Preparation method and device of in-situ synthesized perovskite quantum dot coded resin microspheres

A resin microsphere, in-situ synthesis technology, applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of uncontrollable, harsh synthesis conditions, inaccurate preparation methods of perovskite, etc., to prevent Leakage, expanding the number of codes, and solving the effect of heavy metal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention provides a method of preparing a calcium titanium-based quantum point encoding a resin microsphere in situ synthesis, through a microfluidic device, an in situ synthesis of calcium titanium dots; The device is introduced into the resin solution and aqueous solution with a surfactant; the resin solution precipate the calcium titanium mine dots, disperse the perovskite in the resin solution; aqueous solution with a surfactant clipped the resin solution to form an encapsulation The resin droplet template of the calcium titanium mine dot; finally cures the resin droplet template to obtain a calcium titanium mine dot encoding a resin microsphere. The method of the invention specifically includes the steps of:

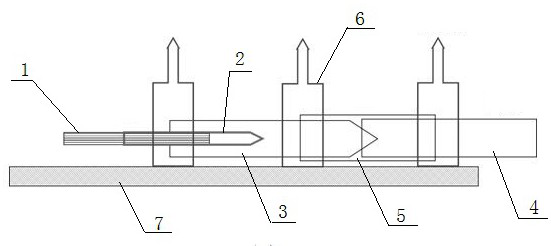

[0036] S1, build a microfluidic device

[0037] Take a plurality of capillaries, form a capillary array, connect the capillary array to one end of the mix tube, and nested within the mix tube; connect the other end of the mix tube to one end of the d...

Embodiment 1

[0050] In situ synthesized perovs and titanium mine quantum dots encodes resin microspheres, including the following steps:

[0051] (1) Preparation of microfluidic device

[0052] Refer figure 1 The seven-well capillary array 1 is selected as the inlet of the pumped raw material, and the seven-well capillary array 1 employed is comprised of 1 mm and a capillary having an inner diameter of 0.58 mm. The capillary array 1 is heated on the alcohol lamp and then pulled it to 100 microns by hand. The fine end of the capillary array 1 is then nestled in the mix tube 2 that is manually pulled to the cone, and the mix tube 2 tapered tube diameter is 100 microns. The mixing tube 2 is assembled in a coaxial manner in a dispersion tube 3 having a tapered end, and the dispersion tube 3 tapered tube diameter is 200 microns. After the tapered end of the dispersion tube 3 is 1 mm, the inner diameter is 0.58 mm, the various tubes and the injection needle 6 are fixed, and the microfluiding device...

Embodiment 2

[0056] In situ synthesized perovs and titanium mine quantum dots encodes resin microspheres, including the following steps:

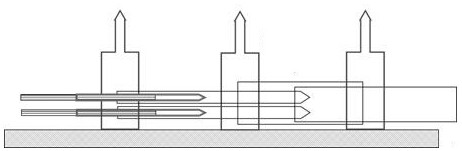

[0057] (1) Preparation of microfluidic device

[0058] Refer figure 2 The seven-well capillary array is selected as the inlet of the pumped raw material, and the seven-well capillary array employed is comprised of a capillary having an outer diameter of 1 mm and an inner diameter of 0.58 mm. The capillary array is heated on the alcohol lamp and then pulled it with a hand to 120 microns. The fine end of the capillary array is then nestled in another manually pulled to the conical mix tube, and its tapered end tube diameter is 120 microns. The mixing tube is mounted in a discharged tube similar to the same tapered end, and the dispersion tube tapered tube diameter is 120 microns. After inserting the dispersion tube tapered end into a collection tube having an outer diameter of 1 mm, an inner diameter is 0.58 mm, and the various tubes and injection needles ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com