Preparation method and application of NaNixMnyM1-x-yO2 material

A nanixmnym1-x-yo2, mixed material technology, applied in chemical instruments and methods, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as poor cycle stability, achieve high capacity retention, simple operation, easy The effect of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]A kind of NaNi0.5Mn0.4Co0.1O2The preparation method of the material includes the following steps:

[0034](1) Press NaNi0.5Mn0.4Co0.1O2The stoichiometric ratio of each element in the stoichiometric ratio, weigh 1.05g sodium carbonate, 2.48g nickel acetate tetrahydrate, 1.96g manganese acetate tetrahydrate, 0.49g cobalt acetate with a balance, and mix them evenly, then add 10.0mL absolute ethanol and 10.0mL Dissolve in deionized water to obtain a mixture;

[0035](2) Pour the mixture into a ball milling tank, then add 0.1g glucose and 0.1g polyethylene glycol, and then ball mill on a planetary ball mill at 200rpm for 2 hours; obtain precursor materials;

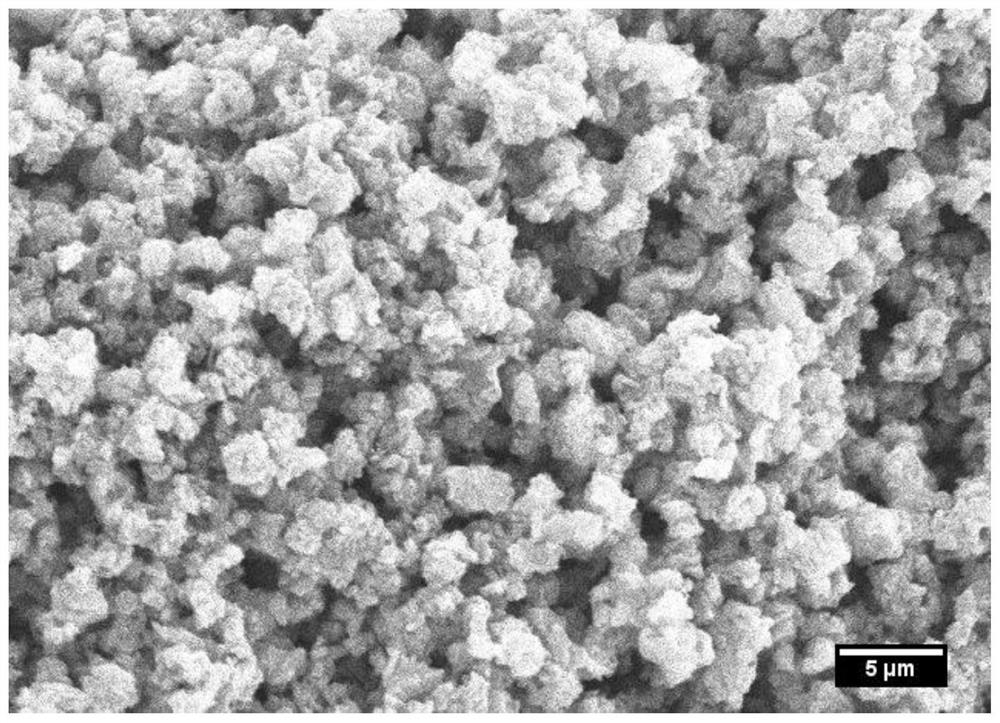

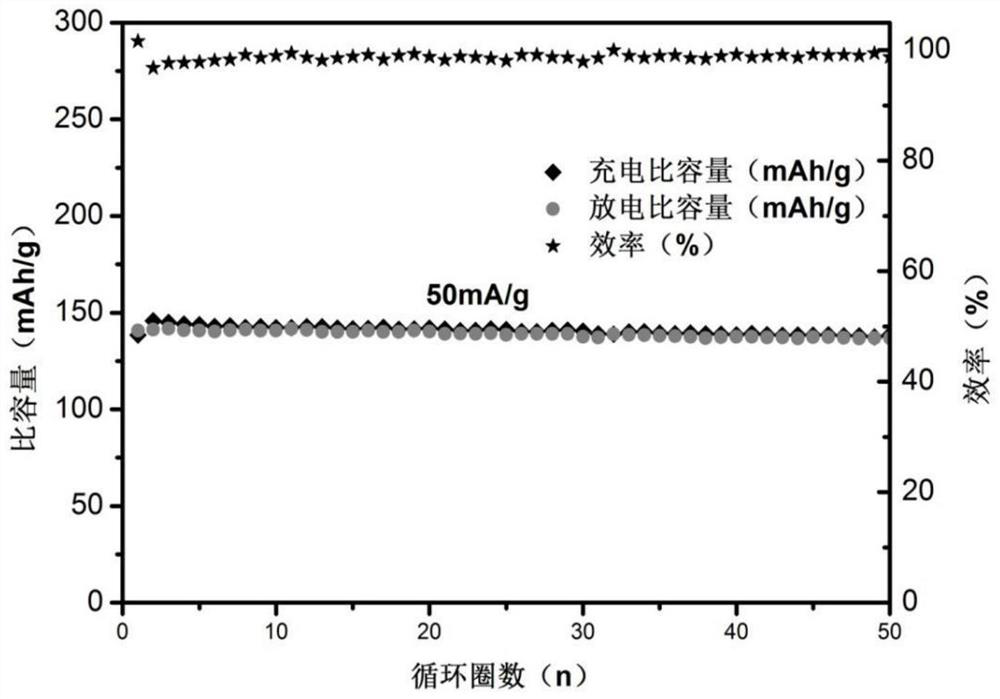

[0036](3) Dry the obtained precursor material with a spray dryer (control the injection rate of the spray dryer to 10mL / min, the inlet temperature of the spray dryer is 120 ℃, the outlet temperature is 80 ℃), after spray drying in Malaysia Calcined in a furnace at 600℃ for 10 hours, NaNi will be obtained after the calcination is comple...

Embodiment 2

[0038]A kind of NaNi0.4Mn0.55Co0.05O2The preparation method of the material includes the following steps:

[0039](1) Press NaNi0.4Mn0.55Co0.05O2For the stoichiometric ratio of each element in the balance, weigh out 1.72g sodium acetate, 1.99g nickel acetate tetrahydrate, 1.96g manganese nitrate, 0.29g cobalt nitrate, and mix them evenly, then add 5.0mL absolute ethanol and 15.0mL deionized Dissolve in water to obtain a mixture;

[0040](2) Pour the mixture into a ball mill tank, then add 0.2g polyvinyl alcohol and 0.2g polyvinylpyrrolidone, and then ball mill on a planetary ball mill at 300rpm for 10 hours; obtain precursor materials;

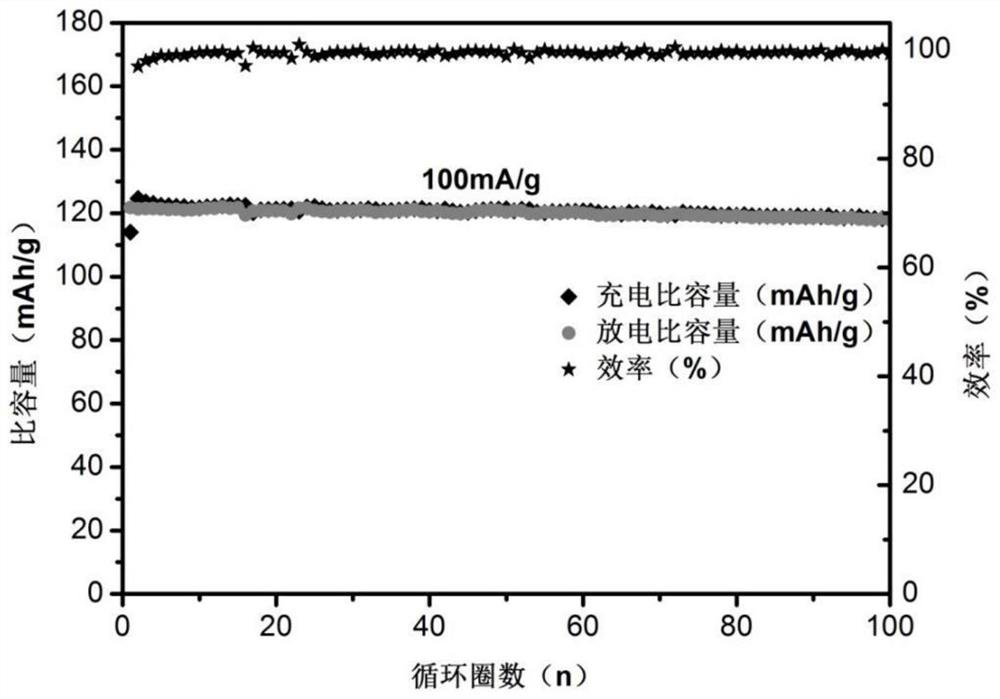

[0041](3) Dry the obtained precursor material with a spray dryer (control the injection rate of the spray dryer to 35 mL / min, the inlet temperature of the spray dryer is 140 ℃, the outlet temperature is 85 ℃), after spray drying in Malaysia Calcined in a Furnace at 700℃ for 24 hours, NaNi is obtained after the calcination is completed0.4Mn0.55Co0.05O2materia...

Embodiment 3

[0043]A kind of NaNi0.4Mn0.4Cu0.1Mg0.1O2The preparation method of the material includes the following steps:

[0044](1) Press NaNi0.4Mn0.4Cu0.1Mg0.1O2The stoichiometric ratio of each element in the stoichiometric ratio, weigh 1.70g sodium nitrate, 2.10g nickel sulfate, 0.56g manganese trioxide, 0.32g copper sulfate, 0.30g magnesium nitrate with a balance, and mix them evenly, then add 5.0mL absolute ethanol Dissolve in 15.0mL deionized water to obtain a mixture;

[0045](2) Pour the mixture into a ball mill tank, then add 0.2g sucrose and 0.2g polyethylene glycol, and then ball mill it on a planetary ball mill at 300 rpm for 3 hours; obtain precursor materials;

[0046](3) Dry the obtained precursor material with a spray dryer (control the injection rate of the spray dryer to be 50mL / min, the inlet temperature of the spray dryer is 160℃, and the outlet temperature is 85℃). Calcined in a Furnace at 800℃ for 14 hours, NaNi will be obtained after the calcination is completed0.4Mn0.4Cu0.1Mg0.1O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com