Porous silicon material, and preparation method and application thereof

A technology of porous silicon and anode materials, applied in the field of material science, can solve the problems of low intrinsic conductivity of silicon, low first Coulomb efficiency, limited practical application, etc., to achieve good battery cycle stability, easy process control, suitable for large-scale The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Preparation method of porous silicon negative electrode active material

[0054] The preparation method of the porous silicon negative electrode active material includes: ultrasonic chemical method, wet chemical method, mechanochemical reaction (such as mechanical alloying method and mechanical ball milling method) and the like.

[0055] In a preferred embodiment, a method for preparing a porous silicon negative electrode active material includes: using a metallurgical iron-silicon alloy as a raw material, preparing the target product through mechanical ball milling and acid etching.

[0056] In a more specific embodiment, the preparation method may include the following steps:

[0057] (i) metallurgical iron-silicon materials that provide silicon sources;

[0058] (ii) ball milling the iron-silicon alloy;

[0059] (iii) performing metal-assisted acid etching of the iron-silicon alloy in an acid etching reagent to prepare a porous silicon material.

[0060] In a prefer...

Embodiment 1

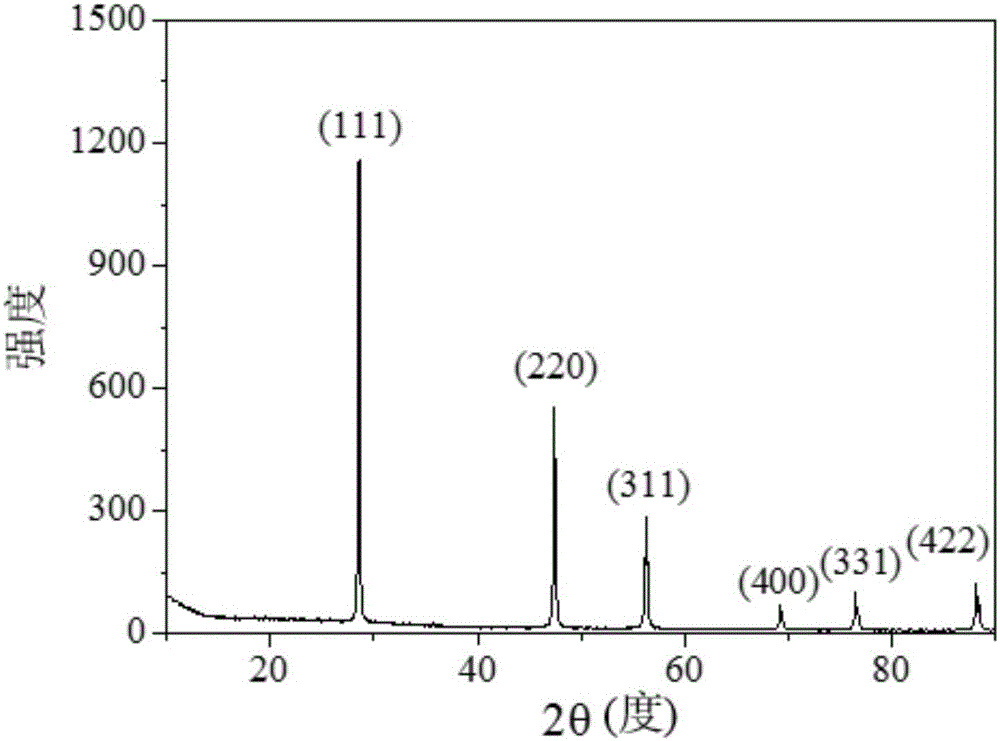

[0142] Preparation of Example 1 Porous Silicon Negative Active Material (i.e. "porous silicon material"):

[0143] 1) Weigh 2g of metallurgical iron-silicon alloy, 2g of absolute ethanol and 16g of agate balls, and add them to a 100ml agate ball mill jar respectively.

[0144] 2) Put the ball mill jar into the ball mill, set the ball mill parameters, the speed is 300r / min, the working time is 24 hours, and every 20 minutes of work is 10 minutes of rest.

[0145] 3) Suction filtration, washing and drying of the ball-milled small particles of iron-silicon alloy.

[0146] 4) Measure 100ml of 2M hydrochloric acid solution into a 200ml beaker, slowly add small grains of iron-silicon alloy, and keep stirring until the addition is complete. Put the beaker into an ultrasonic instrument for ultrasonic dispersion for 30min. Remove the beaker and place it on a magnetic stirrer for 24 h of continuous stirring. Suction filtration and drying.

[0147] 5) Add the sample treated with hydr...

Embodiment 2

[0158] Preparation of Example 2 Porous Silicon Negative Active Material:

[0159] 1) Weigh 2g of metallurgical iron-silicon alloy, 1g of absolute ethanol and 8g of agate balls in an argon atmosphere, and add them to a 100ml agate ball mill jar.

[0160] 2) Put the ball mill pot into the ball mill, set the ball mill parameters, the speed is 400r / min, the working time is 12h, and every 10min of work is 10min of rest.

[0161] 3) Suction filtration, washing and drying of the ball-milled small particles of iron-silicon alloy.

[0162] 4) Measure 100ml of 10% hydrofluoric acid solution into a 200ml plastic beaker, slowly add small grains of iron-silicon alloy, and keep stirring until the addition is complete. Put the beaker into an ultrasonic instrument for ultrasonic dispersion for 30min. Remove the beaker and place it on a magnetic stirrer for 12 h of continuous stirring. Suction filtration, washing and drying to prepare porous silicon material.

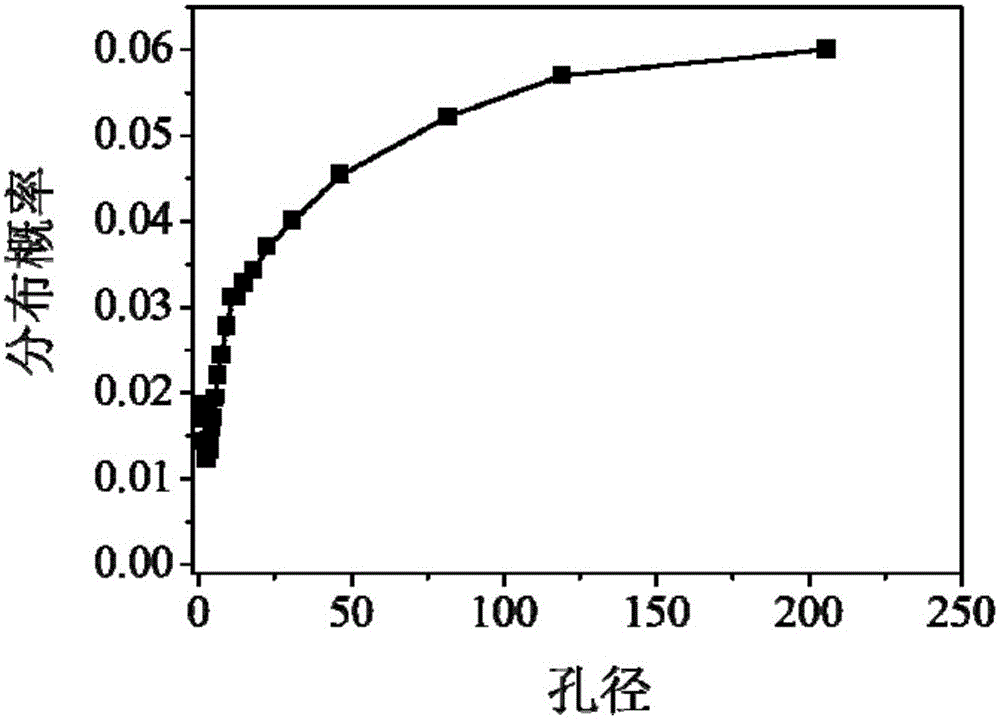

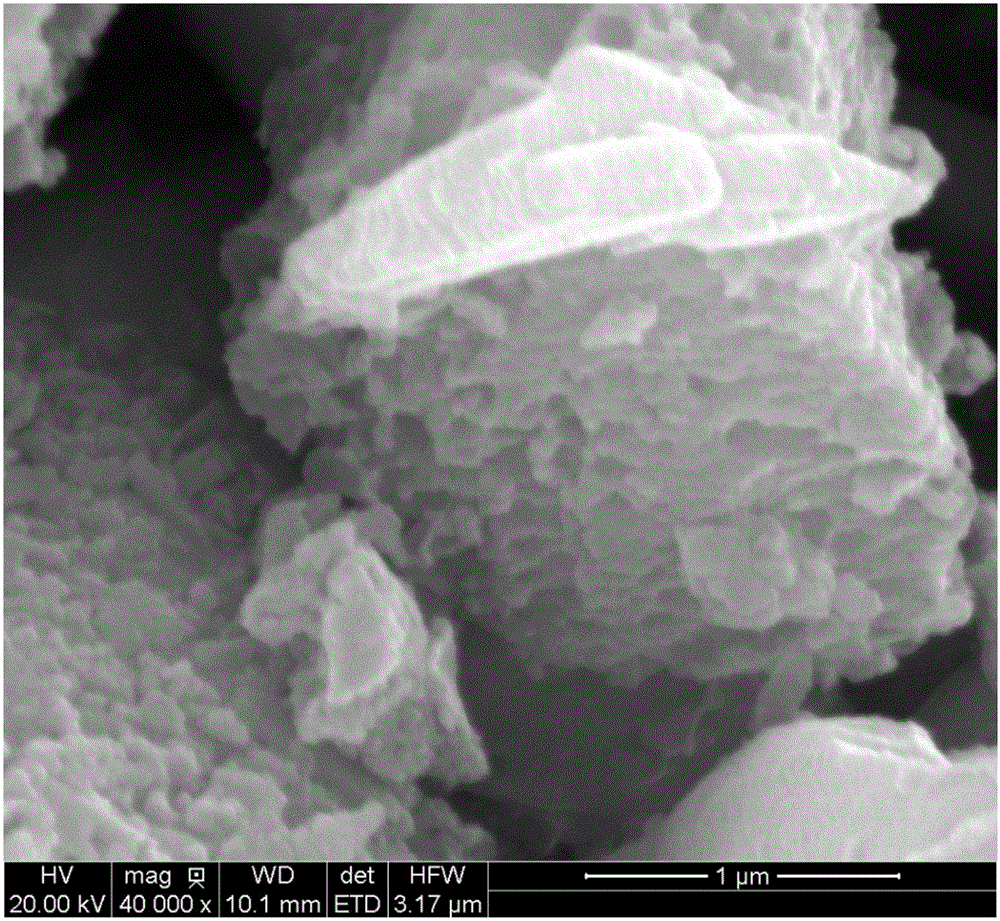

[0163] The porous silicon mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com