Lithium ion battery cathode material and non-aqueous electrolyte batterie

A lithium-ion battery, non-aqueous electrolyte technology, applied in non-aqueous electrolyte batteries, non-aqueous electrolyte battery electrodes, electrolyte battery manufacturing and other directions, can solve the problems of limited application, low theoretical capacity, etc., to achieve low charge-discharge expansion rate, theoretical The effect of high specific capacity and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

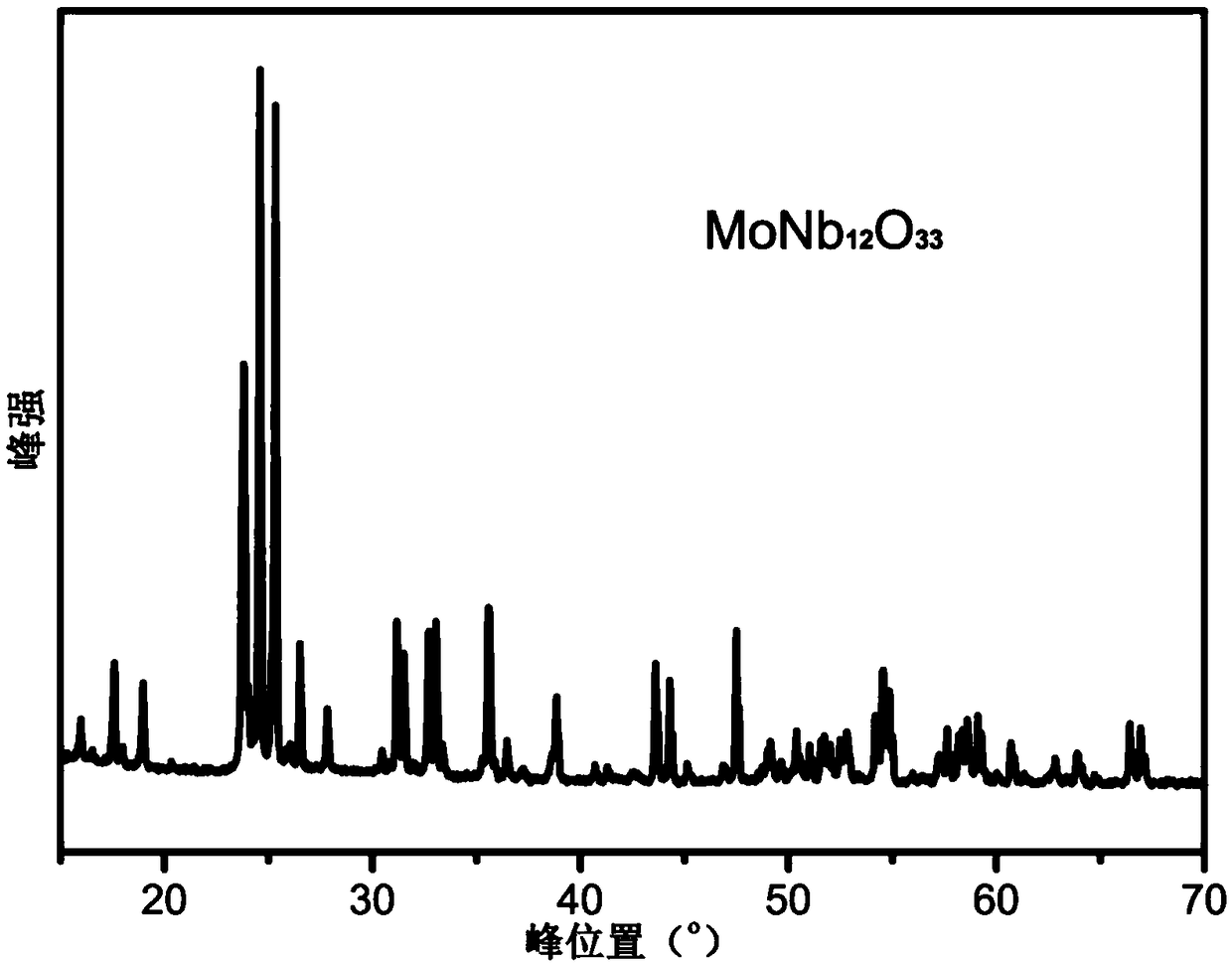

[0083] This embodiment provides a method for preparing MoNb by solid phase method 12 o 33 The method for electrode material, it comprises the following steps:

[0084] MoNb can be obtained by mixing molybdenum trioxide and niobium pentoxide according to the molar ratio of 1:12 by high-energy ball mill and sintering at 900°C for 12 hours. 12 o 33 powder, such as image 3 As shown, the MoNb prepared in this example 12 o 33 The material is a pure phase material with sheared ReO 3 structure.

Embodiment 2

[0086] This embodiment provides a method for preparing W by solid-phase method 4 Nb 26 o 77 The method for electrode material, it comprises the following steps:

[0087] After mixing tungsten trioxide and niobium pentoxide according to the molar ratio of 4:26 by high-energy ball mill, sintering at 1100°C for 5 hours, you can get W 4 Nb 26 o 77 powder, such as Figure 4 As shown, the W prepared in this example 4 Nb 26 o 77 The material is a pure phase material with sheared ReO 3 structure.

Embodiment 3

[0089] This embodiment provides a method for preparing WNb by solid phase method 12 o 33 The method for electrode material, it comprises the following steps:

[0090] WNb can be obtained by mixing tungsten trioxide and niobium pentoxide according to the molar ratio of 1:12 by high-energy ball mill and sintering at 800°C for 12 hours. 12 o 33 powder, such as Figure 5 As shown, the WNb prepared in this example 12 o 33 The material is a pure phase material with sheared ReO 3 structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com