Method of preparing battery electrodes

a battery electrode and electrode technology, applied in the field of lithiumion batteries, can solve the problems of pvdf only soluble in some specific, affecting the performance of electrodes,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

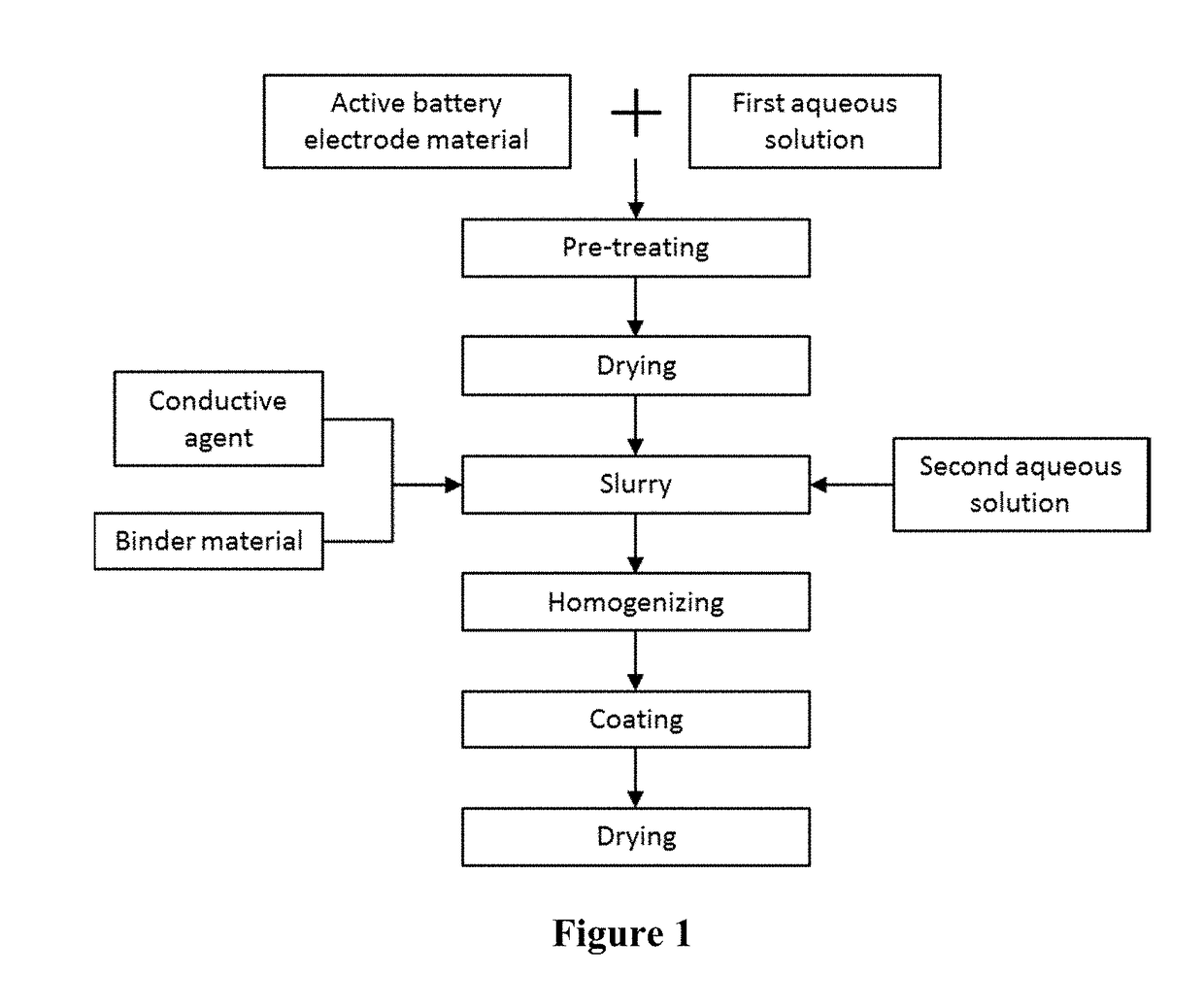

Method used

Image

Examples

example 1

A) Pre-treatment of Active Battery Electrode Material

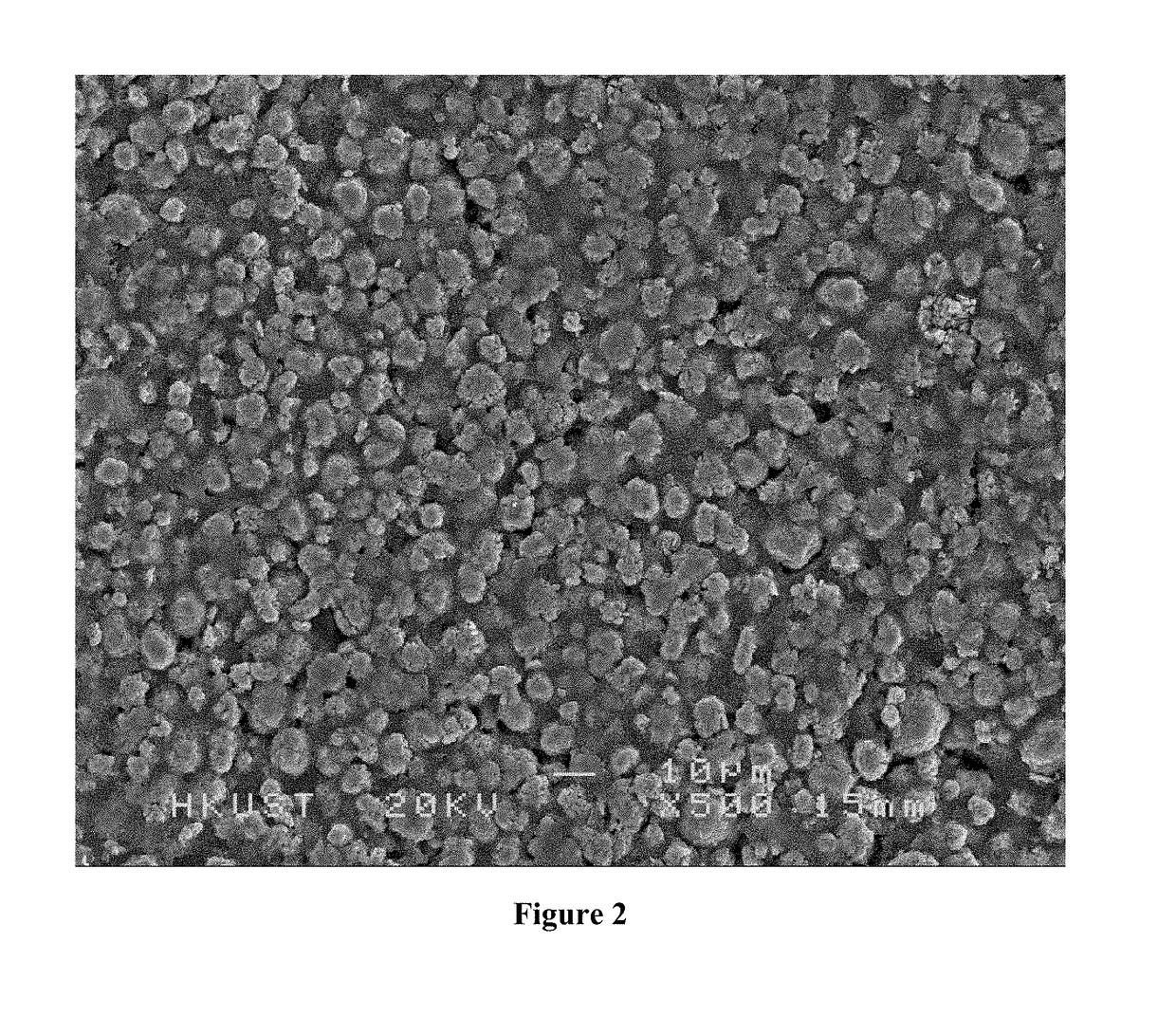

[0180]A particulate cathode material LiNi0.33Mn0.33Co0.33O2 (NMC333) (obtained from Xiamen Tungsten CO. Ltd., China) was added to a stirring solution containing 50% deionized water and 50% ethanol at room temperature to form a suspension having a solid content of about 35% by weight. The pH of the suspension was measured using a pH meter and the pH was about 7. The suspension was further stirred at room temperature for 5 hours. Then the suspension was separated and dried by a 2.45 GHz microwave dryer (ZY-4HO, obtained from Zhiya Industrial Microwave Equipment Co., Ltd., Guangdong, China) at 750 W for 5 minutes to obtain a pre-treated active battery electrode material.

B) Preparation of Positive Electrode Slurry

[0181]A positive electrode slurry was prepared by mixing 91 wt. % pre-treated active battery electrode material, 4 wt. % carbon black (SuperP; Timcal Ltd, Bodio, Switzerland), 4 wt. % polyacrylonitrile (PAN) (LA 132, Chengdu ...

example 2

Assembling of Pouch-Type Battery

[0185]After drying, the resulting cathode film and anode film of Example 1 were used to prepare the cathode and anode respectively by cutting into individual electrode plates. A pouch cell was assembled by stacking the cathode and anode electrode plates alternatively and then packaged in a case made of an aluminum-plastic laminated film. The cathode and anode electrode plates were kept apart by separators and the case was pre-formed. An electrolyte was then filled into the case holding the packed electrodes in high-purity argon atmosphere with moisture and oxygen content6 (1 M) in a mixture of ethylene carbonate (EC), ethyl methyl carbonate (EMC) and dimethyl carbonate (DMC) in a volume ratio of 1:1:1. After electrolyte filling, the pouch cells were vacuum sealed and then mechanically pressed using a punch tooling with standard square shape.

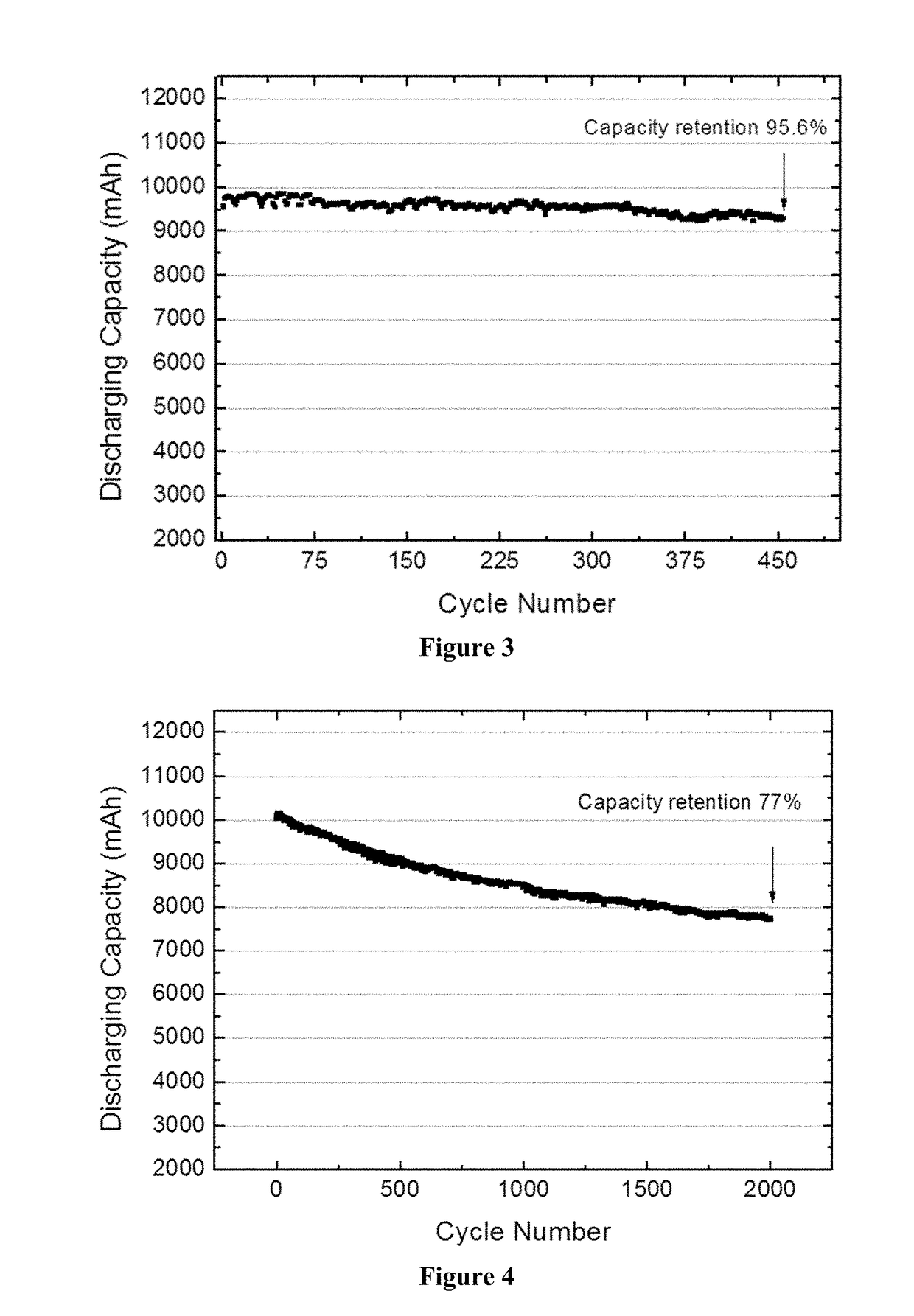

Electrochemical Measurements of Example 2

I) Nominal Capacity

[0186]The cell was tested galvanostatically at a cur...

example 3

A) Pre-Treatment of Active Battery Electrode Material

[0188]A particulate cathode material LiMn2O4 (LMO) (obtained from HuaGuan HengYuan LiTech Co. Ltd., Qingdao, China) was added to a stirring 7 wt. % solution of acetic acid in water (obtained from Aladdin Industries Corporation, China) at room temperature to form a suspension having a solid content of about 50% by weight. The pH of the suspension was measured using a pH meter and the pH was about 6. The suspension was further stirred at room temperature for 2.5 hours. Then the suspension was separated and dried by a 2.45 GHz microwave dryer at 750 W for 5 minutes to obtain a pre-treated active battery electrode material.

B) Preparation of Positive Electrode Slurry

[0189]Carbon nanotube (NTP2003; Shenzhen Nanotech Port Co., Ltd., China) (25 g) was pretreated in 2 L of an alkaline solution containing 0.5 wt. % NaOH for about 15 minutes and then washed by deionized water (5 L). The treated carbon nanotube was then dispersed in deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com