Nanometer silicon/graphene lithium ion battery cathode material and preparation method thereof

A lithium-ion battery and negative electrode material technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of inability to give full play to graphene performance, uneven mixing of mechanical scales, and unsuitability for industrial development. The effect of improved cycle performance and stable cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

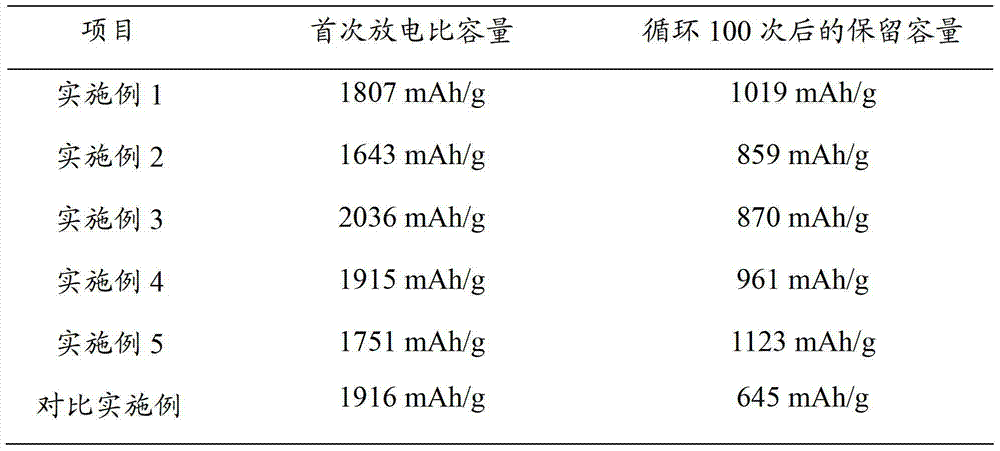

Examples

Embodiment 1

[0038] Under the protection of argon, 1% by mass of lithium metal and 1% of biphenyl were dissolved in 1 kg of ethylene glycol dimethyl ether, and magnetically stirred to dissolve. After dissolution, the solution was dark green. Then, silicon tetrachloride with a mass ratio of 5% was added dropwise to the solution, and the dropwise addition was completed within 1 hour. At the same time, magnetic stirring was added to maintain 100 rpm, and the stirring was stopped after 1 hour.

[0039] Using water as a dispersant, configure a 0.5 g / L graphene suspension, add 60% nitric acid with a volume ratio of 1:2, and then ultrasonically treat it for 0.5 h. After the treatment, the obtained solution was repeatedly centrifuged and washed until pH=7. After vacuum drying, ultrasonic treatment was performed for 0.5 h again to dissolve it in cyclohexanol to form a 0.1 g / L graphene oxide gel-like solution.

[0040] Stir the nano-silicon suspension at a speed of 200 rpm, and during the stirring ...

Embodiment 2

[0042] Under the protection of argon, 3% by mass of lithium metal and 5% of 4,4'-dimethoxybiphenyl were dissolved in 1kg of tripropylamine, and magnetically stirred to dissolve. After dissolution, the solution was close to dark blue. Then, silicon tetrachloride with a mass ratio of 20% was added dropwise to the solution, and the dropwise addition was completed within 3 hours. At the same time, magnetic stirring was added to maintain 150 rpm, and the stirring was stopped after 1 hour.

[0043] Using water as a dispersant, configure a 0.5g / L graphite oxide aqueous solution, add 60% nitric acid with a volume ratio of 1:5, and use ultrasonic treatment for 0.5h. After the treatment, the obtained solution was repeatedly centrifuged and washed until pH=7. After vacuum drying, ultrasonic treatment was performed for 3 h again, and it was dissolved in ethanol to form a 5 g / L graphene oxide colloidal solution.

[0044] Stir the nano-silicon suspension at a speed of 150 rpm, and during t...

Embodiment 3

[0046] Under the protection of argon, dissolve 5% lithium metal and 5% anthracene in 1 kg of morpholine by mass percentage, stir and dissolve with a magnetic force, and the dissolved solution is close to metallic black. Then, silicon tetrachloride with a mass ratio of 20% was added dropwise to the solution, and the dropwise addition was completed within 3 hours. At the same time, magnetic stirring was added to maintain 150 rpm, and the stirring was stopped after 1 hour.

[0047] Using water as a dispersant, configure a 0.5 g / L graphene suspension, add 60% nitric acid with a volume ratio of 1:10, and then use 60 Hz ultrasonic treatment for 0.5 h. After the treatment, the obtained solution was repeatedly centrifuged and washed until pH=7. After vacuum drying, ultrasonic treatment was performed for 3 h again to dissolve it in ethylene glycol and configure a 1 g / L graphene oxide colloidal solution.

[0048] Stir the nano-silicon suspension at a speed of 200 rpm, and during the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com