Preparation method of high-capacity fluoride/porous carbon composite positive electrode material

A technology of porous carbon material and positive electrode material, which is applied in the field of preparation of high-capacity composite positive electrode material, can solve the problems of limited improvement of electrochemical performance, poor long-term cycle stability, easy particle agglomeration, etc. Excellent performance and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Include the following steps:

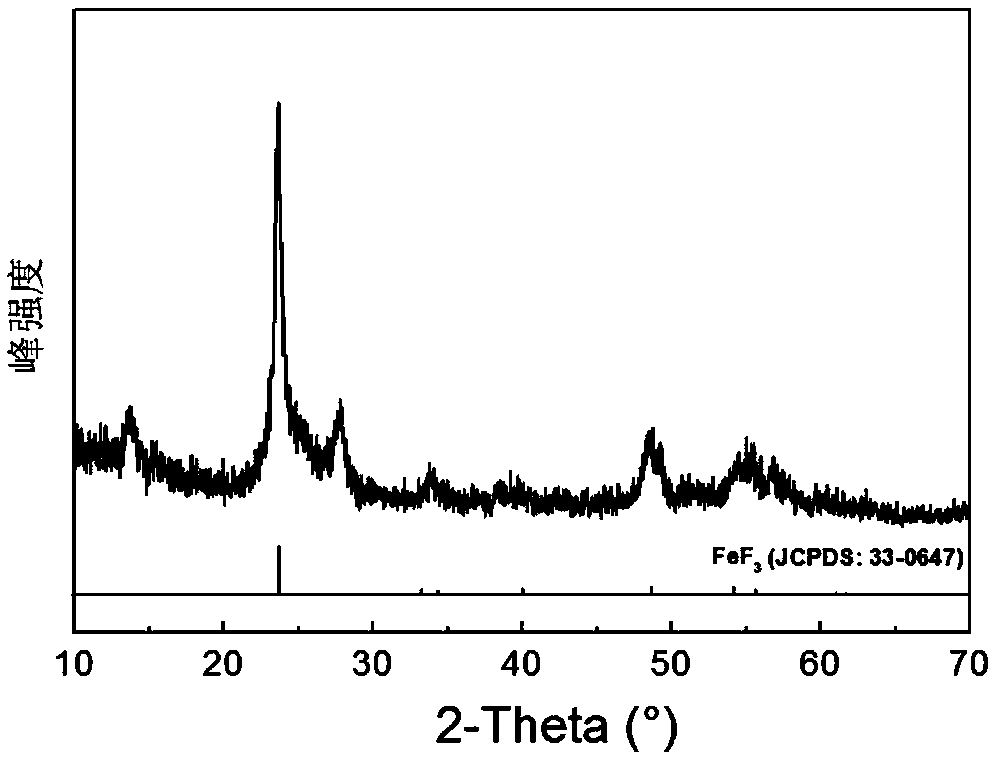

[0060] (1) 3g of anhydrous ferric fluoride (its particle size is 20 microns) and 1g of porous carbon fiber (the specific surface area of porous carbon fiber is 700m 2 / g, the average pore diameter is 5nm) placed in absolute ethanol, it was fully mixed through ultrasonic treatment for 8 hours, then filtered and dried to obtain the ferric fluoride / porous carbon composite precursor ( figure 1 , 2 );

[0061] (2) Disperse the precursor evenly and evenly at the bottom of the small beaker for one "spray-vacuum-dry" treatment, in which the amount of each spray is 2mL, and the volume ratio of water / ethanol in water is 1:1. Place in a sealed suction filter bottle with a vacuum of -0.1MPa for 5 minutes, the drying temperature during the treatment is 120°C, and the drying time is 2 hours;

[0062] (3) Place the product obtained after the "spray-vacuum-dry" treatment at 120°C for 60 hours for final dehydration treatment, and finally obtain nano-f...

Embodiment 2

[0065] The preparation method is the same as in Example 1, except that the quality of anhydrous ferric fluoride and porous carbon in the step (1) of Example 1 is changed to 2g and 2g respectively, and the phase characterization shows that the resulting product is a nano-ferric fluoride / porous carbon fiber composite material , the size of ferric fluoride is about 5nm, which is distributed on the surface and in the pores of the porous carbon fiber. .

[0066] The prepared materials were prepared according to the method in Example 1 to make a positive electrode sheet of a lithium-ion battery, and a simulated battery was assembled. Under the current density of 200mA / g, the prepared battery completed the charge and discharge test with a charge and discharge interval of 2-4.5V. The first reversible specific capacity of the battery is 210mAh / g, and the reversible specific capacity after 200 cycles is 143mAh / g.

Embodiment 3

[0068] The preparation method is the same as in Example 1, except that the quality of anhydrous ferric fluoride and porous carbon fiber in the step (1) of Example 1 is changed to 4g and 1g respectively, and the phase characterization shows that the resulting product is a nano-ferric fluoride / porous carbon fiber composite material , the size of ferric fluoride is about 5nm, which is distributed on the surface and in the pores of the porous carbon fiber.

[0069] The prepared materials were prepared according to the method in Example 1 to make a positive electrode sheet of a lithium-ion battery, and a simulated battery was assembled. Under the current density of 200mA / g, the prepared battery completes the charge and discharge test in the charge and discharge range of 2-4.5V (theoretical specific capacity at this voltage is 237mAh / g). The initial reversible specific capacity of the battery is 266mAh / g, and the reversible specific capacity after 200 cycles is 207mAh / g (relative to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com