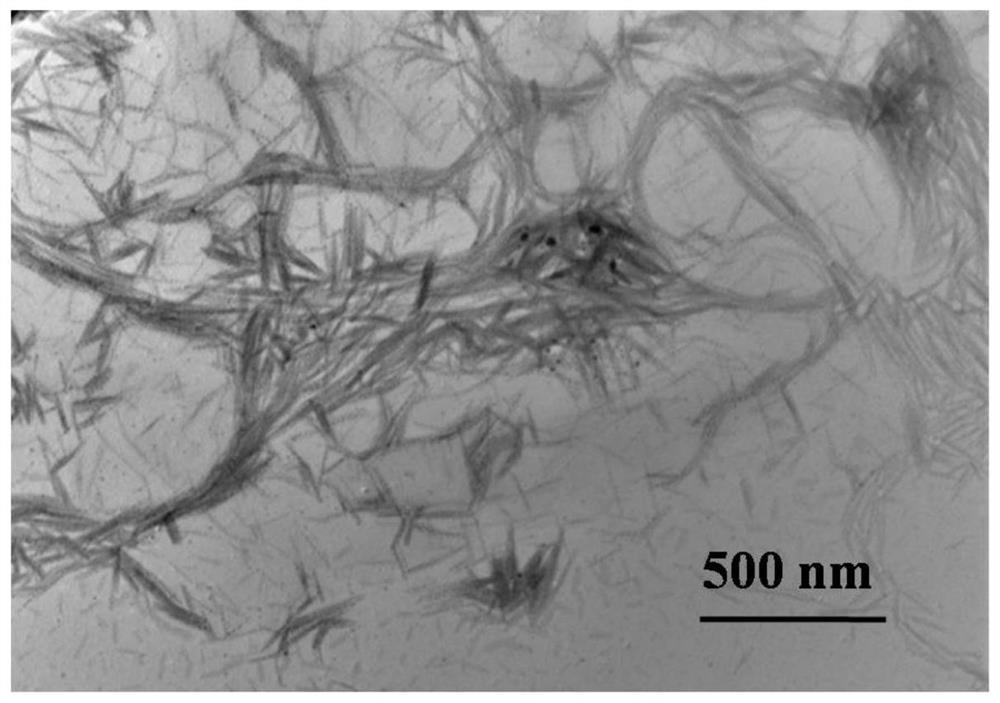

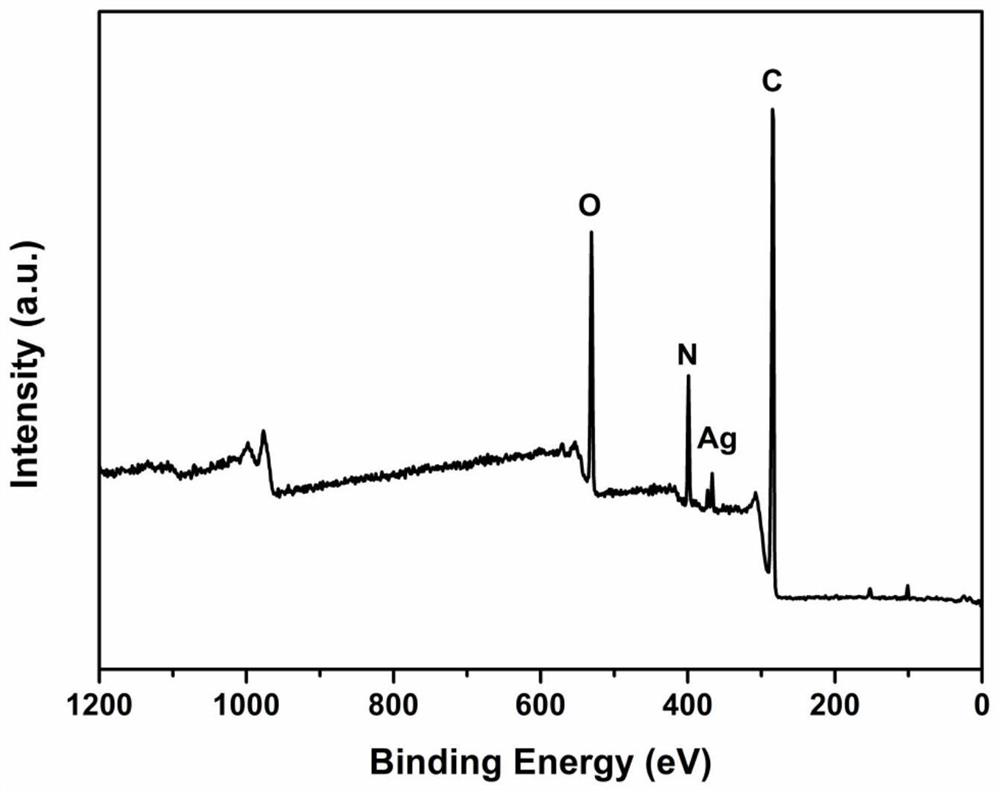

A kind of acicular nano-silver/nitrogen-doped graphene composite material and preparation method thereof

A technology for nitrogen-doped graphene and composite materials, which is applied in the field of needle-shaped nano-silver/nitrogen-doped graphene composite materials and the preparation thereof, can solve the problems of complicated preparation process and the like, achieves simple synthesis method, easy implementation, and inhibition of agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A needle-shaped nano-silver / nitrogen-doped graphene composite material, according to the mass ratio, graphene oxide: ammonia: polyvinylpyrrolidone (K-30): silver nitrate=1:10:60:10.

[0031] (1) disperse the graphene oxide prepared by 30mg Hummers method into the water of 30ml, prepare the graphene oxide dispersion liquid of 1.0mg / ml;

[0032] (2) Add 300mg of ammonia water and 1.8g of polyvinylpyrrolidone (K-30) to the graphene oxide dispersion to prepare a mixed solution;

[0033] (3) in 30ml water, add the silver nitrate of 0.3g, be mixed with silver nitrate aqueous solution;

[0034] (4) After ultrasonically mixing the mixed solution and the silver nitrate aqueous solution, transfer it to a hydrothermal reaction kettle at a temperature of 120° C., and react for 12 hours to obtain a crude composite material;

[0035] (5) centrifuging, washing, and freeze-drying the crude composite material obtained in step (4) to obtain the needle-shaped nano-silver / nitrogen-doped g...

Embodiment 2

[0038] A needle-shaped nano-silver / nitrogen-doped graphene composite material, according to the mass ratio, graphene oxide: urea: polyvinylpyrrolidone (K-30): silver nitrate=1:10:60:10.

[0039](1) disperse the graphene oxide prepared by 30mg Hummers method into 30ml of water, and prepare the graphene oxide dispersion of 1.0mg / ml;

[0040] (2) Add 300mg urea and 1.8g polyvinylpyrrolidone (K-30) to the graphene oxide dispersion to prepare a mixed solution;

[0041] (3) in 30ml water, add the silver nitrate of 0.3g, be mixed with silver nitrate aqueous solution;

[0042] (4) After ultrasonically mixing the mixed solution and the silver nitrate aqueous solution, transfer it to a hydrothermal reaction kettle at a temperature of 120° C., and react for 10 hours to obtain a crude composite material;

[0043] (5) centrifuging, washing, and freeze-drying the crude composite material obtained in step (4) to obtain the needle-shaped nano-silver / nitrogen-doped graphene composite material...

Embodiment 3

[0045] A needle-shaped nano-silver / nitrogen-doped graphene composite material, according to the mass ratio, graphene oxide: ammonia: polyvinylpyrrolidone (K-30): silver nitrate=1:10:60:5.

[0046] (1) disperse the graphene oxide prepared by 30mg Hummers method into 30ml of water, and prepare the graphene oxide dispersion of 1.0mg / ml;

[0047] (2) Add 300mg of ammonia water and 1.8g of polyvinylpyrrolidone (K-30) to the graphene oxide dispersion to prepare a mixed solution;

[0048] (3) in 30ml water, add the silver nitrate of 0.15g, be mixed with silver nitrate aqueous solution;

[0049] (4) After ultrasonically mixing the mixed solution and the silver nitrate aqueous solution, transfer it to a hydrothermal reaction kettle at a temperature of 120° C., and react for 15 hours to obtain a crude composite material;

[0050] (5) centrifuging, washing, and freeze-drying the crude composite material obtained in step (4) to obtain the needle-shaped nano-silver / nitrogen-doped graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com