Fe, Ni and N three-doped carbon nanotube coated type FeNi@NCNT catalyst as well as preparation method and application thereof

A technology of carbon nanotubes and catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of difficult separation of nanofibers, low yield, poor strength, etc., and achieve improved electrochemical performance. Activity and stability, high specific surface area and conductivity, effect of inhibiting aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

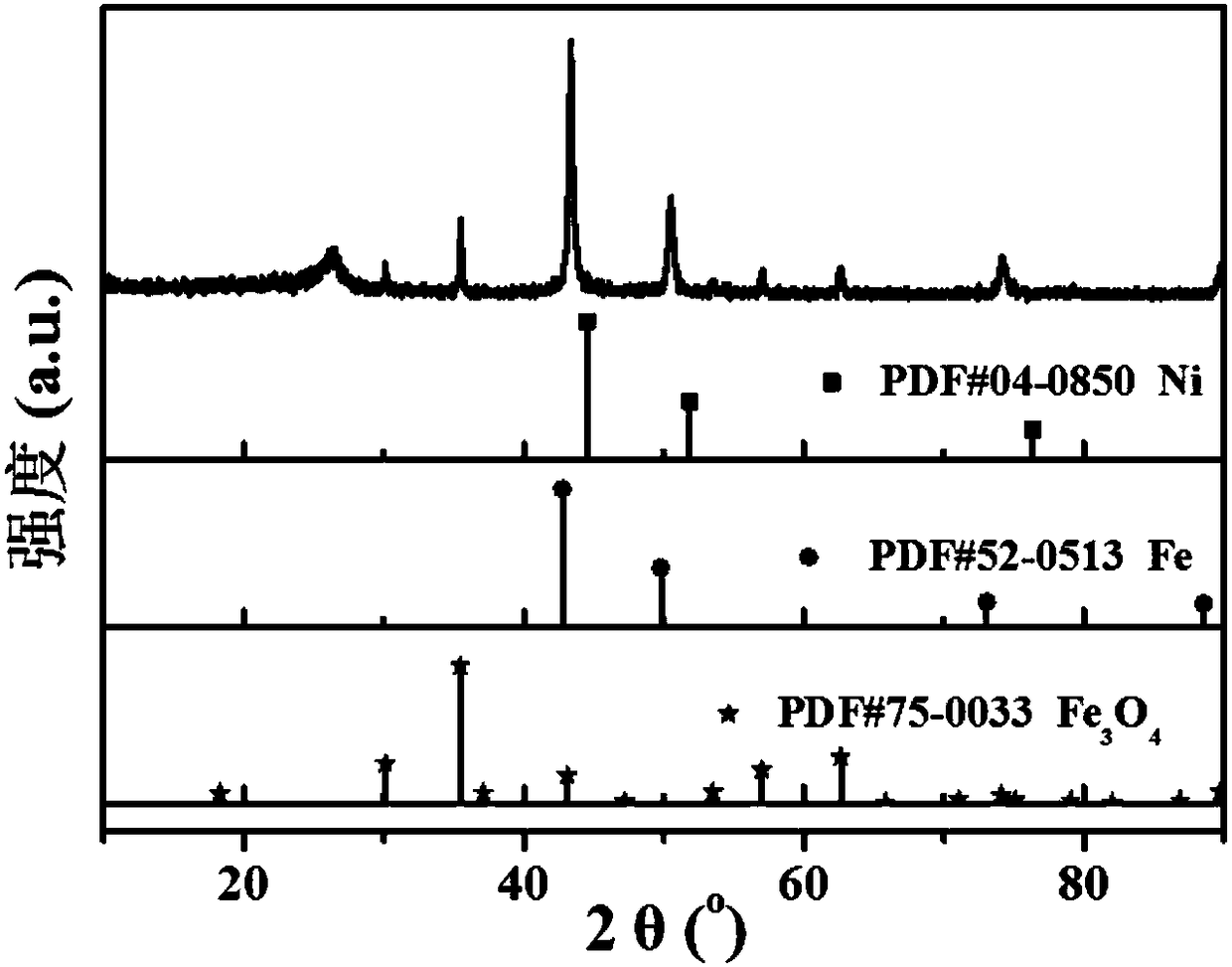

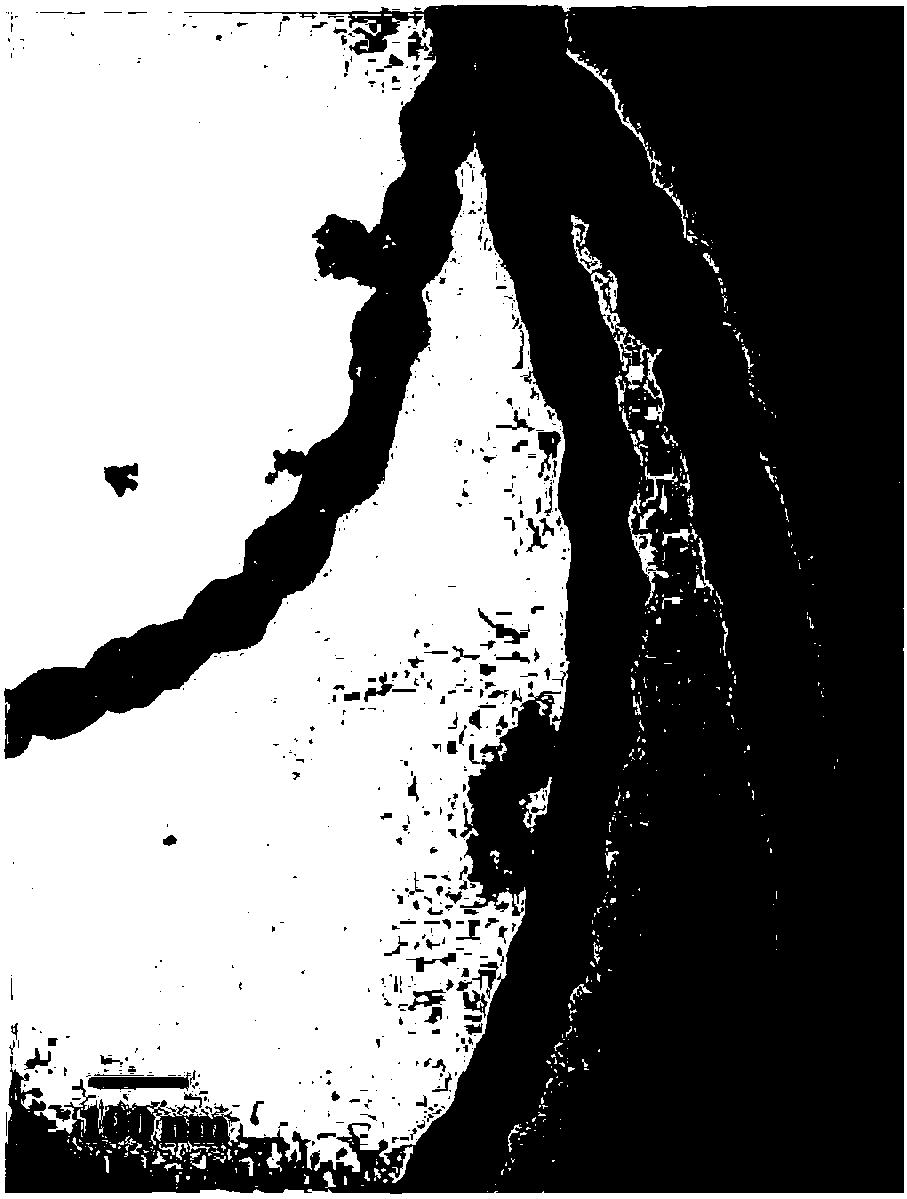

[0046] Example 1: DA-Fe 3 Ni-800 (DA is dicyandiamide, Fe 3 Ni refers to ferric ammonium citrate and NiCl in raw materials 2 ·6H 2 The molar mass ratio of O is 3:1, the molar ratio of DA to metal Fe and Ni is about 40:1, and 800 means the pyrolysis temperature is 800°C)

[0047] 0.1103g of ferric ammonium citrate and 0.0178g of NiCl 2 ·6H 2 Dissolve O in 10mL deionized water to obtain solution A; then weigh 1g of dicyandiamide and dissolve it in a mixed solution of A and 20mL absolute ethanol to obtain solution B, stir in an oil bath at 60°C for 30min to fully dissolve and mix well ; Transfer the uniformly mixed solution B to a petri dish, and dry it in an air drying oven at 60°C for 11 hours to obtain a catalyst precursor; place the dried precursor in a mortar, grind it evenly, place it in a quartz boat, and place it in a nitrogen protection 5°C min -1 Program temperature to 550°C for 1h, then 3°C for min -1 Heat up to 800°C and then calcined for 1 hour, then naturally...

Embodiment 2

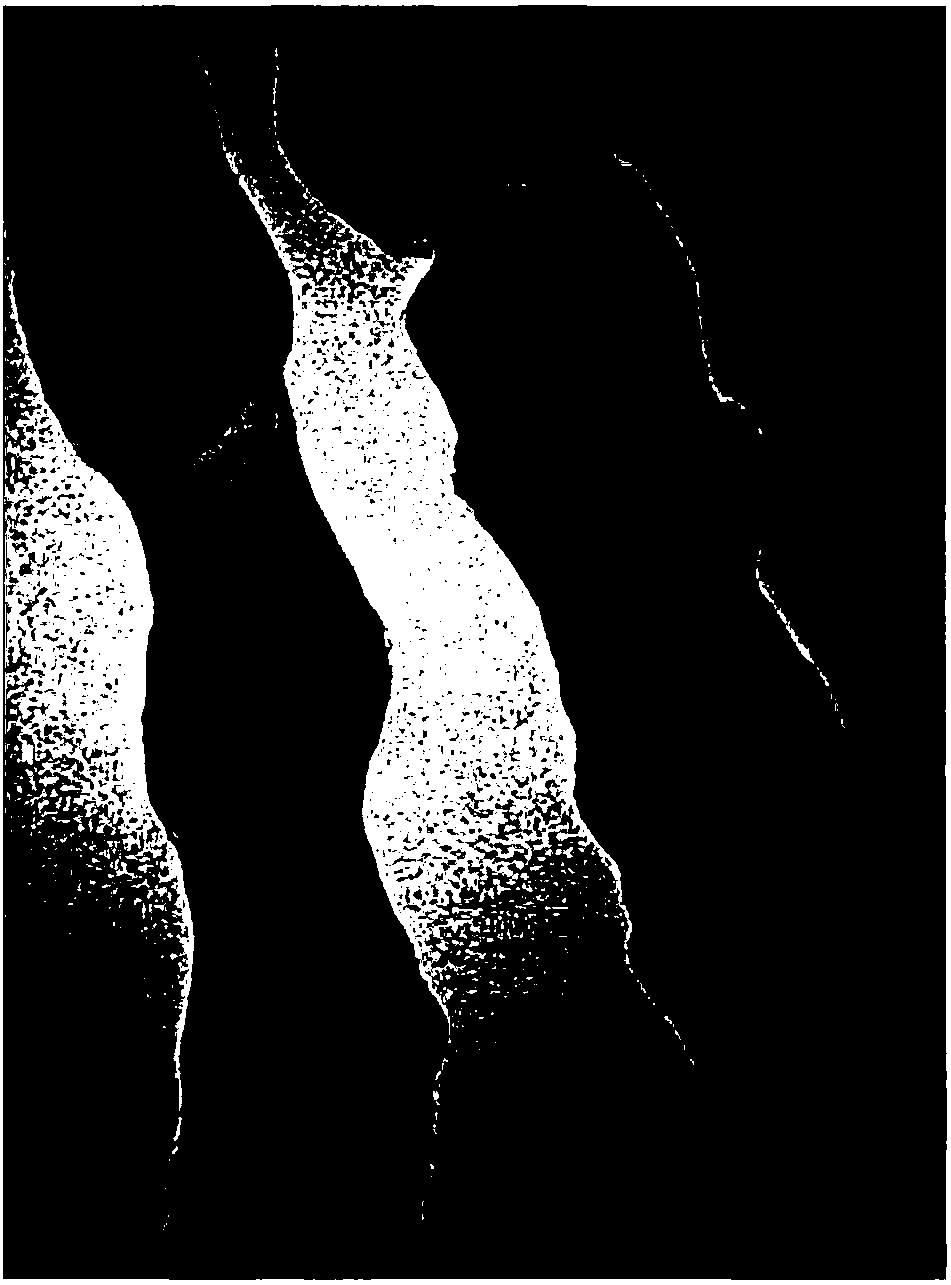

[0048] Embodiment 2: DA-FeNi-800 (DA: dicyandiamide, FeNi refers to ferric ammonium citrate and NiCl in the raw material 2 ·6H 2 The molar mass ratio of O is 1:1, the molar ratio of DA to metal Fe and Ni is about 40:1, and 800 refers to the pyrolysis temperature of 800°C)

[0049] 0.0735g of ferric ammonium citrate and 0.0362g of NiCl 2 ·6H 2 Dissolve O in 10mL of deionized water to obtain solution A; then weigh 1g of dicyandiamide and dissolve it in the mixed solution of A and 20mL of absolute ethanol to obtain solution B, stir in an oil bath at 60°C for 30min to fully dissolve and mix evenly; Transfer the uniformly mixed solution B to a petri dish, and dry it in an air drying oven at 60°C for 11 hours to obtain a catalyst precursor; place the dried precursor in a mortar, grind it evenly, and place it in a quartz boat, under nitrogen protection 5°C min -1 Program temperature to 550°C for 1h, then 3°C for min -1 The temperature was raised to 800°C and then calcined for 1 ...

Embodiment 3

[0050] Example 3: DA-FeNi 3 -800 (DA: dicyandiamide, FeNi 3 Refers to ferric ammonium citrate and NiCl in raw materials 2 ·6H 2 The molar mass ratio of O is 1:3, the molar ratio of DA to metal Fe and Ni is about 40:1, and 800 means the pyrolysis temperature is 800°C)

[0051] 0.0367g of ferric ammonium citrate and 0.0535g of NiCl 2 ·6H 2 Dissolve O in 10mL of deionized water to obtain solution A; then weigh 1g of dicyandiamide and dissolve it in the mixed solution of A and 20mL of absolute ethanol to obtain solution B, stir in an oil bath at 60°C for 30min to fully dissolve and mix evenly; Transfer the uniformly mixed solution B to a petri dish, and dry it in an air drying oven at 60°C for 11 hours to obtain a catalyst precursor; place the dried precursor in a mortar, grind it evenly, and place it in a quartz boat, under nitrogen protection 5°C min -1 Program temperature to 550°C for 1h, then 3°C for min -1 Raise the temperature to 800°C and then calcinate for 1 hour, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com