A method for in-situ preparation of porous silicon-carbon composites

A carbon composite material, in-situ preparation technology, applied in nanotechnology, structural parts, electrical components, etc. for materials and surface science, can solve problems such as high cost, complex equipment requirements, unfavorable mass production and industrialization, etc. achieve uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Add 0.2g PEI (Mw=70000) into a mixed solvent composed of 30mL ethanol and 2mL water, stir at room temperature for 1h to obtain a mixed solution;

[0054] 2. While stirring, slowly add tetraethyl orthosilicate (1.15mL) dropwise into the mixed solution prepared in step 1, heat and stir at 60°C for 3h to obtain a milky white suspension, and centrifuge (speed: 8000r / min) to obtain transparent colloid;

[0055] 3. Dry the transparent colloid in a vacuum drying oven at 80°C for 6 hours to obtain a white powder, which is the silicon carbon precursor;

[0056] 4. Mix 0.2g of silicon-carbon precursor with magnesium powder of equal mass, put it into a tube furnace and react at 650°C for 6h under a protective atmosphere of argon to obtain a white powder, wash the powder with hydrochloric acid and then dry it in vacuum for 5h to obtain Porous silicon carbon composites.

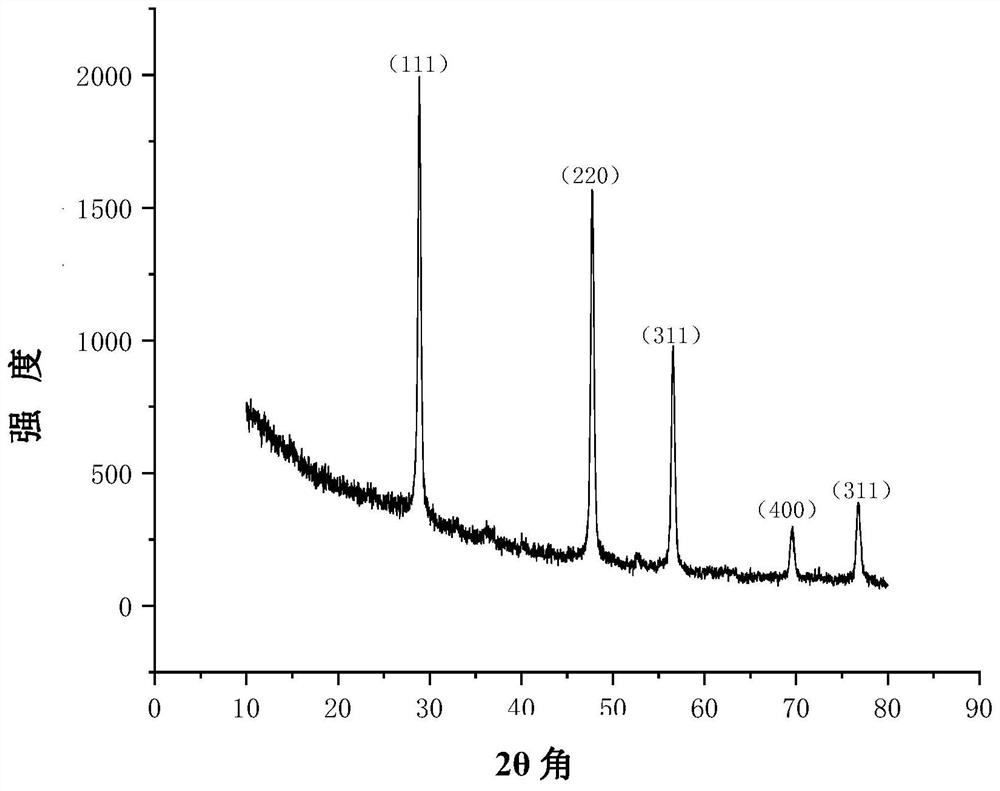

[0057] figure 1 In the XRD pattern of the product prepared in this example, an obvious peak of silicon was...

Embodiment 2

[0068] 1. Add 0.6g PEI (Mw=100000) into a mixed solvent composed of 30mL ethanol and 0.5mL water, and stir at room temperature for 1 hour to obtain a mixed solution;

[0069] 2. While stirring, slowly add tetraethyl orthosilicate (1.15mL) dropwise into the mixed solution prepared in step 1, heat and stir at 60°C for 3h to obtain a milky white suspension, and centrifuge (speed: 8000r / min) to obtain transparent colloid;

[0070] 3. Dry the transparent colloid in a vacuum drying oven at 80°C for 6 hours to obtain a white powder, which is the silicon carbon precursor;

[0071] 4. Mix 0.2g of silicon-carbon precursor with magnesium powder of equal mass, put it into a tube furnace and react at 650°C for 6h under a protective atmosphere of argon to obtain a white powder, wash the powder with hydrochloric acid and then dry it in vacuum for 5h to obtain Porous silicon carbon composites.

Embodiment 3

[0073] 1. Add 0.4g PEI (Mw=70000) into a mixed solvent composed of 30mL ethanol and 3mL water, stir at room temperature for 1h to obtain a mixed solution;

[0074] 2. While stirring, slowly add tetraethyl orthosilicate (3mL) dropwise into the mixed solution prepared in step 1, heat and stir at 60°C for 3h to obtain a milky white suspension, and centrifuge (rotating at 8000r / min) to obtain transparent colloid;

[0075] 3. Dry the transparent colloid in a vacuum drying oven at 80°C for 6 hours to obtain a white powder, which is the silicon carbon precursor;

[0076] 4. Mix 0.2g of silicon-carbon precursor with magnesium powder of equal mass, put it into a tube furnace and react at 650°C for 6h under a protective atmosphere of argon to obtain a white powder, wash the powder with hydrochloric acid and then dry it in vacuum for 5h to obtain Porous silicon carbon composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com