following steps that 1, a silane coupling agent is subjected to hydrolysis for 12-15 h; 2, nano silicon powder is ultrasonically treated in a water / ethyl alcohol mixed solution for 0.3-2 h; 3, the hydrolyzed silane coupling agent and a nano silicon powder mixed solution are mixed and flow back under the inert gas atmosphere to conduct a temperature-raising reaction; 4, the mixed solution is centrifugally washed and dried in vacuum to obtain a silicon-based negative electrode material with a silane coupling agent coating layer; 5, the negative electrode material is sintered at inert atmosphere to obtain the silicon-based negative electrode material with the SiO2 coating layer, wherein the silicon-based negative electrode material can be applied to a lithium ion battery. Compared with other oxide coating layers, the prepared SiO2 coating layer can improve the circulation stability of the silicon-based material and has high theoretical specific capacity, and the technology is simple and feasible, low in cost and suitable for large-scale production.

Owner:HARBIN INST OF TECH

Sodium-ion battery positive plate, preparation method thereof and sodium-ion battery

InactiveCN112768699AIncrease energy densityHigh theoretical specific capacityElectrode carriers/collectorsElectrode collector coatingPhysical chemistrySodium-ion battery

The invention belongs to the technical field of sodium ion batteries, and relates to a sodium ion battery positive plate. The sodium ion battery positive plate comprises a positive current collector, a positive active material layer and a sodium supplement additive layer; the positive active material layer is arranged on at least one surface of the positive current collector; the sodium supplement additive layer is arranged on at least one surface of the positive active material layer; and the sodium supplement additive layer comprises a sodium supplement additive, and the residue of the sodium supplement additive obtained an electrochemical reaction is gas. According to the sodium-ion battery positive plate disclosed by the invention, the sodium supplementing additive layer is uniformly distributed on the surface of the positive active material layer; and the sodium supplementing additive in the sodium-supplementing additive layer can reduce the consumption of reversible sodium ions, so that the energy density of the sodium-ion battery can be improved. The product of the sodium supplement additive after electrochemical reaction is gas and is distributed on the surface of the positive plate, and the residual component can be removed by a degassing process after high-temperature formation in the battery production process, and does not generate side reaction with the electrode plate to influence the electrochemical performance of the battery.

Owner:SO-FUN TECH CORP LTD

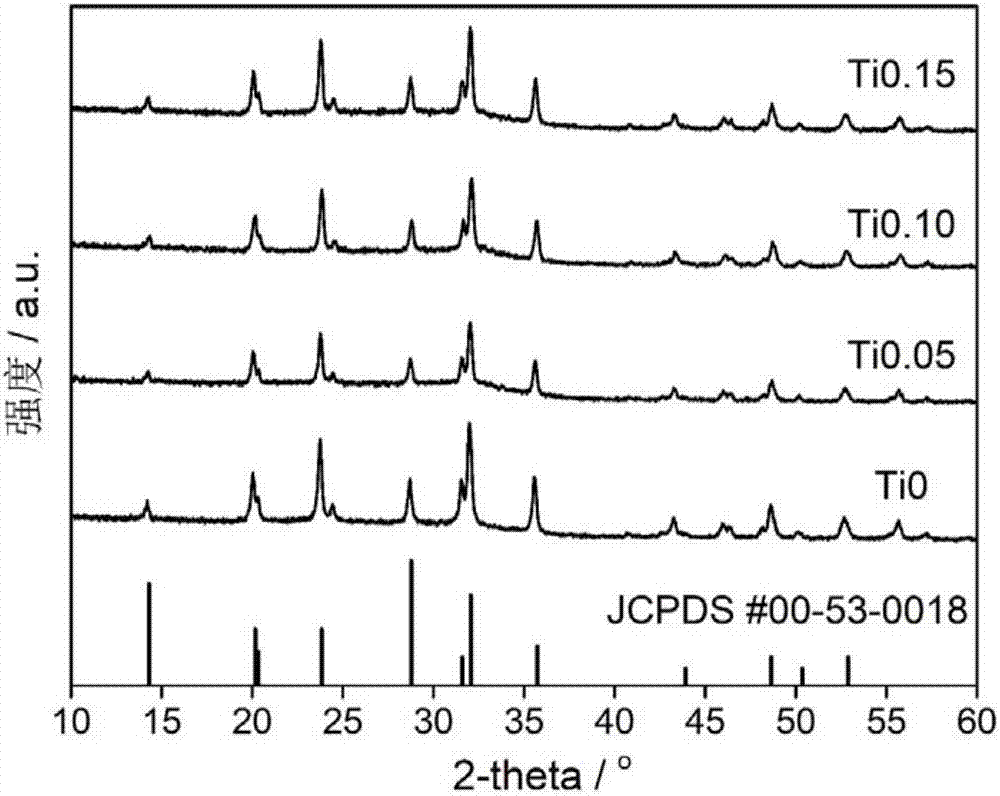

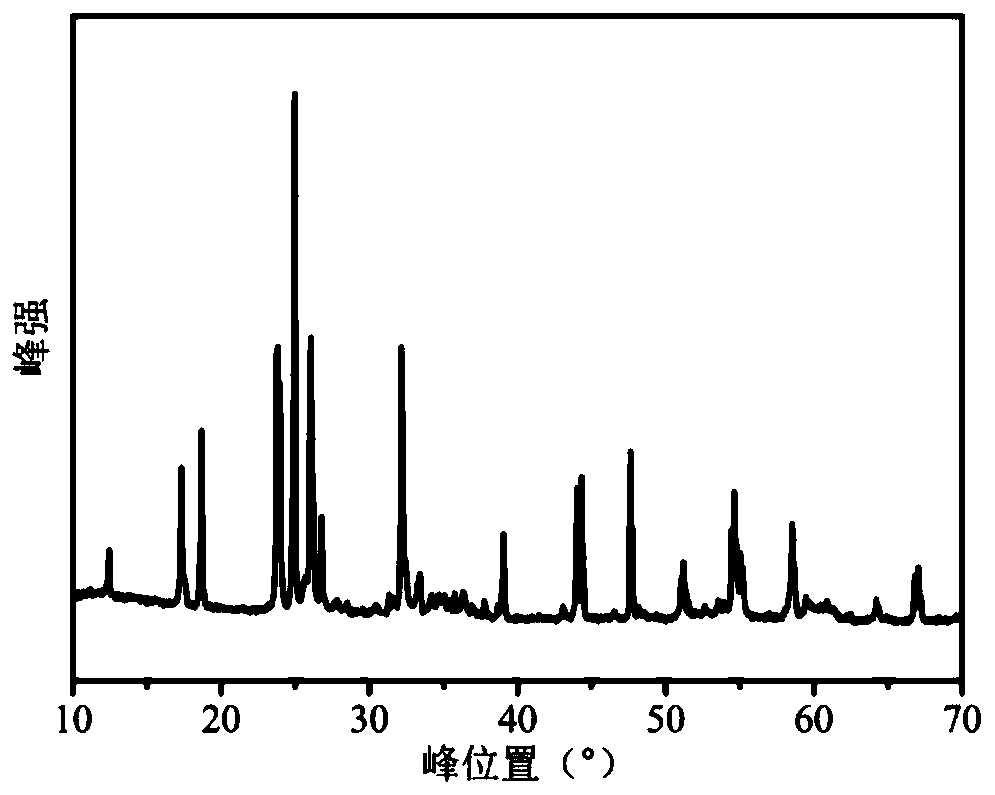

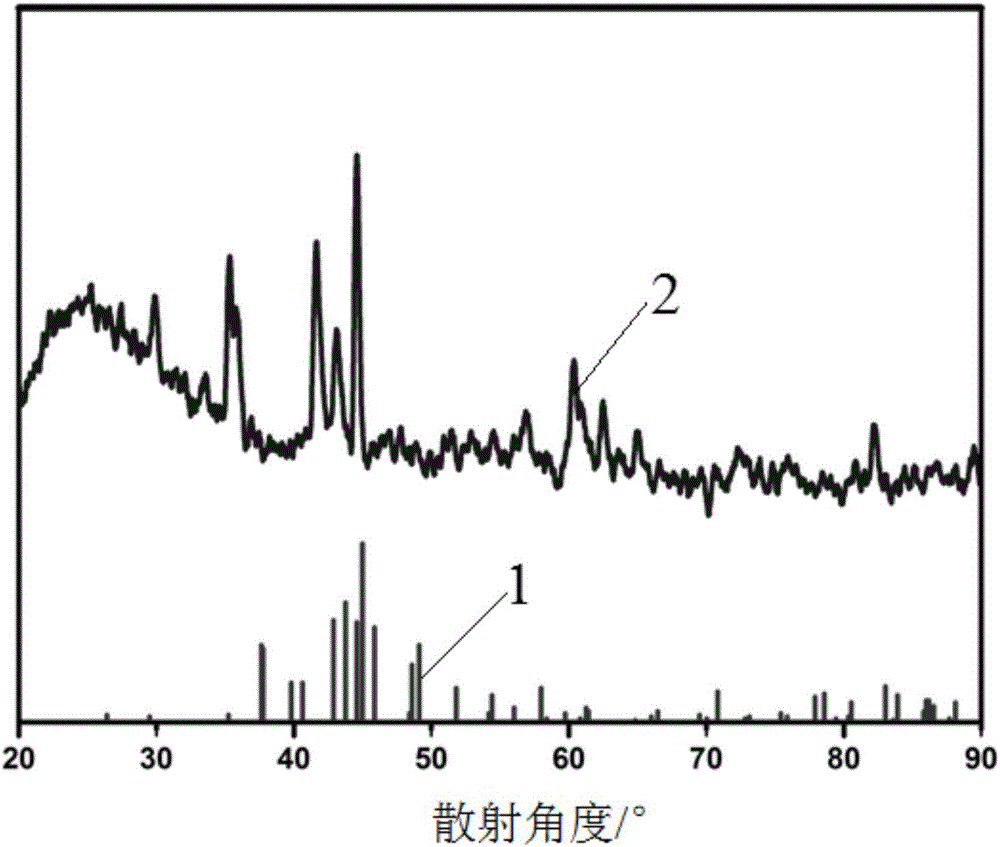

Sodium vanadium phosphate composite electrode material as well as preparation method and application thereof

InactiveCN107425190AElectrochemically activeHigh discharge specific capacityCell electrodesSecondary cellsSodium-ion batteryPromotion effect

The invention relates to a sodium vanadium phosphate composite electrode material as well as a preparation method and application thereof. The sodium vanadium phosphate composite electrode material is a Na3TixV[2-x](PO4)3 / C composite electrode material with a core-shell structure. According to the preparation method, an organic reducing agent and a carbon source are selected, the carbon source can be thermally decomposed into amorphous carbon in the heat treatment process, the formed core refers to Na3TixV[2-x](PO4)3 / C particles, and the shell is a core-shell structure of the amorphous carbon. The unique nano-particle core-shell structure is capable of shortening the sodium ion transport path, improving the ionic conductivity of the material and improving the electronic conductivity through an in-situ coating carbon material, and has a huge promotion effect of improving the electrochemical performance of the Na3TixV[2-x](PO4)3 / C composite electrode material. The composite electrode material disclosed by the invention is widely applied to the technical field of energy storage material and secondary sodium-ion batteries. The invention belongs to the field of electrode materials.

Owner:UNIV OF SCI & TECH BEIJING

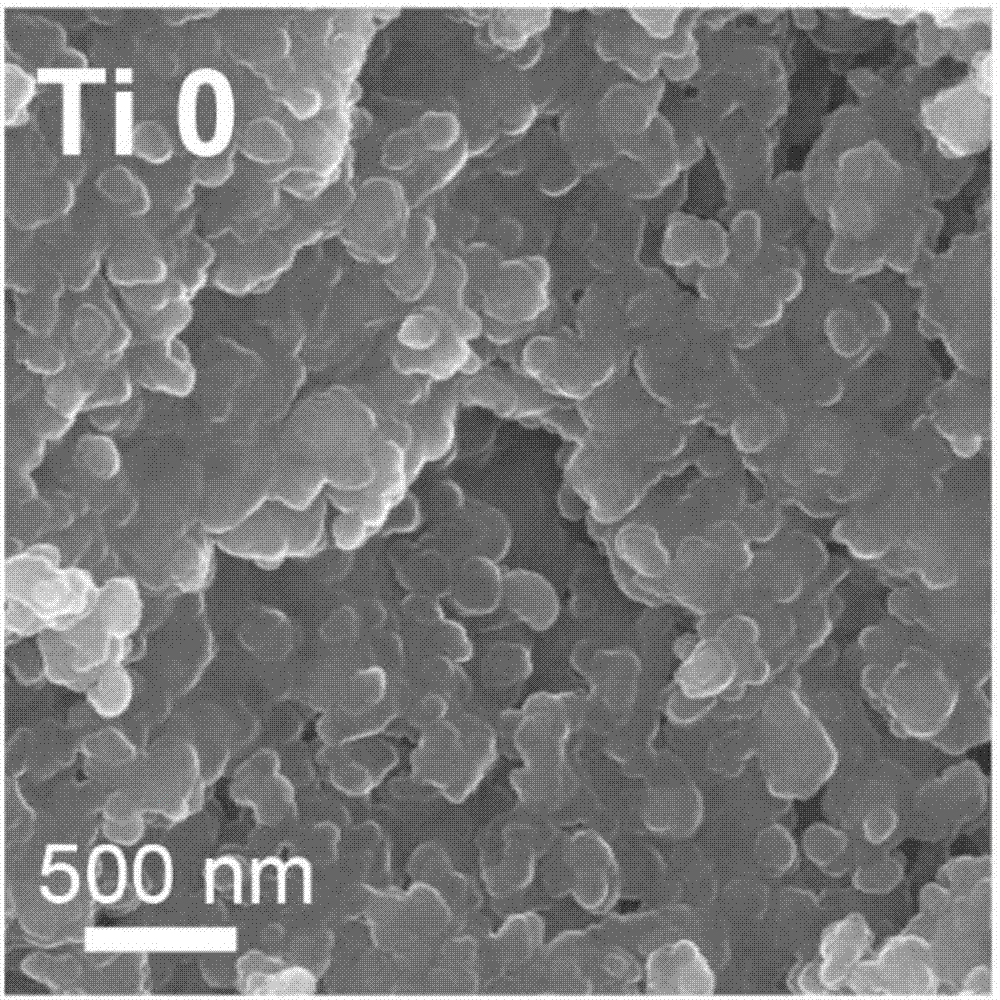

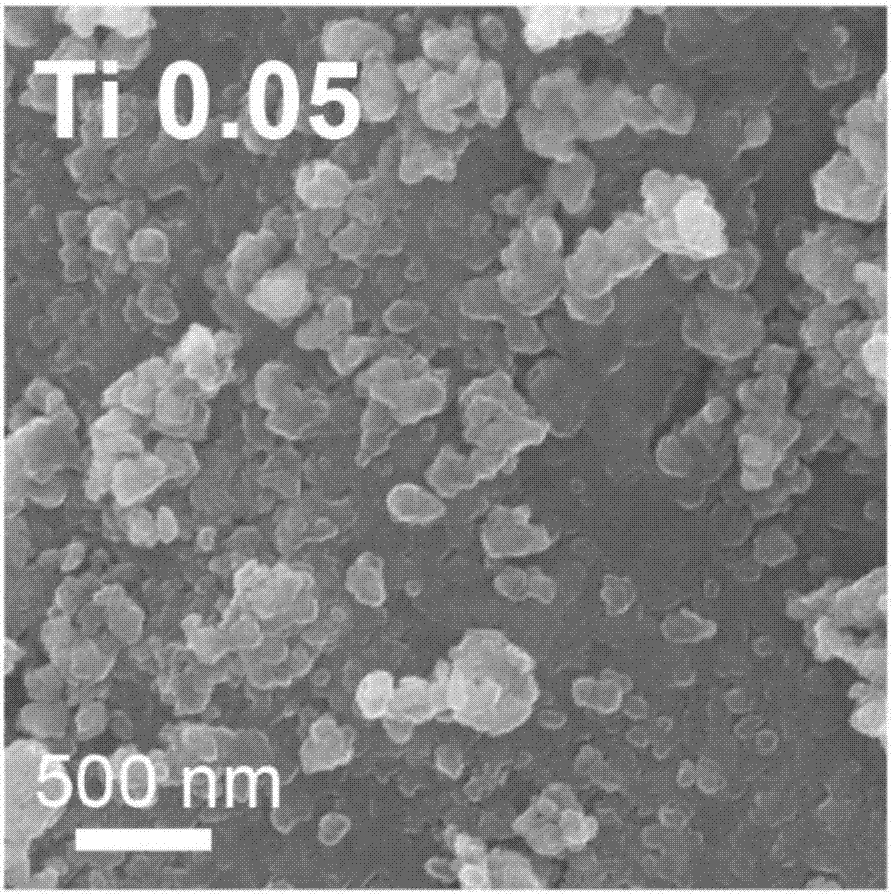

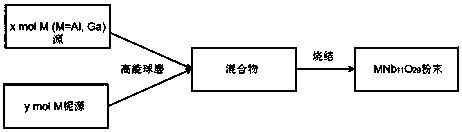

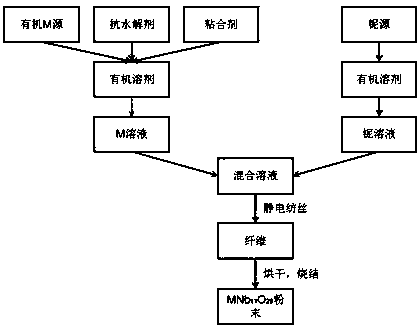

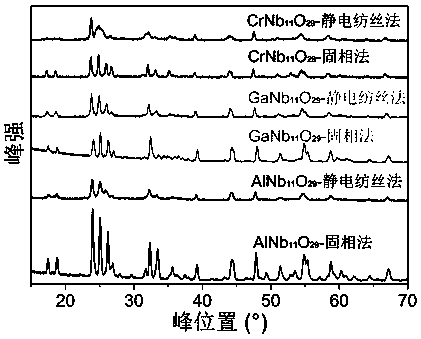

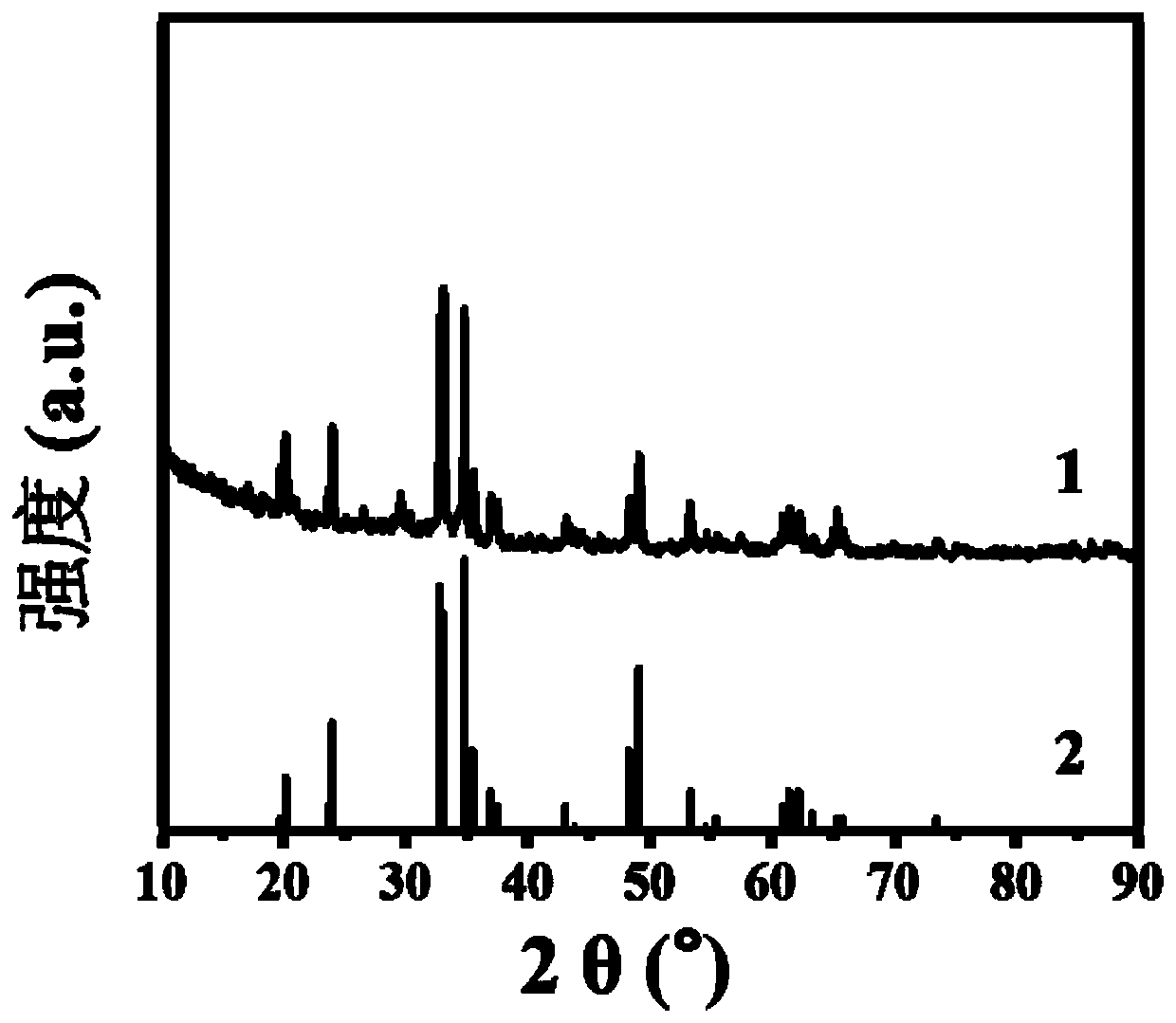

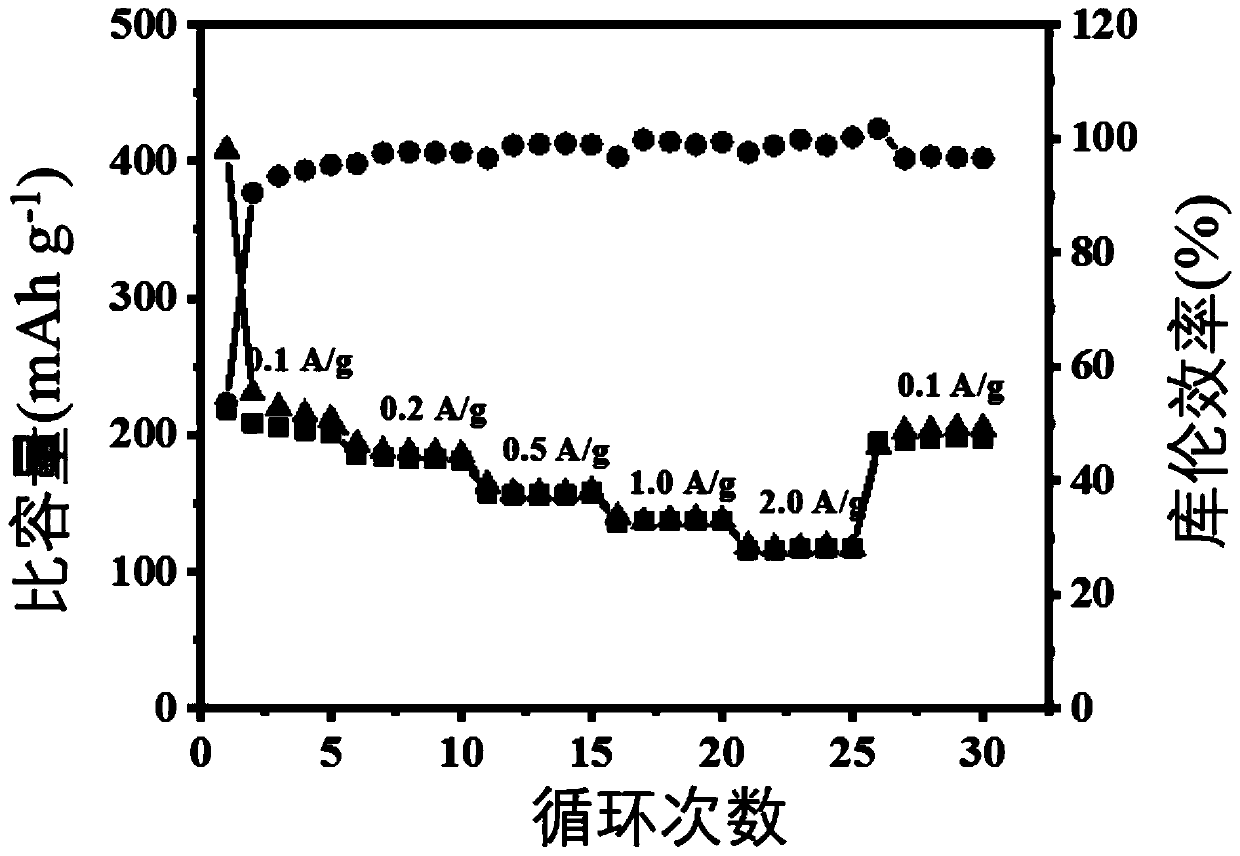

Electrode material of lithium-ion battery and preparation method thereof

ActiveCN107742716AHigh theoretical specific capacityImprove safety performanceCell electrodesSecondary cellsElectrical batteryHigher Power

The invention belongs to the technical field of electrochemistry, material chemistry and chemical power products, and more particularly, relates to an electrode material of a lithium-ion battery and apreparation method thereof. The chemical formula of the electrode material provided by the invention is MNb11O29, wherein M is Al, Ga or Cr. As a negative-electrode material of the lithium-ion battery, the electrode material provided by the invention has the advantages of high theoretical specific capacity, high safety performance, high reversible specific capacity, high coulombic efficiency, excellent cycling performance and the like. The preparation method provided by the invention is simple in synthesis process, is applicable to charging and discharging of high-power devices such as electric vehicles, and has a wide application prospect in the field of the lithium-ion battery. The electrode material and the preparation method thereof have the advantages that more selections are provided for using the M-Nb-O material in the negative-electrode material of the lithium-ion battery, the application prospect is wide in the field of electric vehicles using the lithium-ion battery, and thepromotion of the electric vehicles is accelerated.

Owner:HAINAN UNIVERSITY

Preparation method of carbon-coated sodium iron phosphate electrode material with hollow structure

InactiveCN110957490ASimple processEasy to operateSecondary cellsPositive electrodesElectrical batteryTube furnace

The invention discloses a preparation method of a carbon-coated sodium iron phosphate electrode material with a hollow structure, and relates to a preparation method of an electrode material. The invention solves the problem that the existing NaFePO4 has low electron conductivity and ion diffusion coefficient, so that the NaFePO4 has poor sodium rate capability when being used as the sodium ion battery positive electrode material. The preparation method comprises the following steps: 1, dissolving an iron source, a sodium-containing phosphorus source and a nitrogen-containing organic polymer compound in water to obtain a mixed solution; 2, magnetically stirring to obtain a uniformly mixed solution; 3, keeping the temperature of the uniformly mixed solution until water is completely evaporated to obtain uniformly mixed powder; 4, carrying out heat treatment in a tubular furnace. The preparation method is used for preparing the carbon-coated sodium iron phosphate electrode material withthe hollow structure.

Owner:HARBIN INST OF TECH

Lithium-ion battery anode material, non-aqueous electrolyte lithium-ion battery and preparation method of non-aqueous electrolyte lithium-ion battery

PendingCN109904441AHigh theoretical specific capacityImprove safety performanceFinal product manufactureCell electrodesIonLithium electrode

The invention provides a lithium-ion battery anode material. A general formula of a compound of the lithium-ion battery anode material is M<x>Ti<2+xy-5x>Nb<10+x(4-y)>O<29>, wherein M denotes metal ions, x denotes the atomic weight of M in the compound, y denotes the valence state of the metal ions, and the relations that 0<x<=10, 0<y<=5, 2+xy-5x>=0, and 10+x(4-y)>=0 are met. The invention furtherprovides a non-aqueous electrolyte lithium-ion battery and a preparation method thereof. The lithium-ion battery anode material has high theoretical specific capacity, and high safety performance, andhas the advantages of high reversible specific capacity, high coulomb efficiency, excellent cycle performance and the like.

Owner:AAC TECH PTE LTD

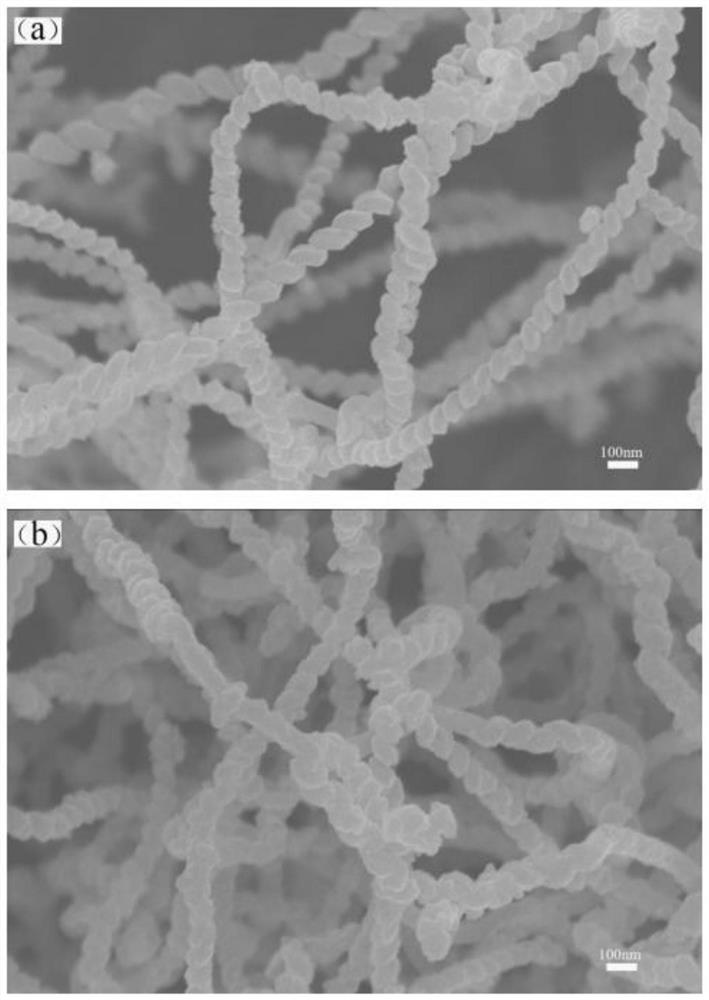

Battery negative electrode material and preparation method thereof

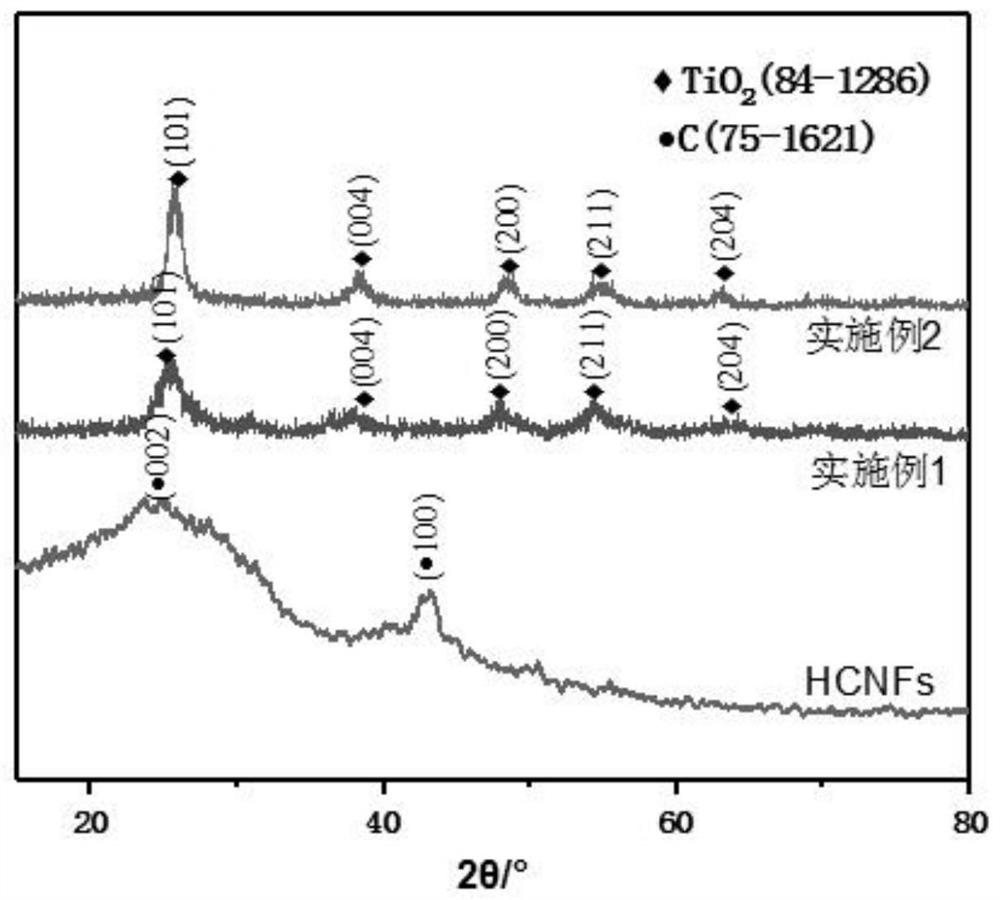

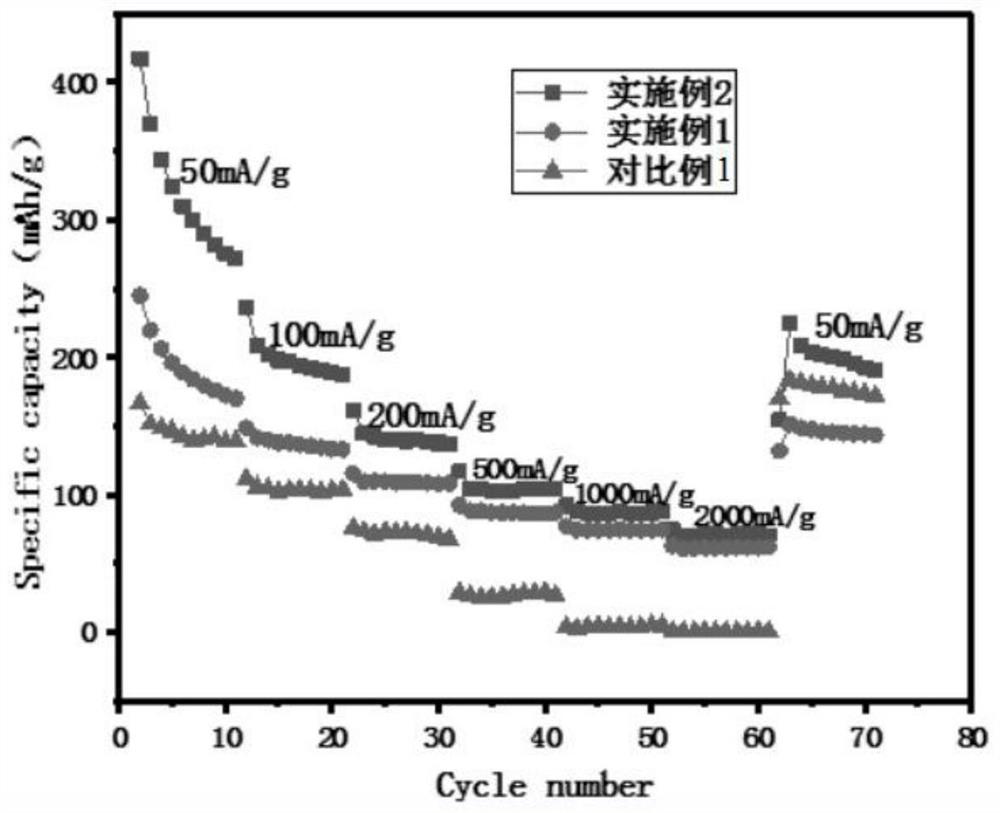

ActiveCN112310377AImprove electrochemical performanceShort tripMaterial nanotechnologyNegative electrodesNanoparticleCarbon nanofiber

The invention relates to the technical field of batteries, and particularly relates to a battery negative electrode material and a preparation method thereof. The preparation method comprises the following steps: carrying out heat treatment on spiral carbon nanofibers to obtain modified spiral carbon nanofibers; and by taking modified spiral carbon nanofibers as a matrix and butyl titanate as a titanium source, loading TiO2 nanoparticles on the surfaces of the modified spiral carbon nanofibers through a low-temperature solvothermal method to form the spiral carbon nanofiber loaded TiO2 composite battery negative electrode material. According to the invention, the spiral carbon nanofibers have a special spiral structure and a large specific surface area, and are mutually stacked to form a three-dimensional reticular support structure so that the dispersity of nano TiO2 can be improved, and meanwhile, a large amount of nano TiO2 can provide more two-dimensional diffusion channels for sodium ions. Through related tests, the prepared sodium battery has excellent specific capacity and cycling stability.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

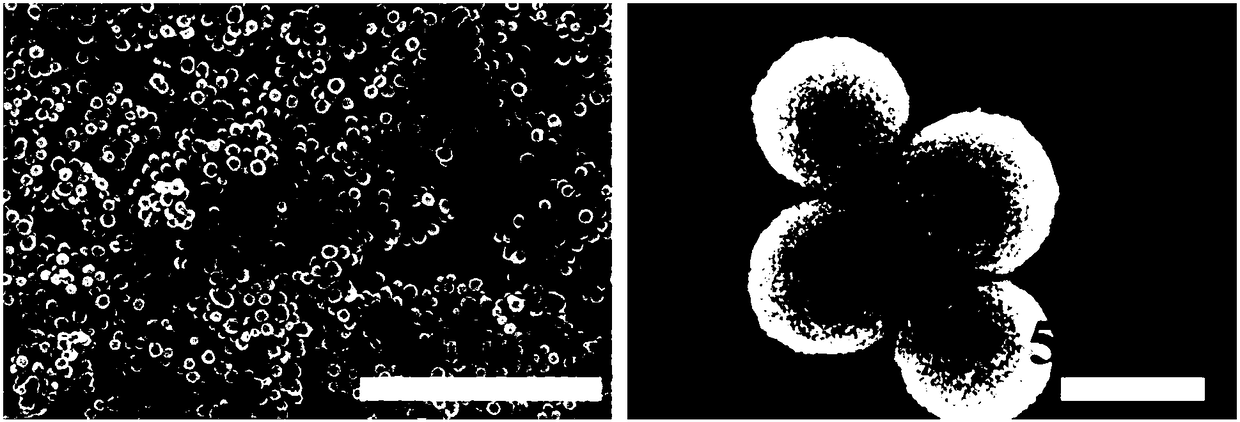

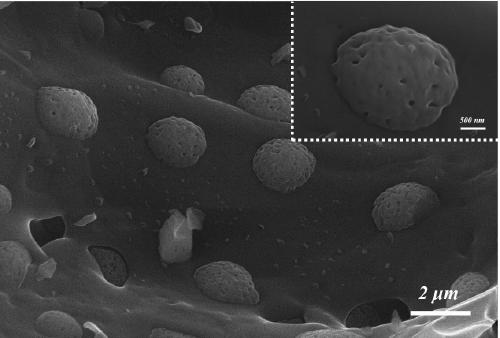

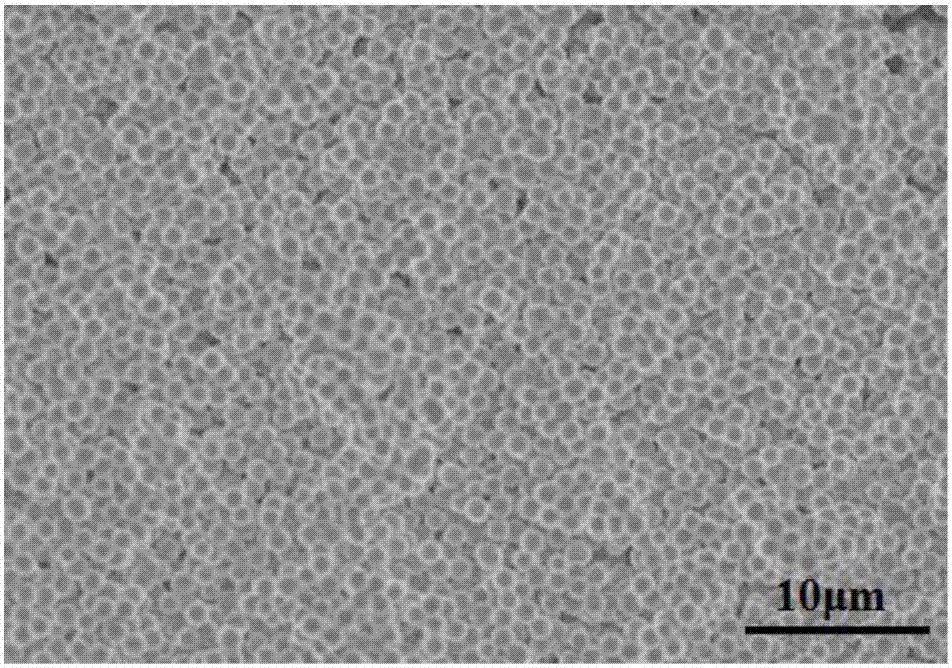

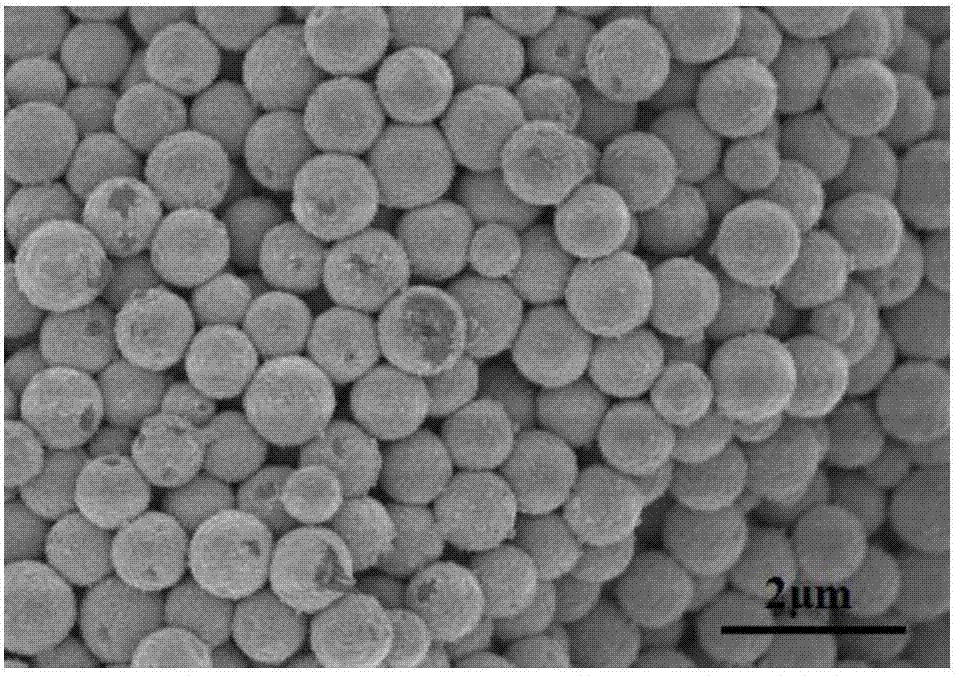

Hollow hybrid microsphere for negative electrode material of lithium ion battery and preparation method

ActiveCN109449399AAvoid damageIncrease contactCell electrodesSecondary cellsMicrosphereCarbonization

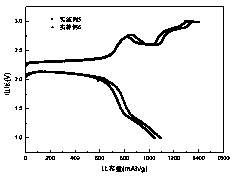

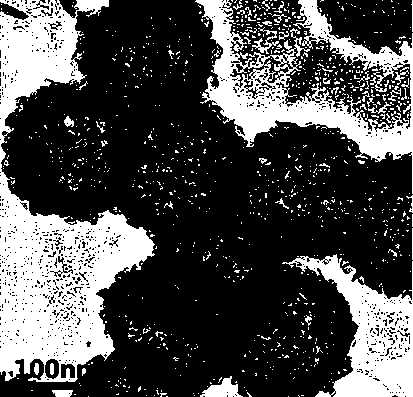

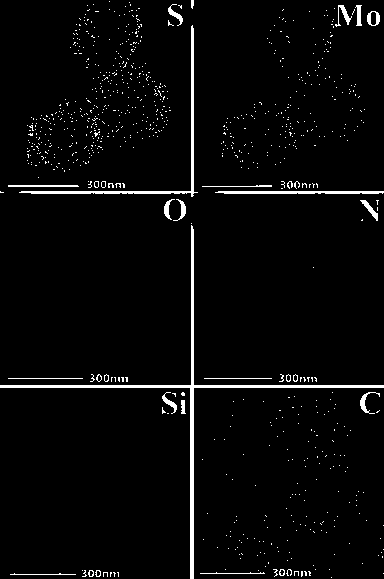

The invention belongs to the field of new materials, and particularly relates to a hollow hybrid microsphere for a negative electrode material of a lithium ion battery and a preparation method thereof. The hybrid microsphere takes monodisperse polystyrene microspheres as a template; and hydrolysis of tetrabutyl titanate on the surface of the microsphere, polymerization of dopamine on the surface of the microsphere, hydrothermal treatment in the presence of sodium molybdate dihydrate and a high-temperature carbonization process are carried out in sequence so as to prepare a TiO2 / C / MoS2 hollow hybrid microsphere. When the microsphere is used as a negative material of a lithium ion battery, high reversible capacity, excellent rate performance and excellent cycling stability are presented, anda wide application prospect is shown in the field of lithium ion batteries.

Owner:ZHENGZHOU UNIV

Silicon-carbon composite material in bubble coral form, manufacturing method and application thereof

InactiveCN110828809AReduce contentIncrease contentNegative electrodesSecondary cellsCarbon compositesPore distribution

The invention discloses a silicon-carbon composite material in a bubble coral form, a manufacturing method and an application thereof. The silicon-carbon composite material comprises porous silicon and a carbon shell. An outer layer of the carbon shell is consistent with a geometrical configuration of the porous silicon, and the porous silicon and the carbon shell have a common-angle characteristic. The carbon shell grows close to a surface of the porous silicon. The porous silicon is an inner core of the silicon-carbon composite material, and a hollow gap exists between the surface of the porous silicon and the carbon shell. The silicon-carbon composite material has an effect of relieving a volume effect. A content of carbon can be reduced to the maximum extent, and the content of siliconis improved so that a theoretical specific capacity, especially a volume specific capacity, of the material is improved. The porous silicon is more uniform in pore distribution and larger in pore proportion, silicon volume expansion is effectively relieved, and structural integrity of the silicon-carbon composite material can be maintained. During transmission, a Li<+> transmission channel can be formed through holes in the surface of silicon, and transmission can be enhanced through an N element.

Owner:XIAMEN UNIV

Method for preparing outer wall-fluorinated multi-walled carbon nanotube containing iron fluoride intercalated substance

ActiveCN107634224AGuaranteed electrical conductivityIncrease the output voltageCell electrodesLi-accumulatorsHydrogen fluorideCarbon nanotube

The invention belongs to the field of preparation of functional materials, and especially relates to a method for preparing an outer wall-fluorinated multi-walled carbon nanotube containing an iron fluoride intercalated substance. The problems of too low electric conductivity and volume expansion of multi-walled carbon nanotubes with the polarization in the charge and discharge process are solved.The end caps of a multi-walled carbon nanotube are opened, the multi-walled carbon nanotube is purified, iron fluoride is used to carry out intercalation in a heating reactor which can be vacuumized,hydrogen fluoride is sued to convert the iron chloride into iron fluoride, and fluorine gas is used to properly fluorinate the multi-walled carbon nanotube in order to finally form a compounded multi-walled carbon nanotube with the outer wall being fluorinated to a certain degree, the interlayer being iron fluoride and the inner layer having a certain electric conductivity. The method enables theabove material to provide a high output voltage and a theoretical specific capacity through the outer wall fluorination and the iron fluoride interlayer, and keeps the electric conductive of the inner wall of the material as possible, so the material is suitable for being used as a novel lithium battery positive electrode material.

Owner:LIAONING LANJING TECH CO LTD

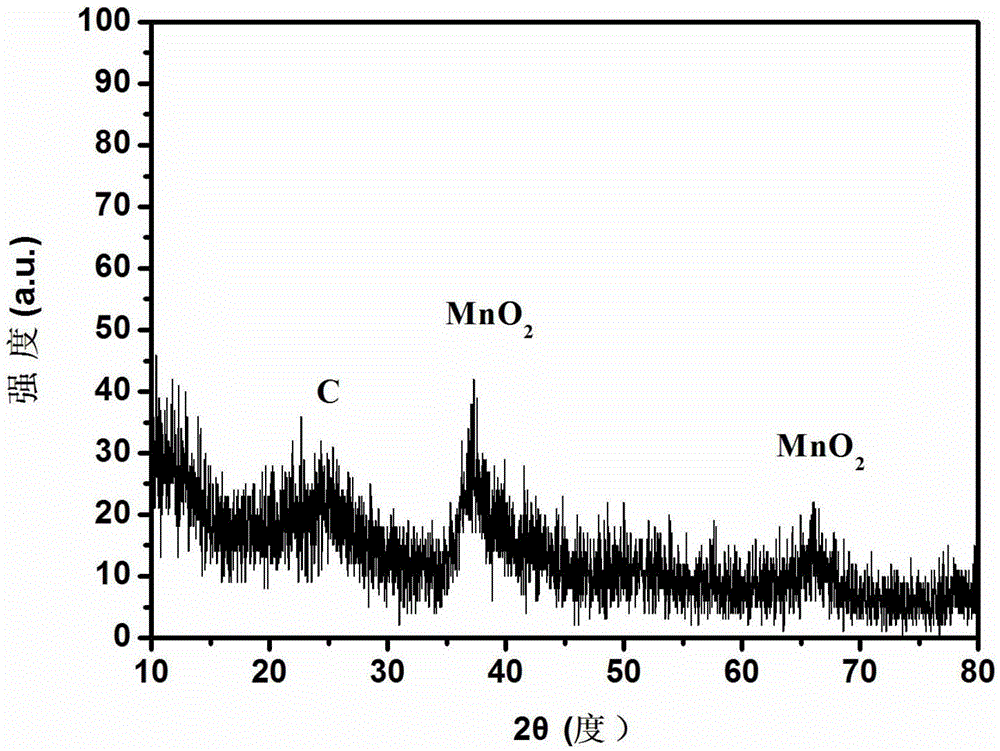

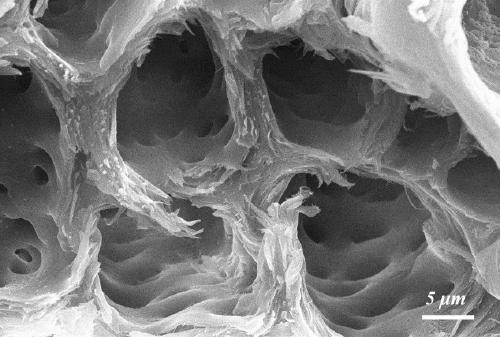

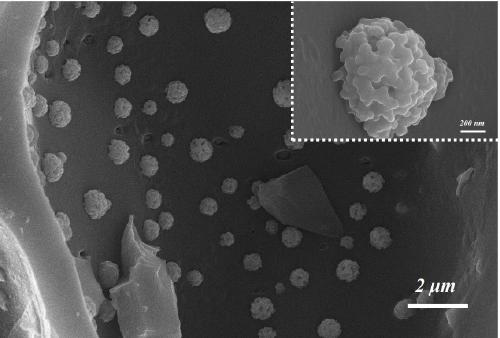

Bamboo-based porous carbon/manganese dioxide nano composite electrode material for super capacitor and preparation method thereof

InactiveCN111180214ARaw materials are easy to getWide variety of sourcesHybrid capacitor electrodesPorous carbonCarbonization

The invention relates to a bamboo-based porous carbon / manganese dioxide nano composite electrode material for a supercapacitor and a preparation method thereof. The preparation method comprises the following steps: selecting moso bamboos as raw materials, processing the moso bamboos into small blocks, carrying out drying treatment, carrying out high-temperature carbonization on the small bamboo blocks in an inert atmosphere, dipping the carbonized product in an alkali metal hydroxide solution, carrying out high-temperature activation in the inert atmosphere, washing the activated product to beneutral, and drying to obtain bamboo-based porous carbon; potassium permanganate and manganese sulfate are used as raw materials, generating manganese dioxide nanospheres through adoption of a low-temperature hydrothermal method, loading the manganese dioxide nanospheres on the surface of the bamboo-based porous carbon, and obtaining the bamboo-based porous carbon / manganese dioxide nano compositematerial for the supercapacitor. The bamboo-based porous carbon / manganese dioxide nano composite electrode material for the supercapacitor and a preparation method thereof are simple to operate, lowin equipment requirement and wide in raw material source, and the bamboo is a renewable and biocompatible green material and has excellent electrochemical performance when used as a supercapacitor electrode material.

Owner:BEIJING UNIV OF CHEM TECH +1

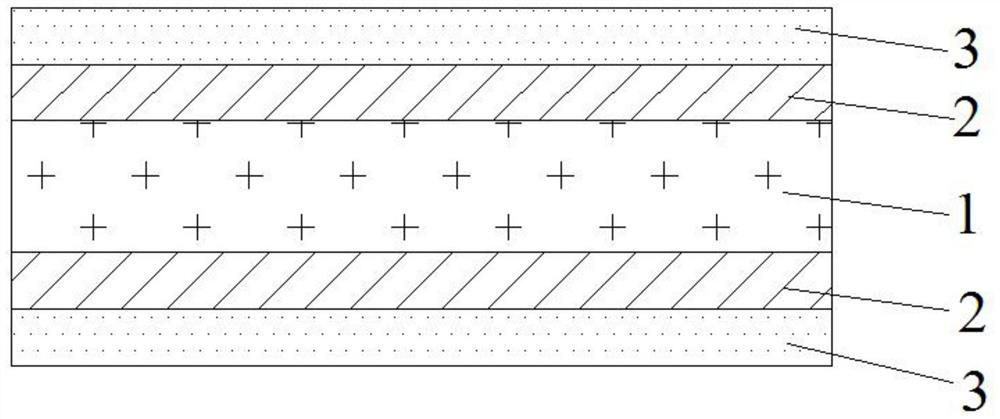

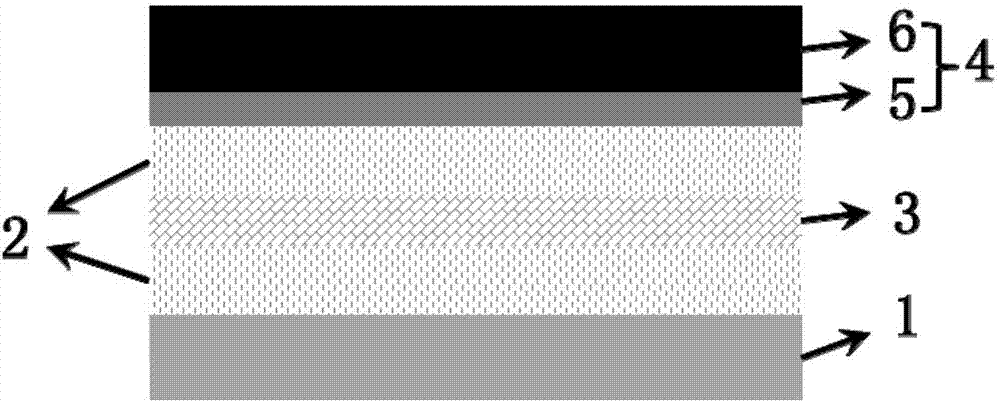

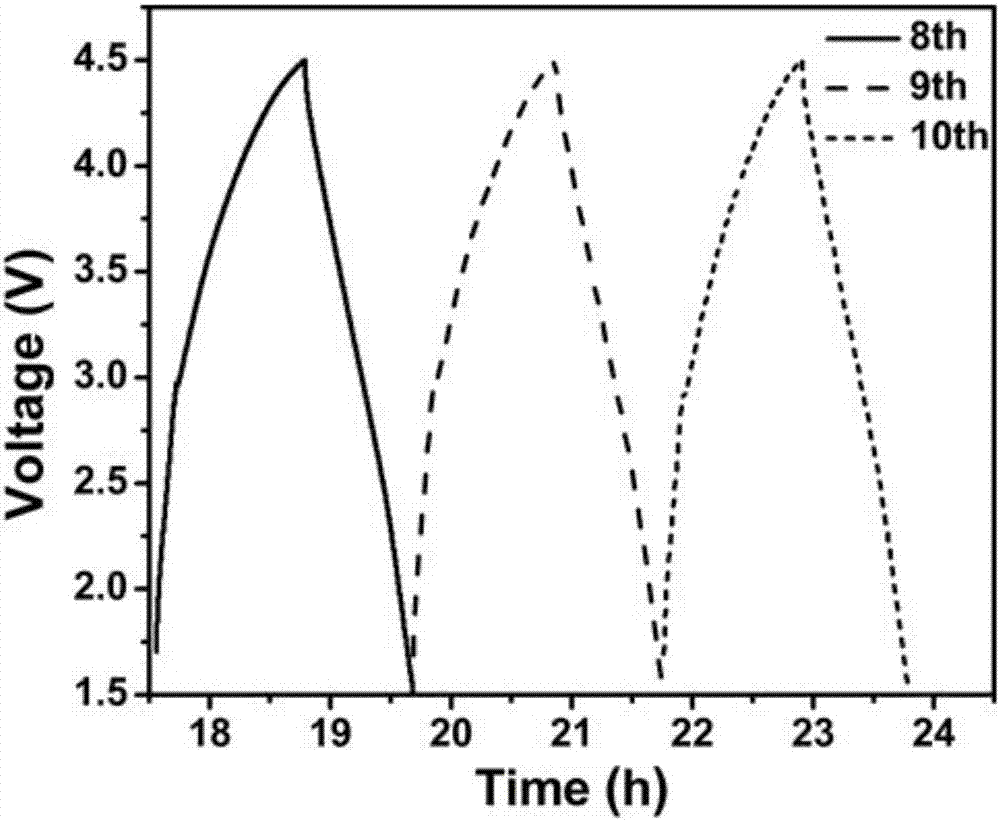

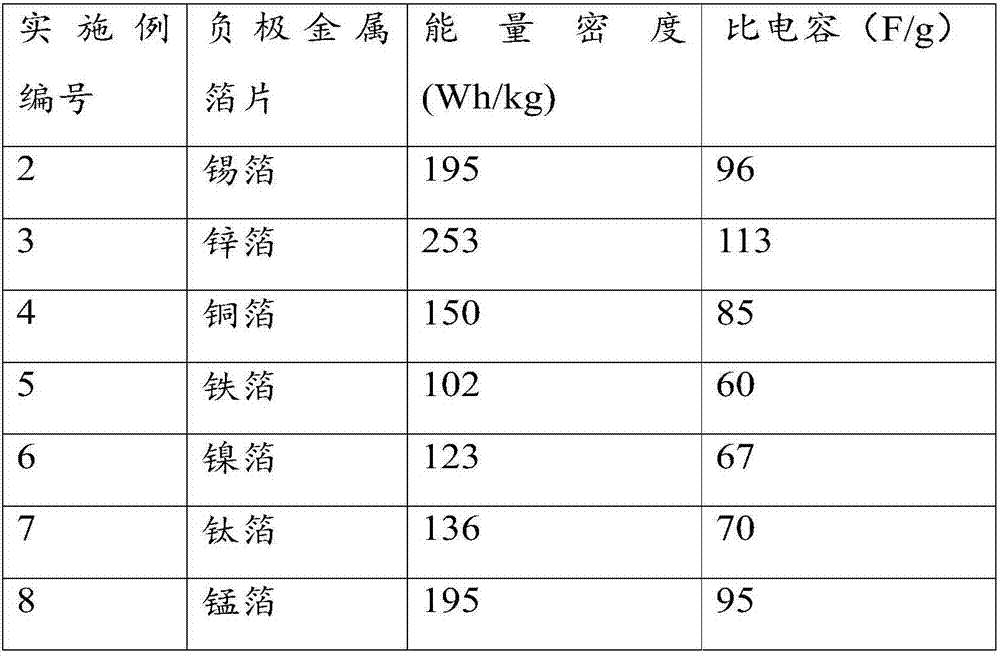

Lithium ion hybrid super capacitor and preparation method thereof

InactiveCN107230555ALight weightIncrease energy densityHybrid capacitor electrodesDouble layer capacitorsLithiumSupercapacitor

The invention relates to the field of the super capacitor, specifically, provides a lithium ion hybrid super capacitor and a preparation method thereof. The lithium ion hybrid super capacitor comprises a cathode, a diaphragm, an anode and electrolyte; the cathode is the metal, alloy or metal composite material capable of alloying with the lithium ion in the electrolyte; the anode comprises the anode material and the anode collector; the anode active material in the anode material is carbon material capable of reversibly adsorbing and desorbing the anion in the electrolyte; and the lithium ion is existent in the electrolyte of the hybrid super capacitor. The lithium ion hybrid super capacitor disclosed by the invention takes the metal, alloy or metal composite material capable of alloying with the lithium ion in the electrolyte as the cathode, the above mentioned material plays the dual function of the cathode active material and the cathode collector; the production process of the capacitor is simplified, the production cost is lowered, and the energy density and the theoretical specific capacity of the capacitor are further improved.

Owner:REAL POWER IND LTD +1

High-capacity all-solid-state lithium-sulfur battery

InactiveCN109449383AHigh theoretical specific capacityImprove conductivityCell electrodesSecondary cellsSolid state electrolyteIndium

The invention discloses a high-capacity all-solid-state lithium-sulfur battery. The high-capacity all-solid-state lithium-sulfur battery comprises a positive electrode, a negative electrode and a solid-state electrolyte, wherein the solid-state electrolyte is arranged between the positive electrode and the negative electrode, a positive electrode material is powder obtained by mixing a positive active substance, a conductive agent and the solid-state electrolyte according to a certain mass ratio and then ball-milling, the positive active substance is a solid solution formed by ball-milling a lithium sulfide and a lithium halide according to a certain mole ratio, the negative is metal lithium or lithium magnesium alloy, lithium aluminum alloy and lithium indium alloy, and the solid-state electrolyte is a solid solution of different constituents of Li2S-P2S5, Li2S-P2S5-GeS2, Li2S-P2S5-P2S3 and Li2S-P2S5-P205 and Li2S-P2S5-LiX, and X is one or more of F, Cl, Br and I. The all-solid-statelithium-sulfur battery has the advantages of high voltage, large capacity, safety and environmental friendliness.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Hollow sandwiched SiO2/C/MoS2 hybridized microsphere for lithium ion battery anode material

ActiveCN109830670AHigh specific capacityIncrease energy densityCell electrodesSecondary cellsMicrosphereCarbonization

The invention belongs to the field of lithium ion battery anode materials and particularly relates to hollow sandwiched SiO2 / C / MoS2 hybridized microsphere for a lithium ion battery anode material. Thehollow sandwiched SiO2 / C / MoS2 hybridized microsphere is prepared by using a monodispersed polystyrene microsphere as a template, and performing hydrolysis of tetraethyl orthosilicate on the surface of the microsphere, polymerization of dopamine on the surface of the microsphere, hydrothermal treatment in the presence of sodium molybdate dihydrate, and high temperature carbonization. When used asa lithium ion battery anode material, the microsphere exhibits a large reversible capacity, excellent rate performance and excellent cycle stability, and has broad application prospect in the field oflithium ion batteries.

Owner:ZHENGZHOU UNIV

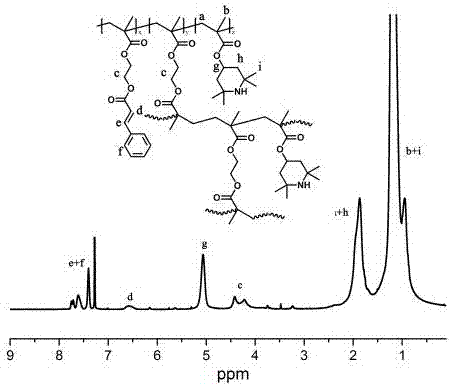

Photo-crosslinking stabilized hyperbranched free radical polymer and preparation method and application thereof

ActiveCN107880161AHigh theoretical specific capacityImprove sustainabilityCell electrodesMethacrylatePolymer science

The invention discloses a photo-crosslinking stabilized hyperbranched free radical polymer and a preparation method and application thereof. 2,2,6,6-tetramethyl-4-piperidyl methacrylate, a photo-crosslinked monomer and a branched monomer are subjected to free radical polymerization and then an oxidation reaction, and the hyperbranched free radical polymer is obtained. The polymer has a structure unit which can be ultraviolet photo crosslinked, after the structure is compounded with carbon materials, stabilization of in situ photo crosslinking can be achieved, the situation that the polymer isdissolved out in electrolyte, the service life is thus shortened and repeated charging is not allowed, the cycling stability of a battery is improved, no additional crosslinking agent or binder needsto be added, the adverse effects of adding materials on an electrode are avoided, moreover, the polymer has the hyperbranched structure which can be crosslinked, the dispersing performance is good, meanwhile the molecular weight and the glass transition temperature are significantly improved, the mechanical properties are good, and the application prospect is wide.

Owner:广州新驰化工科技有限公司

Preparation method and application of NaNixMnyM1-x-yO2 material

InactiveCN112279309AHigh theoretical specific capacityEasy to operateFinal product manufacturePositive electrodesElectrical batteryPhysical chemistry

The invention discloses a preparation method and application of a NaNixMnyM1-x-yO2 material. The preparation method comprises the following steps: (1) mixing and dissolving a sodium source, a nickel source, a manganese source and an M source according to the stoichiometric ratio of each element in the NaNixMnyM1-x-yO2 material to obtain a mixed material, wherein M is any one of Cu, Co, Zn, Mg, Crand Zr, 0 < = x < = 1, 0 < = y < = 1, and 0 < = 1xy < = 1; (2) adding an organic additive into the mixed material, and then carrying out ball milling to obtain a precursor material; and (3) drying theprecursor material, and then calcining the precursor material to obtain the NaNixMnyM1-x-yO2 material. The sodium ion battery positive electrode material (NaNixMnyM1-x-yO2 ) prepared by the method has the advantages of high theoretical specific capacity, simplicity in operation and easiness in industrialization; the prepared NaNixMnyM1-x-yO2 material is used as a positive electrode material of asodium ion battery to assemble the sodium ion battery, the assembled sodium ion battery has relatively high specific capacity, excellent cycling stability and rate capability and high capacity retention ratio, a new method is provided for large-scale application of the sodium ion battery in the future, and the NaNixMnyM1-x-yO2 material has a wide application prospect.

Owner:JIANGSU UNIV OF TECH

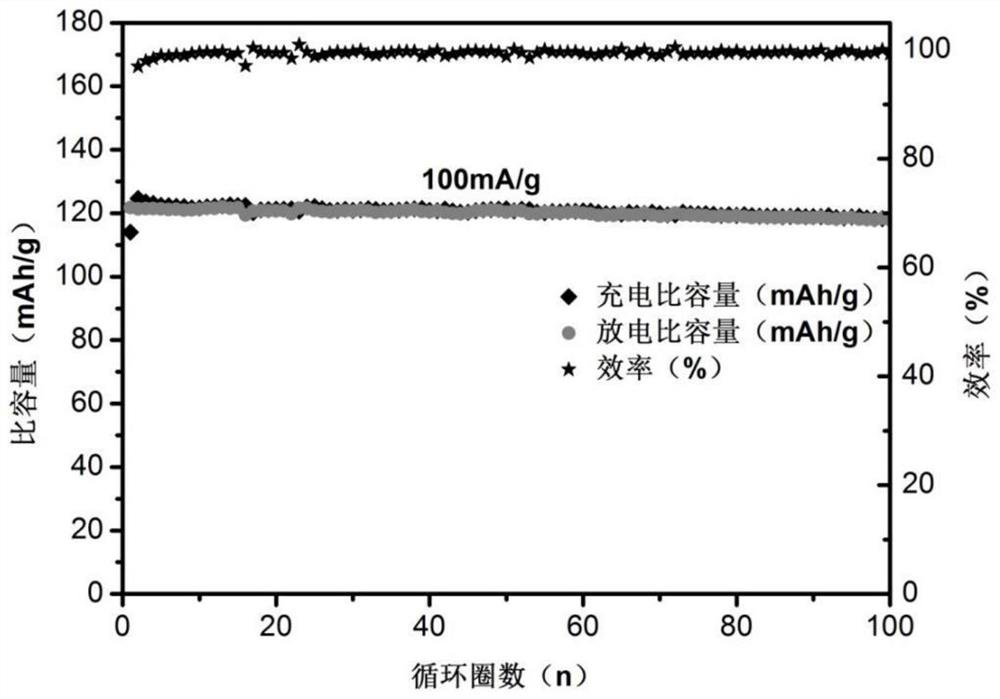

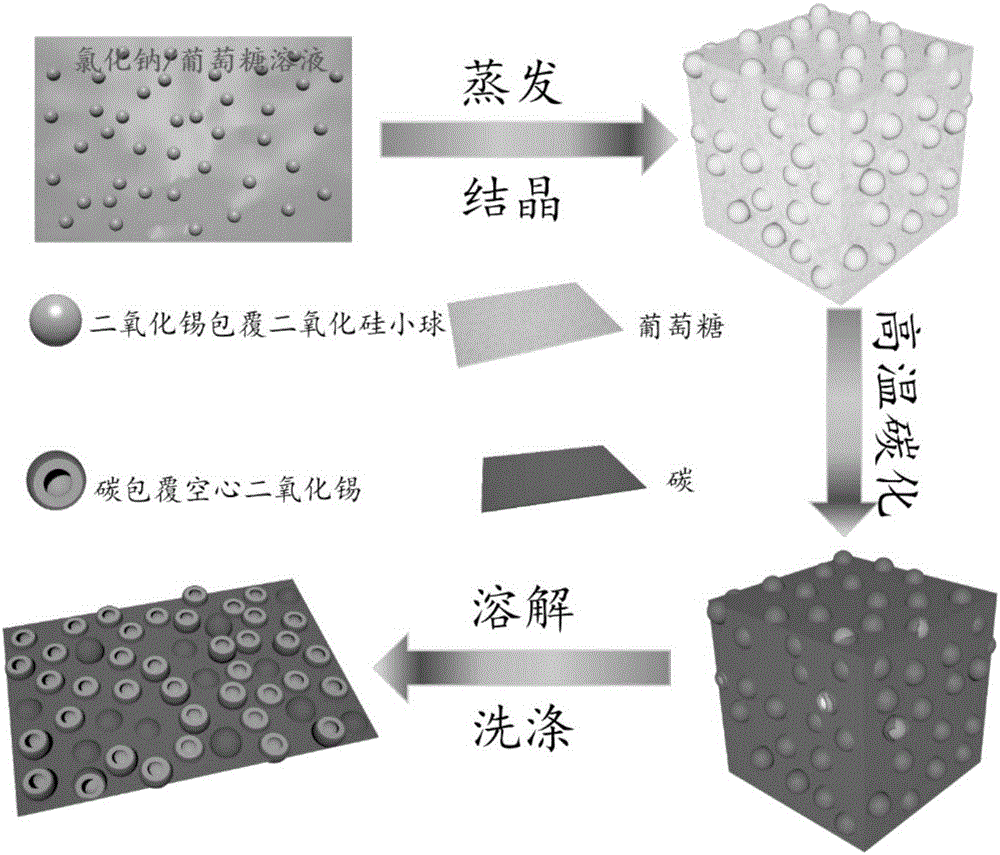

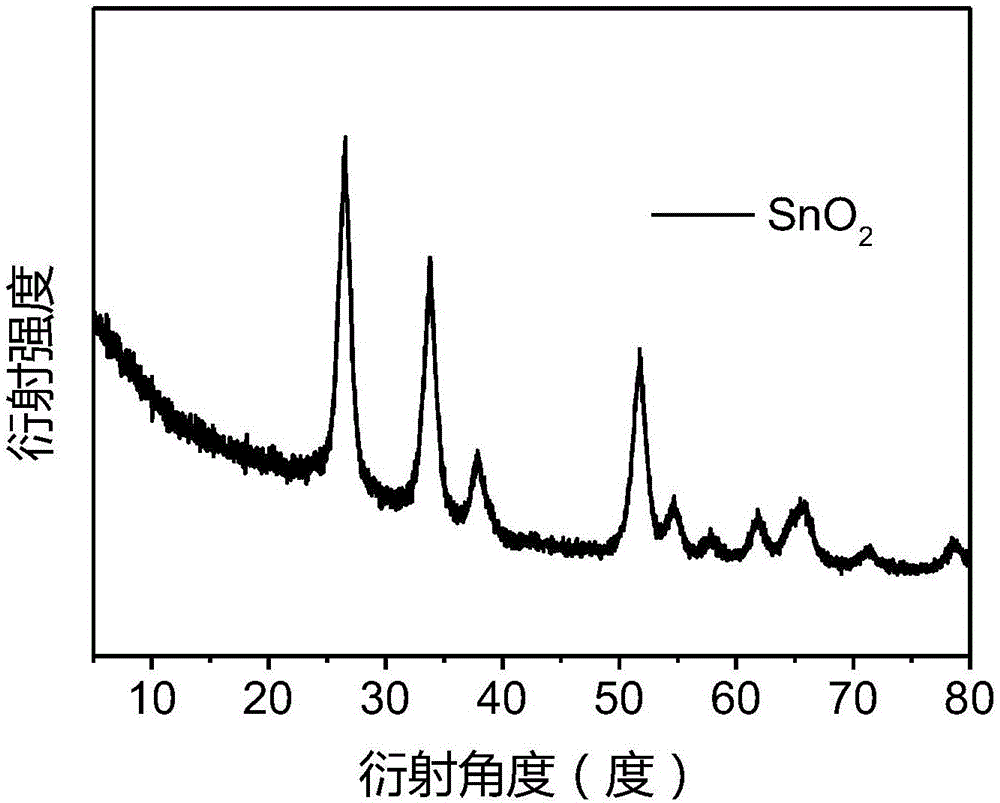

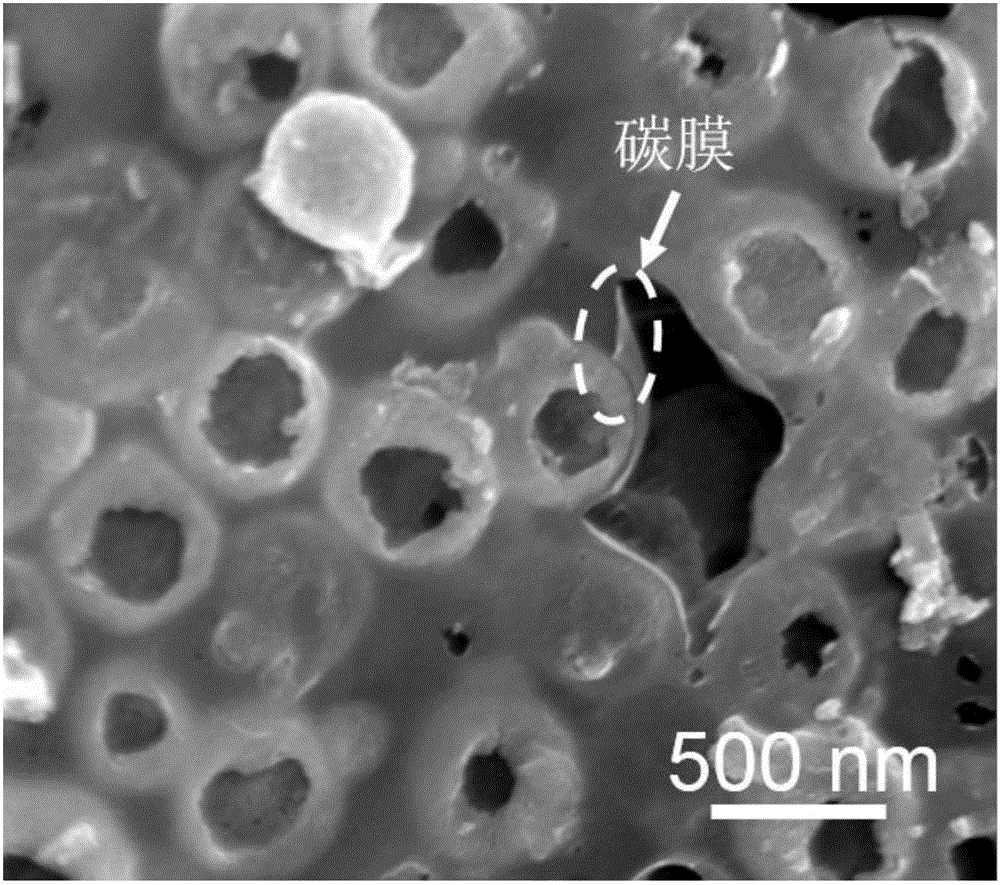

Honeycomb stannic oxide material and preparation method thereof

InactiveCN106830058AHigh theoretical specific capacityImprove conductivityCell electrodesSecondary cellsCarbon filmCarbon composites

The invention provides a preparation method of a honeycomb stannic oxide material, belongs to the technical field of preparation of lithium (sodium) ion battery electrode materials, and mainly aims to solve the problems of poor cycle stability and low specific capacity of conventional electrode materials. The method comprises the following steps: one, mixing a certain proportion of tetraethoxysilane, ethanol, water and ammonia water, stirring at room temperature to obtain silica beads; two, growing a layer of stannic oxide on the silica beads prepared in the step one by a hydrothermal method; and three, with sodium chloride as a template and glucose as a carbon source, carbonizing at high temperature to obtain a carbon film coating the nano beads, and etching silica by using sodium hydroxide, to obtain the honeycomb stannic oxide / carbon composite material. The stannic oxide / carbon composite material prepared by the template method shows excellent electrochemical performance such as high specific capacity and good cycle stability in lithium (sodium) ion batteries.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of graphene/metal carbide porous micro-sphere electrode

ActiveCN106374107AEfficient compositeHigh theoretical specific capacityCell electrodesSecondary cellsLithiumCarbide

The invention discloses a preparation method of a graphene / metal carbide porous micro-sphere electrode, and relates to a preparation method of a hierarchically structured three-dimensional composite material. The invention aims to solve the problems of battery performance degradation and cycling stability influence caused by volume expansion of an existing anode material. The method comprises the following steps: firstly, preparation of oxidized graphene; secondly, preparation of a mixed solution; thirdly, drying; fourthly, annealing treatment to obtain the graphene / metal carbide porous micro-sphere electrode. The graphene / metal carbide porous micro-sphere electrode prepared in the invention as a lithium ion battery anode material has good electrochemical lithium storage performance, the capacity of a battery prepared by using the graphene / metal carbide porous micro-sphere electrode as the battery anode material under the current density of 0.1 A / g is greater than 500 mAh / g, the capacity of the battery under the current density of 3 A / g is greater than 300 mAh / g, and the capacity is hardly attenuated after 500 times of circulation. The preparation method is suitable for preparing the graphene / metal carbide porous micro-sphere electrode.

Owner:内蒙古元瓷新材料科技有限公司

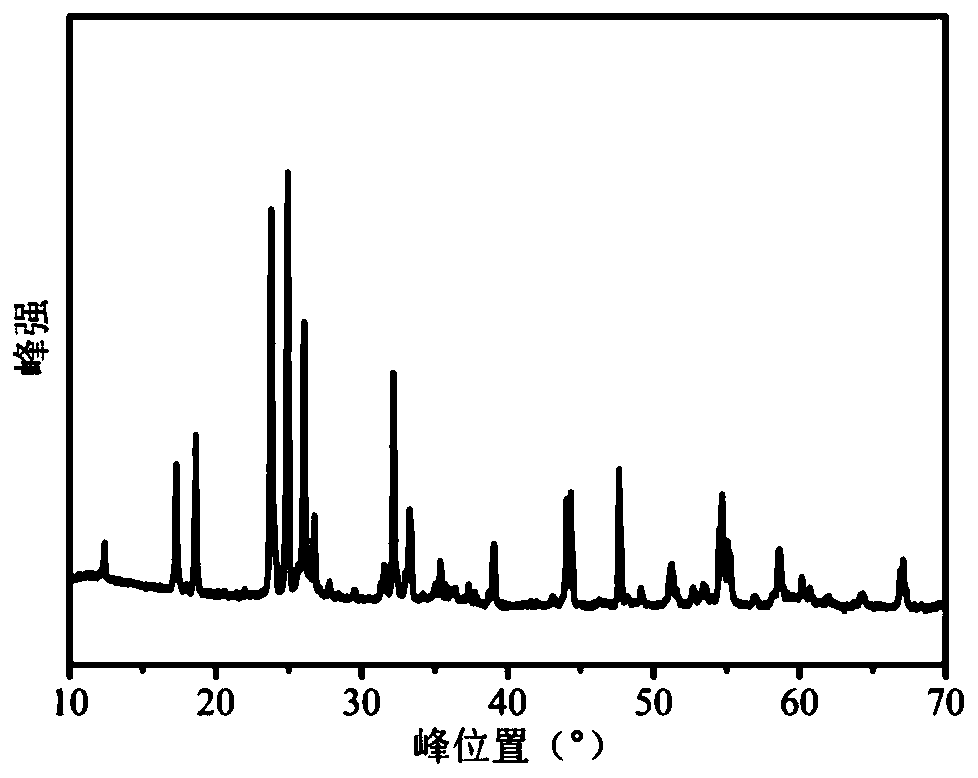

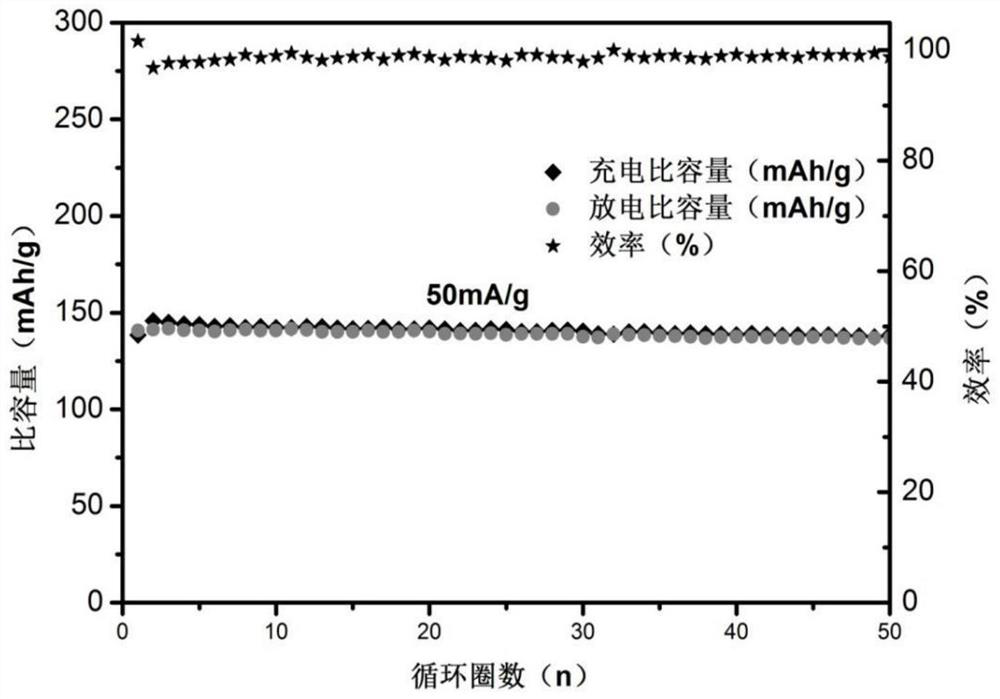

Preparation method of hollow TiNb2O7 microsphere

ActiveCN107482178AWide variety of sourcesShort preparation cycleNegative electrodesSecondary cellsMicrosphereNiobium

Belonging to the technical field of nanomaterial synthesis, the invention specifically relates to a preparation method of a hollow TiNb2O7 microsphere. The method includes: firstly selecting glucose as the carbon source, using deionized water as the solvent, synthesizing uniformly dispersed carbon spheres homogeneous in size by solvothermal method, then taking titanium isopropylate as the titanium source, adopting niobium pentachloride as the niobium source, using ethanol as the solvent, and performing mixing to obtain a uniformly dispersed suspension, and finally using solvothermal method to prepare the hollow TiNb2O7 microsphere with larger specific surface area successfully. Because of high theoretical specific capacity (388 mA h g<-1>), high discharge voltage platform (1.65V) and large specific surface area, the material is expected to become a novel lithium ion battery anode material. In addition, the method has the advantages of simple preparation process, wide raw material sources and low production cost, thus having very broad market application prospects.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com