Natural gas hydrate cave well completion evaluating and testing device and method

A testing device, a technology for natural gas, applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the difficulty in evaluating and interpreting the stimulation mechanism, the implementation effect has not been effectively evaluated, and the cave completion mechanism is unclear, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

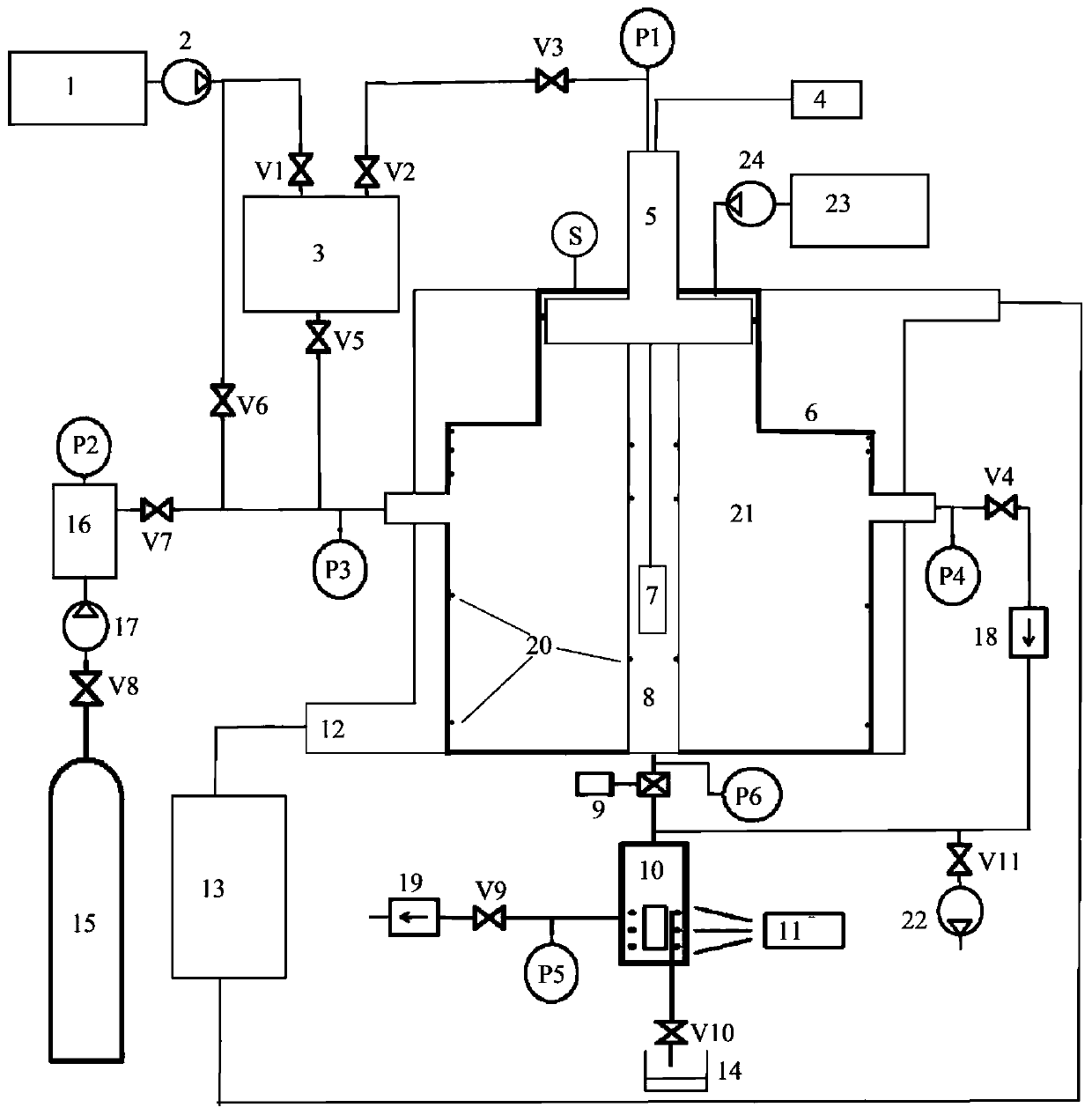

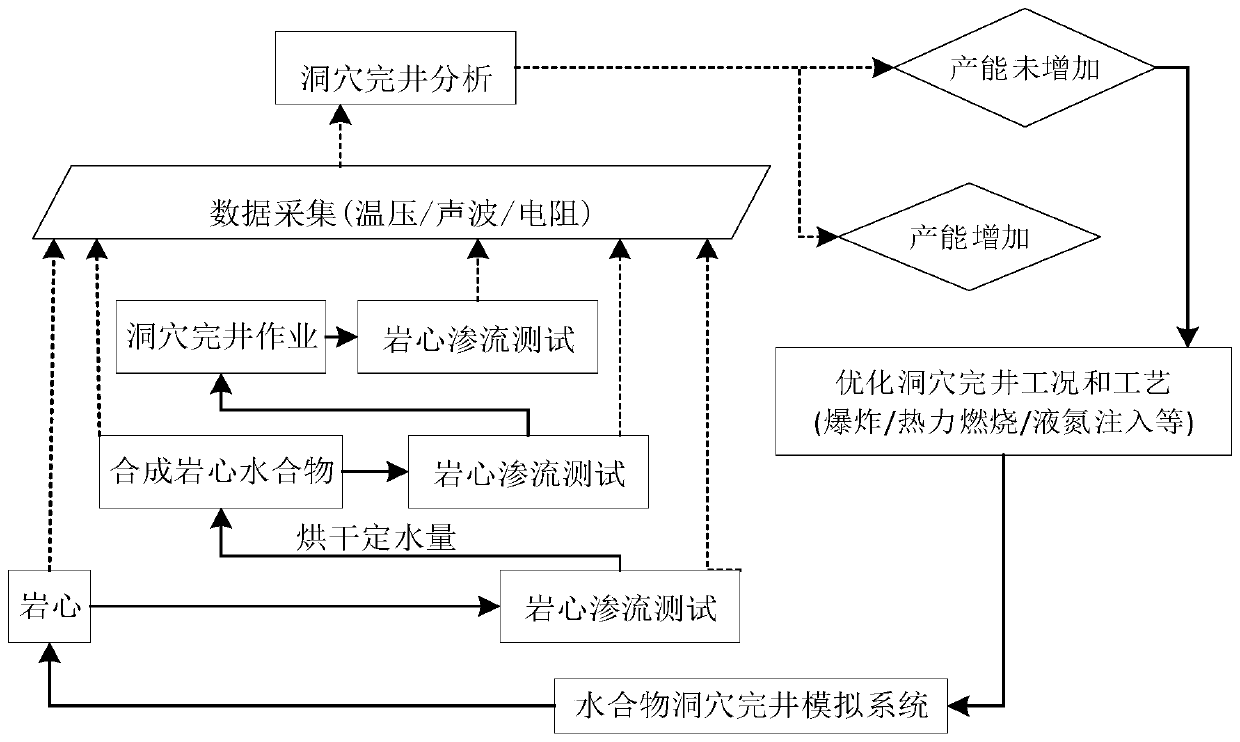

[0032] Such as figure 1 and figure 2 As shown, a natural gas hydrate cave completion evaluation test device includes a reactor system, a cave completion system, a confining pressure control system, an inlet pressure control system, an outlet pressure control system, a gas-liquid-solid separation system, a temperature control system, Data acquisition and processing system, as well as pipelines, valves and control systems connecting various components.

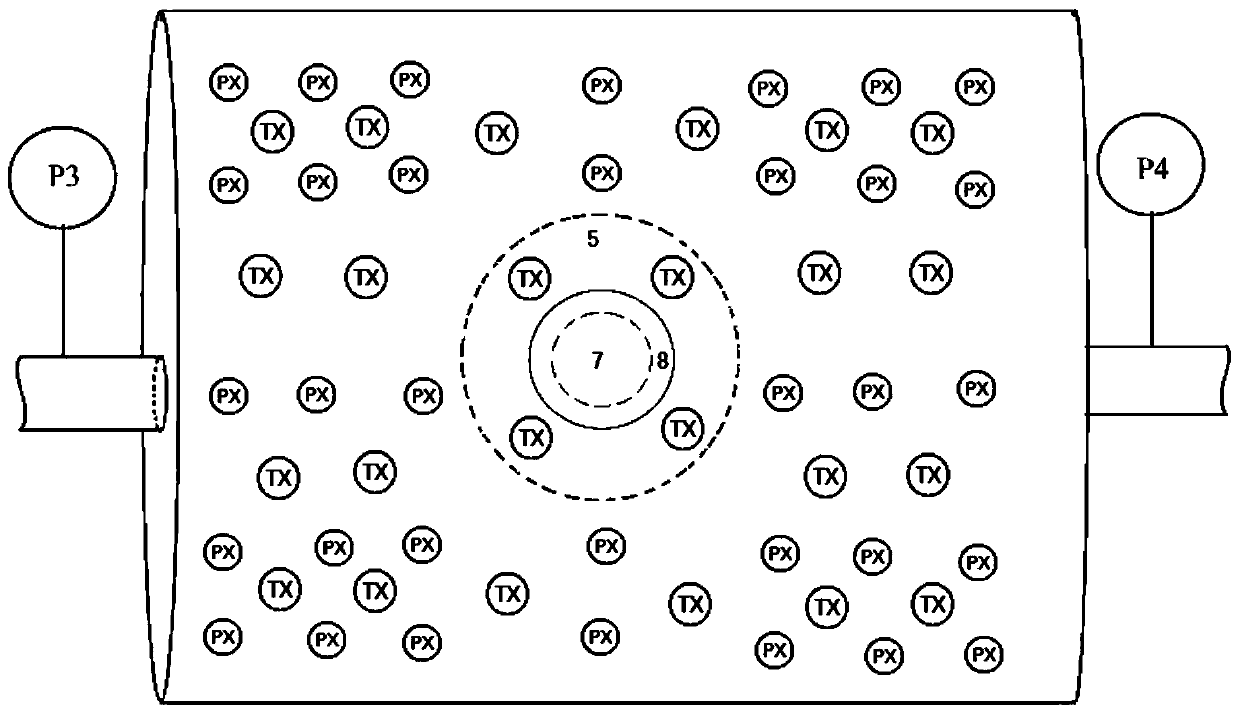

[0033] The reactor system is used for simulating the in-situ generation of natural gas hydrate, cave completion and exploitation, including the reactor 6, the confining pressure piston 5 and the wellbore 8. The reaction kettle 6 is cylindrical, placed horizontally, and the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com