Nanometer FeF3/C composite positive electrode material, preparation method thereof and lithium ion battery

A composite positive electrode material and lithium-ion battery technology, applied in the field of energy storage materials, can solve the problems of reversible specific capacity, rate performance and cycle performance to be improved, and achieve in-situ coating, excellent rate performance and high uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a nano-FeF 3 / C composite cathode material and preparation method thereof, the preparation method comprising the following steps:

[0045] (1) Ferrocene and polytetrafluoroethylene are mixed evenly in a ratio of 1:3 according to the mol ratio of iron and fluorine;

[0046] (2) The resulting mixed powder is transferred to a closed reaction kettle, and the reaction kettle is filled with argon;

[0047] (3) Heat-treat the closed reaction vessel under an argon atmosphere, raise the temperature to 600°C for 1 hour at a rate of 5°C / min, and obtain FeF after cooling. 3 / C cathode material.

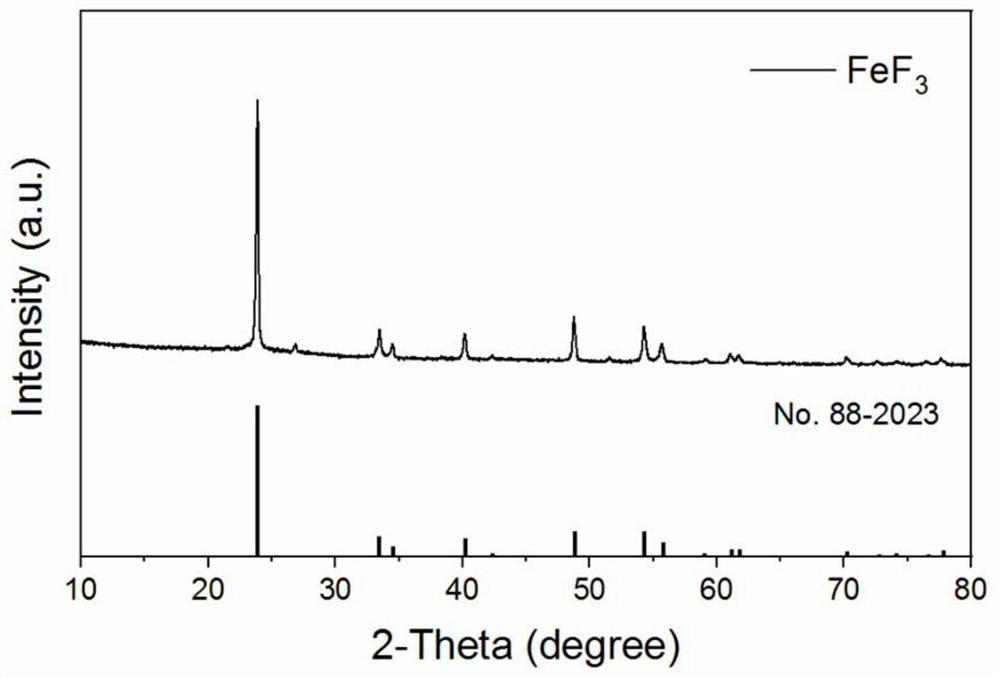

[0048] figure 1 It is the FeF prepared in this example 3 / C positive electrode material XRD pattern, as can be seen from the figure, the diffraction peaks of the prepared sample are consistent with the FeF 3 (PDF#88-2023) has a high degree of agreement with the standard spectrum, confirming that FeF has been successfully obtained 3 , and there is no impurity ...

Embodiment 2

[0052] This embodiment provides a nano-FeF 3 / C composite cathode material and preparation method thereof, the preparation method comprising the following steps:

[0053] (1) Ferrous chloride, polytetrafluoroethylene are mixed evenly according to the ratio of 1:6 according to the mol ratio of iron and fluorine;

[0054] (2) The resulting mixed powder is transferred to an airtight reactor, and the reactor is filled with nitrogen;

[0055] (3) Heat-treat the closed reactor in a nitrogen atmosphere, heat up to 900°C at a rate of 30°C / min for 0.5h, and obtain FeF after cooling. 3 / C cathode material.

[0056] The obtained positive electrode material was used as the lithium ion battery positive electrode material for electrochemical performance testing, and the ratio of the electrode sheet was positive electrode material: acetylene black: PTFE (mass ratio) = 90:5:5. A CR2025 button cell was prepared with a lithium sheet as a reference electrode. In the voltage window of 1.2-4.5...

Embodiment 3

[0058] This embodiment provides a nano-FeF 3 / C composite cathode material and preparation method thereof, the preparation method comprising the following steps:

[0059] (1) Ferrocene, ferrous chloride, and polytetrafluoroethylene are uniformly mixed in a ratio of 1:1 according to the mol ratio of iron and fluorine; wherein, the mol ratio of ferrocene and ferrous chloride is 1:1 .

[0060] (2) The resulting mixed powder is transferred to an airtight reactor, and the reactor is filled with helium;

[0061] (3) Heat-treat the closed reactor in a nitrogen atmosphere, raise the temperature to 400°C for 12 hours at a rate of 1°C / min, and obtain FeF after cooling. 3 / C cathode material.

[0062] The obtained positive electrode material was used as the lithium ion battery positive electrode material for electrochemical performance testing, and the ratio of the electrode sheet was positive electrode material: acetylene black: PTFE (mass ratio) = 90:5:5. A CR2025 button cell was p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com