Patents

Literature

34results about How to "In situ synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

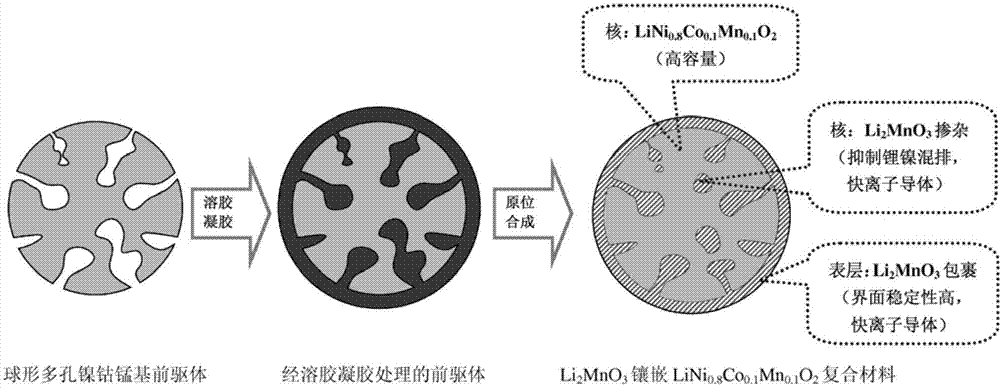

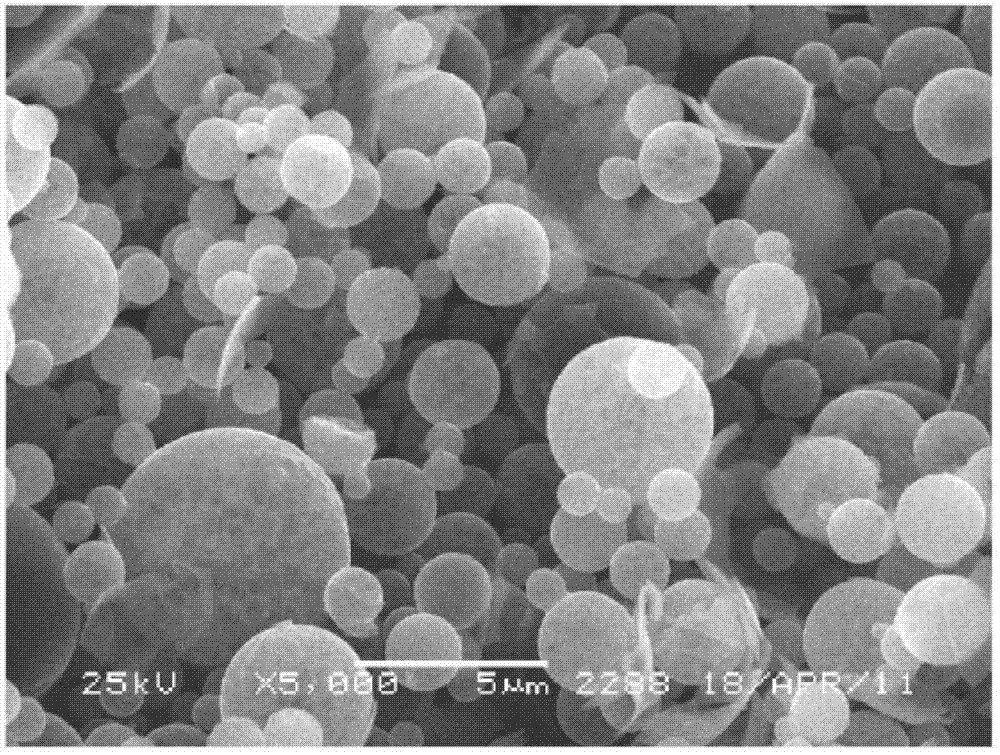

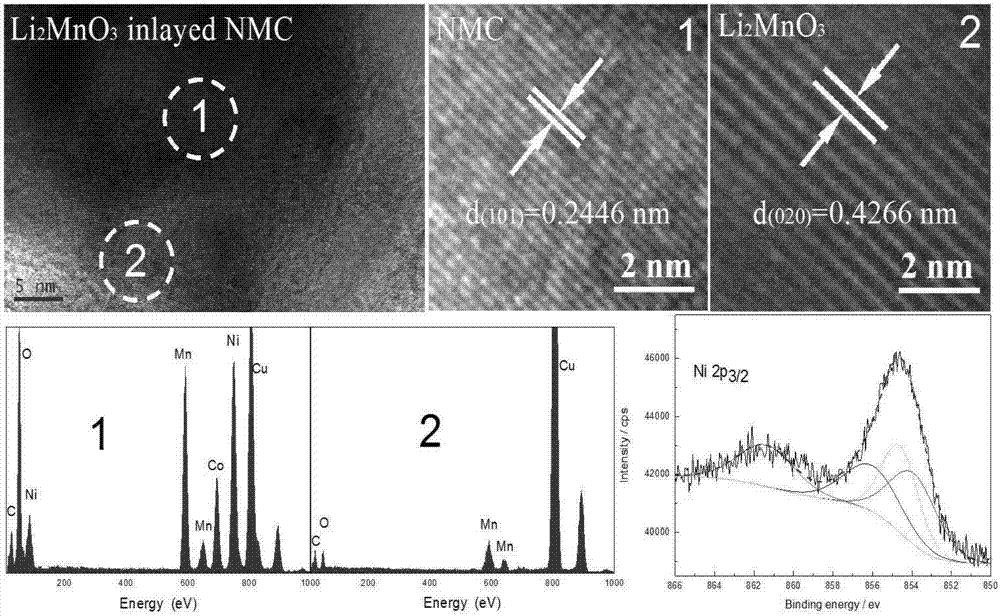

In-situ synthesis method of fast ion conductor inlaid lithium ion battery cathode material

The invention discloses an in-situ synthesis method of fast ion conductor inlaid lithium ion battery cathode material. Nickel salt, cobalt salt, M salt (M is one of Mn or Al) and a surface active agent are added into a solvent, and precursor powder is prepared through a spray drying method. Precursor is subjected to presintering, so that spherical porous nickel / cobalt / M-based precursor is obtained. Appropriate lithium salt, an organic sequestering agent, a solvent and a fast ion conductor material are mixed through a sol-gel heat treating method, so as to obtain sol, and then the spherical porous precursor is spread in the sol till the solvent is evaporated to form gel, and the fast ion conductor inlaid composite cathode material is synthesized through heat treatment. The method abandons the thinking that the cathode material is firstly prepared and then surface modification is performed in the traditional technology, and realizes the in-situ growth of inlaid composite material. The surface layer of the inlaid composite material adopts a uniformly coated fast ion conductor thin layer, the inner core adopts fast ion conductor doped cathode material, and the inlaid composite material has the advantages of excellent electrochemical property, good safety and storage performance and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for in-situ synthesizing silicate/carbon composite cathode material by taking rice husk carbon as silicon source

ActiveCN103346300ARealize resource utilizationIn situ synthesisCell electrodesCarbon compositesSilicon dioxide

A disclosed method for in-situ synthesizing a silicate / carbon composite cathode material by taking rice husk carbon as a silicon source comprises the following preparation steps: (1) primary smashing of rice husks; (2) purification of the rice husks; (3) pyrolyzing the rice husks under catalysis of metal elements to obtain a SiMO / C mixture; (4) smashing the SiMO / C mixture to D50=1-2 [mu]m by an jet mill; (5) adding a lithium source, ball milling and mixing; and (6) sintering under gas protection to obtain Li2MSiO4 / C. According to the method, cheap biological silica is used to prepare the silicate cathode material, resource utilization of agriculture wastes is realized, and high added-value products are produced; at the same time, the rice husk carbon is obtained by the middle-temperature pyrolysis method, the residual carbon of the rice husk carbon is taken as a carbon source, and the synthesis process of the silicate cathode material does not need extra carbon, and the in-situ synthesis of the Li2MSiO4 material is realized synchronously.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

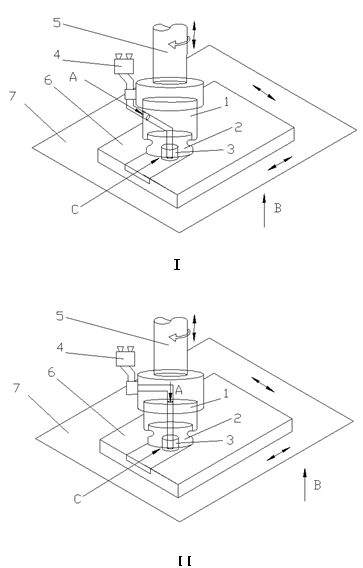

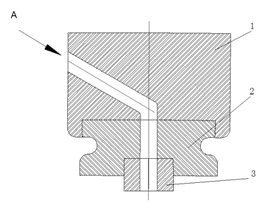

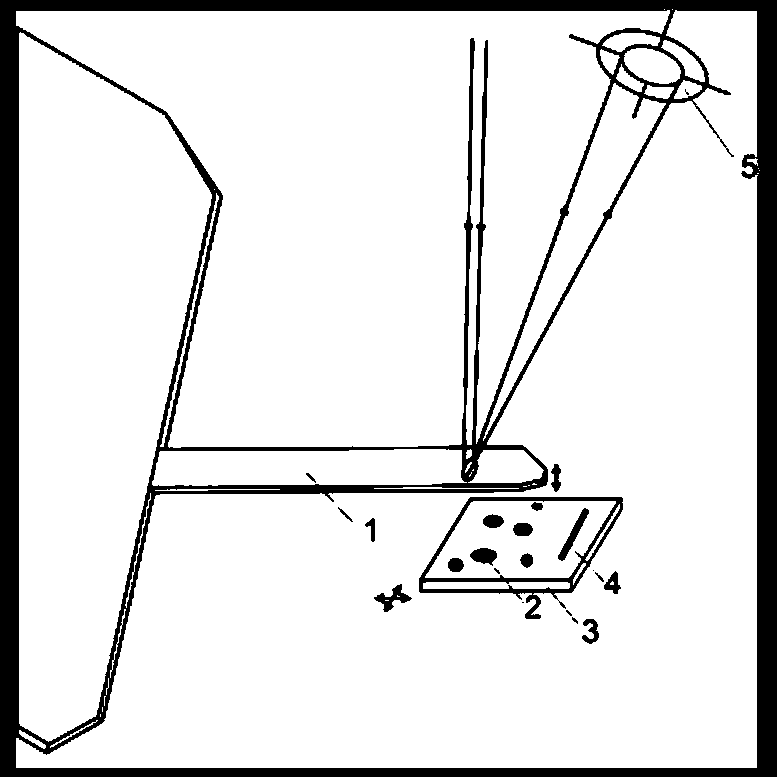

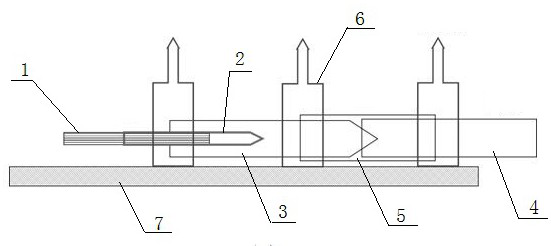

Metal surface nano-composite processing device with stirring head capable of synchronously feeding powder, and method

InactiveCN102560472AMaintain integrityImprove processing efficiencyMetallic material coating processesMetal substrateRotational axis

The invention relates to a processing device for synthesizing a surface layer of a nano-composite material in situ by performing friction stir processing (FSP) on a metal workpiece through a stirring head capable of synchronously feeding powder, and a method. A clamping part 1, a shaft shoulder 2 and a stirring probe 3 of the stirring head can be a rigid whole body or a fastening coaxial separated body; a powder feeding channel A is arranged in the stirring head; the inlet of the channel A is positioned on the side or middle axial position of the clamping part 1; and the outlet of the channelA is positioned on the surface of the middle axial position of the probe 3, which is contacted with the workpiece. During processing, a hydraulic device in a worktable capable of automatically lifting is used for pressurizing along the axial direction B of the stirring head, a rotating shaft drives the stirring head to rotate at high speed and press the workpiece, an external automatic powder feeder feeds sub-micron reinforcing phase powder into a seriously plasticized area C on the surface layer of the workpiece through the powder feeding channel A of the stirring head, and the nano-composite material is synthesized in situ through friction heat. The device is simple, is convenient to operate, is suitable for the composition and structure refining of various metal substrates, and is highin technical and economic benefit and industrial application potential.

Owner:HOHAI UNIV

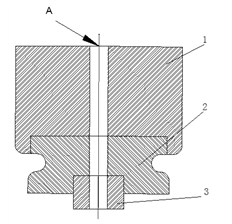

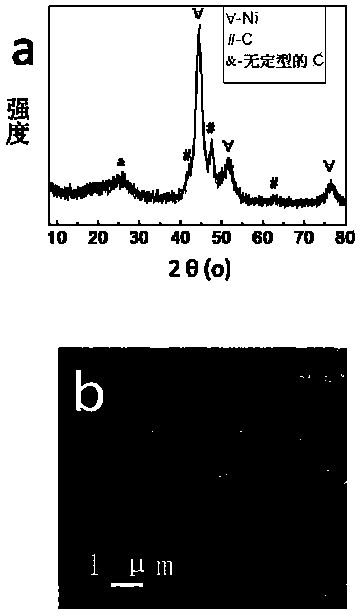

Method for preparing Ni@C or Co@C core-shell nanoparticles

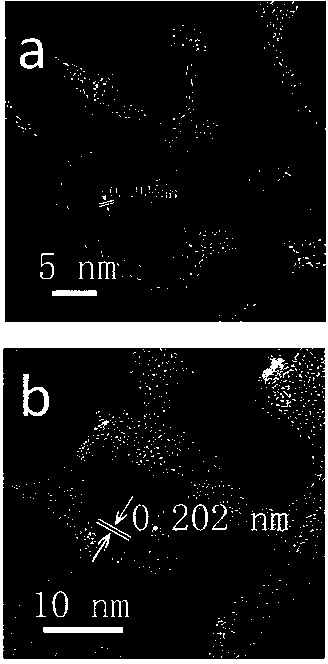

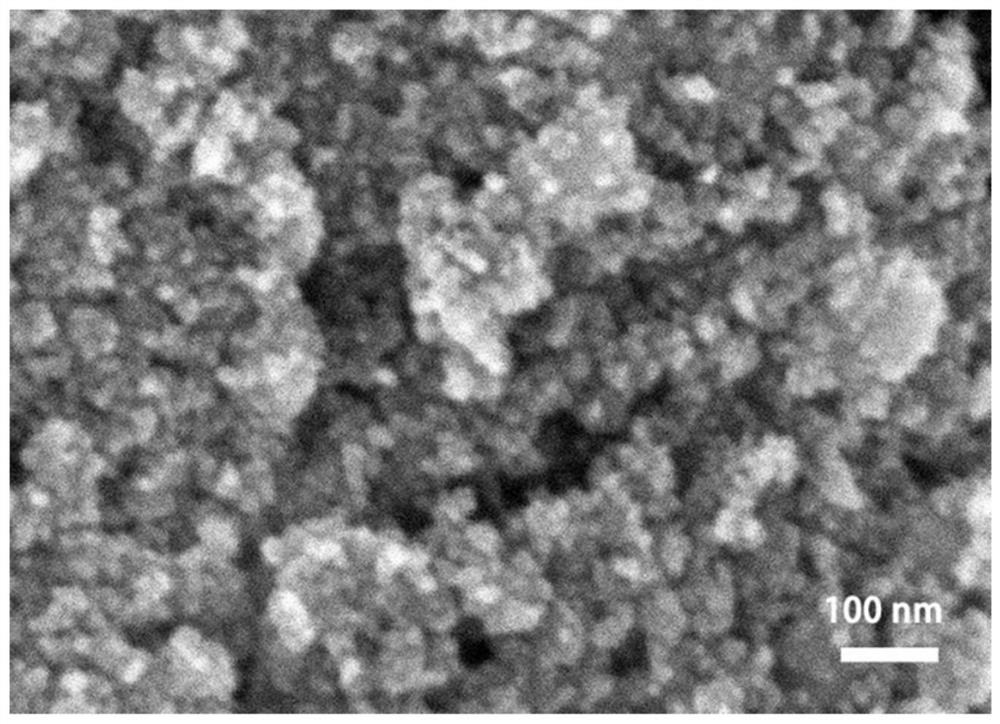

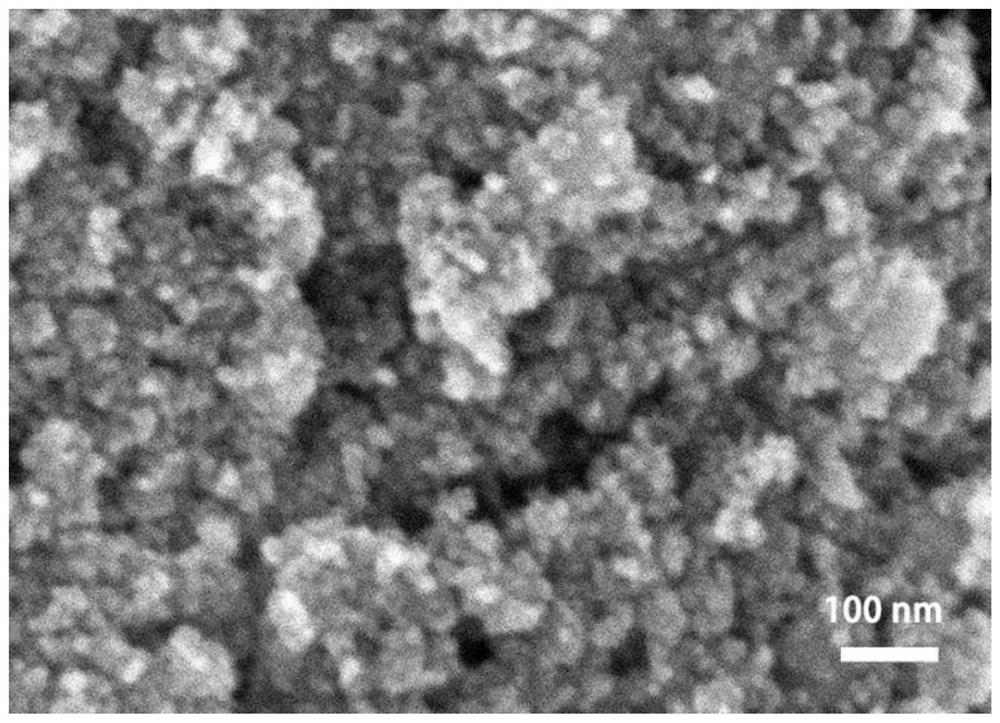

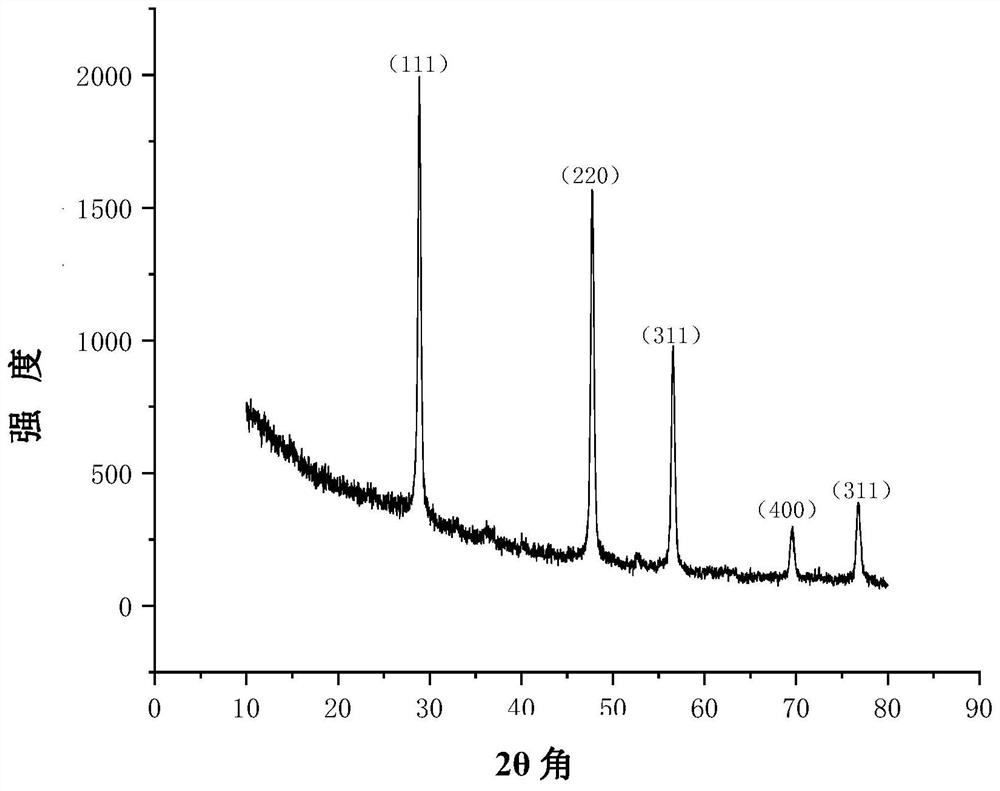

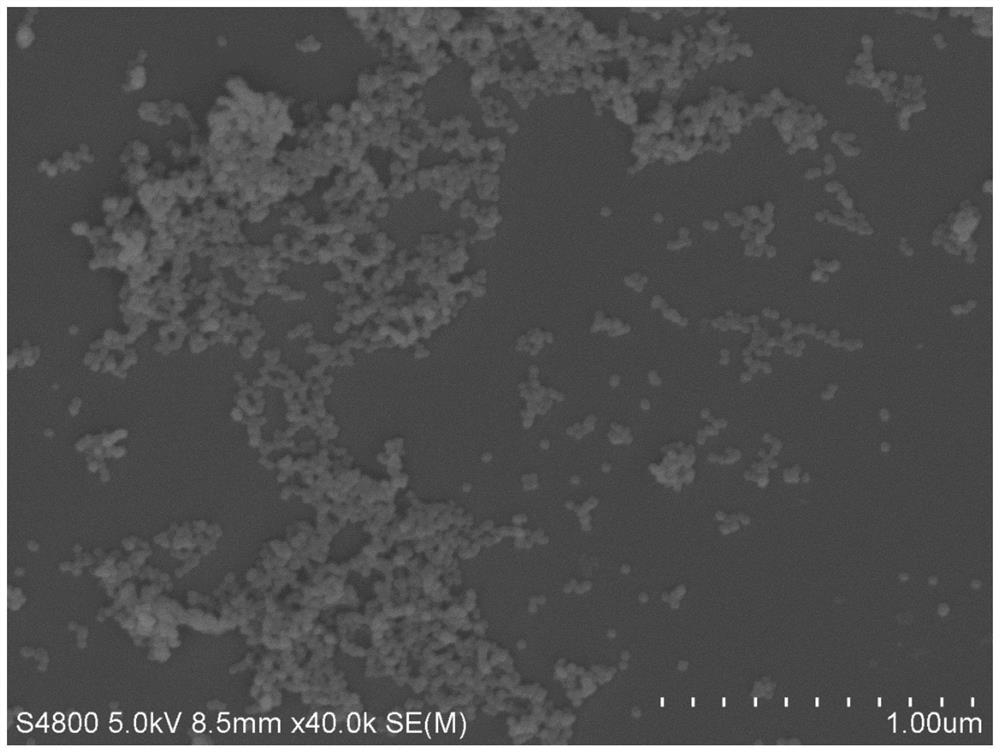

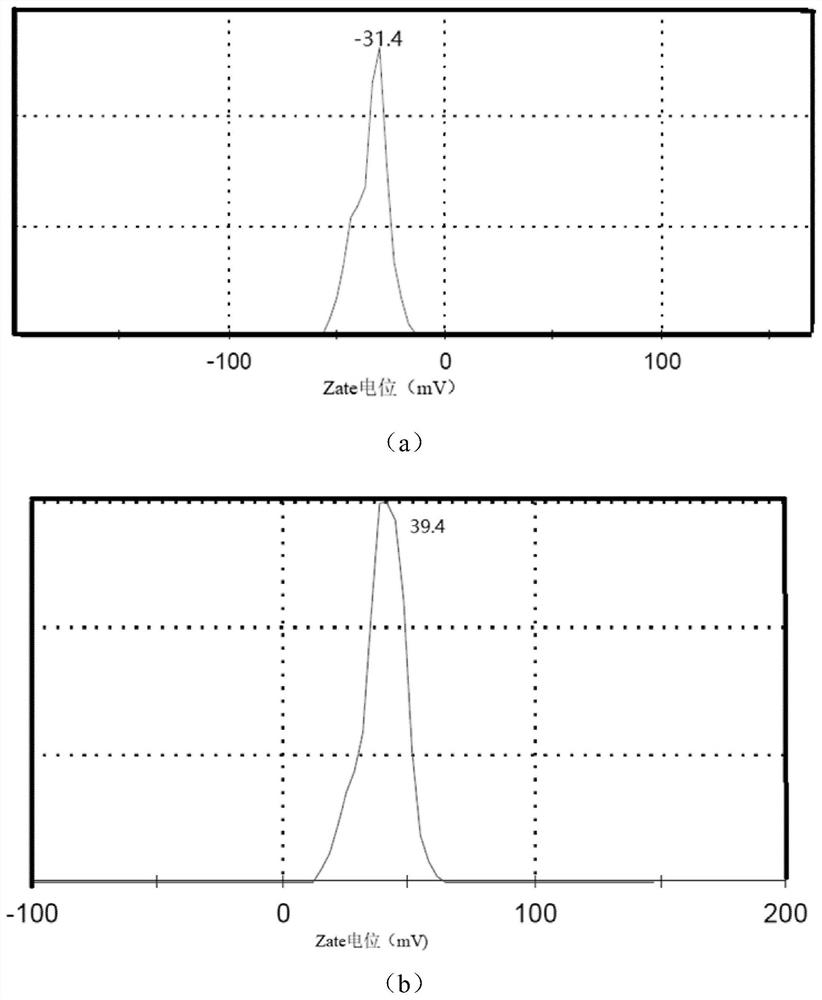

InactiveCN104209514ALarge specific surface areaNarrow pore size distributionMaterial nanotechnologyPtru catalystHeat conservation

The invention relates to a method for preparing Ni@C or Co@C core-shell nanoparticles. The method comprises the steps: (1) adding nickel chloride or cobalt chloride into an isopropanol aqueous solution, adding nitrilotriacetic acid, and stirring for 1 hour at room temperature, so as to obtain a mixed solution; (2) transferring the mixed solution to a reactor, placing the reactor into an air-blasting drying oven, carrying out heat preservation for 6 hours at the temperature of 180 DEG C, cooling, then, separating a product, cleaning and drying in vacuum, so as to obtain a precursor; (3) putting the precursor into a tubular furnace, heating to the temperature of 500-600 DEG C at the heating rate of 2 DEG C / min, and carrying out heat preservation for 2 hours, thereby obtaining a black product, namely the Ni@C or Co@C core-shell nanoparticles. The method has the advantages that the method is simple in process, low in energy consumption, low in cost and free from environmental pollution, and the in-situ synthesis of the Ni@C or Co@C core-shell nanoparticles is realized; the prepared core-shell nanoparticles have porous structures and are larger in specific surface area and narrower in pore size distribution, thereby being a promising catalyst or energy storage material.

Owner:NANKAI UNIV

Method for treating gaseous contamination using with ferrate

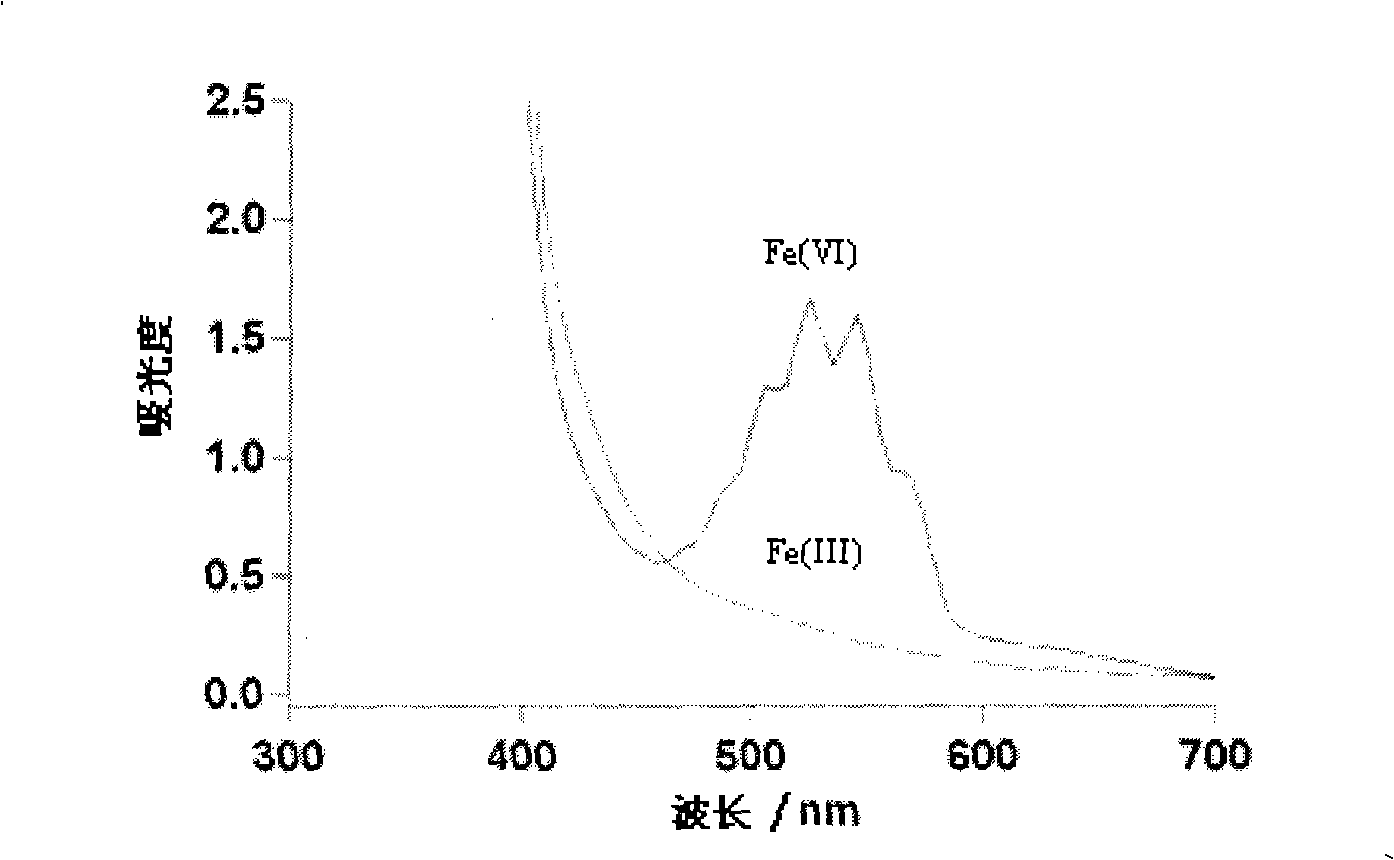

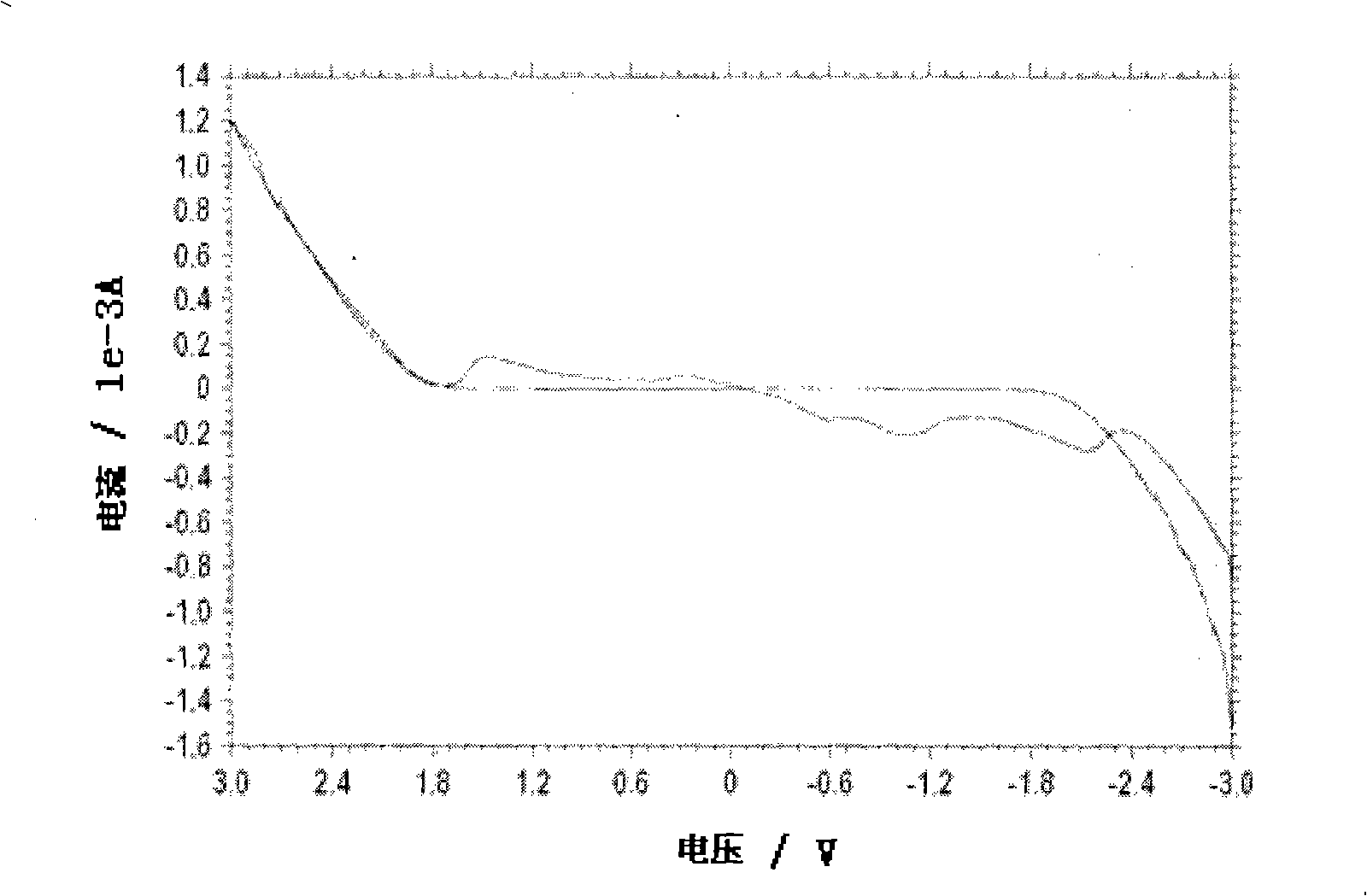

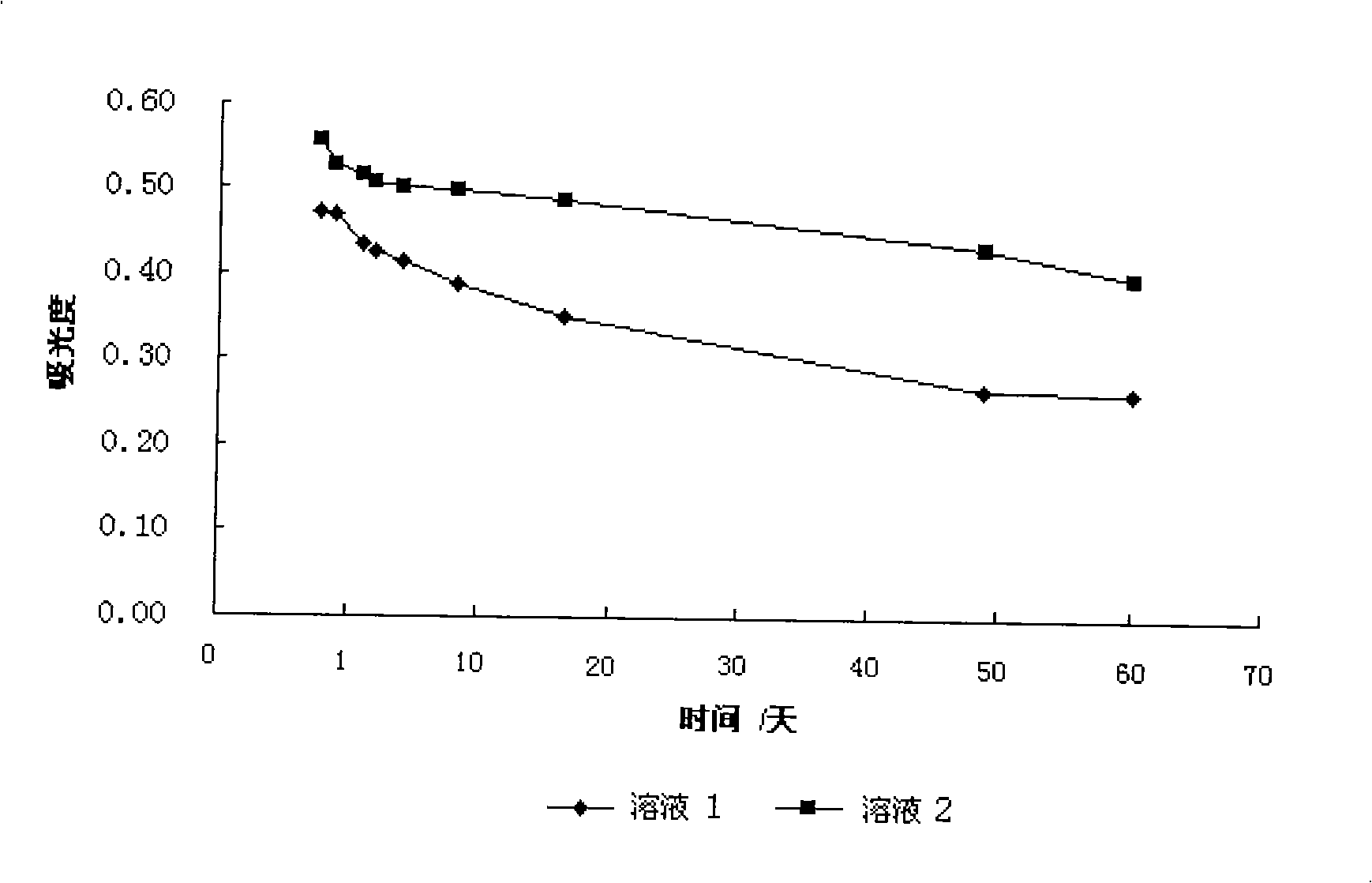

InactiveCN101288824ASimple and fast operationIn situ synthesisDispersed particle separationElectrolysisContamination

The invention provides a method for disposing gas pollution making use of ferrate. In the method, the polluted gas is directly pumped into ferrate solution to achieve better effects on gas contaminant disposal after absorption and oxidation; the ferrate solution is prepared under the room temperature by adopting a diaphragm-typed electrolyser, taking the mixed solution of NaOH with low concentration and Na2SiO3 as electrolyte and electrolysing iron-based anodes under direct current. The method of the invention is suitable for being applied to the removal and disposal of gas contaminant such as volatile organic gas, sulphur and oxynitride in the flue gas and sulfureted hydrogen, etc. and prevents the secondary pollution at the same time; the prepared ferrate has good stability, easy recurrence and obvious disposal effects on the gas contaminant. The method of the invention has the advantages of simple and continuous technology, low cost, simple and convenient operation and mild conditions.

Owner:HUAZHONG UNIV OF SCI & TECH

In-situ synthesis of Pt-supported fullerene catalyst

InactiveCN101007273AGood dispersionReduce aggregationCell electrodesMetal/metal-oxides/metal-hydroxide catalystsSynthesis methodsMetal particle

The invention discloses an original position synthesis method of fullerene Pt catalyst. The method uses the chloroplatinic acid and deionized water to produce chloroplatinic acid solution, places it in containers and then immerses the negative pole and anode under liquid surface to energizing and striking of arc, the electric arc discharges to make the anode evaporate and provide carbon resource for the growth of fullerene structure, while the metal positive ion in brine solution is deacidized to generating Pt metal particles and load is under the surface of fullerene; then stops discharge, collect product after cooling and gains the fullerene Pt catalyst after drying. The innovation of the invention lies on: fullerene is prepared while Pt is loaded on the surface of carbon material, it achieves the original position synthesis of fullerene Pt catalyst; it is tested that the fullerenes Pt catalyst has excellent catalytic activity to carbinol oxidation, and the process is simple and easy to control, the application prospects are charming.

Owner:TAIYUAN UNIV OF TECH

Method for preparing porous silicon-carbon composite material in situ

ActiveCN110350168ASave structureSave shapeMaterial nanotechnologyCell electrodesCarbon compositesOrganic solvent

The invention discloses a method for preparing a porous silicon-carbon composite material in situ; the method comprises the following steps that (1) a polymer with positive charges is mixed with a solvent to obtain a mixed solution, wherein the main chain or the side group of the polymer with positive charges has an amino group; and the solvent is a mixed solvent composed of an organic solvent andwater; (2) a silicon source is mixed with the mixed solvent obtained in the step (1), the mixture is subjected to hydrolysis reaction to obtain a suspension, and then the suspension is subjected to post-treatment A to obtain a silicon-carbon precursor; and (3) the silicon-carbon precursor is mixed with magnesium powder, magnesium thermal reduction reaction is carried out to obtain a crude product, and post-treatment B is performed to obtain the porous silicon-carbon composite material. The invention discloses the method for preparing the porous silicon-carbon composite material in situ; the prepared porous silicon-carbon composite material is complete in morphology, the particle sizes of the composite material are relatively small, and the particle sizes of the composite material are about 20-60 nm. By taking the porous silicon-carbon composite material as a negative electrode, the cycling stability of the lithium battery can be remarkably improved.

Owner:ZHEJIANG UNIV

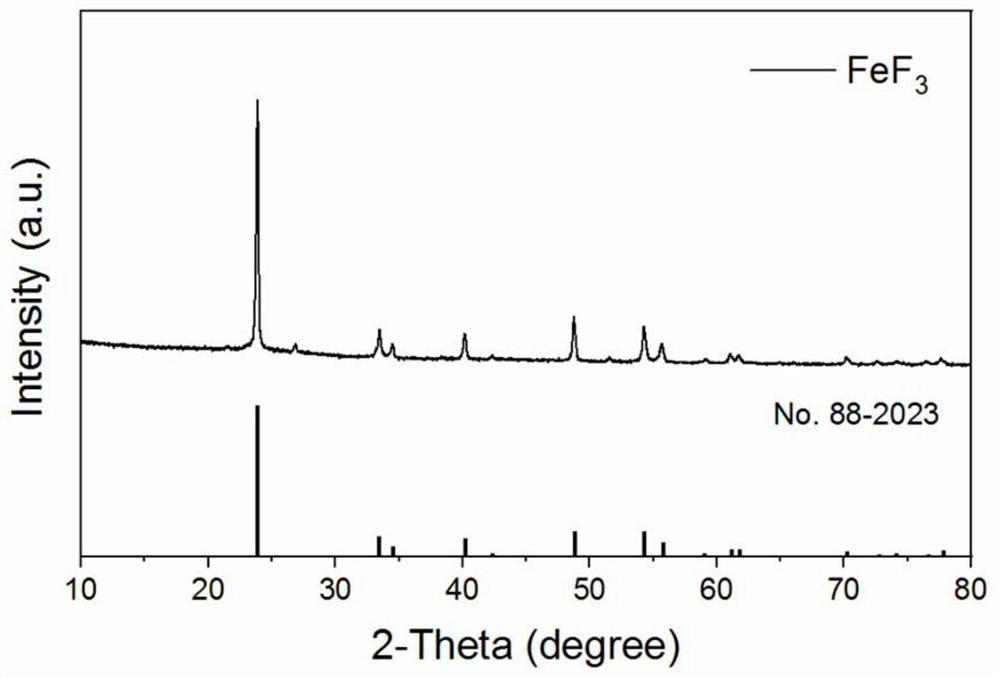

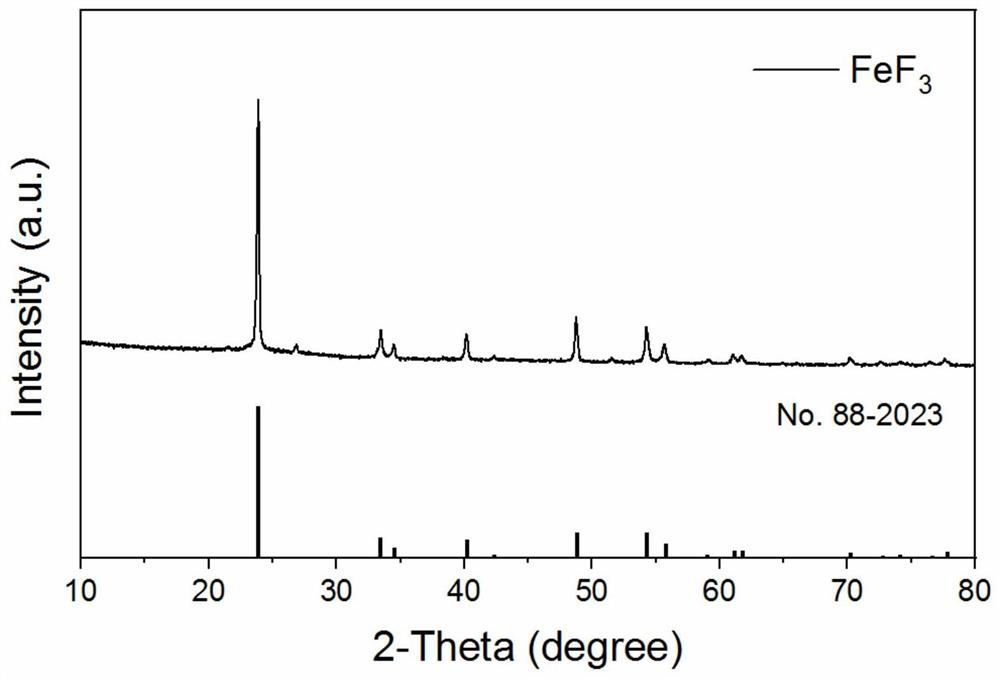

Nanometer FeF3/C composite positive electrode material, preparation method thereof and lithium ion battery

InactiveCN112803021AStable structureImproved magnification performanceMaterial nanotechnologySecondary cellsTrifluorideIron fluoride

The invention discloses a nanometer FeF3 / C composite positive electrode material, a preparation method thereof and a lithium ion battery. The method comprises the following steps: (1) putting reaction raw materials into a reaction kettle, filling the reaction kettle with protective gas, and sealing; wherein the reaction raw materials comprise an iron source and polytetrafluoroethylene; and (2) carrying out heat treatment on the sealed reaction kettle at the temperature of more than or equal to 400 DEG C to obtain the nano FeF3 / C composite positive electrode material. According to the invention, the property of sublimation of polytetrafluoroethylene at low temperature is utilized, and an iron source and a fluorine source are fully reacted by using a closed reaction kettle; the used polytetrafluoroethylene can provide a fluorine source and can be cracked to obtain the iron trifluoride composite positive electrode material with superfine nano-particles at the same time. The lithium ion battery positive electrode material provided by the invention has the advantages of high reversible specific capacity, excellent rate capability and good cycling stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

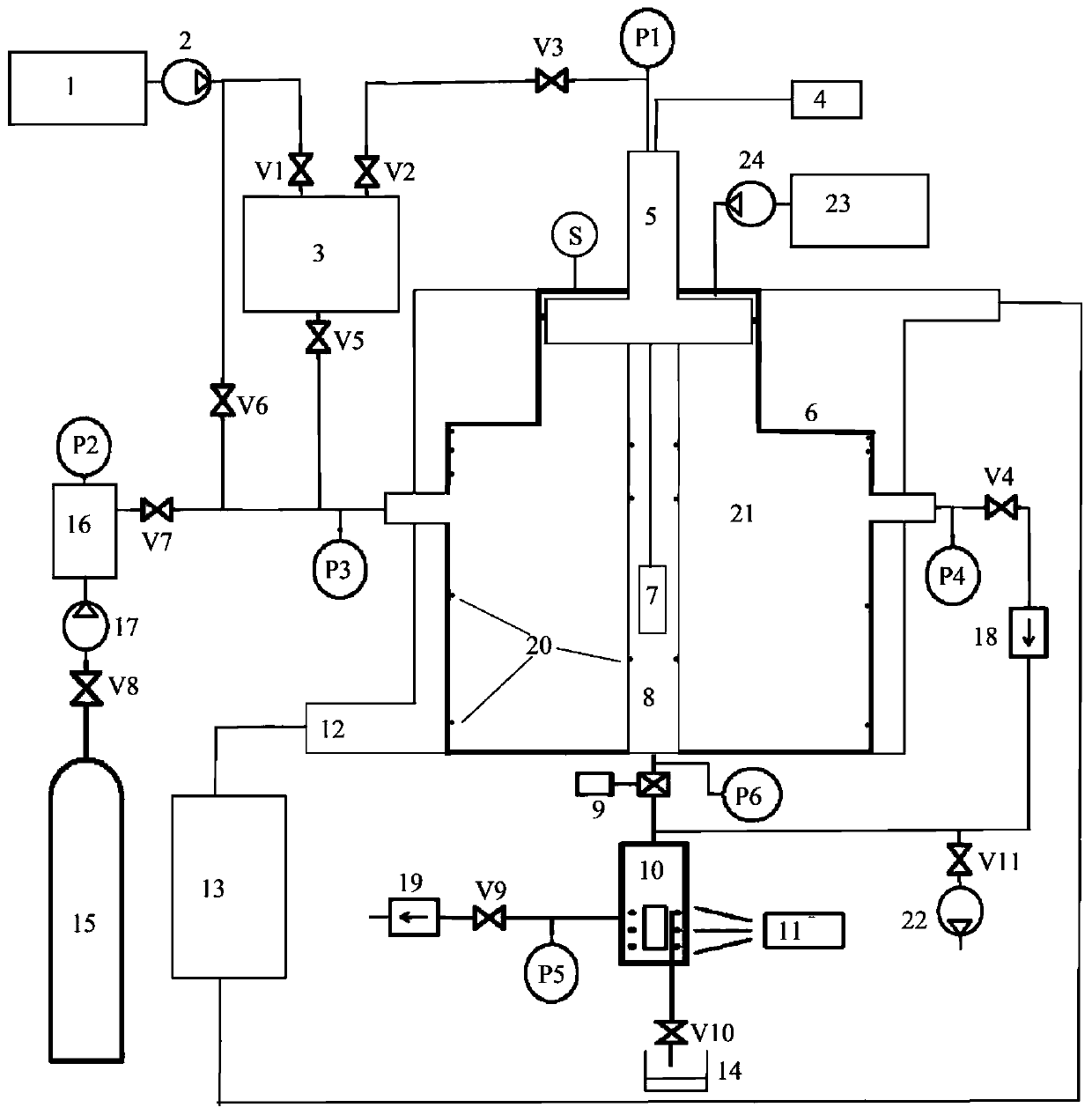

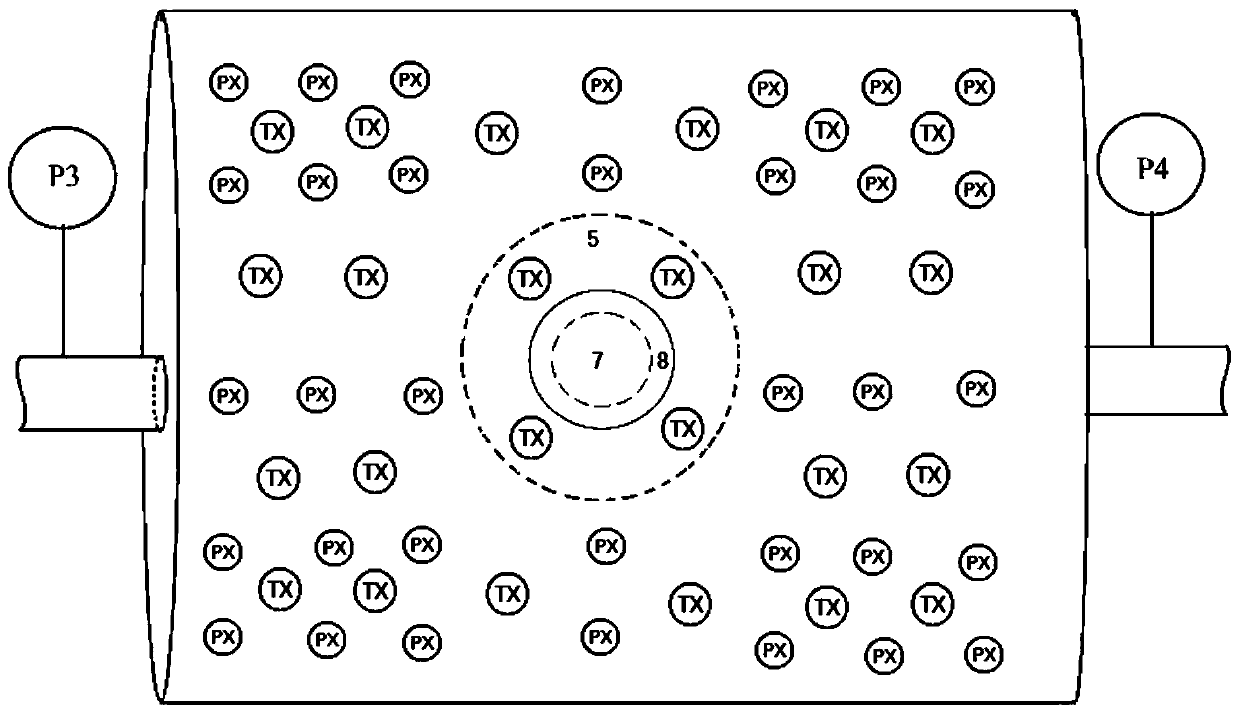

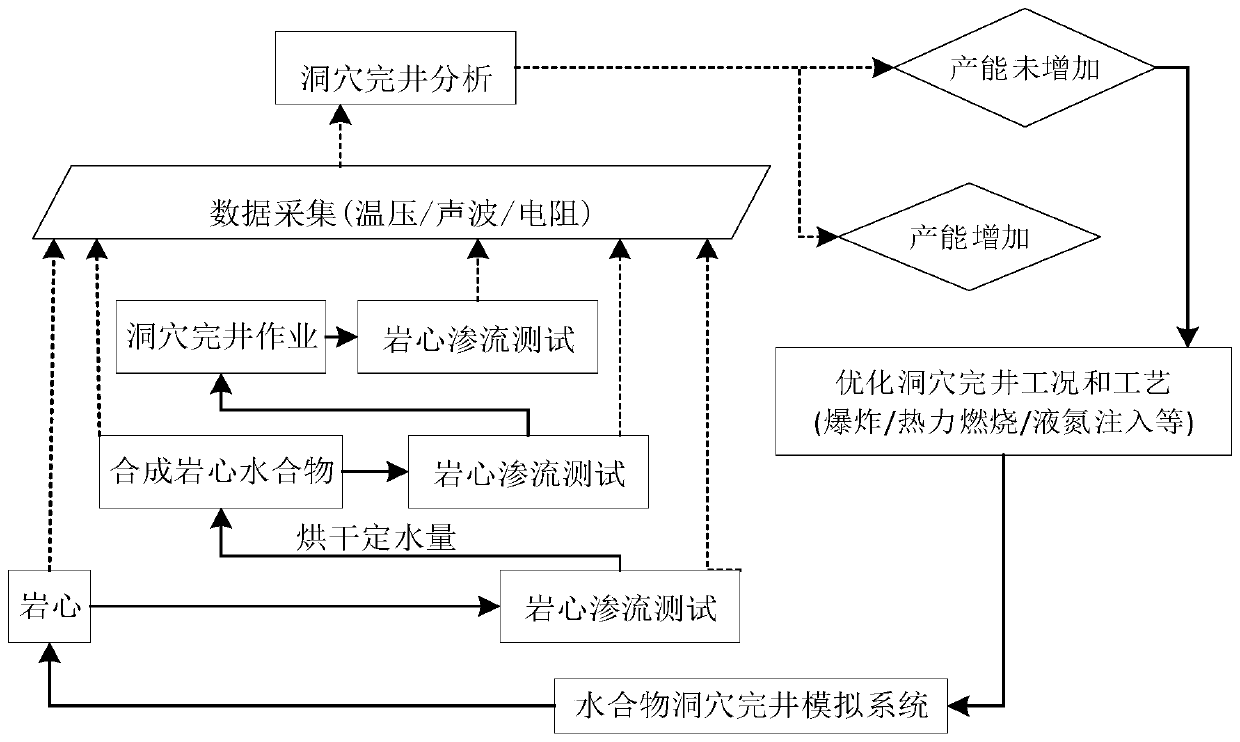

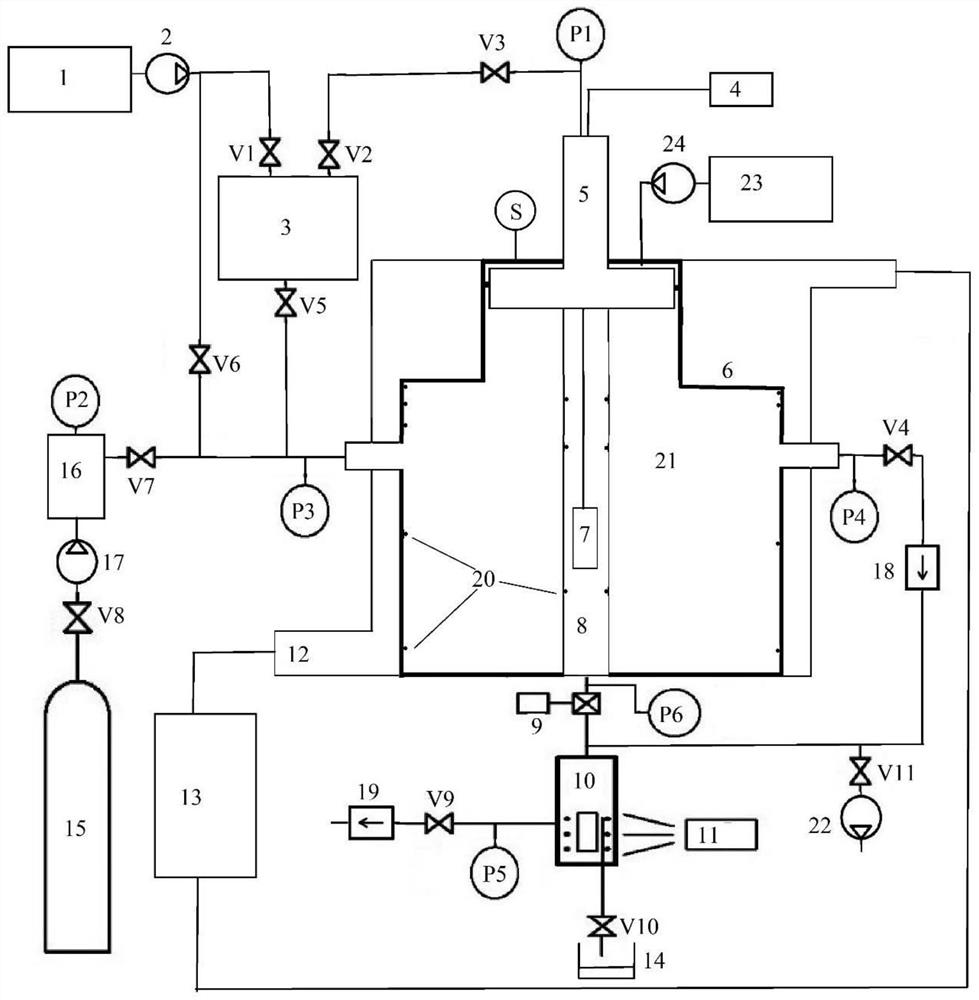

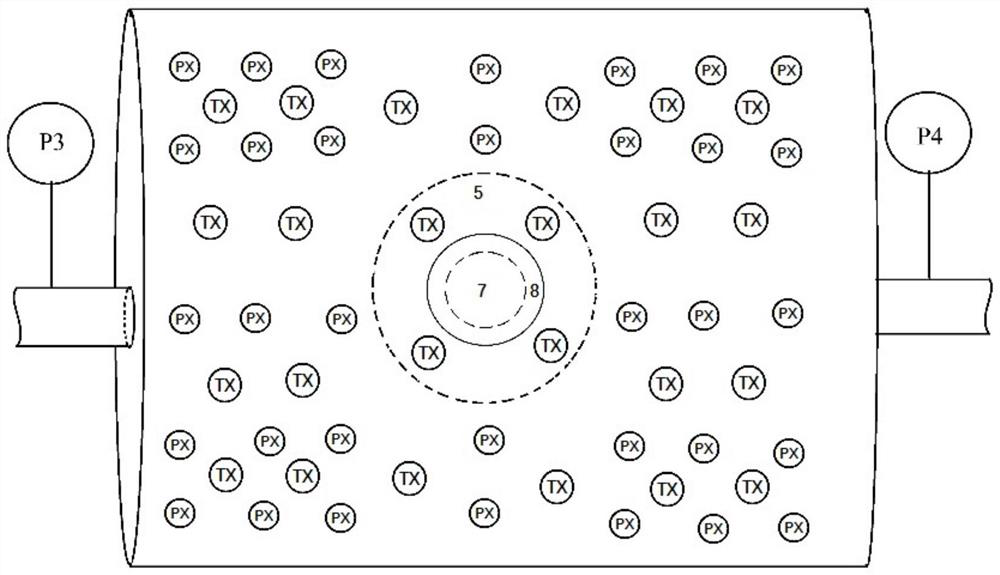

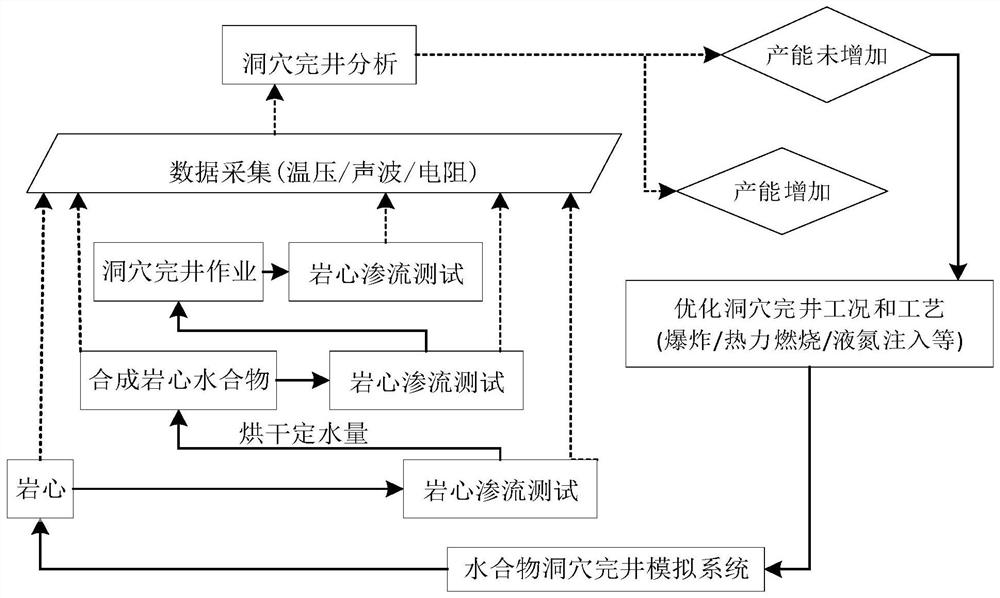

Natural gas hydrate cave well completion evaluating and testing device and method

The invention discloses a natural gas hydrate cave well completion evaluating and testing device which comprises a reaction still system, a cave well completion system, a confining pressure control system, an inlet pressure control system, an outlet pressure control system, a gas-liquid-solid separating system, a temperature control system and a data collecting and processing system. The reactionstill system is used for simulating in-situ generation, cave well completion and extraction of natural gas hydrate; the temperature control system provides a constant temperature environment for the device; the cave well completion system, the confining pressure control system, the inlet pressure control system, the outlet pressure control system and the gas-liquid-solid separating system are usedfor controlling the pressure and flowing state of the experiment process; and the data collecting and processing system is used for collecting and processing the parameters of the experiment process.The invention further relates to a natural gas hydrate cave well completion evaluating and testing method. According to the natural gas hydrate cave well completion evaluating and testing device andmethod, cave well completion testing can be carried out on a hydrate-containing rock core synthesized artificially, and the device and method are used for evaluating the cave well completion conditionof the hydrate.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

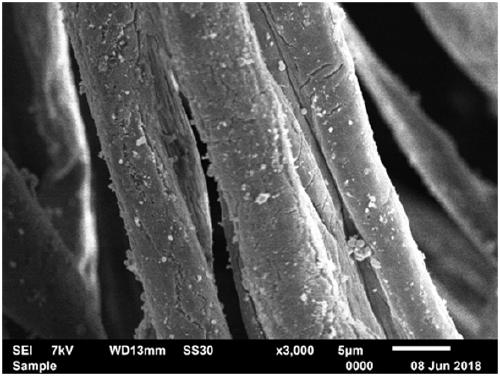

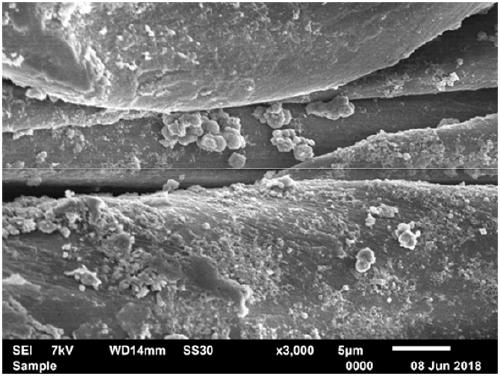

Method for directly synthesizing titanium dioxide nanoparticles on fabric fiber in situ

InactiveCN108998962AIn situ synthesisImprove photocatalytic performanceWater/sewage treatment by irradiationWater treatment compoundsFiberHigh pressure

The invention discloses a method for directly synthesizing titanium dioxide nanoparticles on a fabric fiber in situ, belongs to the technical field of application of titanium dioxide nanoparticles, and aims to solve the problems that TiO2 is liable to agglomeration, liable to lose, hard to recycle and low in sunshine utilization rate in photocatalysis. The method comprises the following steps: firstly, preparing a butyl titanate solution from absolute ethyl alcohol and butyl titanate, and soaking a pure cotton fabric into the butyl titanate solution for 24 hours; hydrolyzing for 0.5 hour, further transferring into a polytetrafluoroethylene high-pressure kettle, and carrying out hydrothermal treatment for 8 hours at 120-150 DEG C; finally respectively calcining for 1 hour in a muffle furnace at 200-400 DEG C, so as to obtain a TiO2 nanoparticle supported fabric. By adopting the method, nano TiO2 can be conveniently recycled and reused, the problems that conventional TiO2 powder is liable to agglomeration and liable to lose and thus low in photocatalysis activity can be avoided, and organic pollutants in sewage can be effectively degraded.

Owner:TAIYUAN UNIV OF TECH

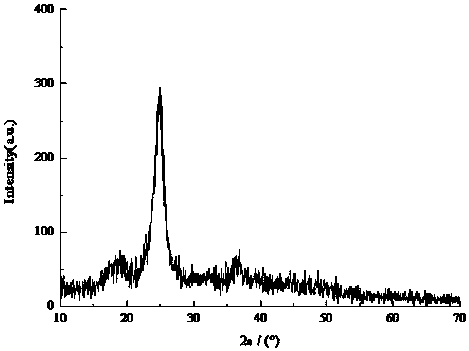

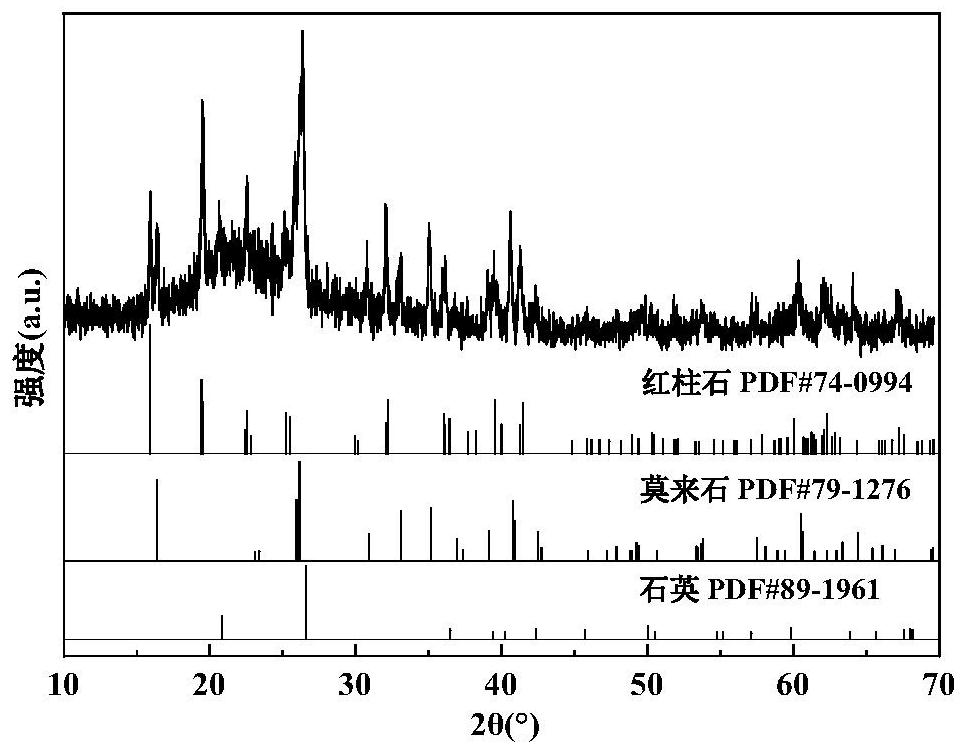

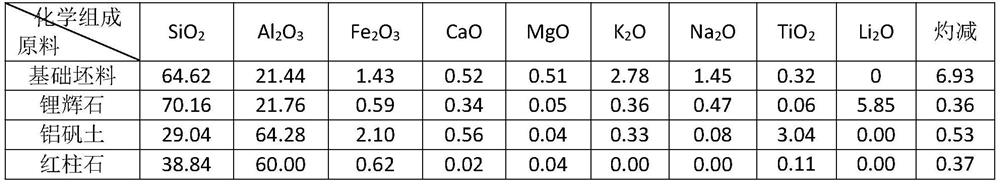

In-situ generated mullite whisker reinforced ceramic green body and preparation method thereof

ActiveCN114380576AIn situ synthesisRaise Al

<sub>2</sub>

o

<sub>3</sub>

contentClaywaresAndalusiteMullite

The invention discloses an in-situ generated mullite whisker reinforced ceramic green body. The ceramic green body comprises the following raw materials: 70-80 wt% of a basic blank, 1-5 wt% of spodumene, 3-8 wt% of bauxite and 10-20 wt% of andalusite, the basic blank is prepared from the following raw materials: 21 to 24 weight percent of chinastone, 18 to 22 weight percent of potassium feldspar, 30 to 34 weight percent of kaolin, 6 to 11 weight percent of black mud, 4 to 7 weight percent of washing mud, 10 to 14 weight percent of white mud and 1 to 3 weight percent of talc. In addition, the invention also discloses a preparation method of the in-situ generated mullite whisker reinforced ceramic body. By optimizing a formula system, formation of a large number of mullite crystals can be promoted, so that the breaking strength of the ceramic green body is effectively improved, the thickness of a product is reduced, and thin-wall light weight of the building sanitary ceramic green body is realized.

Owner:JINGDEZHEN CERAMIC INSTITUTE +1

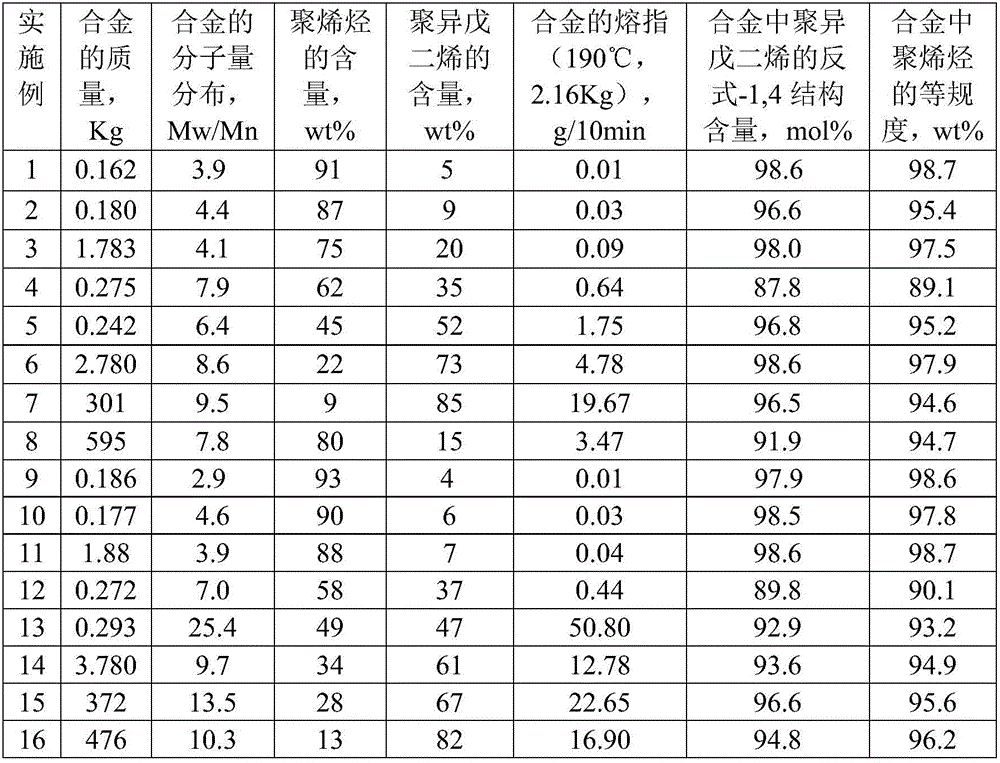

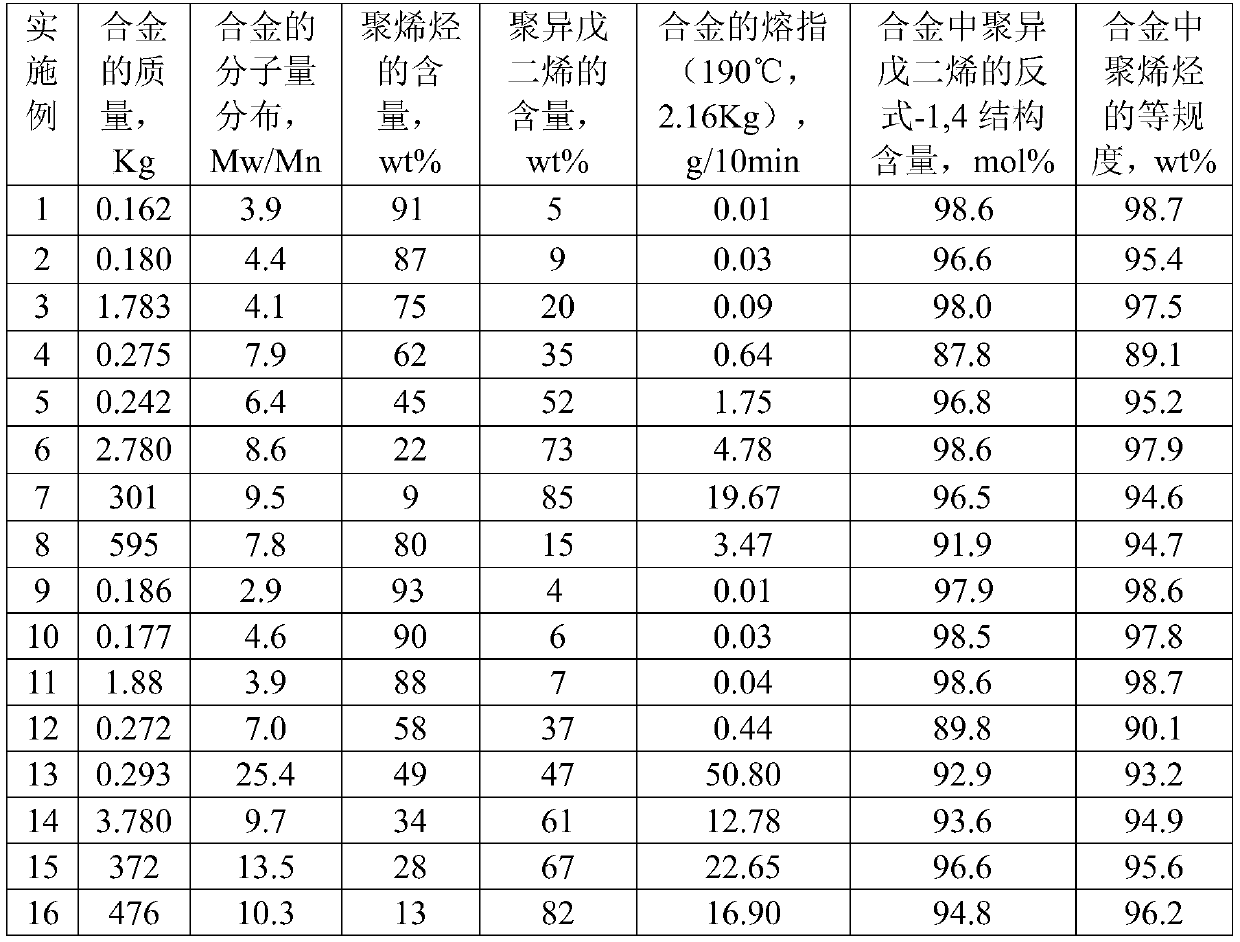

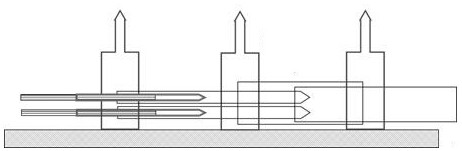

Polyolefin/polyisoprene alloy material and preparation method thereof

The invention discloses a polyolefin alloy material and a preparation method thereof, belongs to the field of polyolefin materials and particularly relates to a polyolefin / polyisoprene alloy material as well as a preparation method and application thereof. In a polyolefin / polyisoprene alloy, the mass content of polyolefin is 5 to 99.4 percent, and the isotacticity is greater than 85 weight percent; the mass content of polyisoprene is 0.5 to 85 percent; the mole content of a trans-1,4 structure is greater than 85 percent, and the mass content of a block copolymer is 0.1 to 10 percent. The polyolefin / polyisoprene alloy material synthesized by adopting supported titanium and / or a vanadium catalyst through a two-segment polymerization method, disclosed by the invention, is a granular product with a core-shell structure, has the characteristics of high strength and high toughness, and is a novel polyolefin material.

Owner:QINGDAO UNIV OF SCI & TECH +2

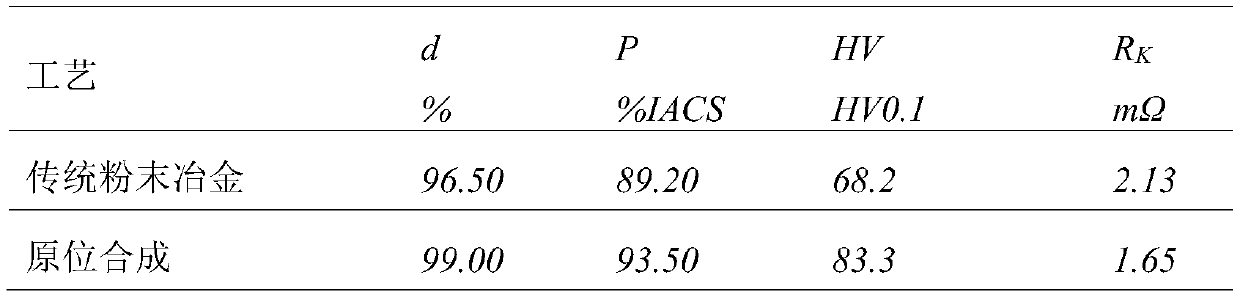

Preparation method of cadmium molybdate modified copper-based composite electric contact material

ActiveCN110791672AImprove the bonding strength of the interfaceUniform dispersionContactsCopper matrixPlastic property

The invention discloses a preparation method of a cadmium molybdate modified copper-based composite electric contact material. According to the method, uniform nucleation and growth of CdMoO4 are completed on the surface of copper powder particles through an in-situ synthesis method, so that cadmium molybdate modified copper-based (CdMoO4 / Cu) composite electrical contact material with second-phaseuniform dispersion distribution is prepared. According to the method, the problems of pollution problem of Cd vapor in a CdO / Ag contact material and Ag resource shortage are solved, and the purpose of uniform dispersion distribution of the CdMoO4 is achieved; and through the steps of hot extrusion, rolling, stamping and the like, the characteristics of good plasticity of copper alloy are used, sothat the efficient densification of CdMoO4 / Cu composite material is realized, the uniform dispersion degree of the CdMoO4 in a copper matrix is further improved, and thereby the microstructure performance and the service performance of an electrical contact are improved.

Owner:宁波坤铜合金材料有限公司

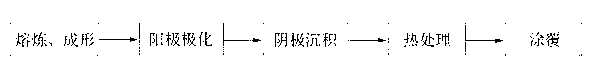

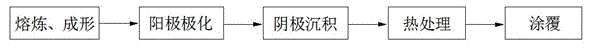

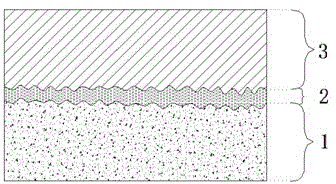

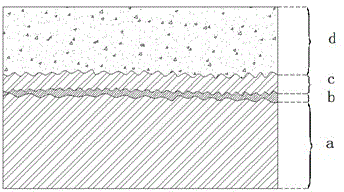

Biomedical material and preparation method thereof

InactiveCN103286053AHas "deactivation" effectGood biocompatibilityAnodisationPretreated surfacesThermal treatmentBiological materials

The invention discloses biomedical material and a preparation method thereof. The preparation method includes: 1, melting and forming; 2, polarizing an anode; 3, depositing the anode; 4, performing thermal treatment; 5, coating. The biomedical material comprises a pure magnesium or magnesium-alloy base and a functional film which covers the surface of the base and which has the functions of degradation protection and self-degradation. The biomedical material features controllability, full degradation and full absorption, and the strict requirements for ideal features of the degradable biomaterial are met. The biomedical material has the advantages that an optimal solution is provided for the absorbable biomedical material, especially the contradiction between biodegradability and degrading speed control in medical magnesium alloy, and related materials and techniques are applicable to common medical instruments and are more competitive in production of high-end medical instruments, such as implant instruments, especially 'secondary-operation-free' implants.

Owner:SOUTH CHINA UNIV OF TECH

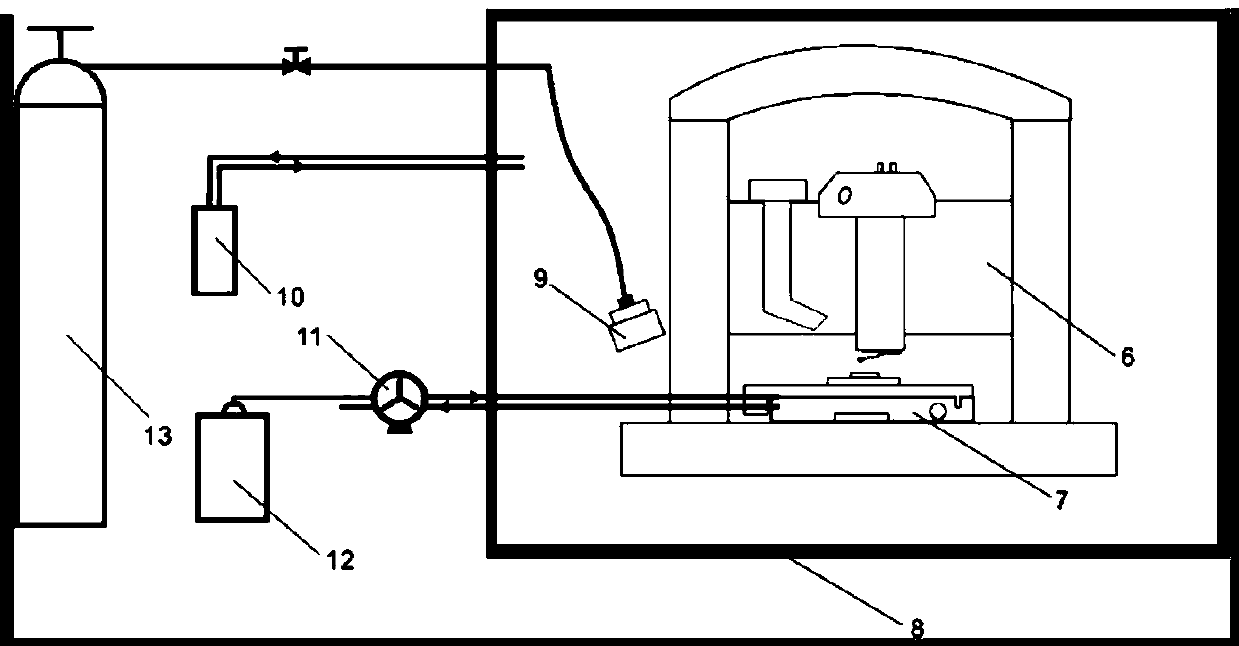

A device and method for testing the adhesion between gas hydrate and mineral particles

ActiveCN109323986BIn situ synthesisImprove adhesionConstructionsUsing mechanical meansAdhesion forceAfm atomic force microscopy

A testing device for testing adhesion force includes a thermal insulated glove box, an atomic force microscope, a cryogenic sample stage, a high pressure gas source and a circulating chiller. The atomic force microscope includes a probe for adhering mineral particles. The cryogenic sample stage is configured for preparing gas hydrate sample. The cryogenic sample stage is arranged below the probe. The atomic force microscope and the cryogenic sample stage are placed in the thermal insulated glove box. The high pressure gas source provides pressure required for synthesis of gas hydrates, the high pressure gas source comprises a high pressure chamber covered on the cryogenic sample stage and a high pressure gas cylinder connected with the high pressure chamber. The circulating chiller, an outlet of the circulating chiller is connected with the thermal insulated glove box to control humidity and temperature inside the thermal insulated glove box.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Metal surface nano-composite processing device with stirring head capable of synchronously feeding powder, and method

InactiveCN102560472BIntegrity guaranteedUniform compositionMetallic material coating processesRotational axisWhole body

Owner:HOHAI UNIV

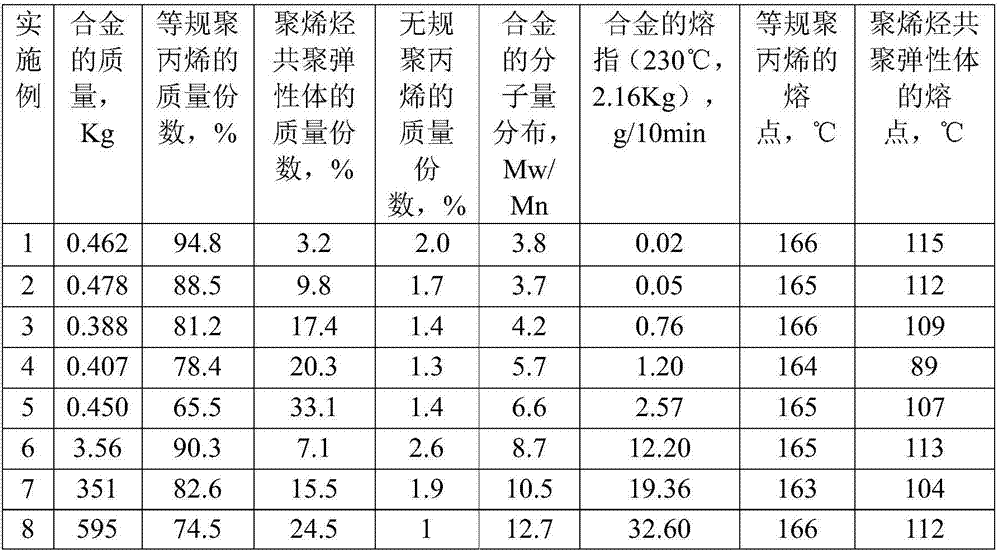

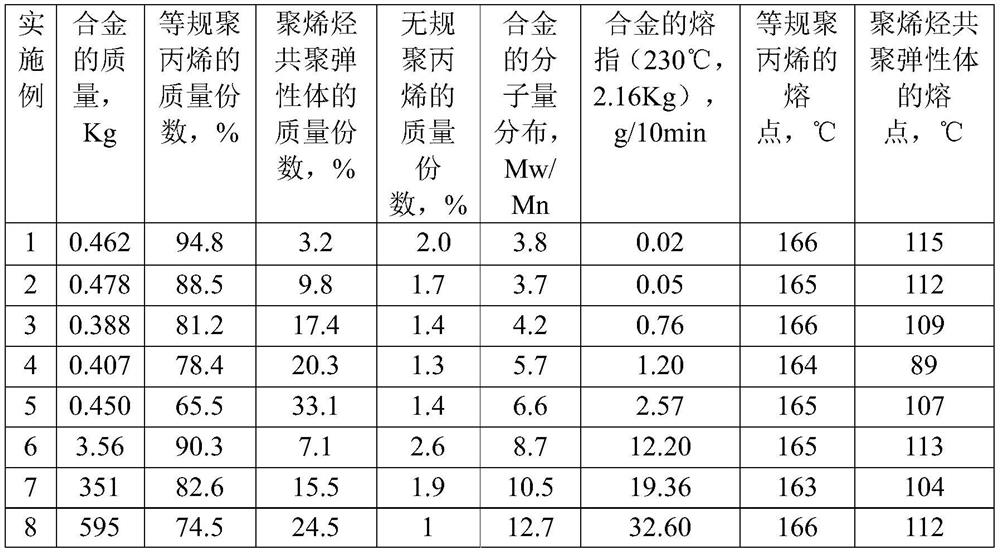

High-isotactic polypropylene alloy and preparation method thereof

ActiveCN107540949AWide molecular weight distributionGood hydrogen sensitivityElastomerPolymer science

The invention discloses a high-isotactic polypropylene alloy and a preparation method thereof. The high-isotactic polypropylene alloy comprises the following components in percentage by mass: 60-98% of isotactic polypropylene, 1-35% of a polyolefin copolymerization elastomer and 1-5% of atactic polypropylene. The igh-isotactic polypropylene alloy is prepared by the following two steps: I, catalyzing polymerization of propylene slurry or a gas-phase or liquid-phase body by using a Ziegler-Natta catalyst so as to prepare isotactic polypropylene, and II, continuously performing gas-phase copolymerization on butane and higher alkene on polypropylene granules, thereby obtaining the high-isotactic polypropylene alloy.

Owner:QINGDAO UNIV OF SCI & TECH

Biomedical material and preparation method thereof

InactiveCN103286053BHas "deactivation" effectGood biocompatibilityAnodisationPretreated surfacesControllabilityThermal treatment

Owner:SOUTH CHINA UNIV OF TECH

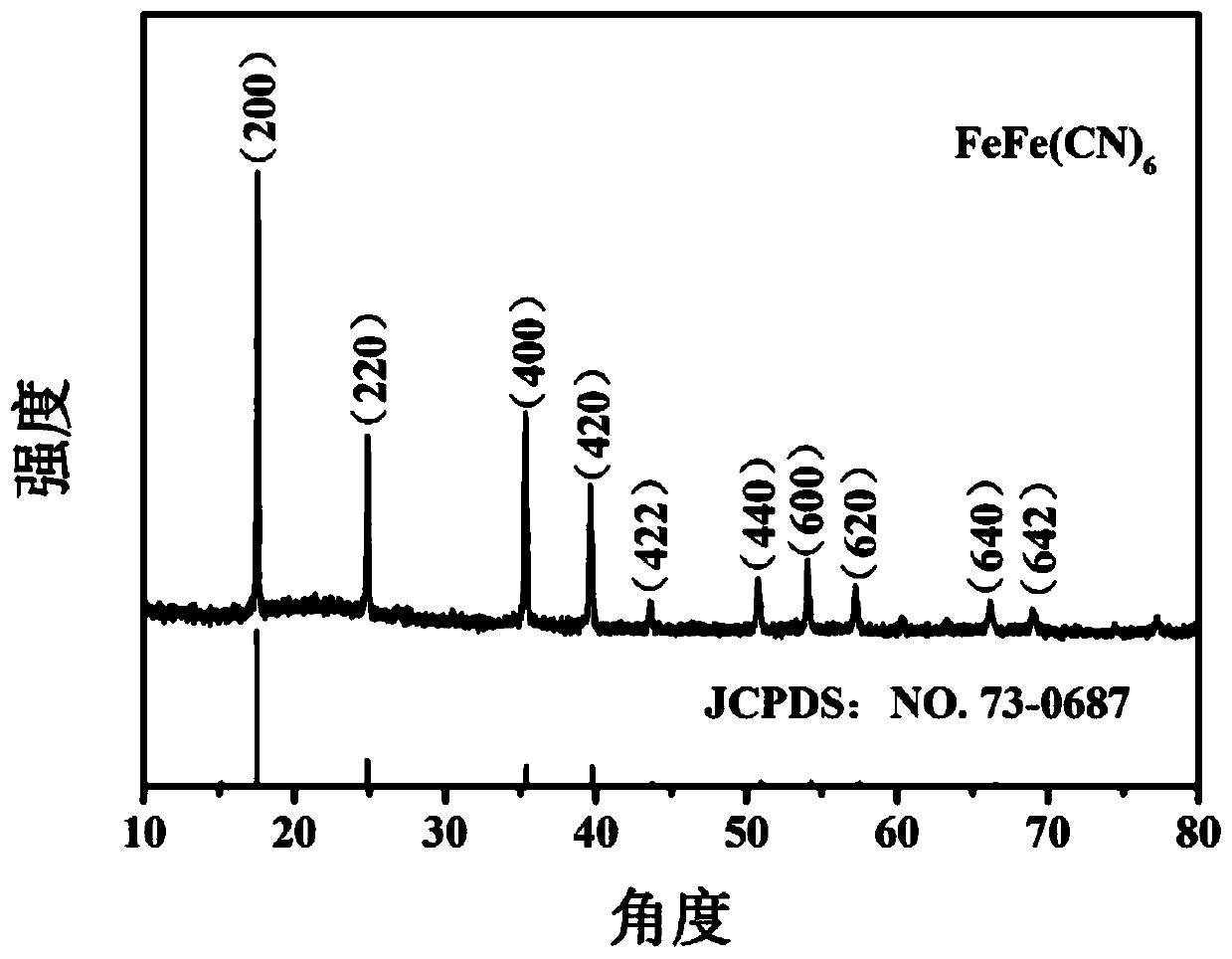

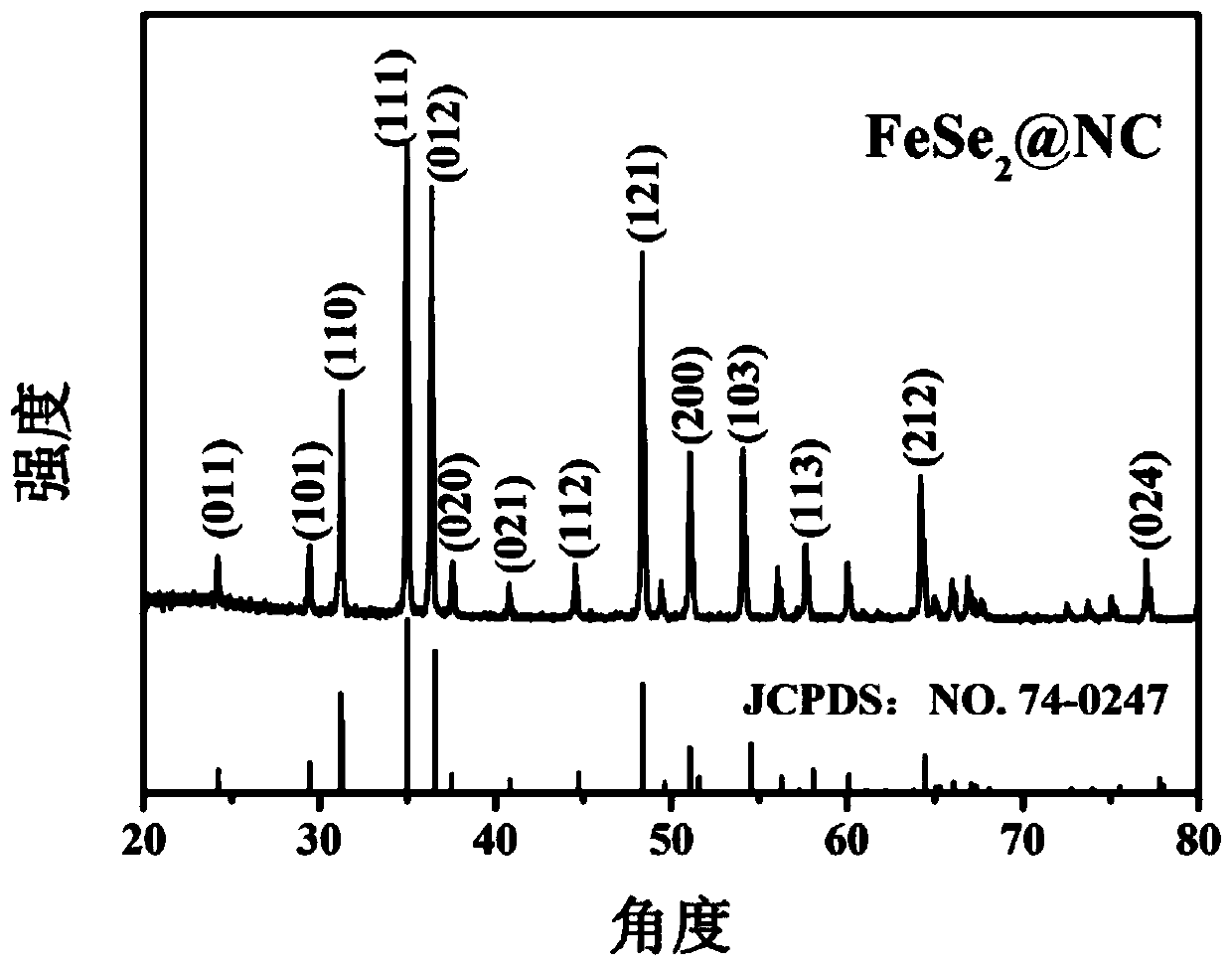

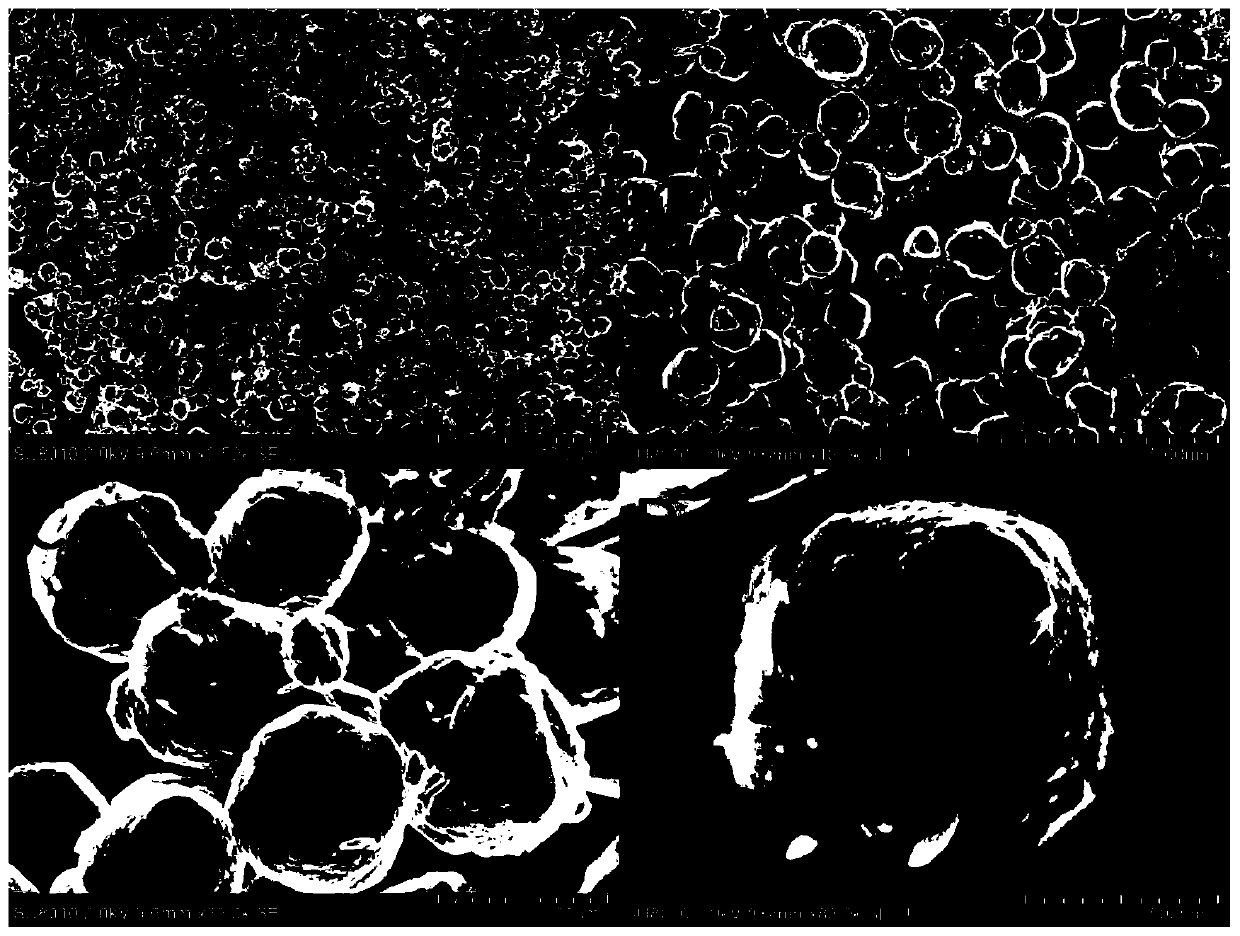

Microcubic composite material with hierarchical structure, electrode sheet, sodium ion battery and preparation method thereof

InactiveCN110459766AEasy to prepareReduce energy consumptionNegative electrodesSecondary cellsSodium-ion batteryElectrochemistry

The invention relates to a microcubic composite material with a hierarchical structure, an electrode sheet, a sodium ion battery and a preparation method thereof. The preparation method firstly prepares a precursor FeFe(CN)6 by a simple heat-assisted method, and in a later selenization process, the iron atoms in the precursor are converted in-situ to FeSe2, and at the same time, packaging by a carbon skeleton converted simultaneously by an organic framework is carried out. The compound prepared by the method is prepared to an electrode as the negative electrode of a sodium ion battery, and through testing, electrochemical characteristics such as high specific capacity, long cycle life, and excellent rate performance are presented, and the preparation method has the series of advantages such as a simple process, low energy consumption, and low cost, and therefore has broad application prospects.

Owner:SOUTH CHINA NORMAL UNIVERSITY

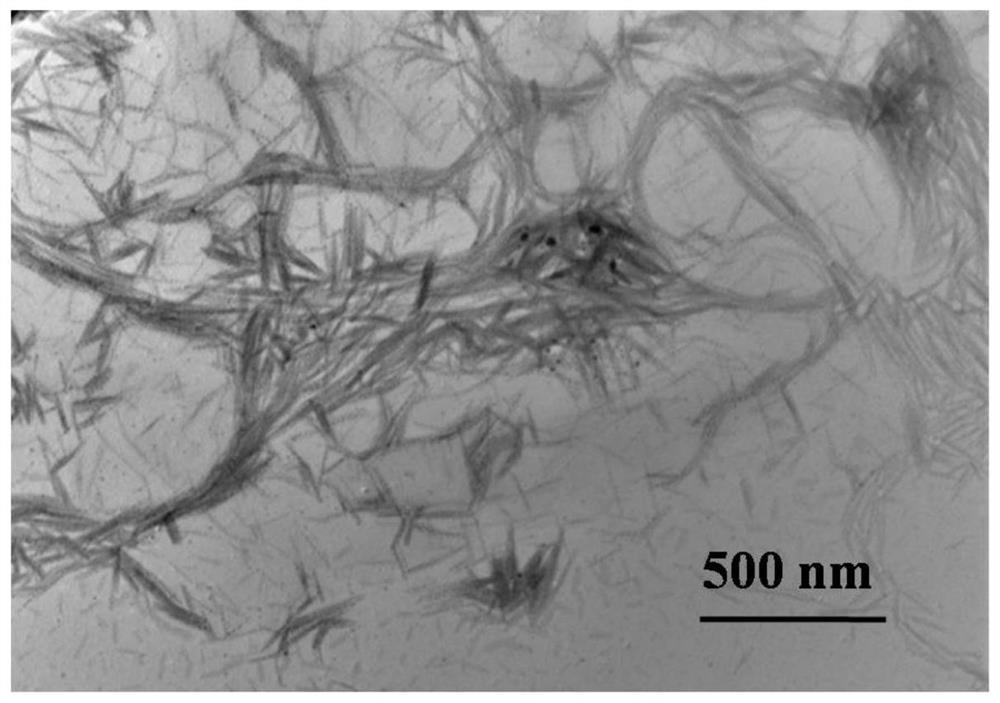

A kind of acicular nano-silver/nitrogen-doped graphene composite material and preparation method thereof

ActiveCN109437161BInhibition of agglomerationEvenly dispersedGrapheneNanotechnologyDoped grapheneNitrogen doped graphene

Owner:SHENYANG LIGONG UNIV

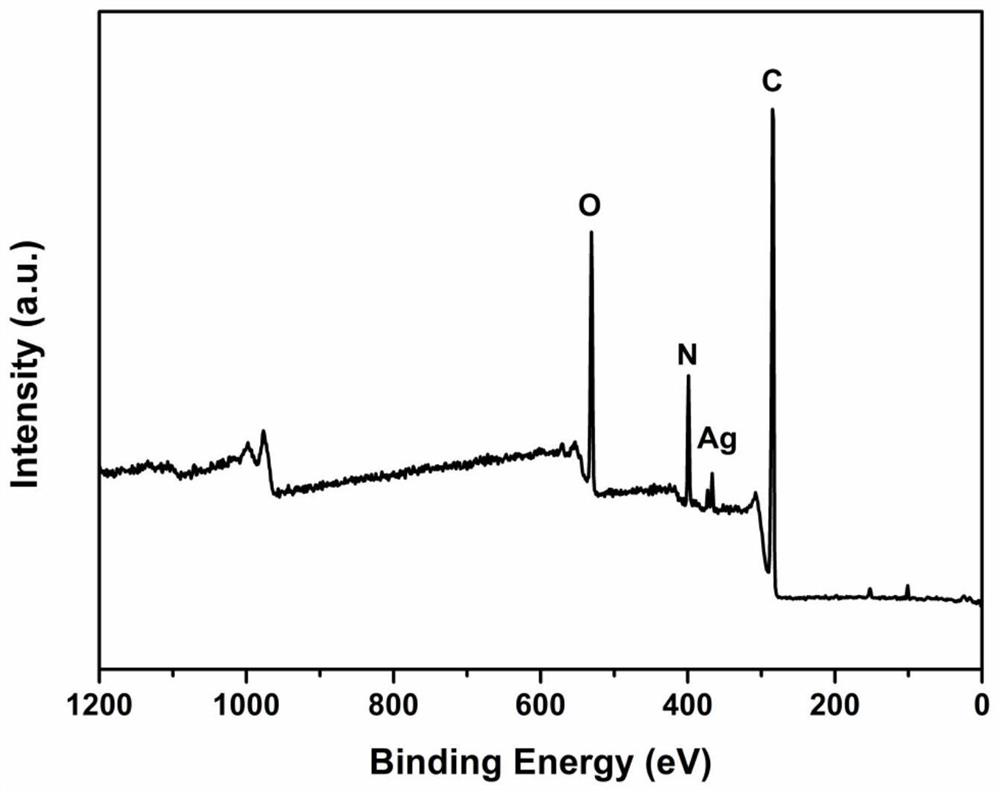

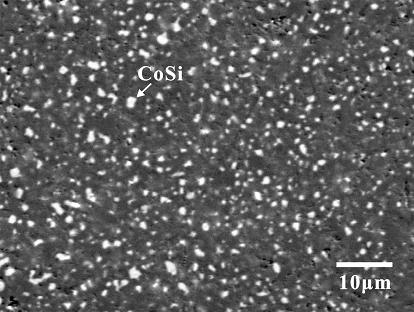

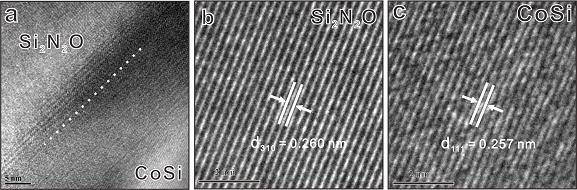

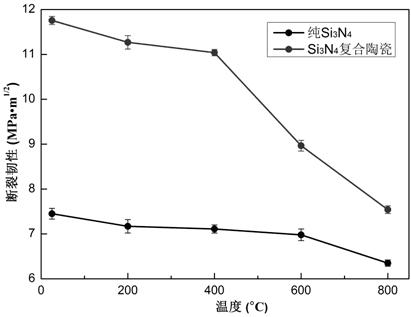

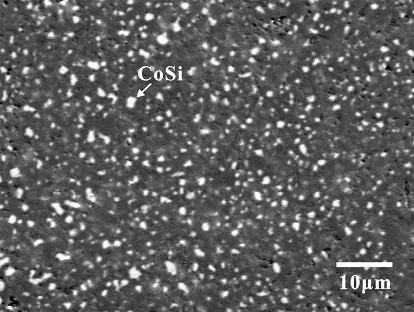

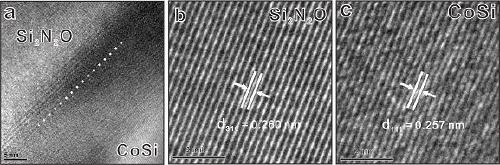

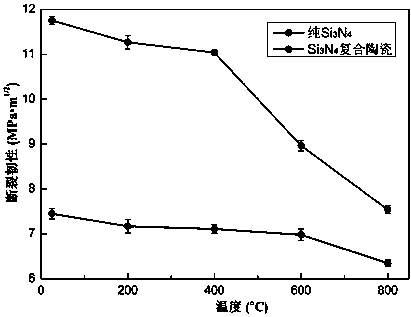

Preparation method of a tough and wear-resistant silicon nitride-based composite ceramic

The invention relates to a preparation method of a tough and wear-resistant silicon nitride-based composite ceramic, comprising the following steps: (1) by mass percentage, adding 80 to 95% of α-Si 3 N 4 powder and 5~20% C 4 h 6 CoO 4 • 4H 2 After the O aqueous solution is mixed, it is magnetically stirred under heating conditions until the solvent is completely evaporated to dryness to obtain a mixed powder; (2) the mixed powder is crushed through a 100-mesh sieve and put into a steel mold for pre-pressing to obtain a pre-pressed sample; (3) The pre-pressed sample is sintered at high temperature and high pressure, and then cooled with the furnace to obtain a blank; (4) After the blank is subjected to surface polishing treatment, a silicon nitride-based composite ceramic is obtained. The process of the invention is simple and controllable, the production efficiency is high, the powder does not need special treatment, and is suitable for mass production. The prepared finished product has excellent high-temperature toughness and anti-wear performance, and greatly prolongs the service life of ceramic parts in a high-temperature environment.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Nano-silver composite material for drinking water disinfection and preparation method thereof

The invention discloses a nano-silver composite material for drinking water disinfection and a preparation method thereof, belonging to the field of environment function materials. According to the composite material disclosed by the invention, polypropylene fiber is used as a carrier; the composite material is rich in ultra-large pore structures; the porosity factor is 30 to 80%; the apertures are 1 to 20mu m; the inner walls of pores are loaded with nano-silver particles; nano-silver is evenly distributed; the content is 0.1 to 5wt%; and the particle sizes are 5 to 80nm. The preparation method of the nanocomposite material can be summarized as follows: fully mixing polypropylene fiber with a solution containing silver ions and a surface active agent, stirring for a period of time, then taking out and drying the mixture, adding the mixture into a NaBH4 solution, after reacting for a period of time, taking out the mixture, using deionized water to wash away the residual surface active agent, and drying to obtain the composite material. The nanocomposite material disclosed by the invention is simple and easy in preparation, soft and light in texture, easy to carry and able to be used as a filler, and the material is high in disinfection efficiency, stable in nano-silver combination and low in wastage rate, does not generate disinfection by-products, and has obvious advantages compared with existing water body disinfection materials.

Owner:NANJING UNIV

Preparation method of tough wear-resistant silicon nitride based composite ceramic

The invention relates to a preparation method of a tough wear-resistant silicon nitride based composite ceramic. The preparation method comprises following steps: (1) mixing following components in percentage by weight: 80 to 95% of alpha-Si3N4 powder and 5 to 20% of a C4H6CoO4.4H2O water solution, and stirring the solution by a magnetic force under a heating condition until the solvent is totally evaporated to obtain mixed powder; (2) crushing the mixed powder, sieving the mixed powder by a 100-mesh sieve, filling the mixed powder into a steel die, and pre-pressing the mixed powder to obtain a pre-pressed sample; (3) sintering the pre-pressed sample at a high temperature under a high pressure, and cooling the sample in the furnace to obtain a blank; and (4) polishing the surface of the blank to obtain silicon nitride based composite ceramic. The technology is simple and controllable, the production efficiency is high, the powder does not need any special treatment, and the preparation method is suitable for massive production. The high temperature toughness and wear resistant performance of the prepared finished product are excellent. The service life of ceramic parts in a high temperature environment is largely prolonged.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of polyolefin/polyisoprene alloy material and preparation method thereof

The invention discloses a polyolefin alloy material and a preparation method thereof, belongs to the field of polyolefin materials and particularly relates to a polyolefin / polyisoprene alloy material as well as a preparation method and application thereof. In a polyolefin / polyisoprene alloy, the mass content of polyolefin is 5 to 99.4 percent, and the isotacticity is greater than 85 weight percent; the mass content of polyisoprene is 0.5 to 85 percent; the mole content of a trans-1,4 structure is greater than 85 percent, and the mass content of a block copolymer is 0.1 to 10 percent. The polyolefin / polyisoprene alloy material synthesized by adopting supported titanium and / or a vanadium catalyst through a two-segment polymerization method, disclosed by the invention, is a granular product with a core-shell structure, has the characteristics of high strength and high toughness, and is a novel polyolefin material.

Owner:QINGDAO UNIV OF SCI & TECH +2

A kind of high tactic polypropylene alloy and preparation method thereof

The invention discloses a high isotactic polypropylene alloy and a preparation method thereof. In the high isotactic polypropylene alloy of the invention, the mass content of isotactic polypropylene is 60% to 98%, and the mass content of polyolefin copolymerized elastomer is 1 % to 35%, and the mass content of random polypropylene is 1% to 5%. High isotactic polypropylene alloys are prepared by a two-step process: the first step uses Ziegler‑Natta catalyst to catalyze propylene slurry or gas phase or liquid phase bulk polymerization to prepare high isotactic polypropylene, and the second step continues to carry out butene and Gas phase copolymerization of other higher olefins to prepare high isotactic polypropylene alloys.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method and device of in-situ synthesized perovskite quantum dot coded resin microspheres

InactiveCN112495322APrevent leakageSolve heavy metal pollutionChemical/physical/physico-chemical microreactorsMicroballoon preparationPhysicsChemistry

The invention provides a preparation method of in-situ synthesized perovskite quantum dot coded resin microspheres. Perovskite quantum dot raw materials are introduced through a micro-fluidic device to synthesize perovskite quantum dots, a resin solution and an aqueous solution with a surfactant are introduced into the micro-fluidic device, perovskite is dispersed in the resin solution, the aqueous solution with a surfactant shears the resin solution to form a resin droplet template encapsulating the perovskite quantum dots, and finally, the resin droplet template is cured to obtain the perovskite quantum dot coded resin microspheres. The invention further provides a device capable of realizing the method. The perovskite quantum dot coded microspheres prepared by the method have good uniformity and monodispersity, the size is controllable, and the internal perovskite quantum dot coded emission wavelength in the preparation process is controllable. The method can be realized at normal temperature, the perovskite quantum dots cannot leak to cause unstable coding and heavy metal ion pollution after being packaged by resin, and the repeatability is good.

Owner:NANJING DRUM TOWER HOSPITAL

A Gas Hydrate Cave Completion Evaluation and Testing Method

The invention discloses a natural gas hydrate cave completion evaluation and testing device, comprising a reactor system, a cave completion system, a confining pressure control system, an inlet pressure control system, an outlet pressure control system, a gas-liquid-solid separation system, and a temperature control system and data acquisition and processing system; the reactor system is used to simulate the in-situ generation of natural gas hydrate, cave completion and exploitation; the temperature control system provides a constant temperature environment for the device; cave completion system, confining pressure control system, and inlet pressure control system , the outlet pressure control system and the gas-liquid-solid separation system are used to control the pressure and flow state of the experimental process; the data acquisition and processing system is used to collect and process the parameters of the experimental process. The invention also relates to a natural gas hydrate cave completion evaluation and testing method. The invention can carry out cave completion test on artificially synthesized hydrate-containing cores to evaluate the completion conditions of hydrate caves.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

A method for in-situ synthesis of silicate/carbon composite cathode material using rice husk powder as a silicon source

ActiveCN103346300BRealize resource utilizationIn situ synthesisCell electrodesCarbon compositesResource utilization

A disclosed method for in-situ synthesizing a silicate / carbon composite cathode material by taking rice husk carbon as a silicon source comprises the following preparation steps: (1) primary smashing of rice husks; (2) purification of the rice husks; (3) pyrolyzing the rice husks under catalysis of metal elements to obtain a SiMO / C mixture; (4) smashing the SiMO / C mixture to D50=1-2 [mu]m by an jet mill; (5) adding a lithium source, ball milling and mixing; and (6) sintering under gas protection to obtain Li2MSiO4 / C. According to the method, cheap biological silica is used to prepare the silicate cathode material, resource utilization of agriculture wastes is realized, and high added-value products are produced; at the same time, the rice husk carbon is obtained by the middle-temperature pyrolysis method, the residual carbon of the rice husk carbon is taken as a carbon source, and the synthesis process of the silicate cathode material does not need extra carbon, and the in-situ synthesis of the Li2MSiO4 material is realized synchronously.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Nano FeF3/C composite positive electrode material, preparation method thereof and lithium ion battery

ActiveCN113258074AStable structureImproved magnification performanceMaterial nanotechnologySecondary cellsTrifluorideFerrocene

The invention discloses a nano FeF3 / C composite positive electrode material, a preparation method thereof and a lithium ion battery. The method comprises the following steps: (1) putting reaction raw materials into a reaction kettle, filling the reaction kettle with protective gas, and sealing, wherein the reaction raw materials comprise an iron source and polytetrafluoroethylene; and (2) carrying out heat treatment on the sealed reaction kettle at the temperature of more than or equal to 400 DEG C to obtain the nano FeF3 / C composite positive electrode material, wherein the iron source is selected from ferrocene and / or ferric trichloride. According to the invention, the property of sublimation of polytetrafluoroethylene at a low temperature is utilized, and a specific type of iron source and fluorine source are fully reacted by using a closed reaction kettle; and the used polytetrafluoroethylene can provide a fluorine source and can be cracked to obtain the iron trifluoride composite positive electrode material with superfine nano-particles at the same time. The lithium ion battery positive electrode material provided by the invention has the advantages of high reversible specific capacity, excellent rate capability and good cycling stability.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

A method for in-situ preparation of porous silicon-carbon composites

ActiveCN110350168BIn situ synthesisSmall sizeMaterial nanotechnologyCell electrodesCarbon compositesOrganic solvent

The invention discloses a method for preparing a porous silicon-carbon composite material in situ; the method comprises the following steps that (1) a polymer with positive charges is mixed with a solvent to obtain a mixed solution, wherein the main chain or the side group of the polymer with positive charges has an amino group; and the solvent is a mixed solvent composed of an organic solvent andwater; (2) a silicon source is mixed with the mixed solvent obtained in the step (1), the mixture is subjected to hydrolysis reaction to obtain a suspension, and then the suspension is subjected to post-treatment A to obtain a silicon-carbon precursor; and (3) the silicon-carbon precursor is mixed with magnesium powder, magnesium thermal reduction reaction is carried out to obtain a crude product, and post-treatment B is performed to obtain the porous silicon-carbon composite material. The invention discloses the method for preparing the porous silicon-carbon composite material in situ; the prepared porous silicon-carbon composite material is complete in morphology, the particle sizes of the composite material are relatively small, and the particle sizes of the composite material are about 20-60 nm. By taking the porous silicon-carbon composite material as a negative electrode, the cycling stability of the lithium battery can be remarkably improved.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com