Three-dimensional compound structure based on three-dimensional MXene and general synthesis method thereof

A three-dimensional composite and synthetic method technology, applied in the field of nanomaterials, can solve the problems that plague inorganic nanomaterials, and achieve the effects of broad application prospects, low energy consumption, and easy control and versatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

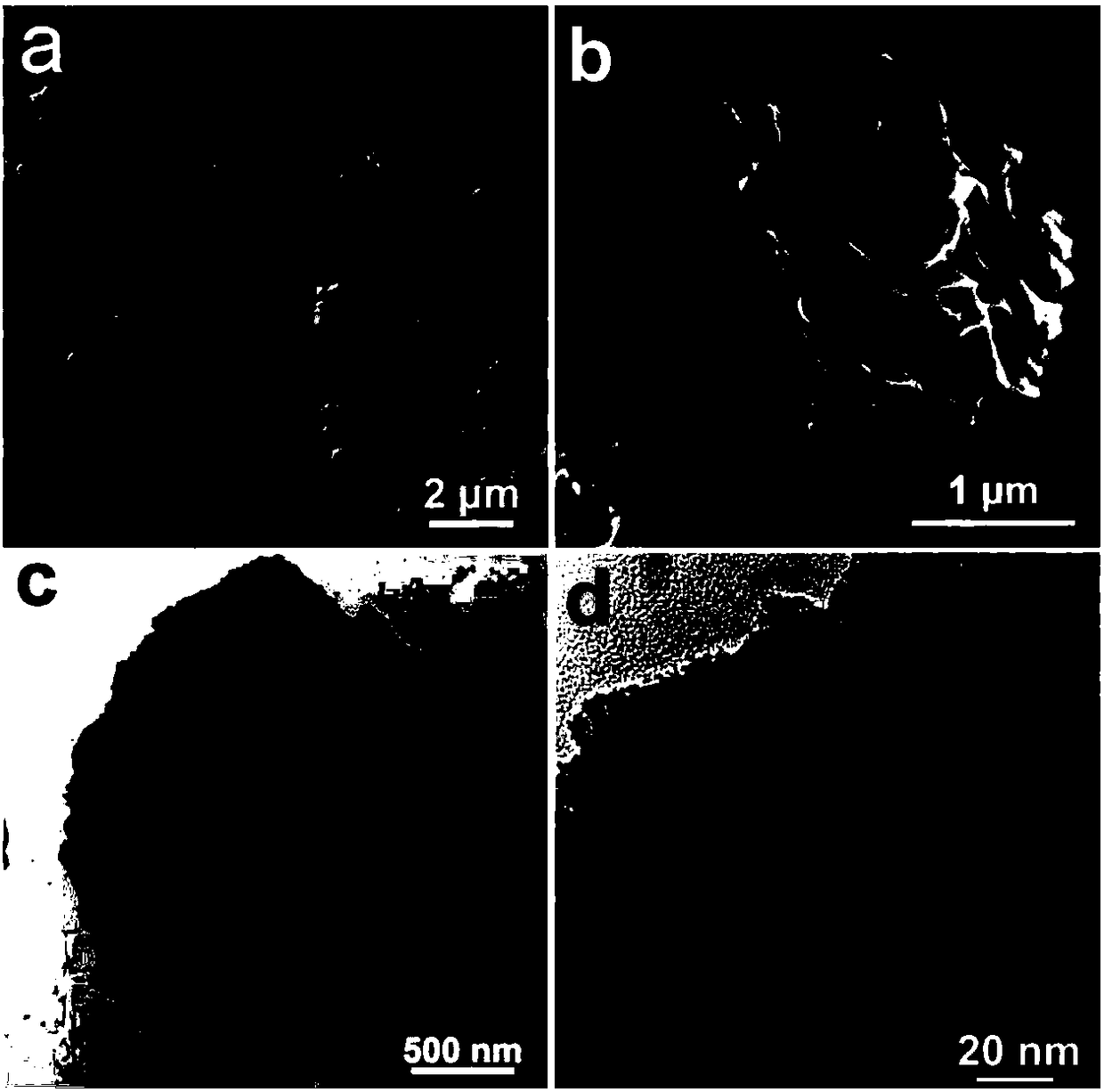

[0039] Example 1 load Co 3 o 4 Preparation method of three-dimensional MXene of nanoparticles (Scheme 1)

[0040] 1) 100mL MXene (2mg mL -1 ), 0.2g auxiliary polyvinylpyrrolidone and 2mmol Co(OAC) 2 4H 2 O is dispersed in water to prepare a suspension.

[0041] 2) Using an ultrasonic atomizer (3.2W, Siansonic DP30) to atomize the mixed suspension described in 1) into aerosol droplets with a size of about several microns;

[0042] 3) Using Ar gas as the carrier gas, the aerosol micro-droplets described in 2) are blown into a tube furnace with a preset temperature of 600° C. to make them dry quickly. The obtained product has an average size of about 4-6 μm, loaded with Co 3 o 4 Flower-like three-dimensional MXene particles of nanoparticles, Co 3 o 4 Nanoparticles are on the order of a few nanometers in size.

Embodiment 2

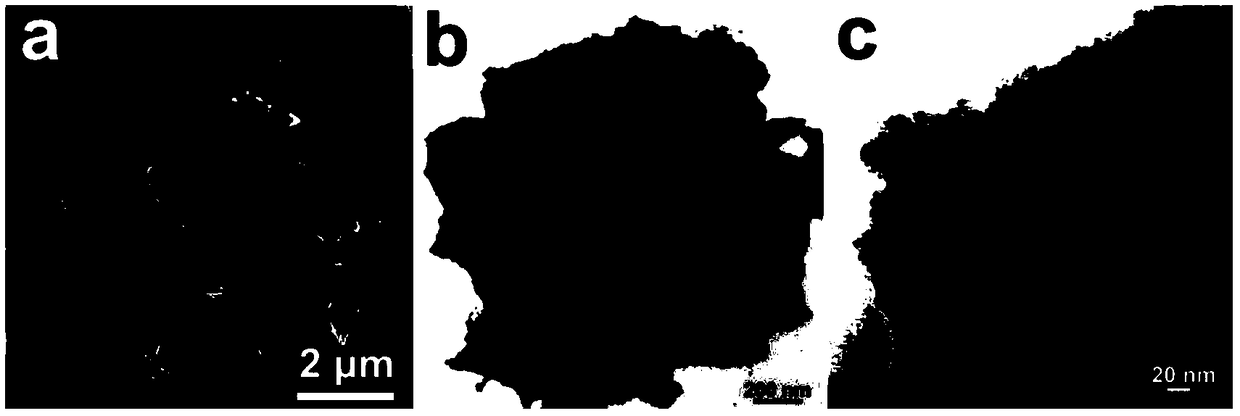

[0043] Example 2 load SnO 2 Preparation method of three-dimensional MXene of nanoparticles (Scheme 1)

[0044] 1) 100mL MXene (10mg mL -1 ), 0.2g auxiliary polyvinylpyrrolidone and 2mmol SnCl 4 Disperse in water to prepare a suspension.

Embodiment 3

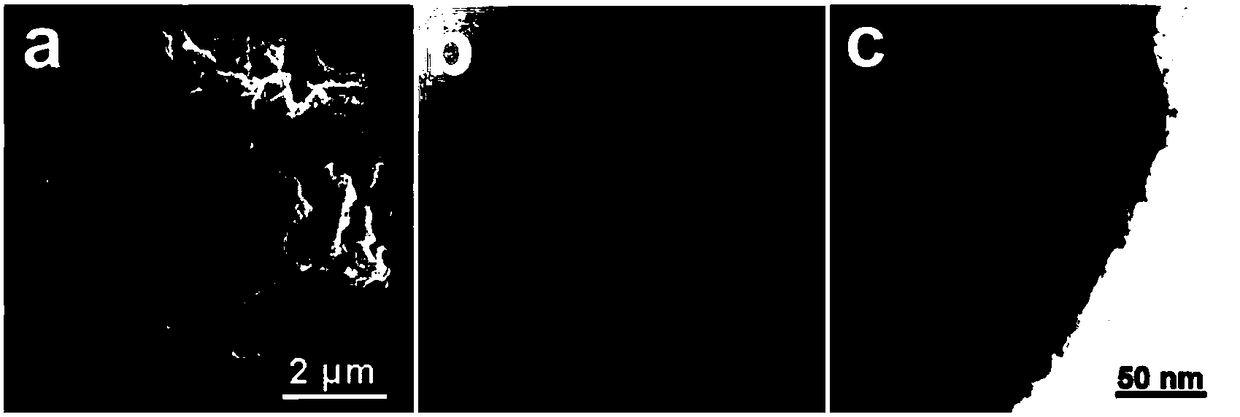

[0047] The preparation method of the three-dimensional MXene of embodiment 3 loading Pt nanoparticles (scheme one)

[0048] 1) 100mL MXene (80mg mL -1 ), 0.2g polyvinylpyrrolidone and 2mmol H 2 PtCl 6 ·6H 2 O is dispersed in water to prepare a suspension.

[0049] 2) with embodiment 3 step 2);

[0050] 3) Using Ar gas as the carrier gas, the aerosol micro-droplets described in 2) are blown into a tube furnace with a preset temperature of 800°C to make them dry quickly. The obtained product is a flower-shaped three-dimensional MXene particle with an average size of about 3-4 μm and loaded with Pt nanoparticles, and the size of the Pt nanoparticles is about several nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com