Patents

Literature

91 results about "Iron fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron fluoride can refer to Iron fluoride, a white solid Iron fluoride, a pale green solid

Separation and purification method of electrolytic aluminum scraps

ActiveCN101818253ASolve stubborn problemsImprove the effect of magnetic separationProcess efficiency improvementPurification methodsIron fluoride

The invention discloses a separation and purification method of electrolytic aluminum scraps, characterized by comprising the following steps of: crushing electrolytic aluminum scraps in a wet type, floating and magnetically separating, firstly removing iron and silicon and separating to obtain carbon powder and another raw material A; and putting the raw material A in an electric furnace, electrifying to dissolve fluoride salt, restoring harmful impurities in the scraps into an elementary substance metal state by utilizing metal aluminum, precipitating at the bottom of the electric furnace and secondarily removing the iron and the silicon to obtain an electrolyte B. The invention has the advantages that metal aluminum particles in electrolytic aluminum scraps in the electric furnace is utilized as a low-cost reducing agent to restore and precipitate iron, silicon and other harmful impurities at the bottom of the furnace when the fluoride salt is in a dissolved state so as to solve the problem that iron fluoride with high stability is hard to remove, and the reducing agent is utilized in the floatation process to improve the magnetic separation effect. For a product obtained in an electric furnace melting system, an acid-method process is adopted to convert alumina into cryolite, thirdly remove silicon and obtain a byproduct of ammonium bicarbonate.

Owner:周俊和 +1

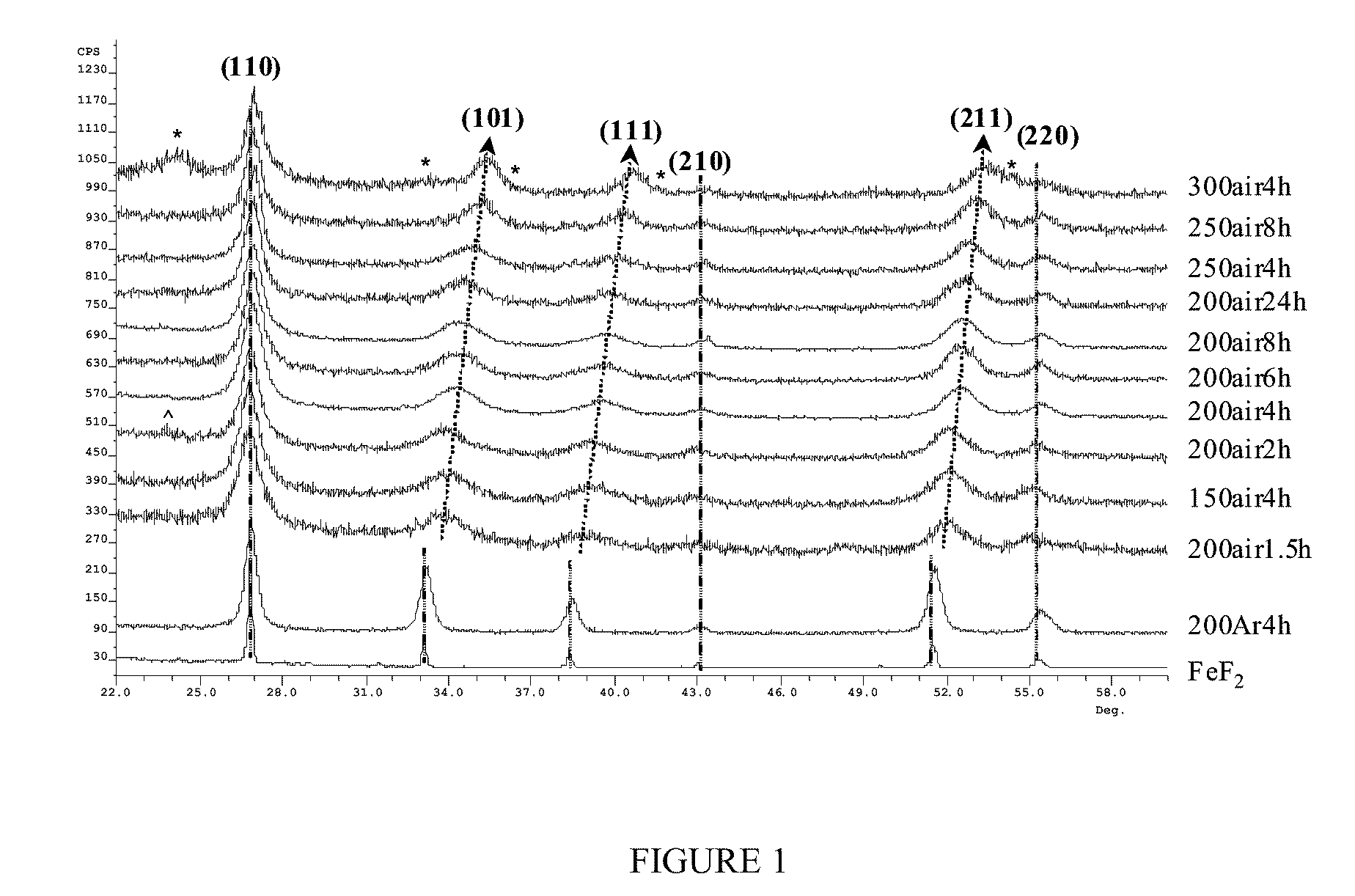

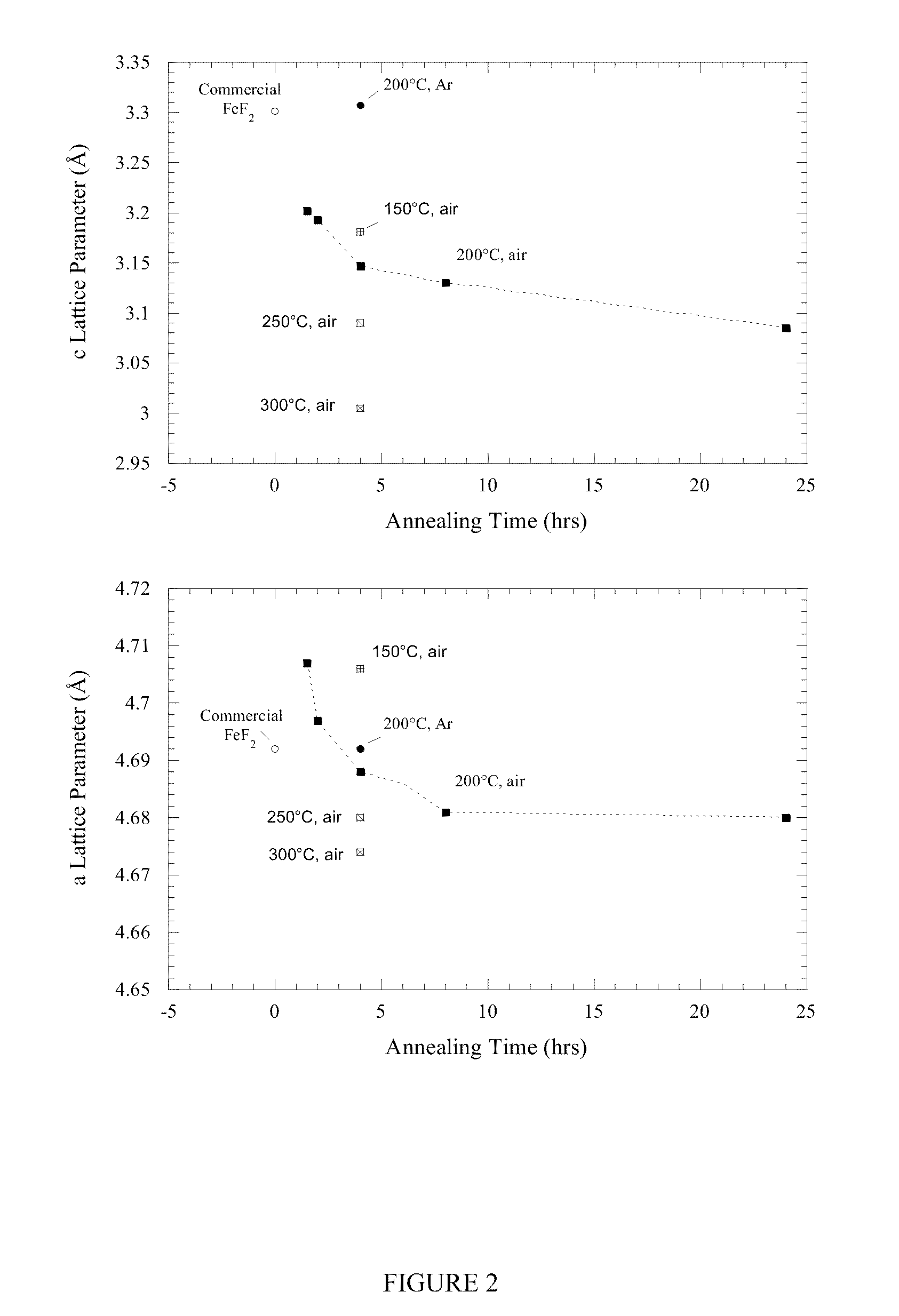

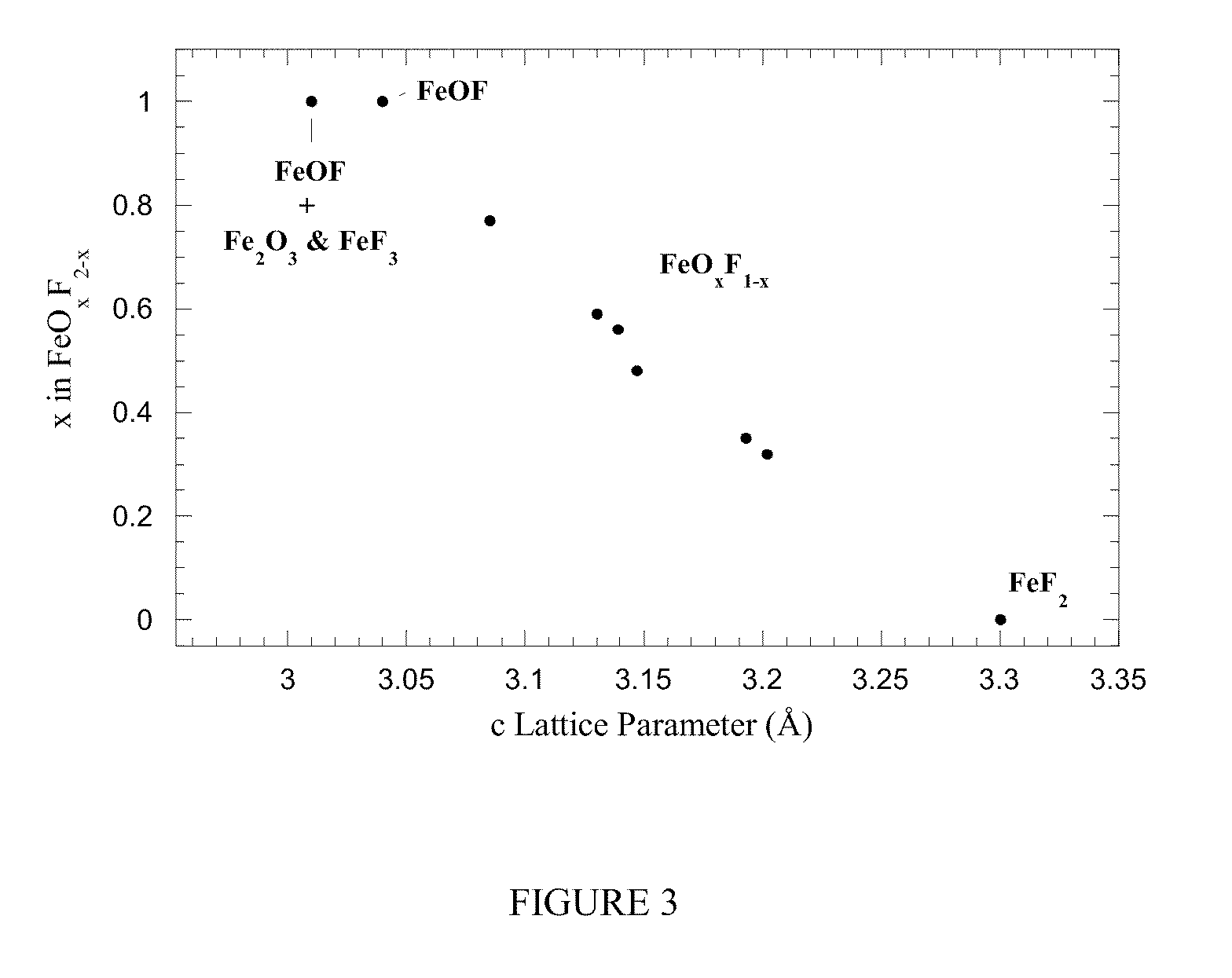

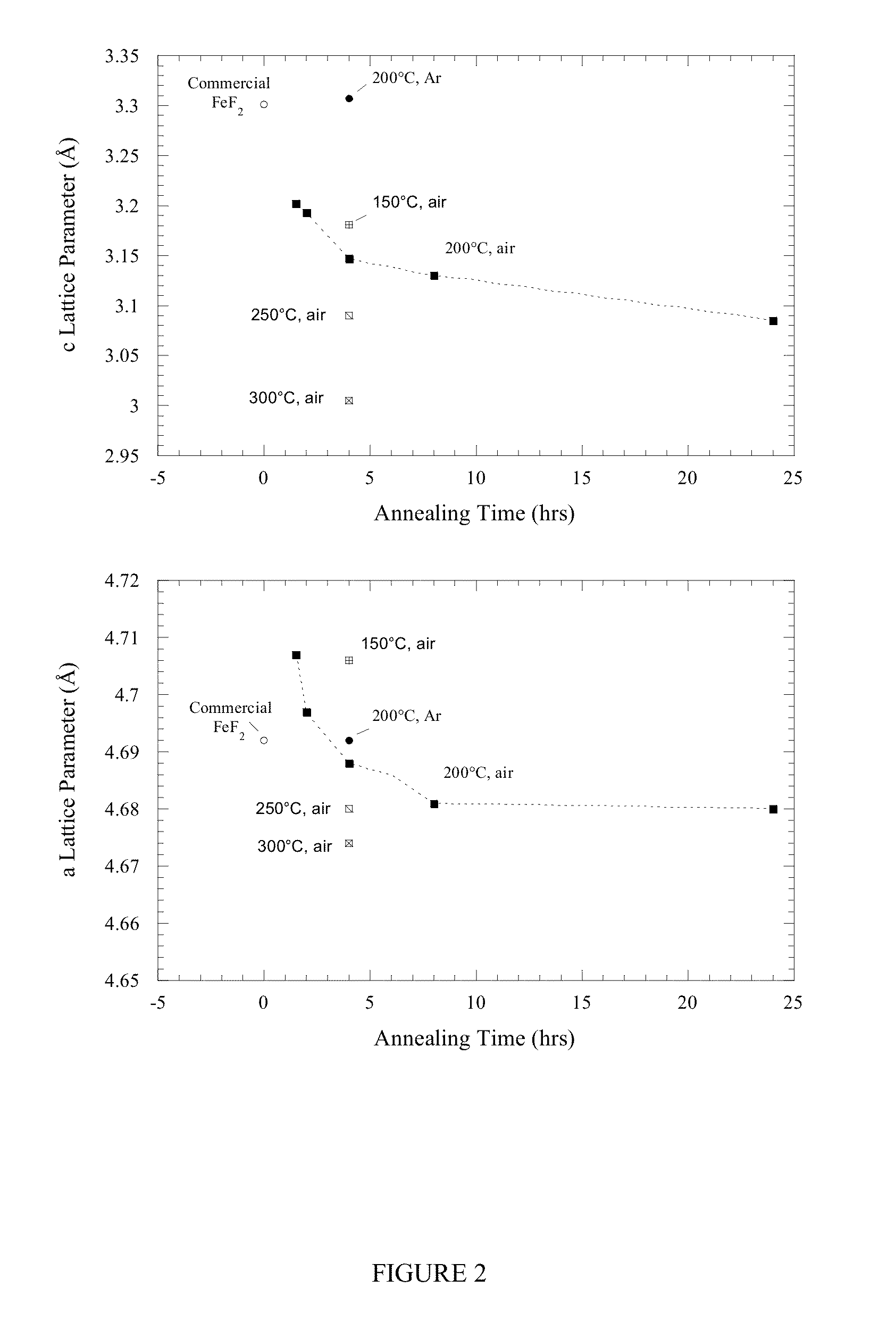

Iron Oxyfluoride Electrodes for Electrochemical Energy Storage

The present invention provides electrochemical energy storage systems comprising metallolyte composites, iron fluoride composites and iron oxyfluoride composites. The present invention further provides methods for fabricating metallolyte composites.

Owner:RUTGERS THE STATE UNIV

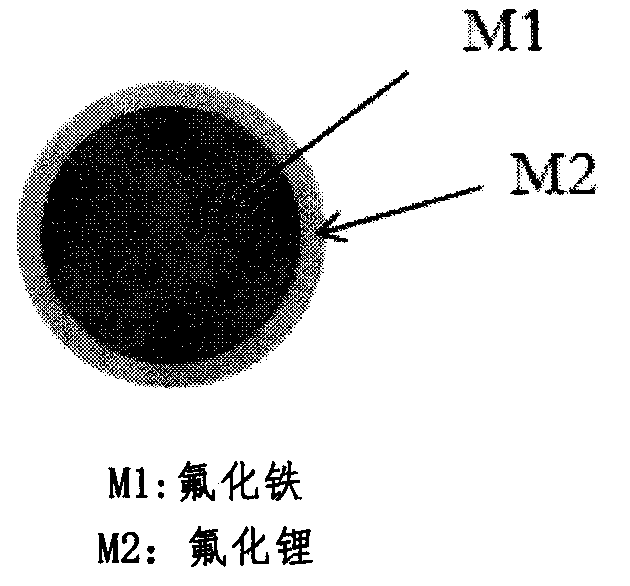

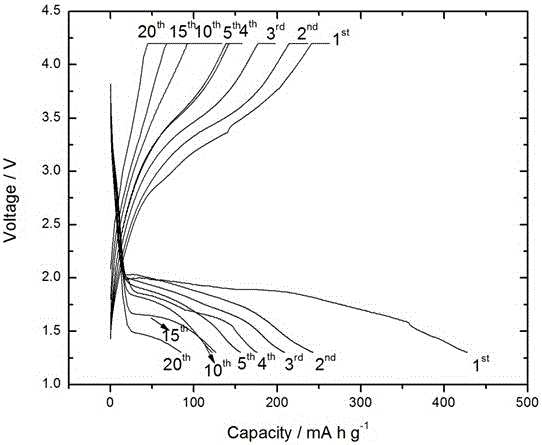

Lithium battery electrode material and preparation method thereof

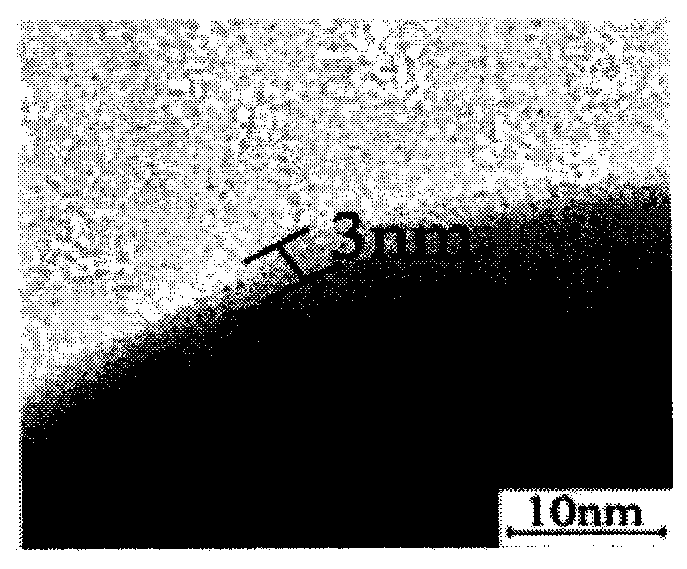

InactiveCN104143639AShorten the diffusion pathImprove cycle performanceCell electrodesSecondary cellsSlurryIron fluoride

The invention provides a long-life nano-iron fluoride electrode material and a preparation method thereof. The electrode material is characterized in that the nano-iron fluoride particle is coated with a lithium fluoride nano-layer on the surface, thus reducing direct contact of the electrolyte solution and iron fluoride, and enhancing the cycle life. The preparation method comprises the steps of: putting iron fluoride particles into a soluble lithium salt solution, performing stirring constantly to form a uniformly dispersed slurry; and drying the slurry, then placing the dried slurry in a sealed container, and introducing a fluoride gas to carry out reaction under certain temperature and certain time, thus obtaining the lithium fluoride coated iron fluoride anode material.

Owner:周明炯 +1

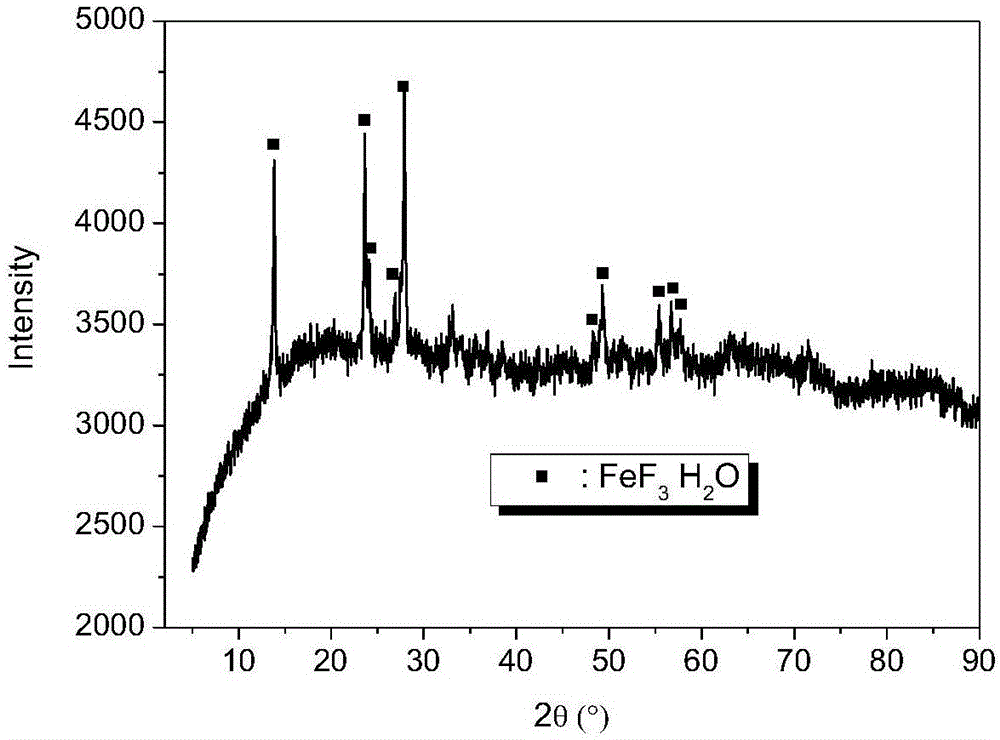

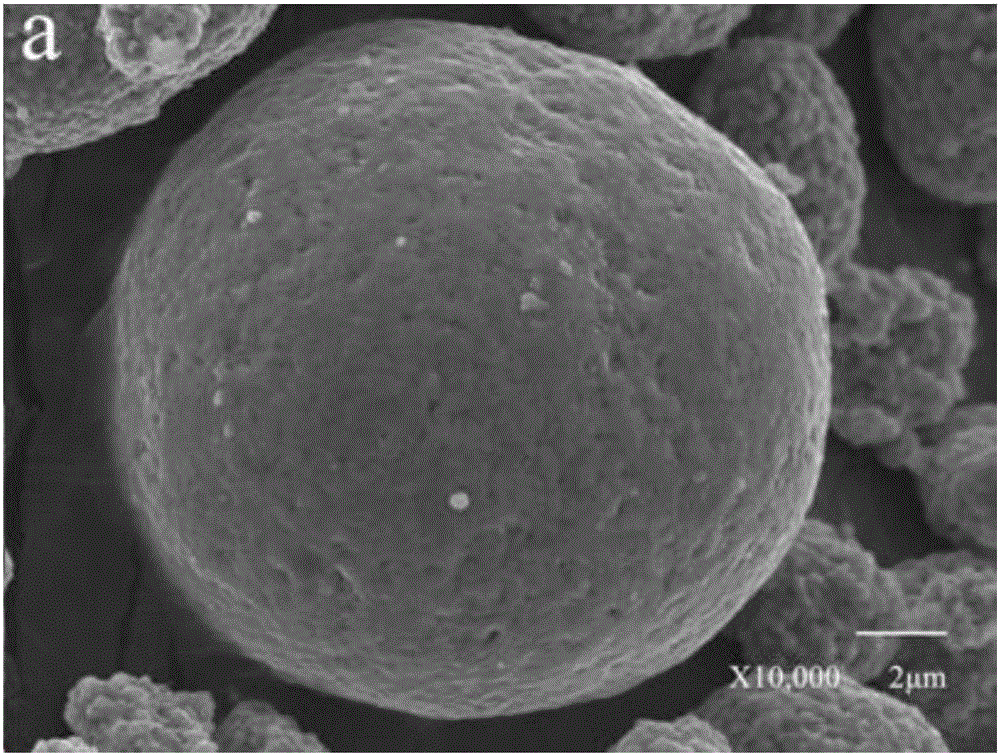

Composite iron trifluoride positive electrode material, preparation method and application

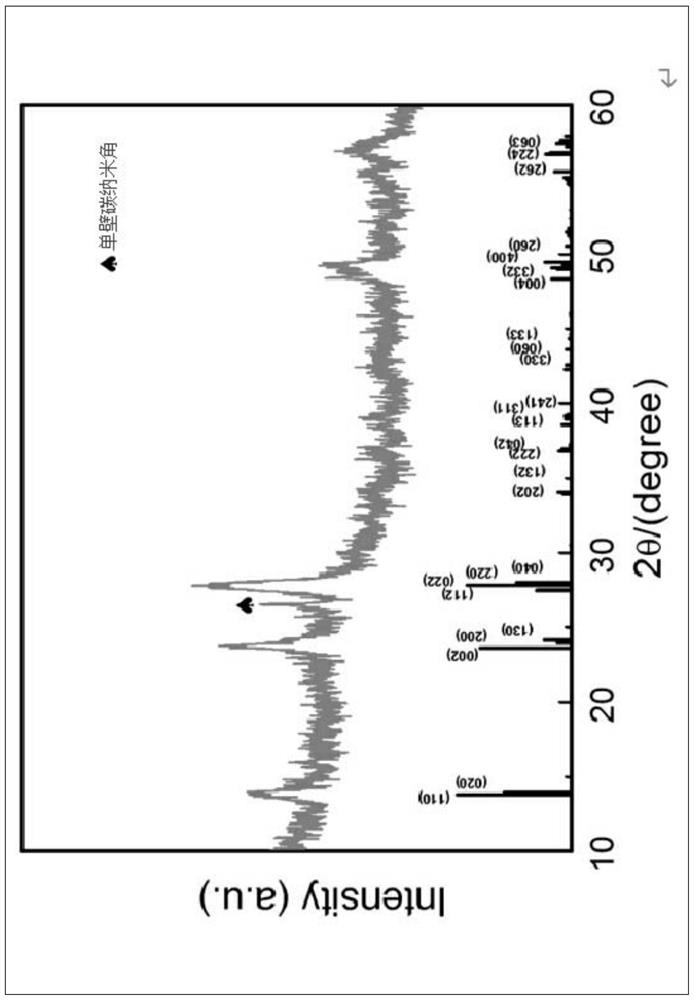

InactiveCN111883770AHigh theoretical capacityLow costMaterial nanotechnologyElectrode manufacturing processesFluid phaseNitrogen gas

The invention discloses a composite iron trifluoride positive electrode material. The composite iron trifluoride positive electrode material is a FeF3.0.33H2O carbon nanohorn composite material synthesized from carbon nanohorns and Fe(NO3)3.9H2O through a liquid-phase synthesis method. The preparation method of the composite material comprises the following steps: dispersing carbon nanohorns subjected to open pore oxidation treatment into ionic liquid, and uniformly dispersing the carbon nanohorns into the ionic liquid through stirring and ultrasonic treatment; then sequentially adding absolute ethyl alcohol and an iron source, and stirring the mixture until reactants are fully and uniformly mixed; putting the reaction solution into a constant-temperature oil bath reactor, carrying out nitrogen protection, and continuously stirring the mixture until the reaction is stopped; diluting the viscous reaction product obtained in the step 3 with acetone, and centrifuging the reaction product;freezing the centrifugal product in the step 4 by using liquid nitrogen, and volatilizing residual acetone to obtain a target product. The invention further discloses application of the composite material to a lithium ion solid-state battery. The material has good conductivity and is suitable for a high-rate system, and the preparation method is simple.

Owner:SIDUS ENERGY TECH LTD

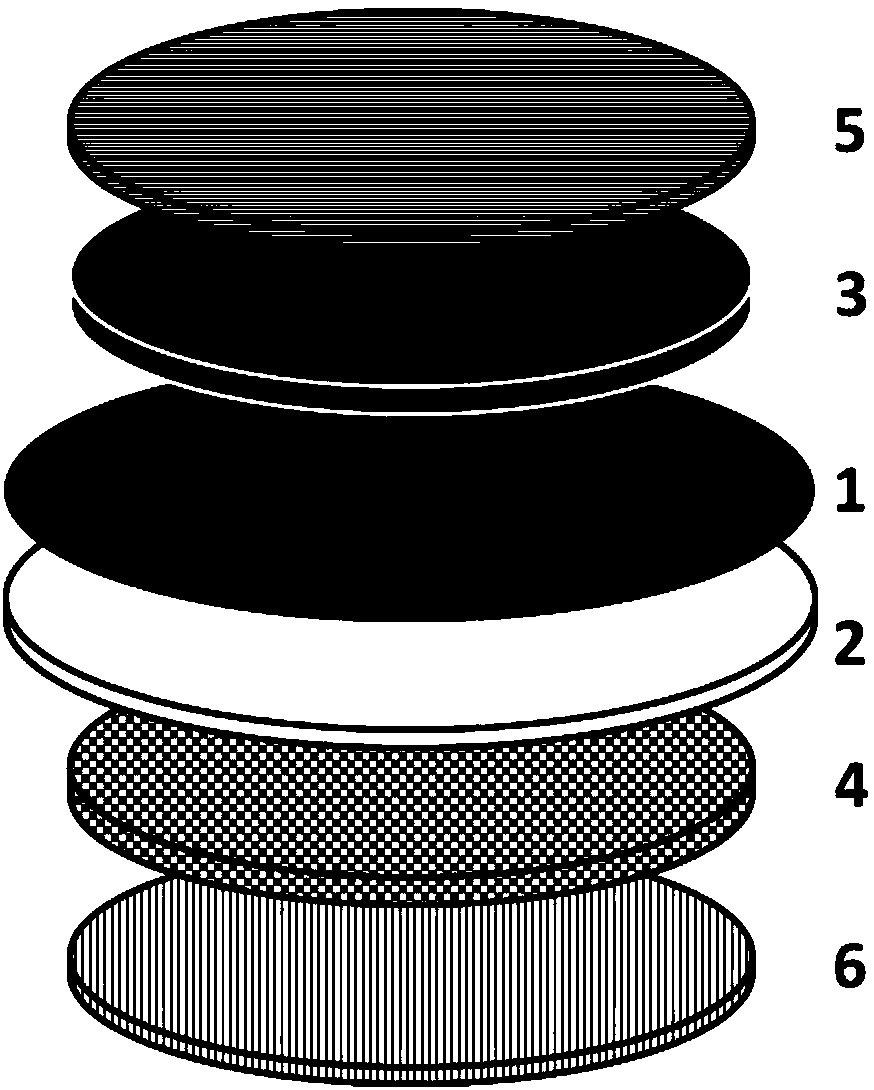

Interface protection structure, preparation method and battery comprising structure

InactiveCN109728249AEffective protectionNo side effectsCell electrodesLi-accumulatorsCyclic processTitanium fluoride

The invention provides an interface protection structure and a preparation method thereof and a battery comprising the interface protection structure. The interface protection structure comprises a metal fluoride and a binder. The metal fluoride is one or more of nickel fluoride, manganese fluoride, iron fluoride, titanium fluoride, copper fluoride, tin fluoride, and the like. The structure can form a protective layer containing lithium fluoride during the cycle process of lithium metal batteries to protect lithium metal electrodes. The interface protection structure is prepared by the following method: (1) providing a mixed slurry comprising a metal fluoride, a binder, a solvent and / or a carbon material; (2) coating one side of a diaphragm with the mixed slurry to obtain a diaphragm containing a first coating; and (3) baking the diaphragm containing the first coating to obtain the interface protection structure.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Iron oxyfluoride electrodes for electrochemical energy storage

The present invention provides electrochemical energy storage systems comprising metallolyte composites, iron fluoride composites and iron oxyfluoride composites. The present invention further provides methods for fabricating metallolyte composites.

Owner:RUTGERS THE STATE UNIV

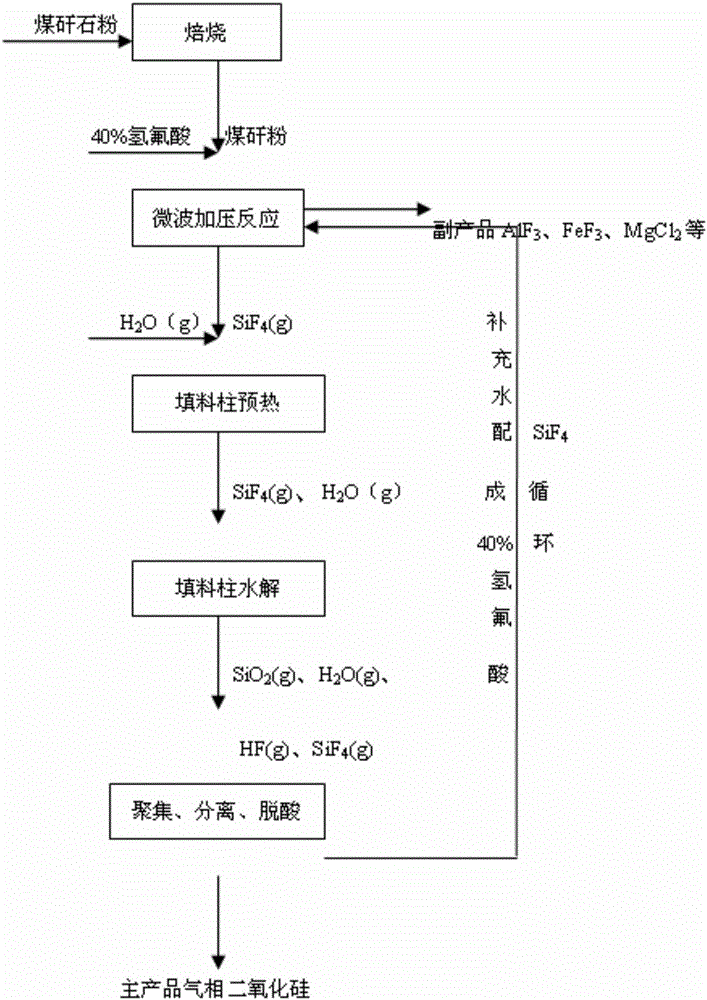

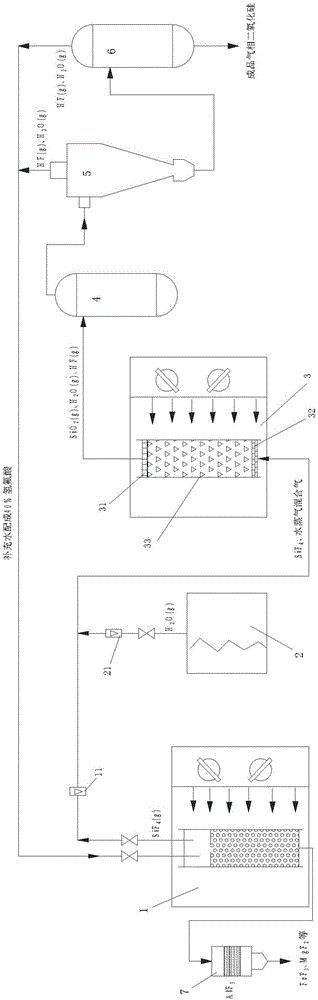

Method and apparatus for preparing fumed silica from coal gangue

The invention discloses a method and an apparatus for preparing fumed silica from coal gangue. The method comprises: performing pressurized reaction, in microwave fields, on activated coal gangue powder and hydrofluoric acid, converging the generated silicon tetrafluoride gas with water vapor to obtain a mixture and introducing the mixture into a micorwave-absorbing agent packed column under microwave irradiation, and performing high-temperature pyrohydrolysis reaction on the mixture to generate gas silicon dioxide and hydrogen fluoride; performing shock chilling, gathering, separating, acid-removing and purging on the generated gas silicon dioxide and hydrogen fluoride as well as unreacted water vapor to prepare a fumed silica product; separating the hydrogen fluoride gas and the water vapor from a cyclone separator and the top of an acid removing furnace, and adding the water to prepare hydrofluoric acid for recycling, wherein the fumed silica product can be used as a thickening agent, a rubber reinforcing agent and a washing assistant agent, and the like; by-products are aluminum fluoride, iron fluoride and magnesium fluoride and the like; the microwave-absorbing agent in the present invention can significantly improve the direct hydrolysis efficiency of silicon tetrafluoride; the pressurized microwave reaction can significantly increase the reaction rate and conversion rate of silicon dioxide and hydrofluoric acid; and the microwave-absorbing agent is recycled and easy to regenerate, and has a high utilization rate, a simple process and low preparation cost.

Owner:LIUPANSHUI NORMAL UNIV

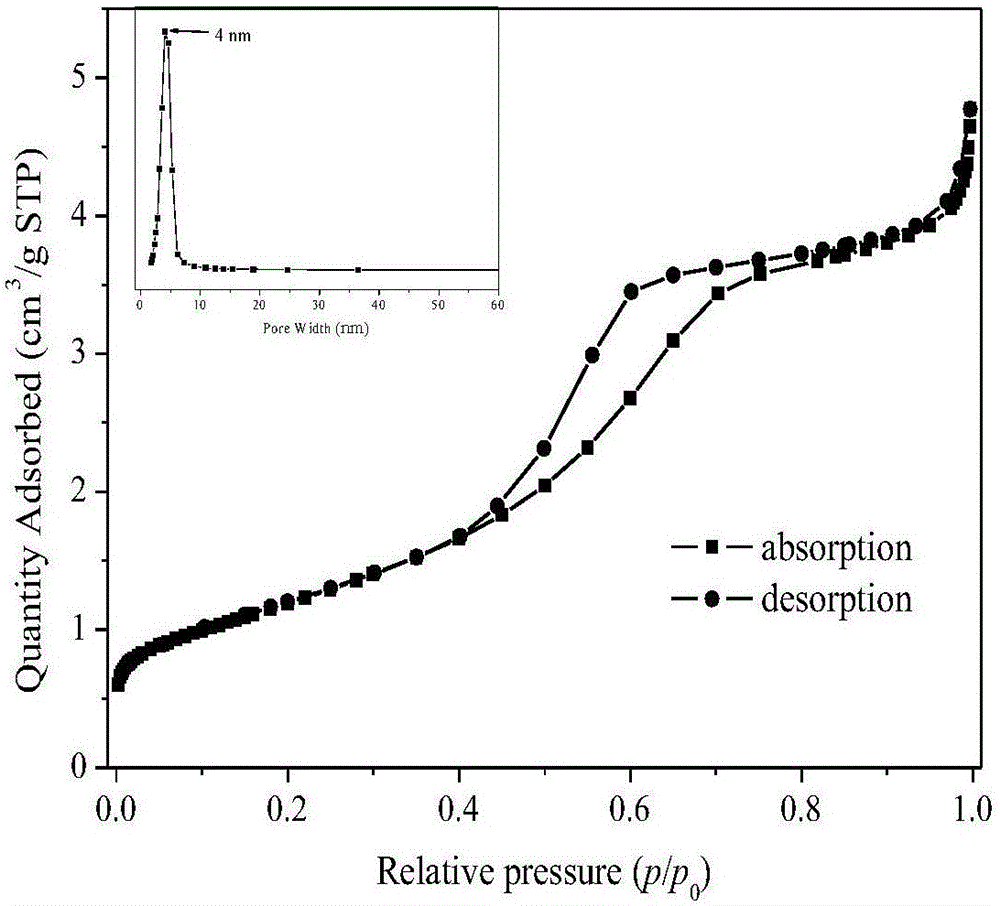

Preparation method of high-capacity fluoride/porous carbon composite positive electrode material

InactiveCN107768636AHigh reactivityIncrease optionalityMaterial nanotechnologyCell electrodesPorous carbonPore diameter

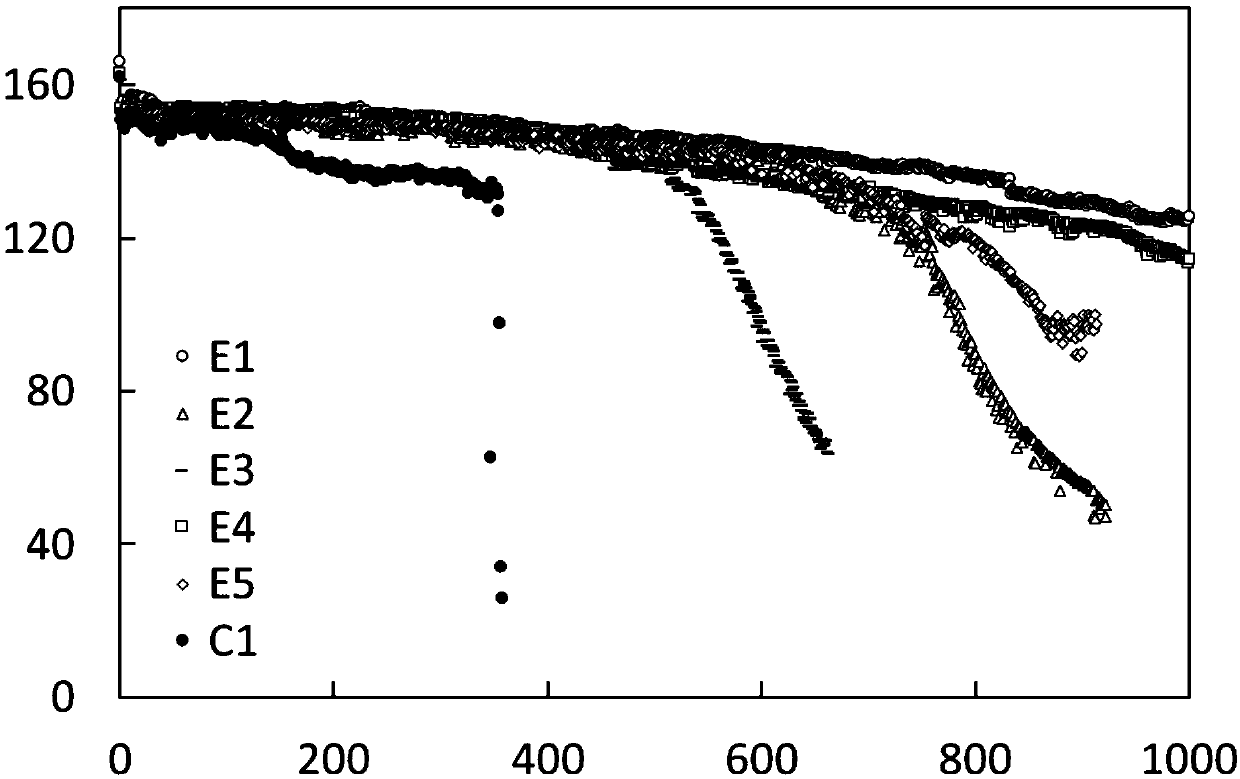

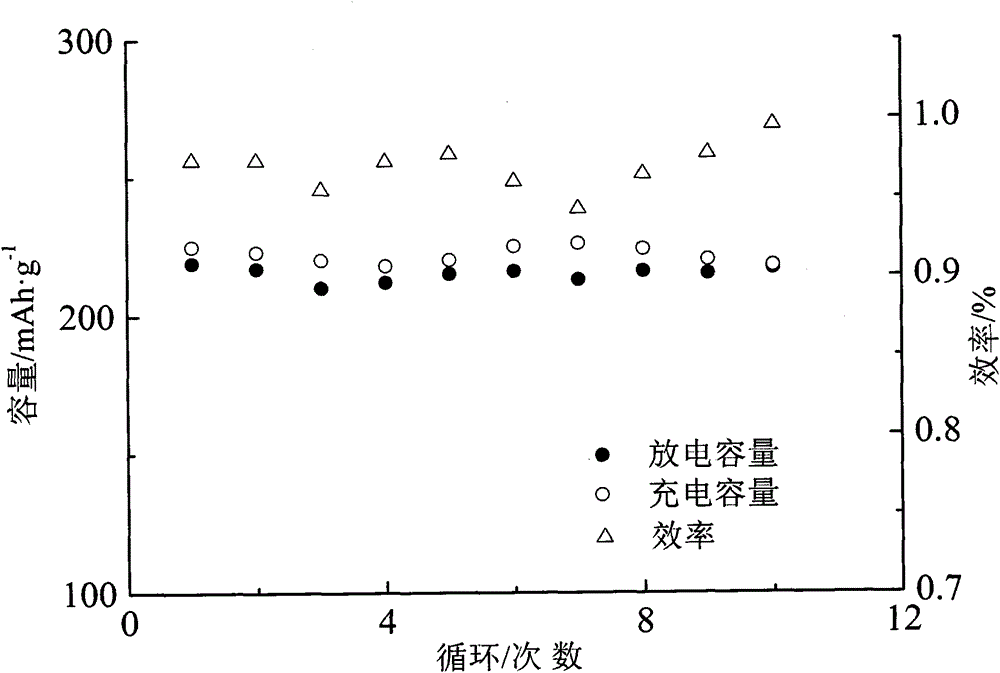

The invention discloses a high-capacity fluoride / porous carbon composite positive electrode material and a preparation method thereof. A nano iron fluoride / porous carbon composite material is obtainedby taking iron fluoride and porous carbon as raw materials through steps of firstly mixing to prepare an iron fluoride / porous carbon compound; then carrying out no less than one time of solvent spraying-vacuumizing-drying treatment on the iron fluoride / porous carbon compound. By controlling the pore diameter of the porous carbon, a compounding ratio and the number of times of treating, the embedding mount of iron fluoride can be flexibly adjusted, so that the nano iron fluoride / porous carbon composite material prepared by the preparation method has the characteristics of simplicity and high efficiency; special experiment equipment and devices are not needed and amplified production is easy to generate; the high-capacity fluoride / porous carbon composite positive electrode material has a wide application prospect in the field of lithium-ion batteries. Meanwhile, after the fluoride / porous carbon composite positive electrode material designed and prepared by the preparation method is subjected to 200 circles of charging-discharging circles under the current density of 200mA / g, the reversible specific capacity is greater than or equal to 116mAh / g.

Owner:CENT SOUTH UNIV

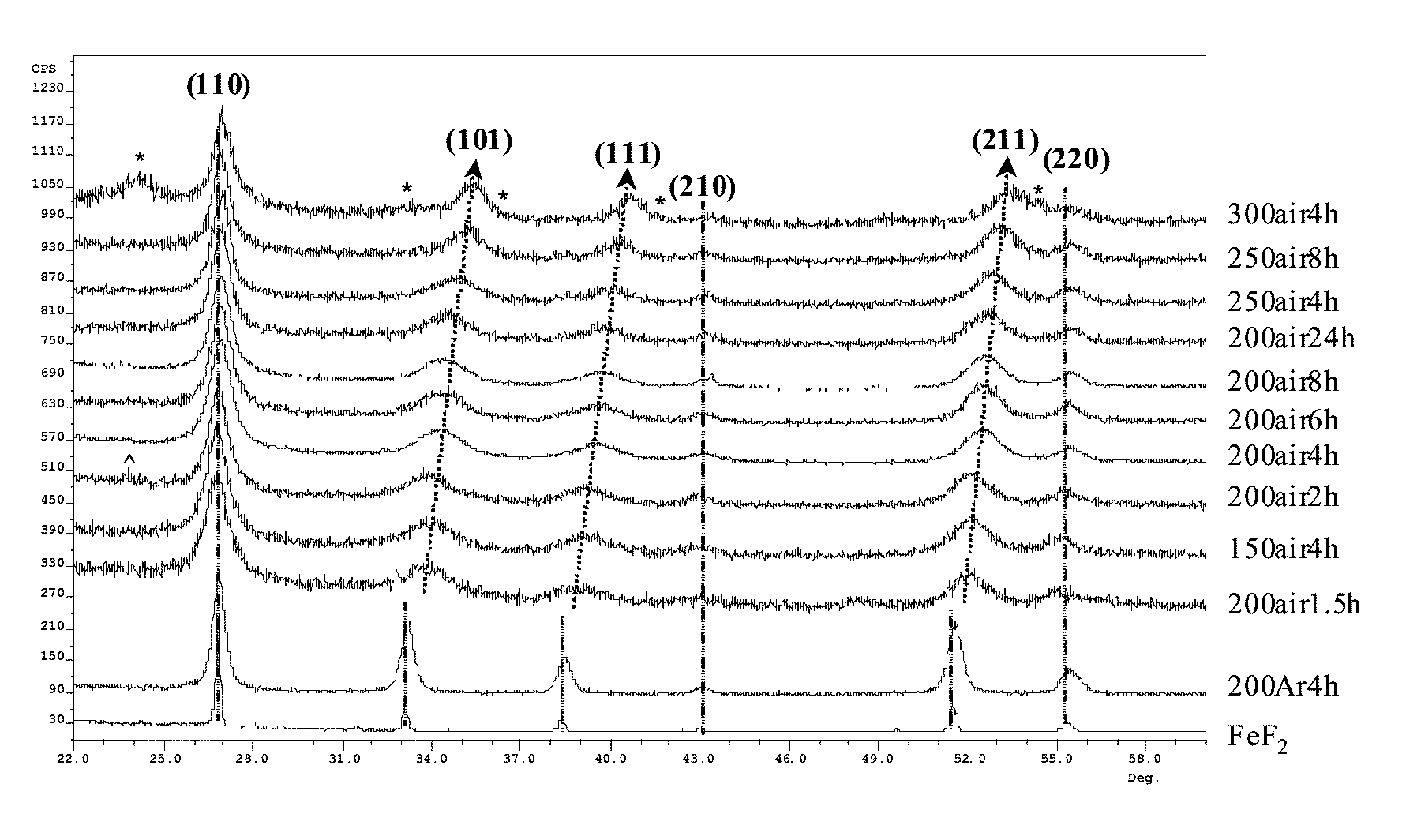

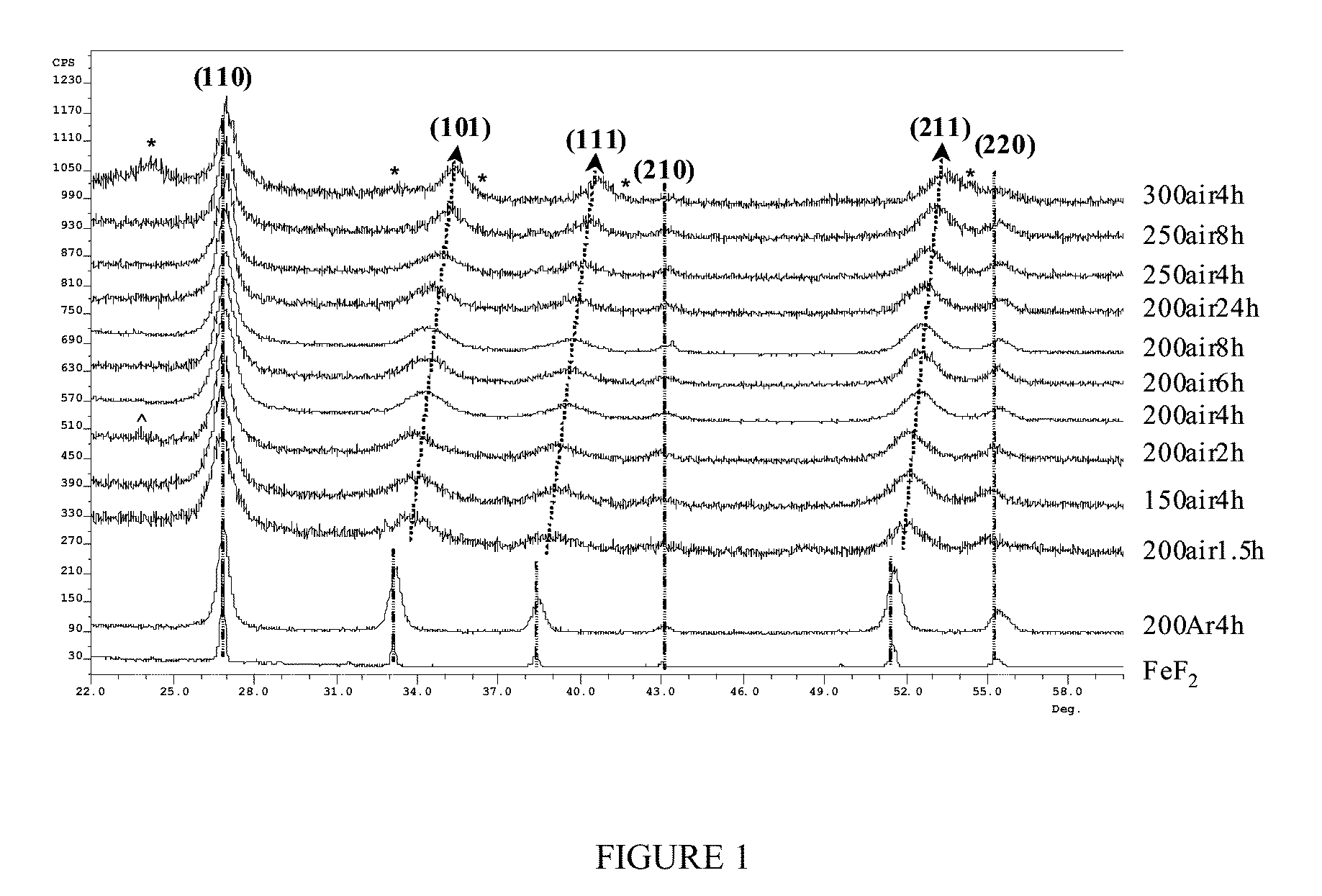

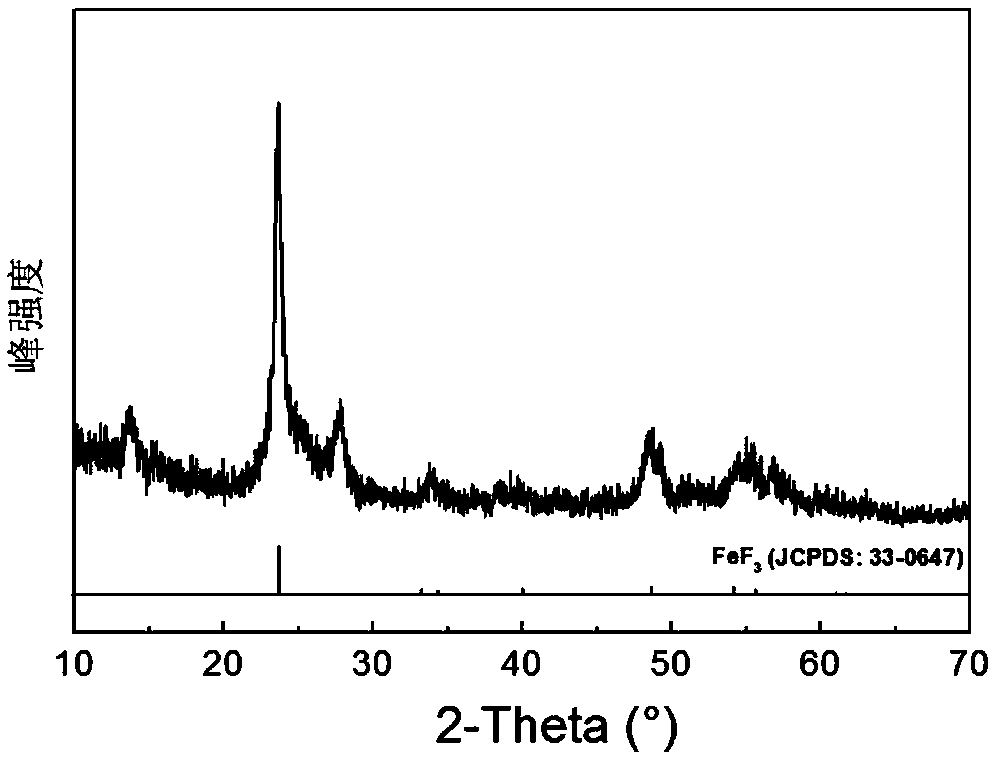

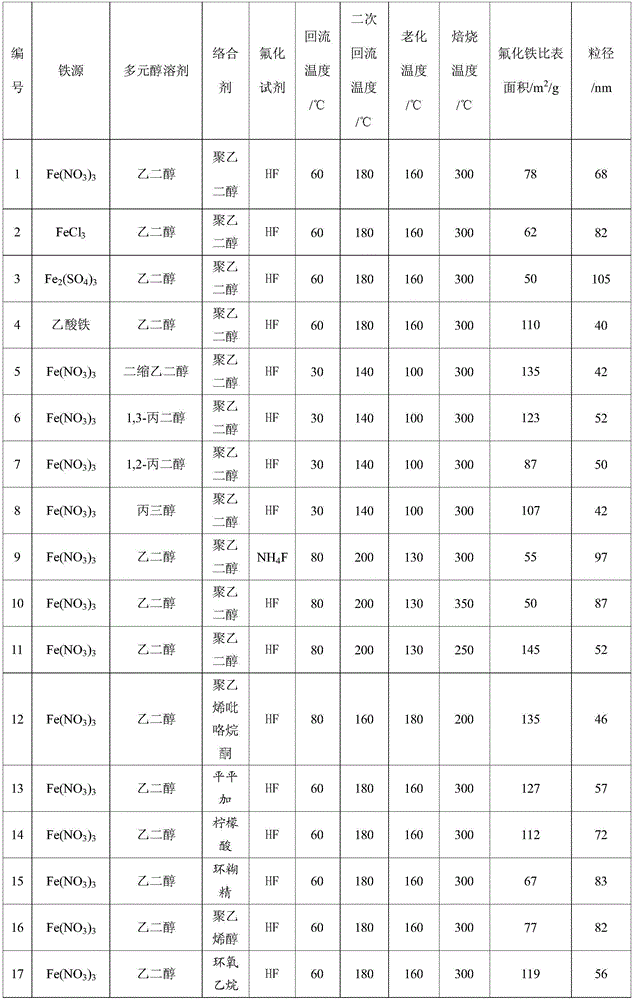

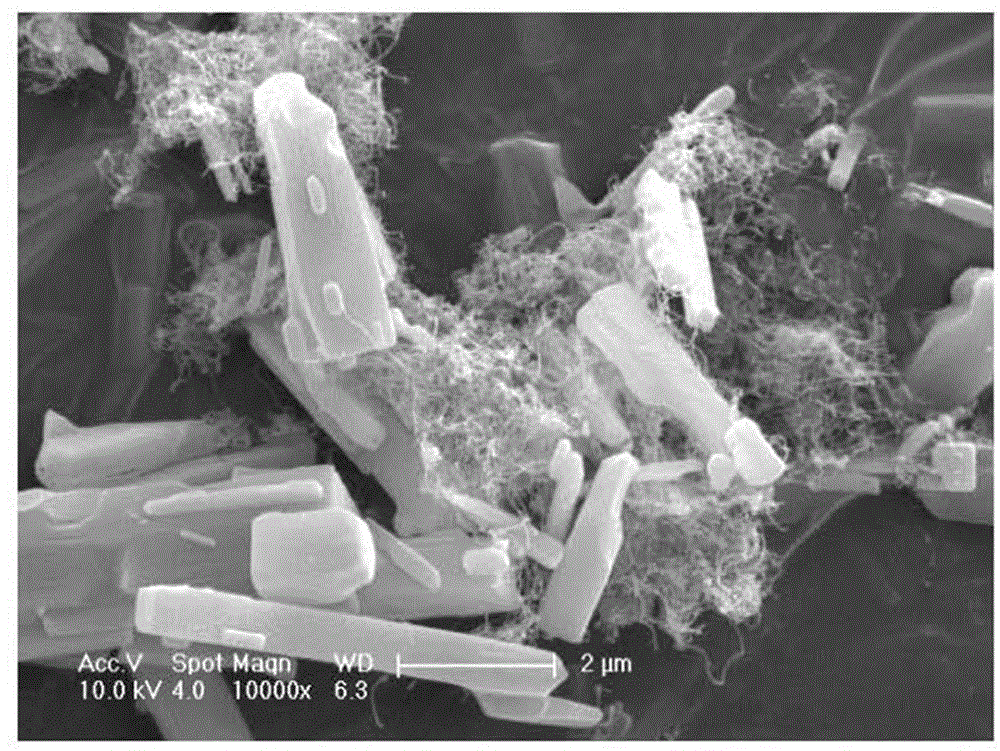

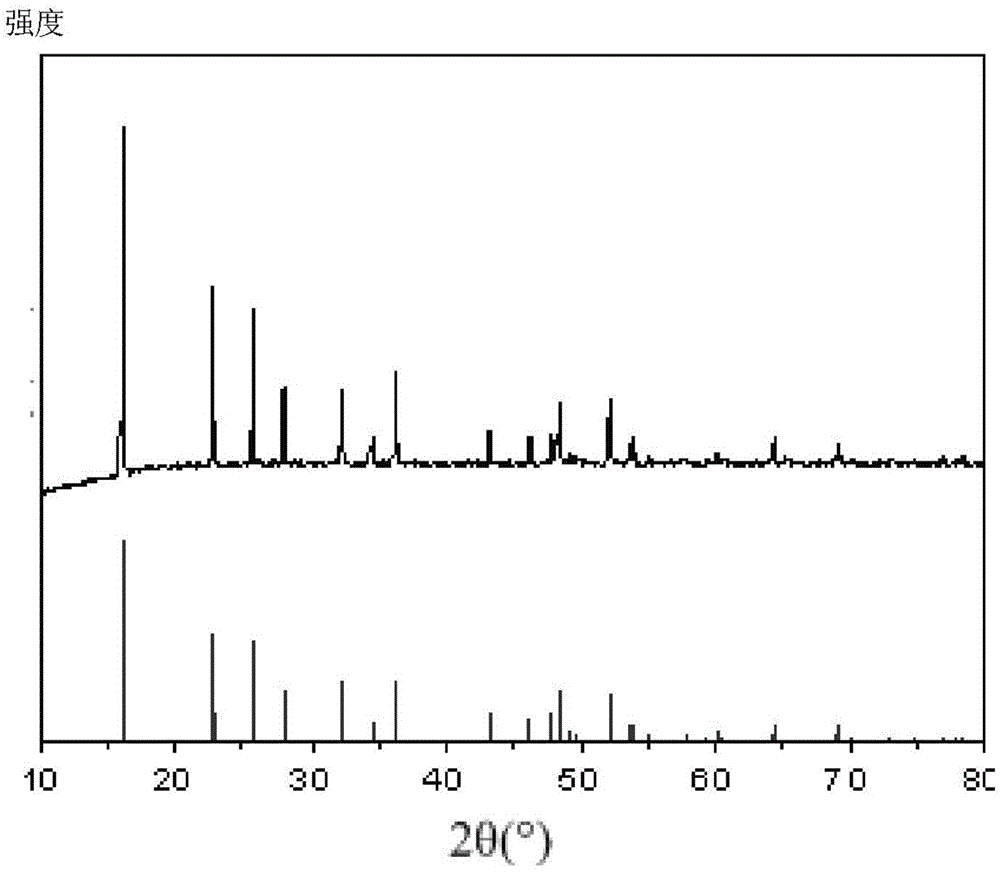

Nano iron fluoride-based composite material, and preparation method thereof

The invention discloses a preparation method of a nano iron fluoride-based composite material, which aims to solve the problems of high raw material cost, complex synthetic process, difficulty in uniform mixing of iron fluoride and carbon and oxygen elements, and inability for effective grain size control of the conventional preparation method. The preparation method of nanocrystalline iron fluoride comprises the following steps: (1) preparing a solution consisting of an iron source precursor, a polyalcohol solvent, and a complexing agent, and carrying out refluxing at a temperature of 30-80 DEG C; (2) adding a fluorinating reagent to a solution obtained through (1) for fluorination, and carrying out refluxing and stirring at a temperature of 140-200 DEG C to obtain a suspension; and (3) carrying out aging of the suspension at a temperature of 100-160 DEGC, carrying out washing and filtering of the aged suspension to obtain a solid, and finally calcinating the solid at a temperature of 200-350 DEG C to obtain the nano iron fluoride.

Owner:XIAN MODERN CHEM RES INST

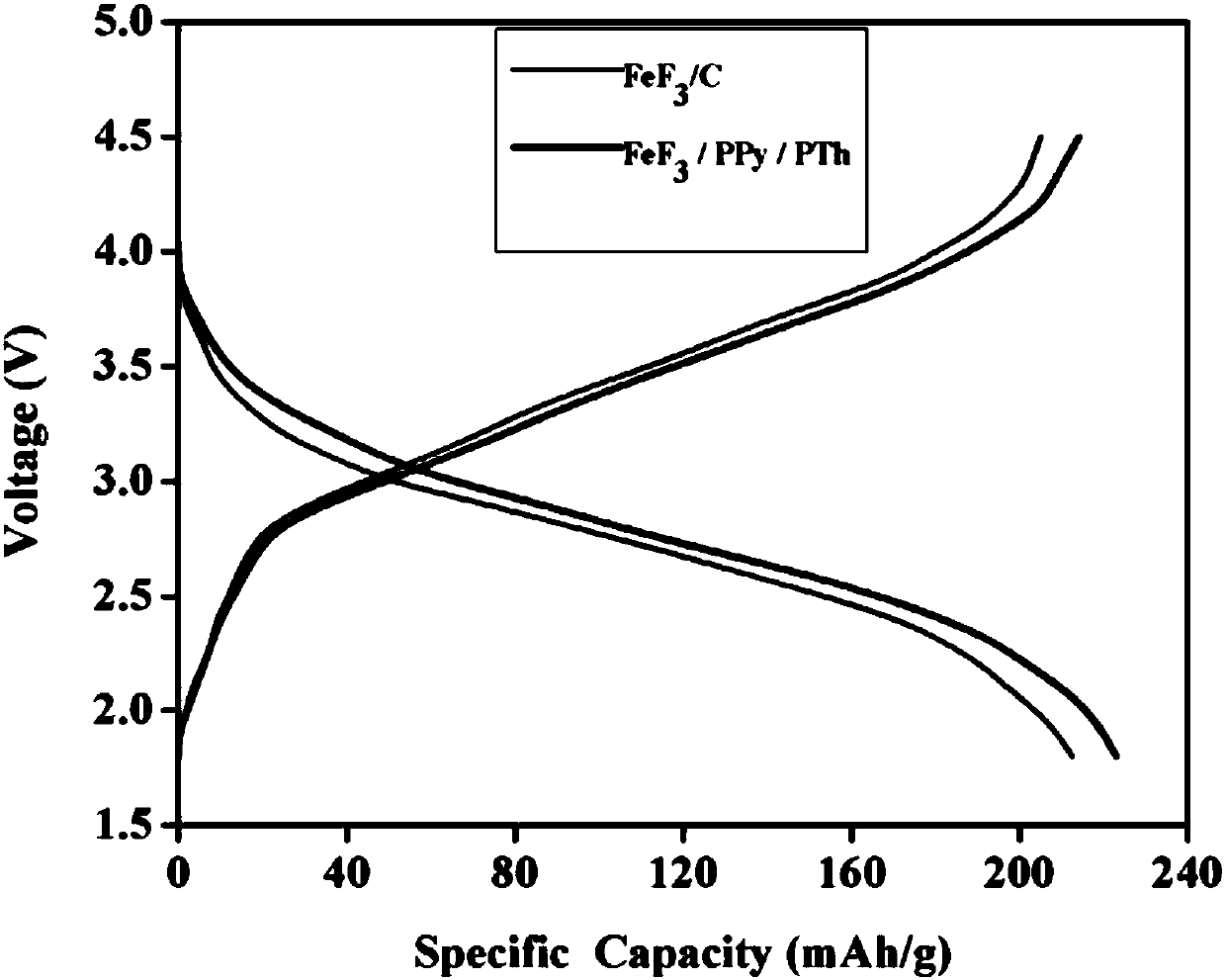

Iron trifluoride composite material, preparation method of iron trifluoride composite material, and lithium secondary battery

InactiveCN105958040AImprove electrochemical performanceImprove stabilityCell electrodesSecondary cellsMetallurgyConductive polymer

The invention provides an iron trifluoride composite material. The iron trifluoride composite material is composed of iron trifluoride and a multi-component conductive polymer doped and hybridized in iron trifluoride. The invention further provides a preparation method of the iron trifluoride composite material. The preparation method comprises the following steps of mixing and grinding multi-component conductive polymer powder and iron trifluoride powder, and then, thermally processing so as to obtain the iron trifluoride composite material. The conductive polymer is doped and hybridized in iron trifluoride nano-particles, such that a conductive polymer / iron trifluoride composite material is obtained; the electrochemical performance of the iron trifluoride composite material can be effectively improved; the stability, the capacity and the rate capability of a cathode material are improved; simultaneously, the problem that the iron trifluoride cathode material is low in electric conductivity can be solved well; furthermore, a one-step method provided in the invention is simple to operate and low in cost; furthermore, reaction is unnecessary to carry out in a solvent; and thus, the preparation method is more suitable for industrial mass production and application.

Owner:GUANGDONG UNIV OF TECH

Preparation method for yttrium iron fluoride doped lithium manganese phosphate-carbon composite cathode material

InactiveCN103825029AHigh specific capacityExtended service lifeCell electrodesRare-earth elementCarbon composites

The invention relates to a preparation method for a yttrium iron fluoride doped lithium manganese phosphate--carbon composite cathode material. The chemical formula of the yttrium iron fluoride doped lithium manganese phosphate is LiMn1-x-y FexYyP1-zFzO4, wherein the x equals to 0.2-0.3; the y equals to 0.01-0.025; the z equals to 0.05-0.15.The preparation method comprises the following steps: (1) preparing the yttrium iron fluoride doped lithium manganese phosphate; (2) preparing conductive carbon dispersion; mixing ytterbium magnesium doped lithium manganese phosphate precursor with the conductive carbon dispersion to obtain a mixture; after ball milling and drying, placing the mixture in a mixed atmosphere of argon and acetylene; sintering and obtaining the yttrium iron fluoride doped lithium manganese phosphate-carbon composite cathode material; according to the invention, rare earth element Y and transitional element Fe are doped in the lithium manganese phosphate composite material, so as to replace part of M n; F is doped to replace part of P for modification and improvement to the electronic conductivity and physical activity; then, coating carbon black and a carbon nanotube mixed carbon network wrap the surface of the lithium manganese phosphate composite cathode material so as to further improve the electrical conductivity and cycling stability.

Owner:吉林新航能源有限公司

Method for one-step synthesis of iron fluoride/C positive electrode material

InactiveCN106207116ASmall granularitySimple processCell electrodesSecondary cellsOxalateRoom temperature

The invention discloses a method for one-step synthesis of iron fluoride / C, and belongs to the technical field of lithium ion batteries. The method disclosed by the invention comprises the following steps of fully mixing and grinding ferrous oxalate and excessivepowdered polytetrafluoroethylene, loading a uniform mixture in an aluminum oxide crucible, and roasting the uniform mixture in an argon environment, wherein the roasting temperature is 500-650 DEG C, and the temperature is maintained for 1-3 hours; cooling the uniform mixture with a furnace to a room temperature after roasting to obtain a roasted product, namely iron fluoride / C; and taking out the product, and grinding the product to obtain fine nanometer iron fluoride / C powder. The nanometer iron fluoride / C prepared according to the method has the advantages that the particle size is small and uniform, and iron fluoride is closely wrapped by carbon; and the heat preservation time in the roasting process is relatively short, and uniform and fine particles are ensured and are prevented from growing up.

Owner:KUNMING UNIV OF SCI & TECH

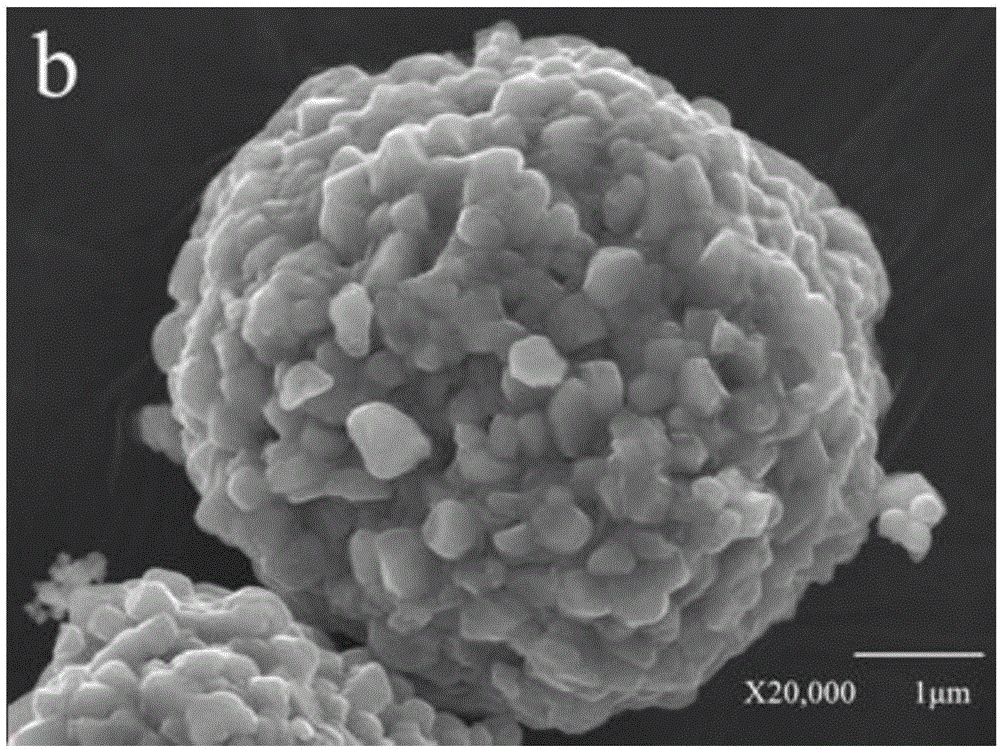

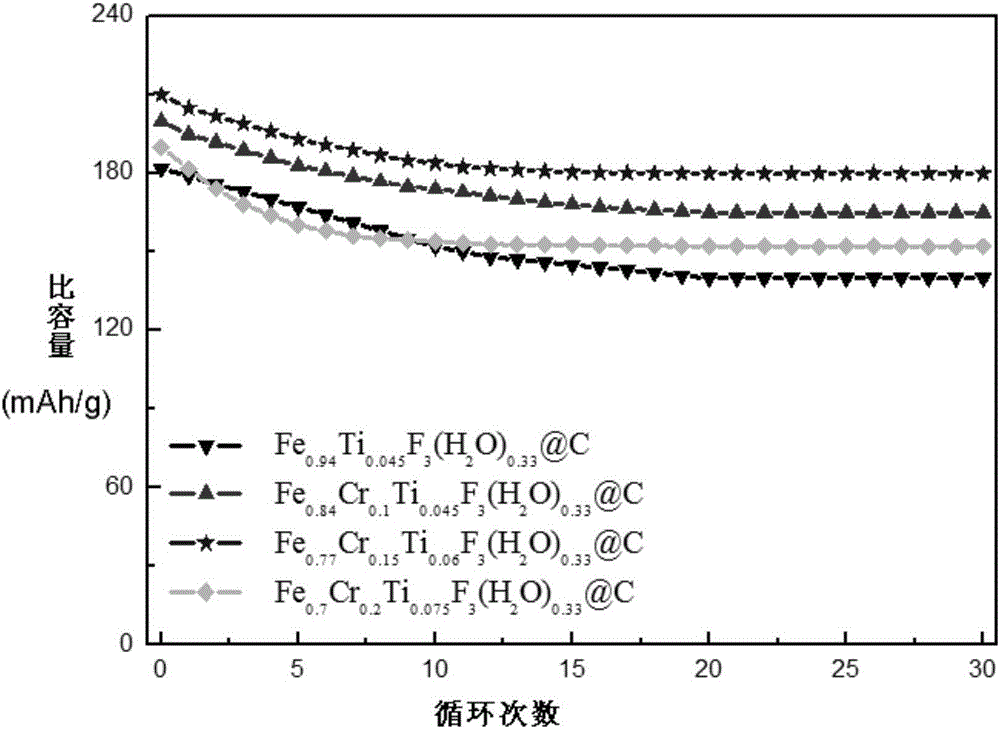

Titanium and chromium doped iron fluoride-carbon nanometer composite positive electrode material, and preparation method and application thereof

ActiveCN106025182AImprove conductivityHigh specific capacityCell electrodesSecondary cellsElectricityChromium doping

The invention provides a titanium and chromium doped iron fluoride-carbon nanometer composite positive electrode material, and a preparation method thereof. The material sis prepared through coating a doped iron fluoride precursor with a carbon-containing conductive material, the doped iron fluoride precursor is represented by formula I, and the positive electrode material is represented by formula II. Titanium ions and chromium ions are doped to adjust the crystal lattice parameters of crystals, so the lithium ion diffusion performance is substantially improved, the electricity conduction performance of the material is enhanced, and the specific capacity of the material is improved. The doped iron fluoride precursor is coated and compounded with the carbon-containing conductive material in order to further improve the electricity conduction performance of the material and reduce particle agglomeration. The rate characteristics and the cycle performances of the material are excellent. The invention also provides a lithium ion battery comprising the positive electrode material. The formula I is Fe1-x-yCrxTi0.75yF3(H2O)0.33, and the formula II is represented by Fe1-x-yCrxTi0.75yF3(H2O)0.33@C.

Owner:深圳鑫茂新能源技术股份有限公司

Silver vanadate-lithium iron phosphate composite anode material preparation method

ActiveCN103187557AIncrease capacityExtended service lifeCell electrodesFerric hydroxideDoped graphene

The invention relates to a silver vanadate-lithium iron phosphate composite anode material preparation method. The method comprises the following steps: (1) preparing silver vanadate; (2) mixing lithium acetate and ammonium phosphate, using water to dissolve the mixture, sequentially adding citric acid and acetone, stirring to be sol, adding glucose into the sol, adding ferric hydroxide of which the molar amount is equal to the lithium molar amount and a reducing agent, namely lamp black, uniformly mixing the mixture, performing vacuum drying on the mixture, and performing ball milling on the mixture to prepare a lithium iron phosphate precursor coated by carbon; and (3) mechanically mixing the silver vanadate and the lithium iron phosphate precursor uniformly to be placed into a vacuum reaction furnace for sintering, then performing cooling, and obtaining a product after ball milling. According to the vanadate-lithium iron phosphate composite anode material for a lithium ion battery, a ferric fluoride material with high discharge capacity is subjected to cobalt doping modification to improve the conductivity of the ferric fluoride material, then is compound with a silicon doping graphene material with good conductivity and stability, so that the vanadate-lithium iron phosphate composite anode material has the characteristics of high capacity and high cycle stability.

Owner:广东比沃新能源有限公司

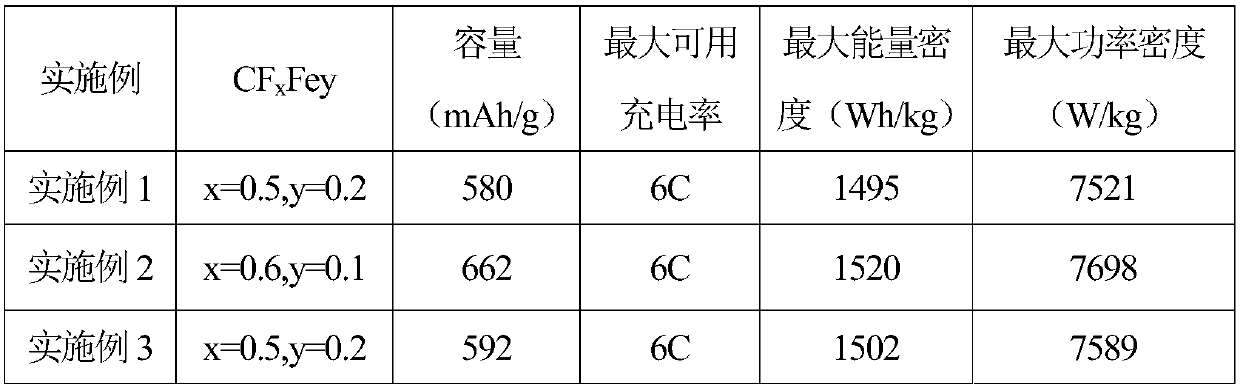

Method for preparing outer wall-fluorinated multi-walled carbon nanotube containing iron fluoride intercalated substance

ActiveCN107634224AGuaranteed electrical conductivityIncrease the output voltageCell electrodesLi-accumulatorsHydrogen fluorideCarbon nanotube

The invention belongs to the field of preparation of functional materials, and especially relates to a method for preparing an outer wall-fluorinated multi-walled carbon nanotube containing an iron fluoride intercalated substance. The problems of too low electric conductivity and volume expansion of multi-walled carbon nanotubes with the polarization in the charge and discharge process are solved.The end caps of a multi-walled carbon nanotube are opened, the multi-walled carbon nanotube is purified, iron fluoride is used to carry out intercalation in a heating reactor which can be vacuumized,hydrogen fluoride is sued to convert the iron chloride into iron fluoride, and fluorine gas is used to properly fluorinate the multi-walled carbon nanotube in order to finally form a compounded multi-walled carbon nanotube with the outer wall being fluorinated to a certain degree, the interlayer being iron fluoride and the inner layer having a certain electric conductivity. The method enables theabove material to provide a high output voltage and a theoretical specific capacity through the outer wall fluorination and the iron fluoride interlayer, and keeps the electric conductive of the inner wall of the material as possible, so the material is suitable for being used as a novel lithium battery positive electrode material.

Owner:LIAONING LANJING TECH CO LTD

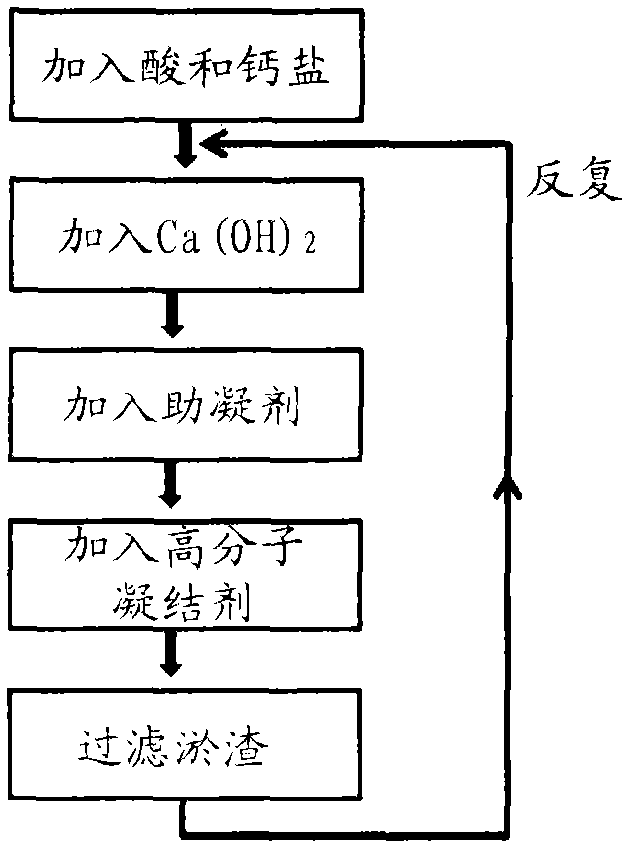

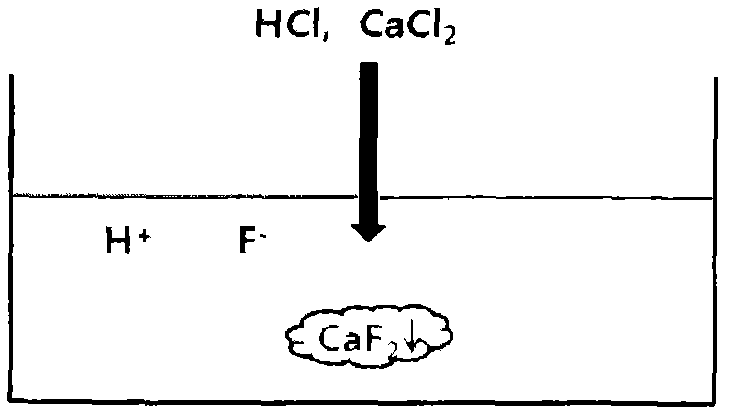

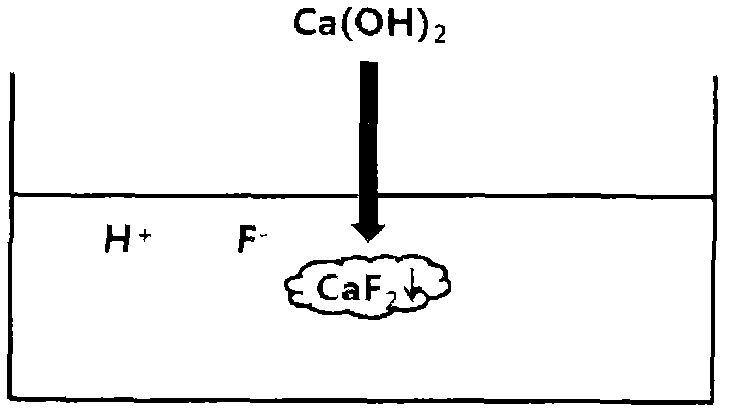

Hydrofluoric acid wastewater treatment method

InactiveCN103159342AReduce concentrationEasy to manufactureWater treatment parameter controlWater contaminantsIron fluorideCalcium EDTA

The invention relates to a hydrofluoric acid wastewater treatment method for treating wastewater after etching glass substrates. According to the invention, acid, calcium salt and calcium hydroxide are added to the wastewater in order to deposit fluoride ions and form calcium fluoride deposit. Coagulant aids containing salt and aluminum salt are added together with acid to form iron fluoride and aluminum fluoride deposit, and the result solution is naturalized. Polymer coagulant aids are added to form slug and the result solution is filtered to reduces the concentration of fluoride ion in the wastewater to a few hundredth. The method is environmental friendly and lowers wastewater treatment cost.

Owner:NOVA TECH INC

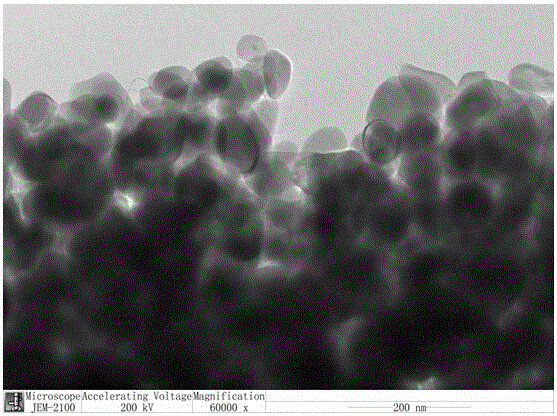

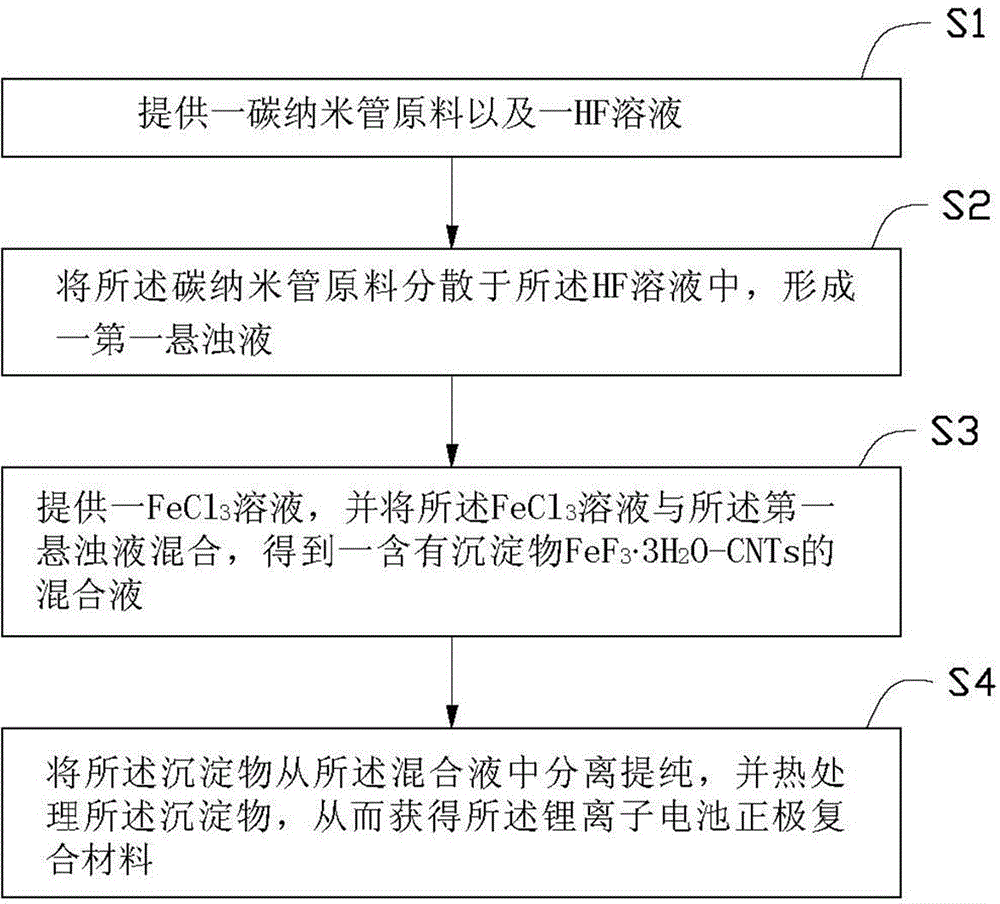

Lithium ion battery anode composite material and its preparation method

InactiveCN103560231AImprove conductivityImprove discharge capacityCell electrodesSecondary cellsIron fluorideNanotube

The invention relates to a lithium ion battery anode composite material, which comprises a plurality of iron fluoride particles and a plurality of carbon nanotubes. The plurality of iron fluoride particles and the plurality of carbon nanotubes form a three-dimensional conductive network, wherein the plurality of carbon nanotubes are uniformly dispersed among the plurality of iron fluoride particles, and at least parts of the iron fluoride particles are connected through the carbon nanotubes. The invention also provides a preparation method of the anode composite material. The method comprises the steps of: providing a carbon nanotube raw material and an HF solution; dispersing the carbon nanotube raw material in the HF solution to form a first suspension solution; providing an FeCl3 solution, and mixing the FeCl3 solution with the first suspension solution to obtain a precipitate FeF3.3H2O-CNTs; and subjecting the precipitate to separation and purification, and carrying out heat treatment on the precipitate, thereby obtaining the lithium ion battery anode composite material.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

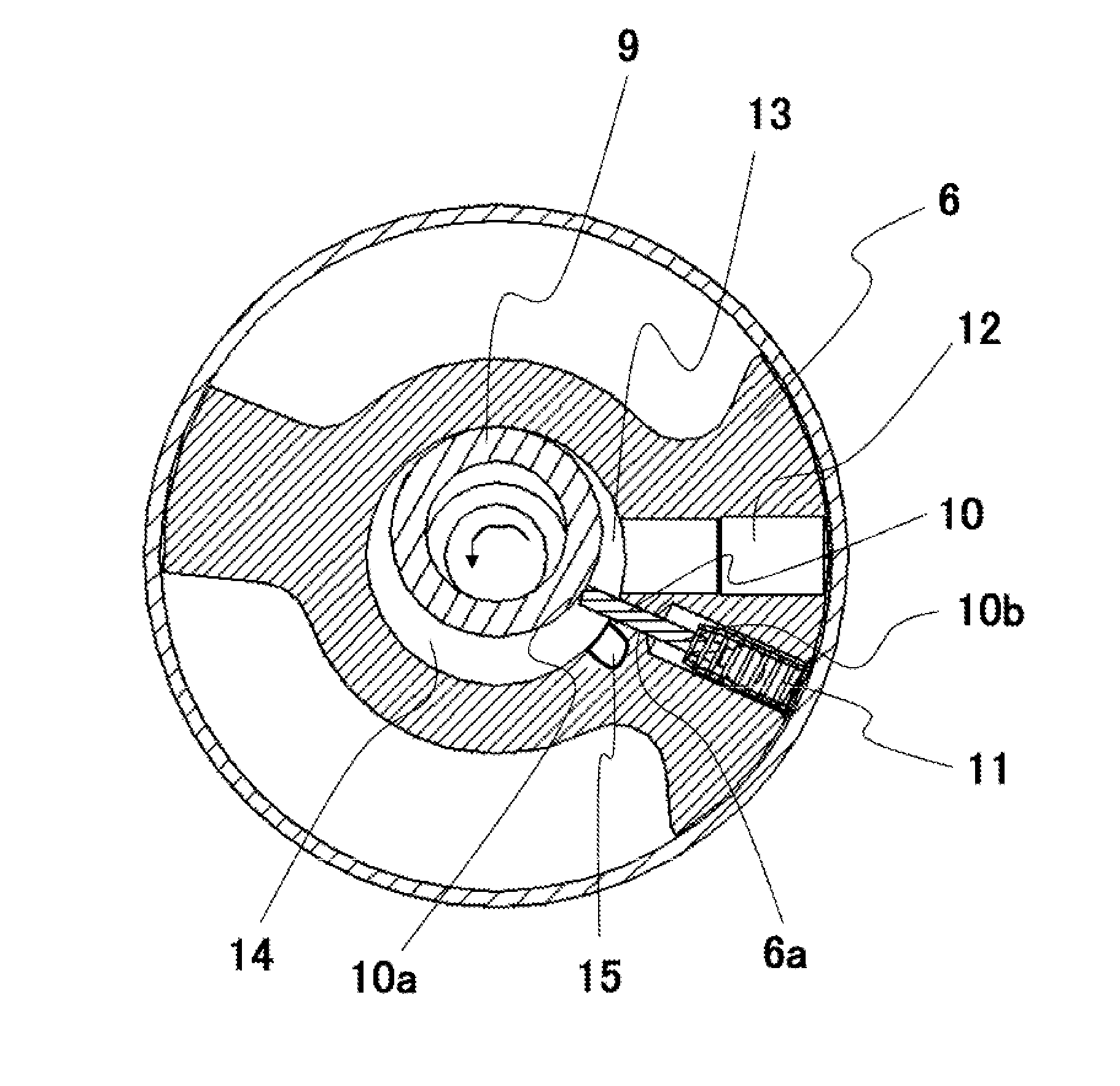

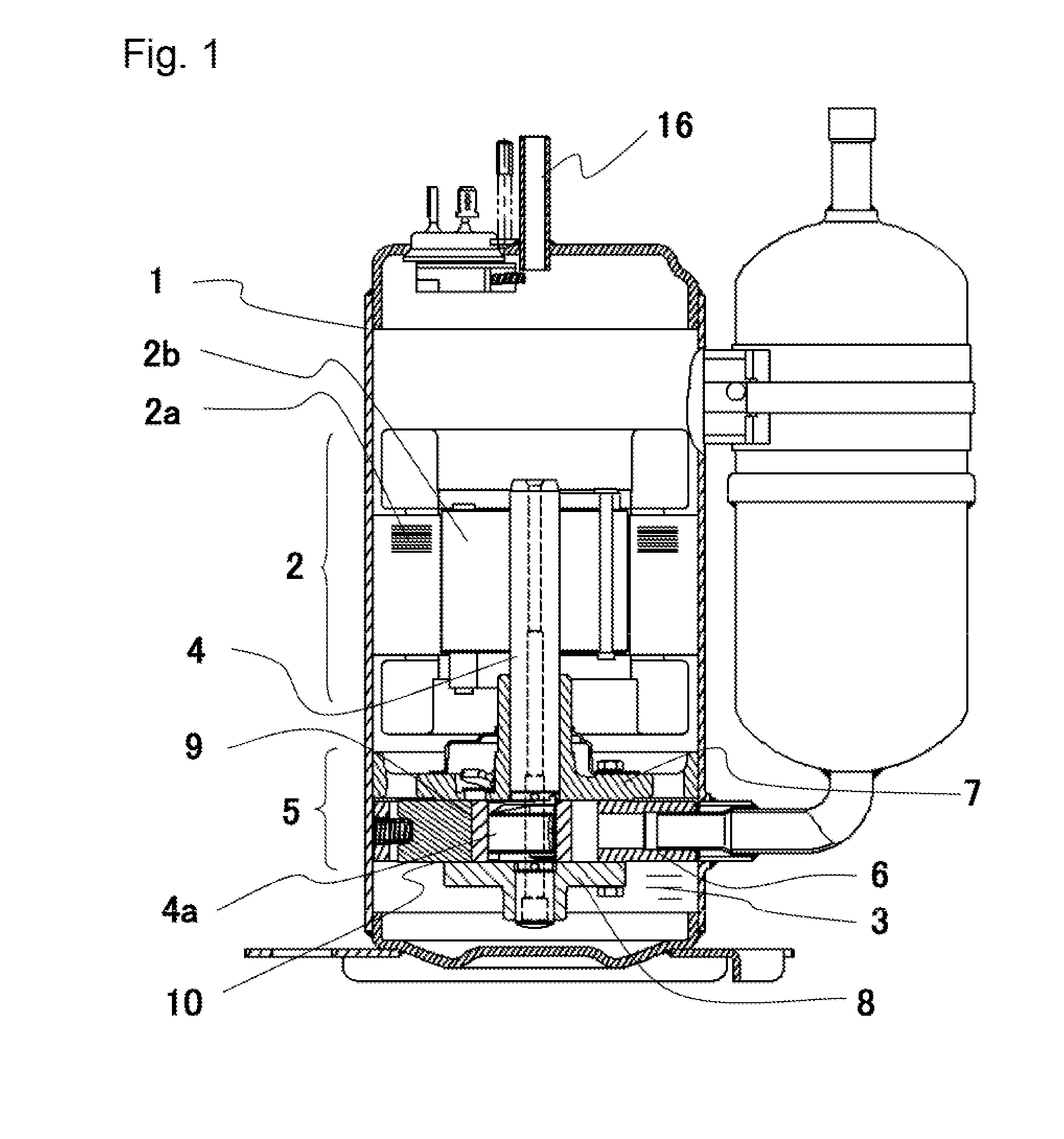

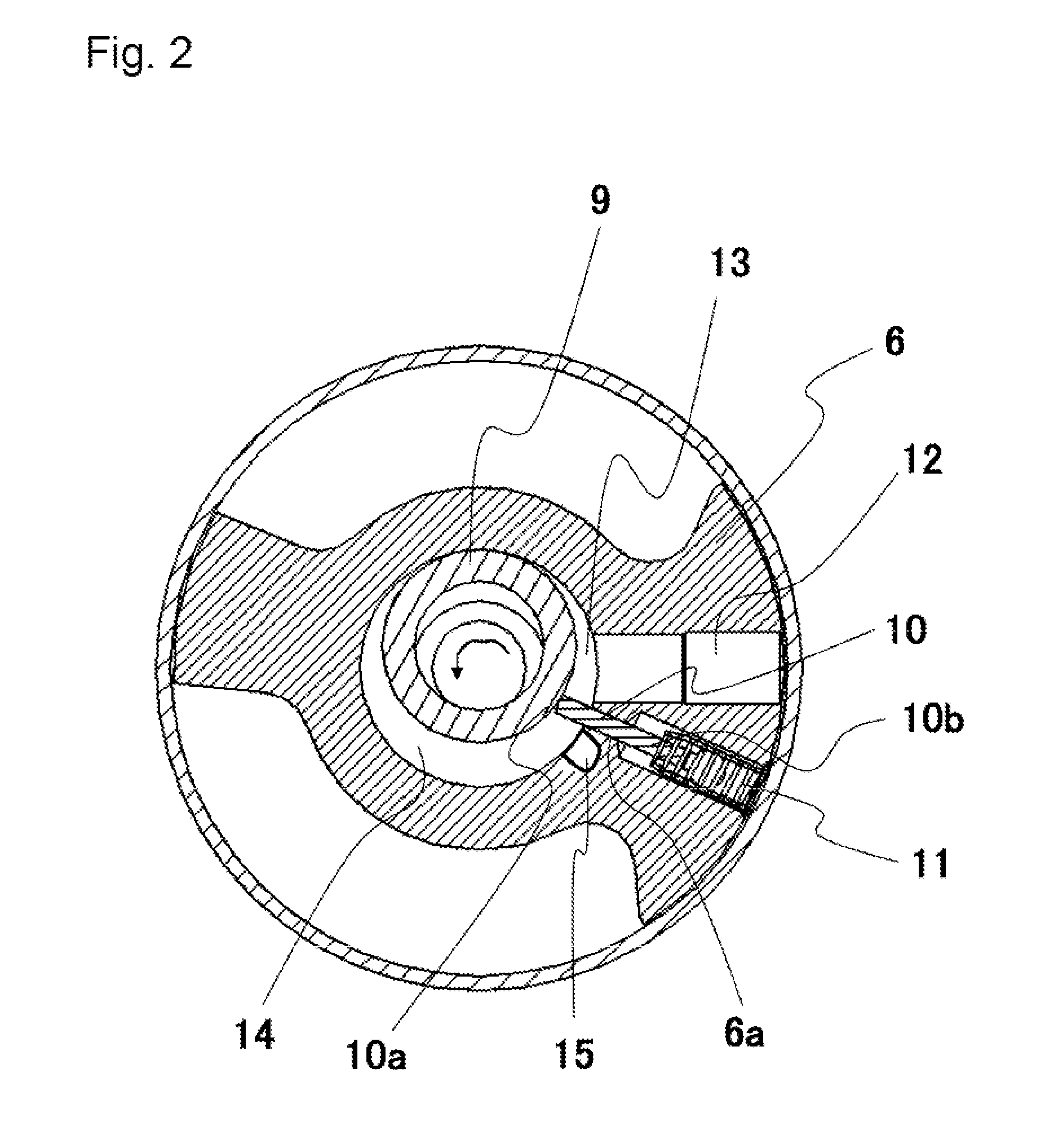

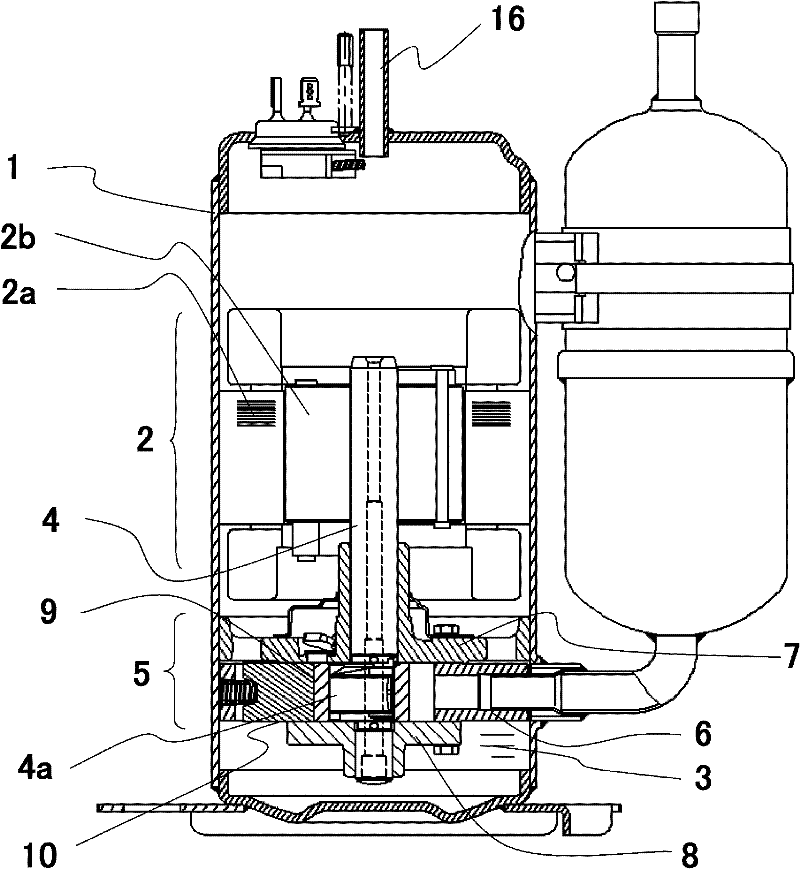

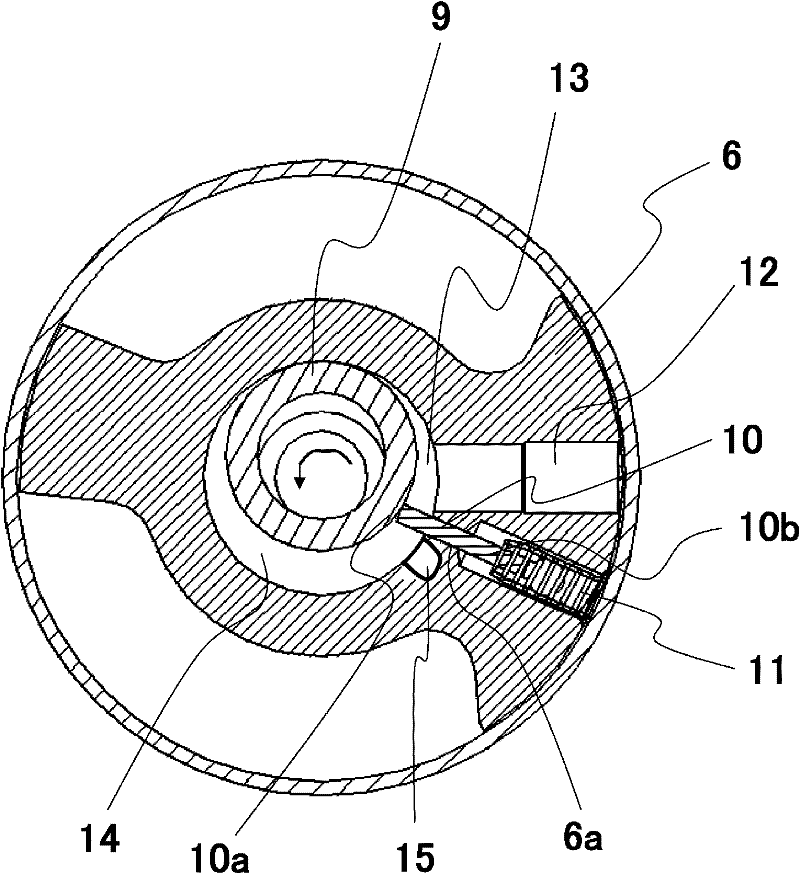

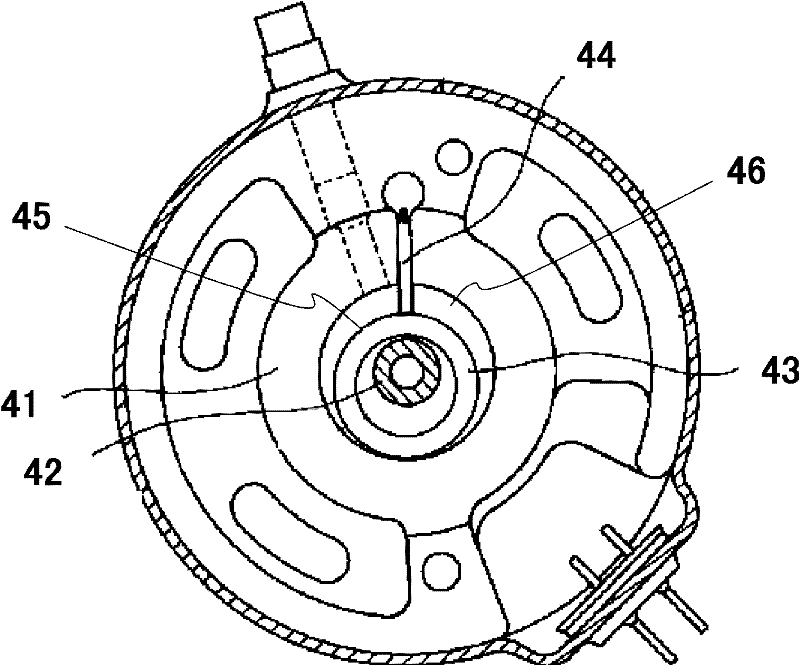

Rotary compressor

InactiveUS20120128519A1Avoid wear and tearImprove reliabilityRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDecompositionEngineering

It was found that a refrigerant mainly containing a carbon-carbon double bond-containing hydrofluoroolefin has a function to suppress abrasive wear, compared to conventional HFC-based refrigerants, because the hydrofluoroolefin generates iron fluoride especially on the surface of the vane and piston, where sliding force is severe, from hydrogen fluoride, even if it is generated in reaction with water and oxygen. It is possible to reduce abrasive wear, by using a refrigerant containing as the base component a hydrofluoroolefin as operating refrigerant and a refrigeration oil 3 miscible with the refrigerant and a vane 10 made of a high-speed tool steel and sintered and quenched, because hydrogen fluoride generated by decomposition of the refrigerant in the region of a vane tip region 10a and a piston 9 peripheral surface, where sliding force is severe is converted to iron fluoride. It is also possible to obtain a hardened structure containing carbides of W, Mo, Cr and V dispersed in a fine martensite matrix and produces the rotary compressor more cost-effectively by quenching and sintering the vane 10.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Process for preparing 2,3,3,3-tetrafluoropropene

ActiveUS20110178344A1High catalytic activityPrevent degradationPreparation by hydrogen halide split-offPreparation by halogen halide additionGas phaseIron fluoride

The present invention provides a process for producing 2,3,3,3-tetrafluoropropene represented by the formula CF3CF═CH2, comprising contacting a fluorine-containing propane represented by the formula CF2XCFYCH2Z, wherein X is Cl, Br, or I; one of Y and Z is H, and the other is F, Cl, Br, or I, with at least one catalyst selected from the group consisting of chromium oxides, fluorinated chromium oxides, and iron fluorides in a gas phase. According to the process of the invention, 2,3,3,3-tetrafluoropropene can be easily produced under economically advantageous conditions.

Owner:DAIKIN IND LTD

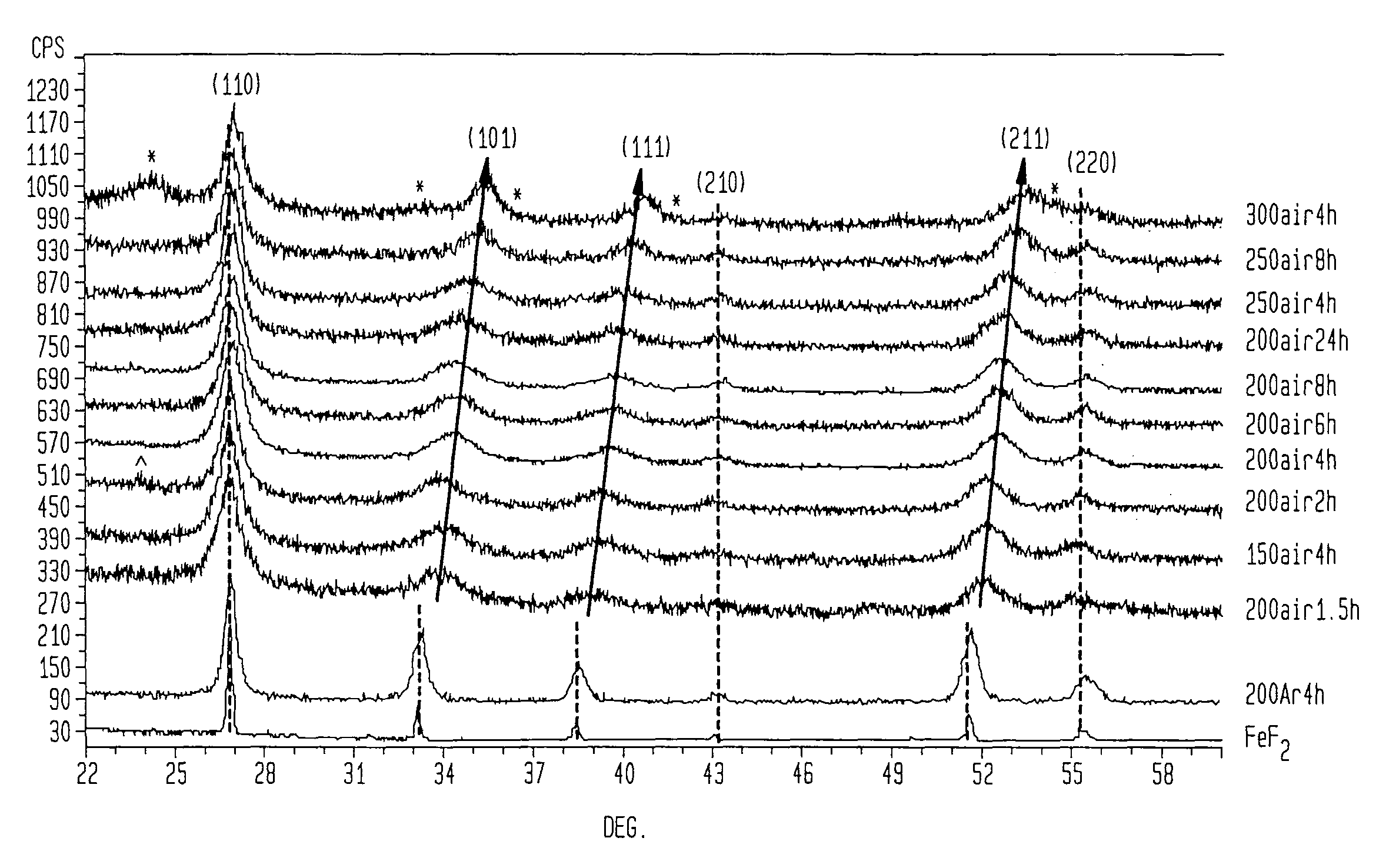

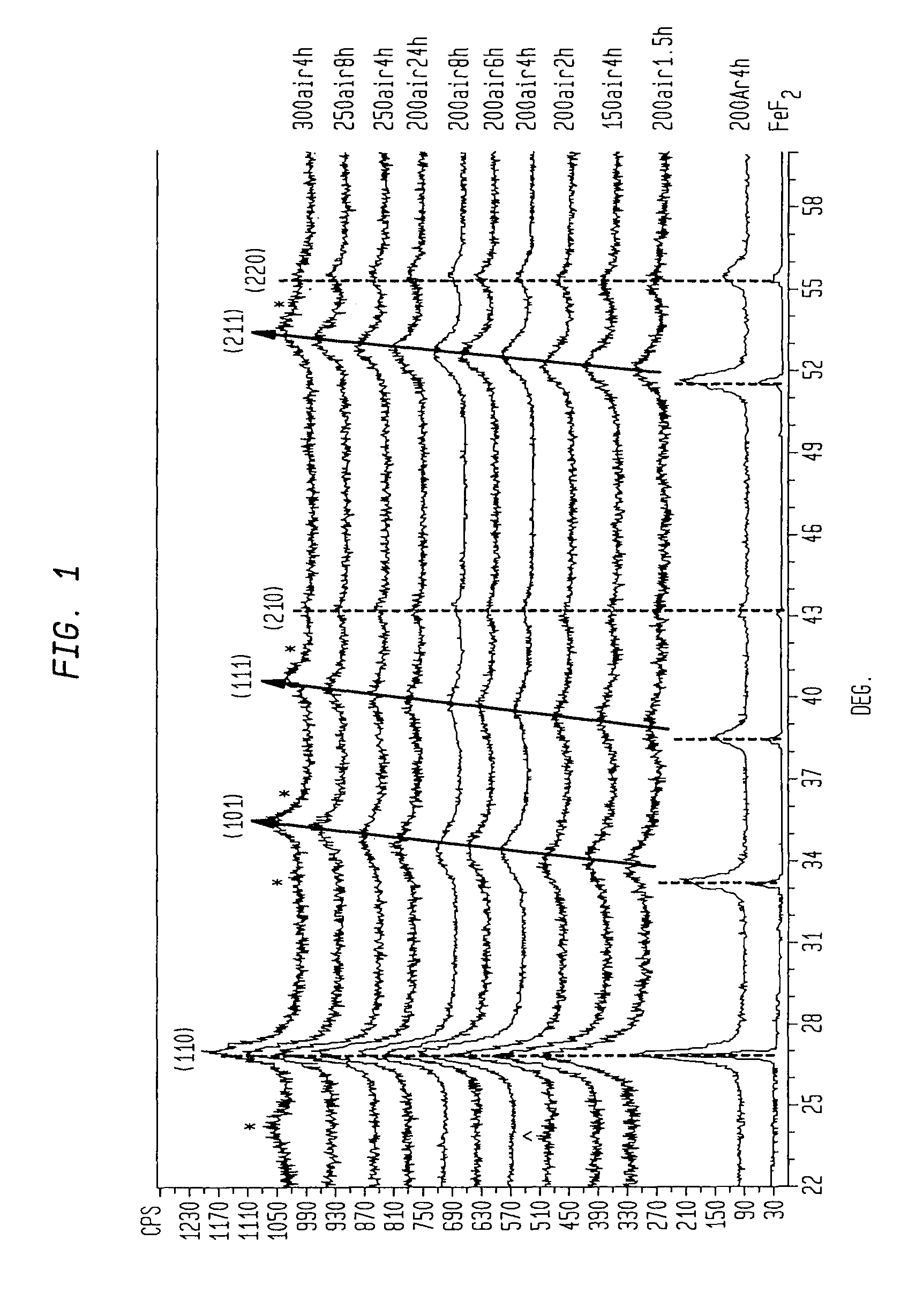

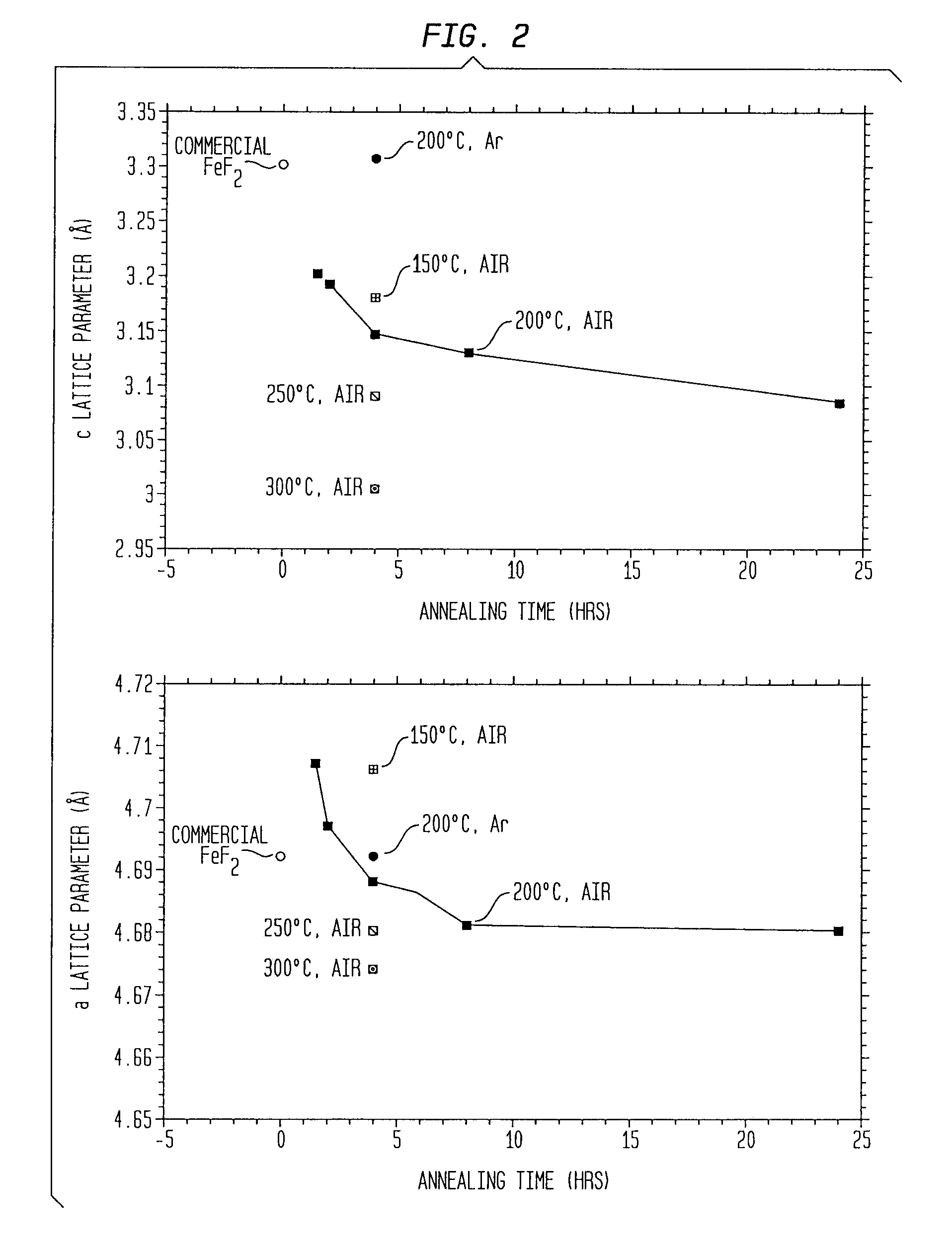

Iron oxyfluoride electrodes for electrochemical energy storage

Owner:RUTGERS THE STATE UNIV

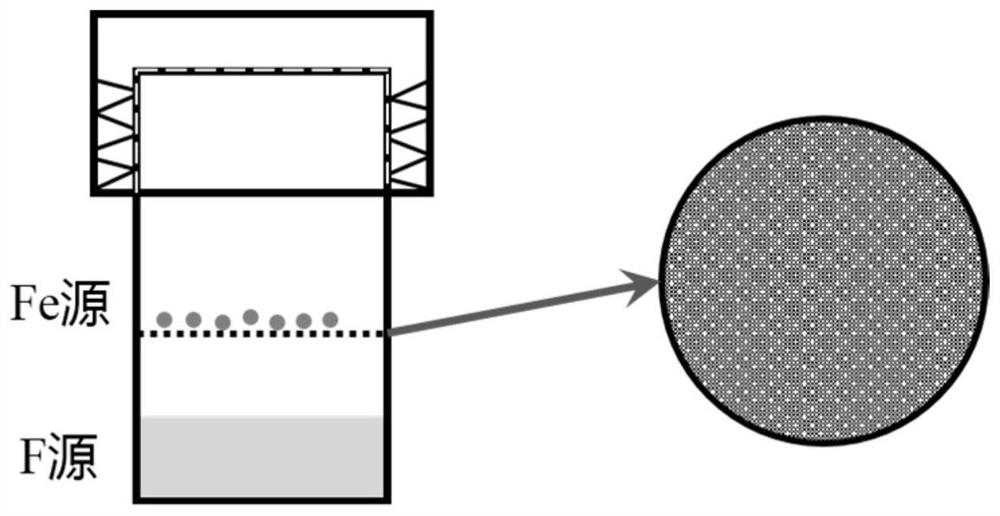

Iron fluoride/carbon composite positive electrode material, preparation method thereof and lithium ion battery

InactiveCN112701286AIn situ recombinationSmooth releaseSecondary cellsPositive electrodesCarbon compositesPhysical chemistry

The invention discloses an iron fluoride / carbon composite positive electrode material, a preparation method thereof and a lithium ion battery. The method comprises the following steps of: (1) reacting steam of a fluorine source and steam of a carbon-containing organic matter with an iron source to prepare a precursor; and (2) carrying out heat treatment on the precursor to obtain the iron fluoride / carbon composite positive electrode material. A fluorine source and a carbon source are introduced through gas-phase reaction, the powder morphology is controlled, and the high-performance iron fluoride positive electrode material is obtained. The lithium ion battery positive electrode material provided by the invention has the advantages of high reversible specific capacity and good cycling stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Process for preparing 2,3,3,3-tetrafluoropropene

ActiveUS8344191B2High catalytic activityPrevent degradationPreparation by hydrogen halide split-offPreparation by halogen halide additionGas phaseIron fluoride

Owner:DAIKIN IND LTD

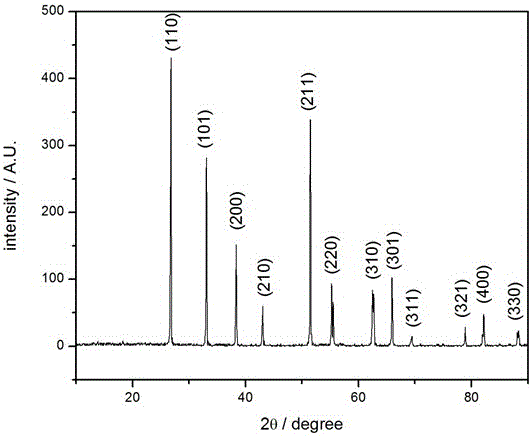

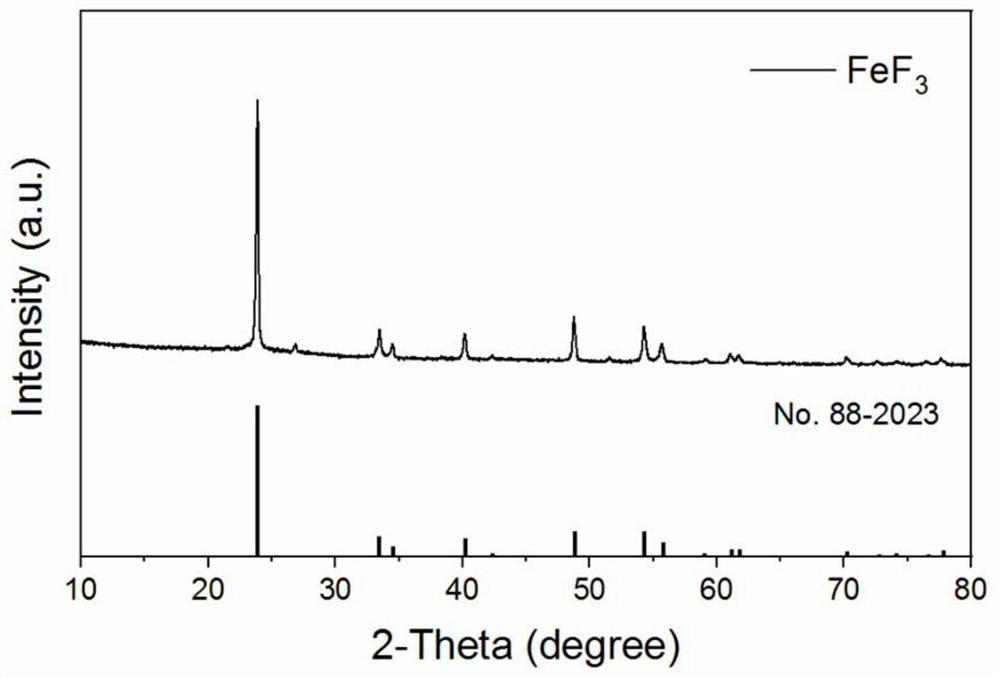

Nanometer FeF3/C composite positive electrode material, preparation method thereof and lithium ion battery

InactiveCN112803021AStable structureImproved magnification performanceMaterial nanotechnologySecondary cellsTrifluorideIron fluoride

The invention discloses a nanometer FeF3 / C composite positive electrode material, a preparation method thereof and a lithium ion battery. The method comprises the following steps: (1) putting reaction raw materials into a reaction kettle, filling the reaction kettle with protective gas, and sealing; wherein the reaction raw materials comprise an iron source and polytetrafluoroethylene; and (2) carrying out heat treatment on the sealed reaction kettle at the temperature of more than or equal to 400 DEG C to obtain the nano FeF3 / C composite positive electrode material. According to the invention, the property of sublimation of polytetrafluoroethylene at low temperature is utilized, and an iron source and a fluorine source are fully reacted by using a closed reaction kettle; the used polytetrafluoroethylene can provide a fluorine source and can be cracked to obtain the iron trifluoride composite positive electrode material with superfine nano-particles at the same time. The lithium ion battery positive electrode material provided by the invention has the advantages of high reversible specific capacity, excellent rate capability and good cycling stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

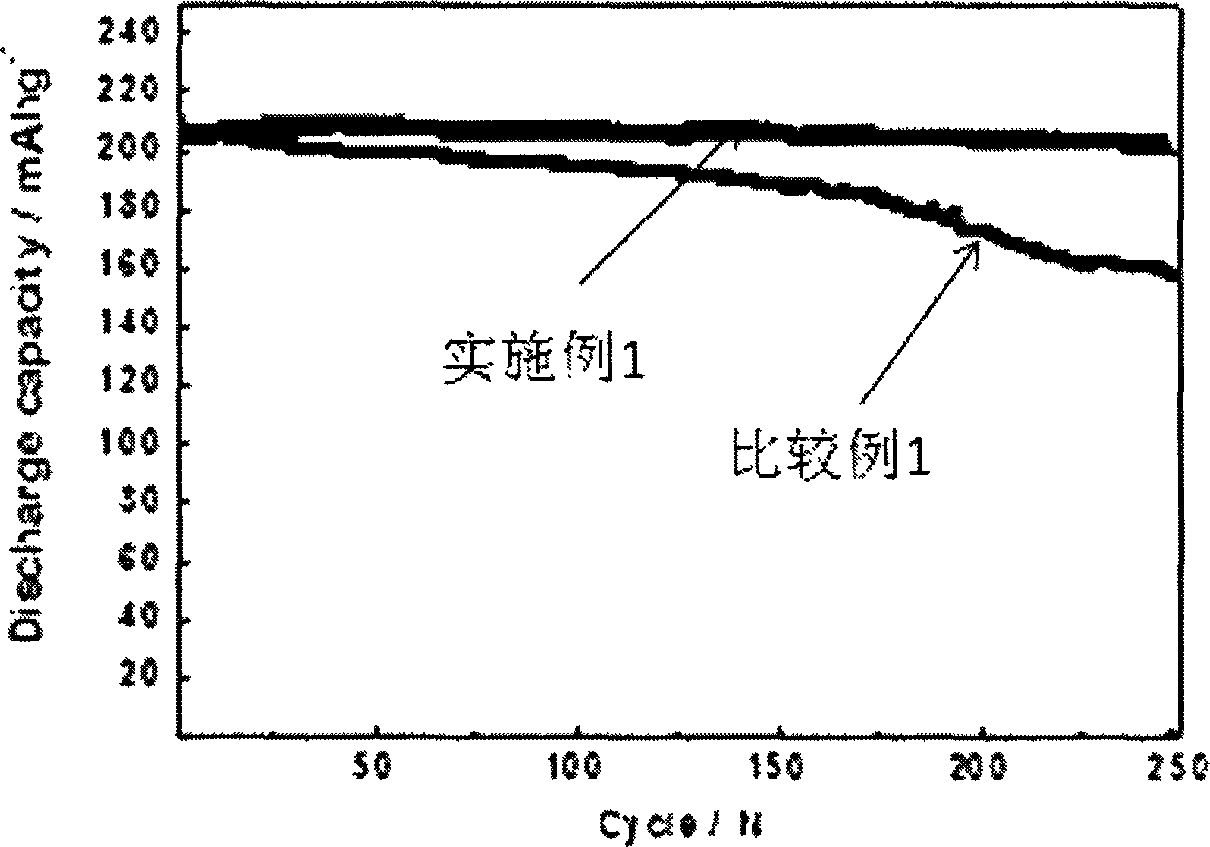

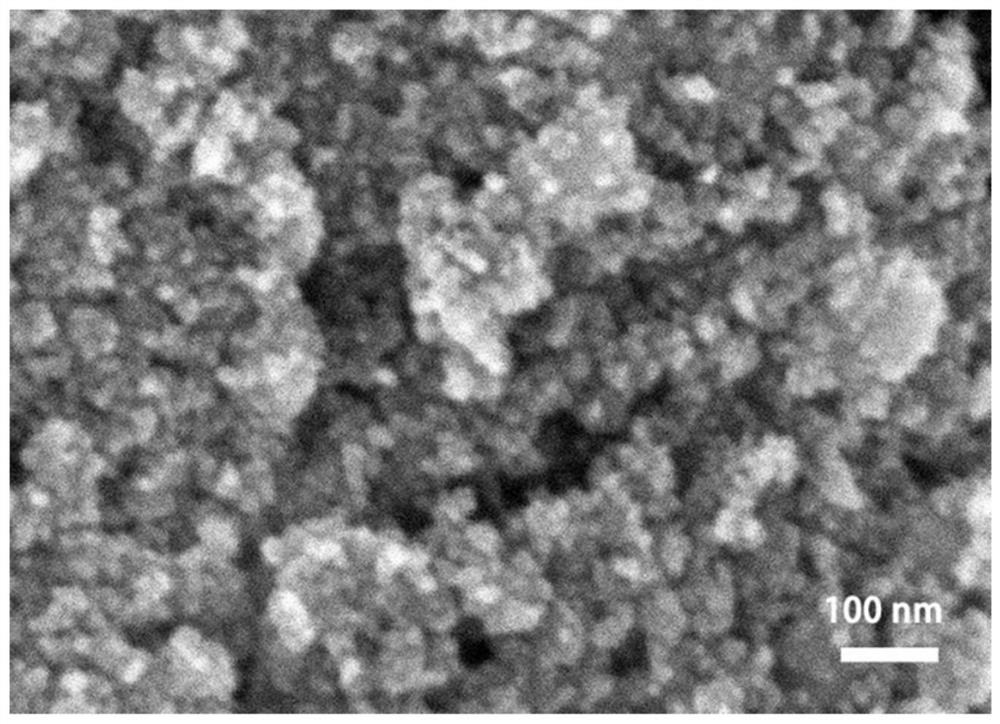

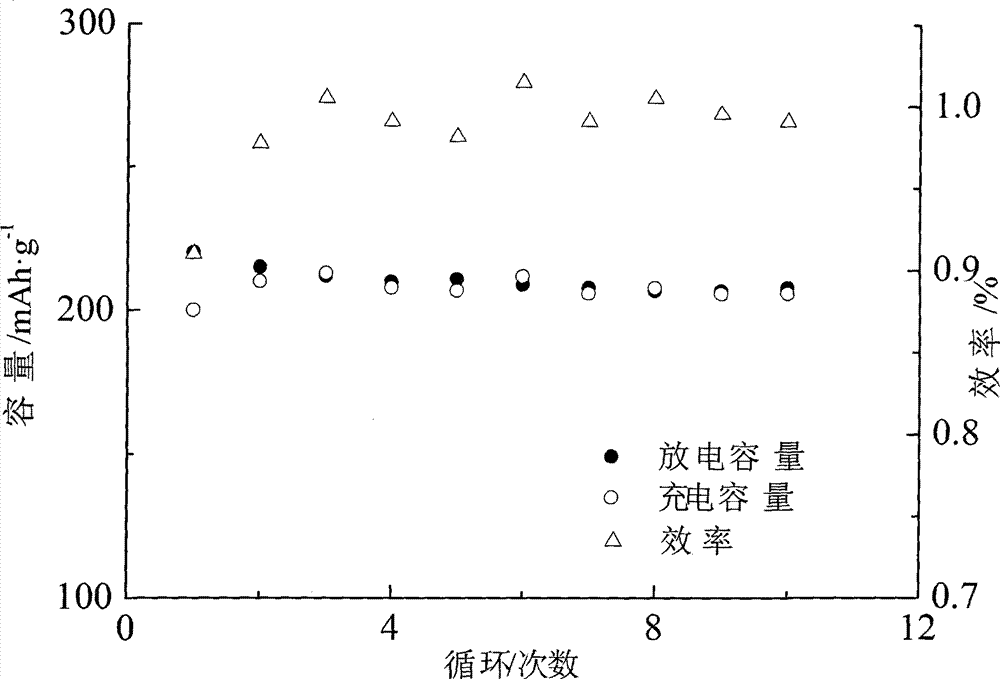

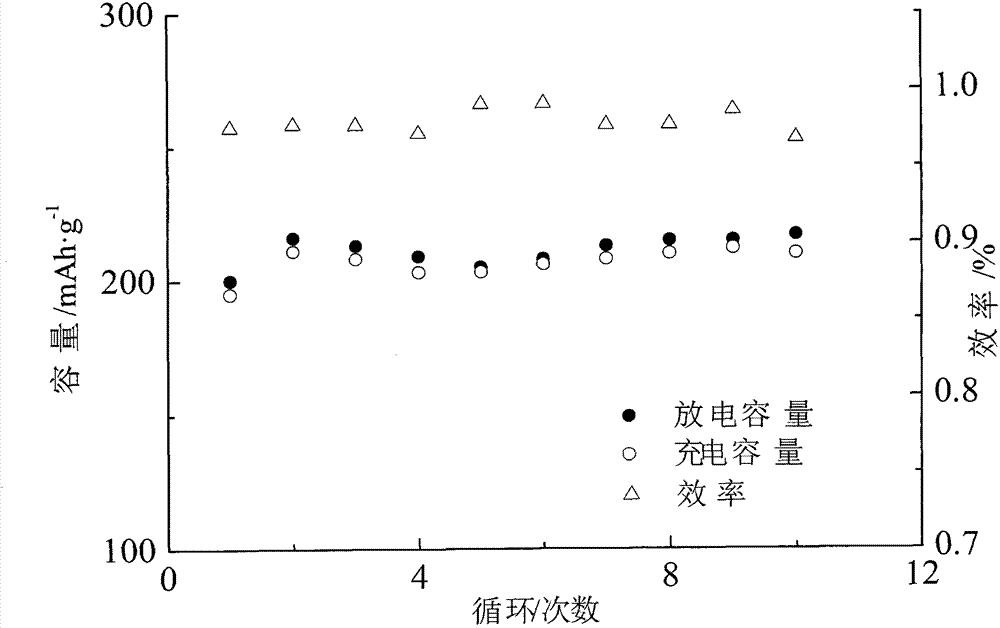

Iron lithium fluoride battery anode material prepared by nitrogen-doped silicon carbide-assisted solid phase one-step process and preparation method

ActiveCN103500830AHigh hardnessGood rate characteristicsCell electrodesSecondary cellsIron saltsHigh energy

The invention discloses an iron lithium fluoride battery anode material prepared by a nitrogen-doped silicon carbide-assisted solid phase one-step process and a preparation method. The preparation method is characterized in that nitrogen-doped silicon carbide is adopted as a ball milling auxiliary, a conductive agent and a surface modifier at the same time in a preparation process; after the ball milling of a certain period of time and thermal treatment by a high-energy ball mill, the raw material is directly supplied to a battery production enterprise for coating production, thereby greatly reducing the intermediate steps, lowering the production cost and avoiding any waste liquid; the prepared FeF3 anode material has a stable capacity over 200mAh.g<-1> and a good multiplying power feature; iron salt containing crystal water and ammonium fluoride at a molar ratio of 1.0:(3.0-3.6), 3-15% of nitrogen-doped silicon carbide by weight and 0.5-3.0% of auxiliary by weight are subjected to normal-temperature ball milling for 5-20 hours under the atmosphere protection in the high-energy ball mill; then the material is taken out and heated to 300-450 DEG C under the protection of the mixed gas of 5% of hydrogen and 95% of argon, and the temperature is kept for 2-10 hours before cooling to obtain the FeF3 anode material which can be directly applied to slurry coating.

Owner:沛县度创科技发展有限公司

Cu<2+>, Ce<4+>, Ag<+> doped iron fluoride composite positive pole material and preparation method thereof

ActiveCN104150543AHigh specific capacityImprove electrochemical performanceCell electrodesIron halidesHigh energyActivation energy

The invention relates to a Cu<2+>, Ce<4+>, Ag<+> doping modified iron fluoride positive pole material and a preparation method thereof. The method comprises the following step: performing ball milling on copper salt, cerium salt, silver salt and synthesis raw materials in a high-energy ball mill for a certain time, and performing heat treatment to obtain the FeF3 positive pole material. The Cu<2+> partially occupies iron ions of FeF3 for coordination, thereby being beneficial to increase the discharge potential and improve the energy density; the high-valence Ce<4+> is doped, thereby being beneficial to increase the specific capacity of the material; and the Ag<2+> is doped, thereby reducing the conversion reaction activation energy during charge. Thus, the invention is beneficial to improve the rate characteristic and energy density, thereby improving the comprehensive electrochemical property of the material.

Owner:山东格新精工有限公司

Preparation method of graphene-ferric fluoride composite positive electrode material

InactiveCN107591524AIncrease capacityImprove cycle stabilityCell electrodesDoped grapheneIron fluoride

The invention discloses a preparation method of a graphene-ferric fluoride composite positive electrode material and relates to a preparation method of a graphene-ferric fluoride composite positive electrode material. A ferric fluoride material with high discharge capacity is subjected to cobalt-doping modification to improve the conductivity thereof, and then is compounded with a silicon-doped graphene material with good conductivity and stability. The preparation method specifically comprises the following steps of (1) preparing a silicon-doped graphite mixture; (2) preparing cobalt-doped ferric fluoride powder; and (3) carrying out ball-milling mixing on the cobalt-doped ferric fluoride powder and the silicon-doped graphite and then carrying out thermal treatment to obtain a product. According to the prepared graphene-ferric fluoride composite positive electrode material for a lithium-ion battery, the lithium-ion battery has the characteristics of high capacity and high cycling stability, and has relatively high capacity and relatively long service life.

Owner:南通德诺尔石墨设备有限公司

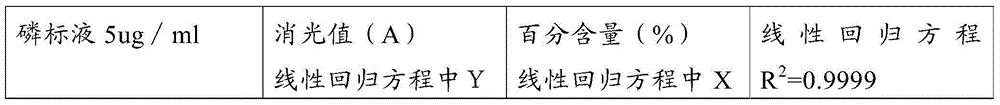

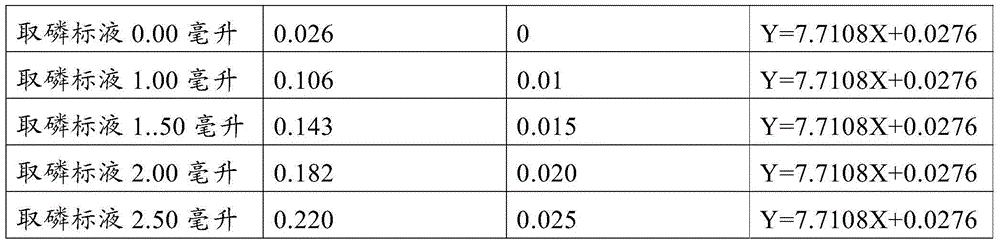

Method for measuring phosphorus in silicon iron by using photometric method

InactiveCN104458623AExtended service lifeLow costColor/spectral properties measurementsIron fluorideAbsorbance

The invention relates to a method for measuring phosphorus in silicon iron by using a photometric method. The method comprises a control experiment and a sample determination experiment, wherein the control experiment comprises the following steps: taking phosphorus standard solutions with same concentration and gradient volume respectively, adding the phosphorus standard solutions into a beaker in which quantitative pure iron powder and quantitative pure aluminum foil or pure aluminum powder are added in advance, dissolving a to-be-measured sample by adopting nitric acid and hydrofluoric acid, oxidizing to orthophosphoric acid by using perchloric acid with smoke emission until hydrofluoric acid is cleaned and dried, transferring into a beaker in tall form, adding nitric acid immediately, adding sodium nitrite until a brown precipitate disappears, boiling for 10 seconds, adding ammonium molybdate and tartaric acid, shaking, adding iron fluoride, and reducing into phosphomolybdenum blue by using stannous chloride, measuring absorbance respectively at 680nm in a spectrophotometer by taking water as a reference, and drawing a working curve or calculating a regression equation; and the sample determination experiment comprises the following steps: performing the same experimental steps in the beaker, then measuring the absorbance at 680nm in the spectrophotometer, and contrasting to obtain the phosphorus content by comparing with the working curve or the regression equation of the control experiment.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Rotary vane compressor with hydrofluoroolefin refrigerant gas and high speed tool steel vane

InactiveCN102472282AImprove reliabilityAvoid wear and tearRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsDecompositionEngineering

A2 refrigerant mainly containing a carbon-carbon double bond-containing hydrofluoroolefin has a function to suppress abrasive wear, compared to conventional HFC-based refrigerants, because the hydrofluoroolefin generates iron fluoride especially on the surface of the vane and piston, where sliding force is severe, from hydrogen fluoride, even if it is generated in reaction with water and oxygen. It is possible to reduce abrasive wear, by using a refrigerant containing as the base component a hydrofluoroolefin as operating refrigerant and a refrigeration oil 3 miscible with the refrigerant and a vane 10 made of a high-speed tool steel and sintered and quenched, because hydrogen fluoride generated by decomposition of the refrigerant in the region of a vane tip region 10a and a piston 9 peripheral surface, where sliding force is severe is converted to iron fluoride. It is also possible to obtain a hardened structure containing carbides of W, Mo, Cr and V dispersed in a fine martensite matrix and produces the rotary compressor more cost-effectively by quenching and sintering the vane 10.

Owner:PANASONIC CORP

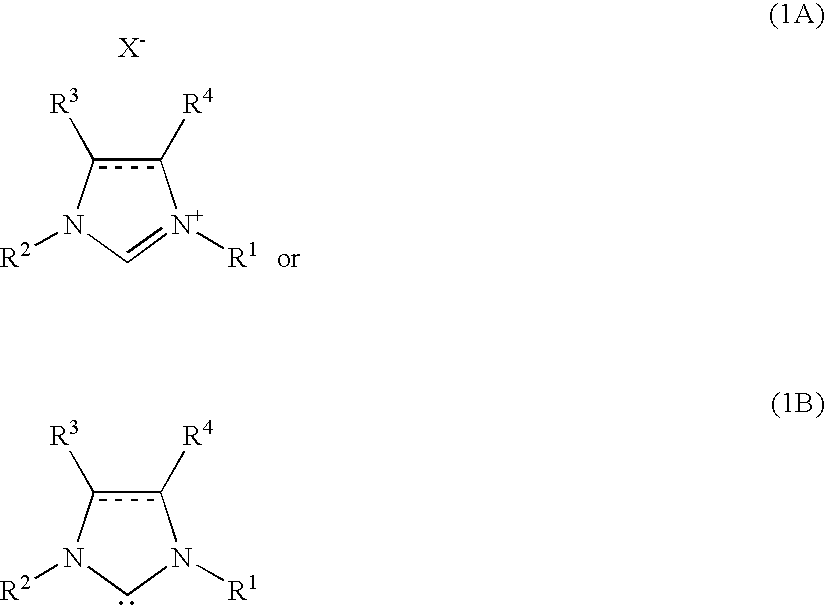

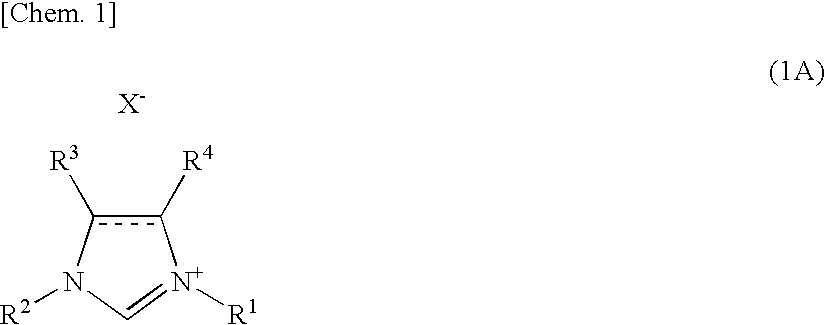

Catalyst composition, and process for production of cross-coupling compound using the same

InactiveUS20100094018A1High yieldLow costAmino preparation from aminesOrganic compound preparationNitrogenous heterocyclic compoundDouble bond

The invention provides a catalyst composition for use in a cross-coupling reaction containing an iron or cobalt fluoride and a nitrogen-containing heterocyclic ring compound represented by General Formula (1A) or (1B),wherein R1 and R2 are same or different, and represent substituted or unsubstituted aryl group etc.; and R3 and R4 are same or different, and represent hydrogen etc., represents a single bond or a double bond, and X− represents a monovalent anion. The invention also provides a method for producing a cross-coupling compound by reacting an organic magnesium compound with an organic halogen compound in the presence of the catalyst composition.

Owner:KYOTO UNIV +1

Carboxyl carbon, titanate and doped titanium lithium phosphate three-component surface modified iron fluoride cathode material and preparation method thereof

ActiveCN103490068AClose contactImprove ionic conductivityCell electrodesSecondary cellsElectrical conductorHigh energy

The invention discloses a carboxyl carbon, titanate and doped titanium lithium phosphate three-component surface modified iron fluoride cathode material and a preparation method thereof. The preparation method is characterized by comprising the following steps: ball-milling carboxyl carbon, titanate and silicon / aluminum-doped titanium lithium phosphate Li1.3Al0.1Ti1.9Si0.2P2.8O12 as well as a synthetic raw material in a high-energy ball mill for a period of time, and carrying out heat treatment to obtain the FeF3 cathode material. Carboxyl carbon coordinates with FeF3 iron ions through carboxyl to form firm bonding; carboxyl carbon is a good electron conductor and is helpful for forming a complete conductive link; Li1.3Al0.1Ti1.9Si0.2P2.8O12 is a good lithium ion conductor; a complete lithium ion conductive link is formed for guaranteeing Li1.3Al0.1Ti1.9Si0.2P2.8O12 to be closely contacted with the FeF3 material through lone pair electrons; the electron conductor-carboxyl carbon and the lithium ion conductor-Li1.3Al0.1Ti1.9Si0.2P2.8O12 are bonded on the FeF3 particle surface by coordinating and bonding reactive groups-fluorine ions of titanate with titanium ions, hydrolyzing alkoxy into hydroxy and bonding hydroxy with Li1.3Al0.1Ti1.9Si0.2P2.8O12, so that a complete electron and ion conductive link is formed, the ion conductivity and the electron conductivity of the FeF3 material are greatly improved, and the electrochemical performance of the material is improved.

Owner:沛县度创科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com