Nano FeF3/C composite positive electrode material, preparation method thereof and lithium ion battery

A composite cathode material and lithium-ion battery technology, applied in the direction of positive electrodes, nanotechnology, battery electrodes, etc., can solve the problems of reversible specific capacity, rate performance and cycle performance to be improved, and achieve process controllable, simple process, high rate The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a nano-FeF 3 / C composite cathode material and preparation method thereof, the preparation method comprising the following steps:

[0048] (1) Ferrocene and polytetrafluoroethylene are mixed evenly in a ratio of 1:3 according to the mol ratio of iron and fluorine;

[0049] (2) Transfer the resulting mixed powder to a closed reactor, which is filled with argon, and the volume of the reaction raw materials accounts for 30% of the volume of the reactor;

[0050] (3) Heat-treat the closed reaction vessel under an argon atmosphere, raise the temperature to 600°C for 1 hour at a rate of 5°C / min, and obtain FeF after cooling. 3 / C cathode material.

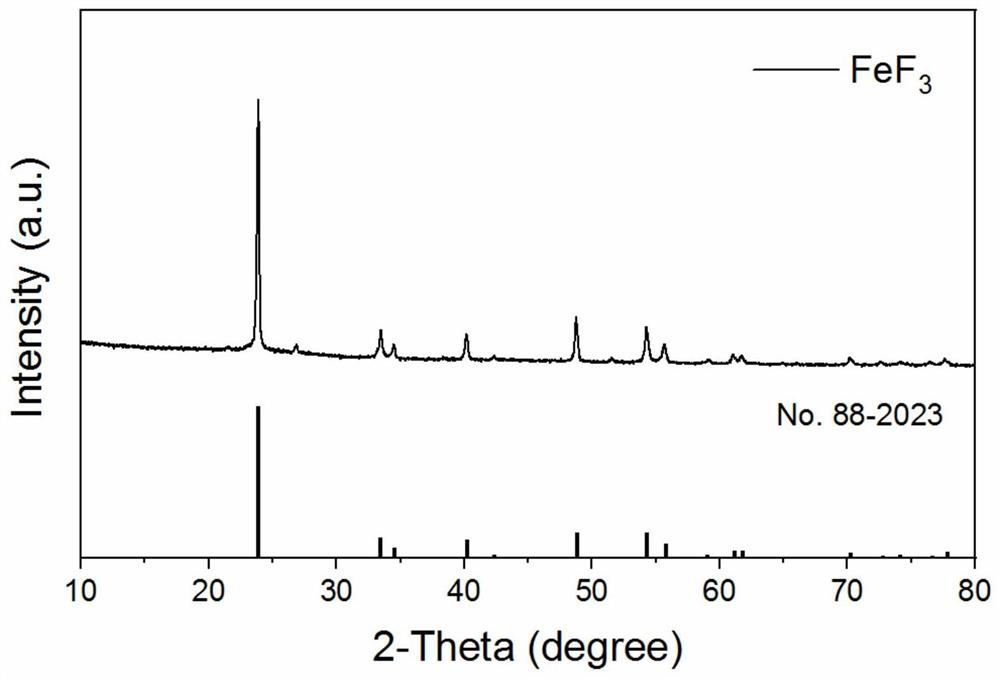

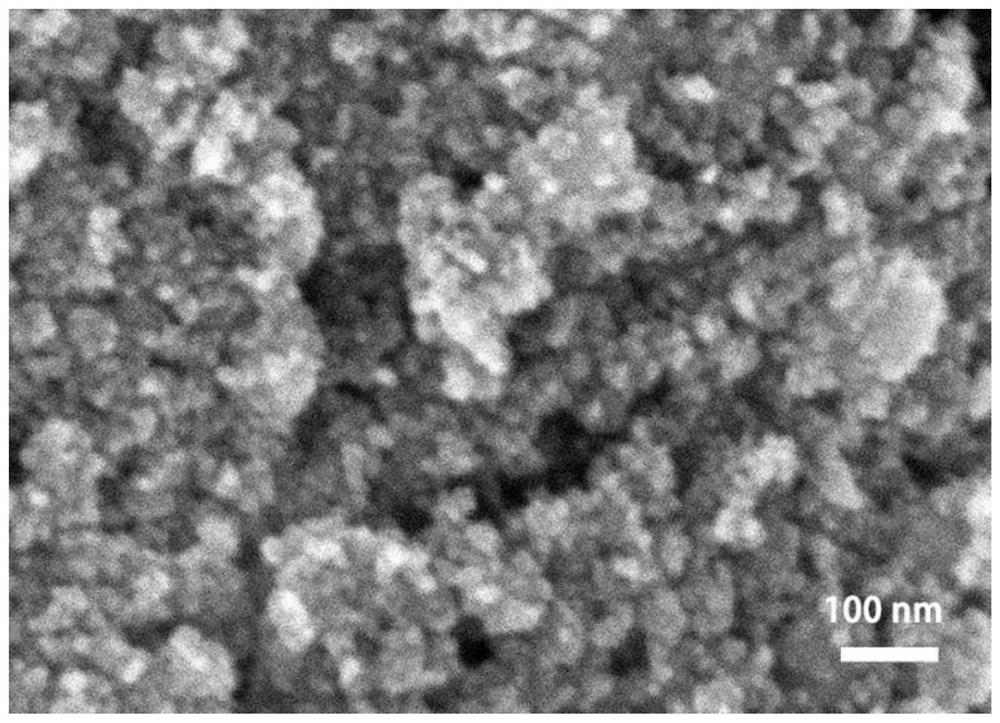

[0051] figure 1 It is the FeF prepared in this example 3 / C positive electrode material XRD pattern, as can be seen from the figure, the diffraction peaks of the prepared sample are consistent with the FeF 3 (PDF#88-2023) has a high degree of agreement with the standard spectrum, confirming that FeF h...

Embodiment 2

[0055] This embodiment provides a nano-FeF 3 / C composite cathode material and preparation method thereof, the preparation method comprising the following steps:

[0056] (1) Iron trichloride, polytetrafluoroethylene are mixed evenly according to the ratio of 1:6 according to the mol ratio of iron and fluorine;

[0057] (2) Transfer the resulting mixed powder to a closed reactor, which is filled with nitrogen, and the volume of the reaction raw materials accounts for 20% of the volume of the reactor;

[0058] (3) Heat-treat the closed reactor in a nitrogen atmosphere, heat up to 900°C at a rate of 30°C / min for 0.5h, and obtain FeF after cooling. 3 / C cathode material.

[0059] The obtained positive electrode material was used as the lithium ion battery positive electrode material for electrochemical performance testing, and the ratio of the electrode sheet was positive electrode material: acetylene black: PTFE (mass ratio) = 90:5:5. A CR2025 button cell was prepared with a ...

Embodiment 3

[0061] This embodiment provides a nano-FeF 3 / C composite cathode material and preparation method thereof, the preparation method comprising the following steps:

[0062] (1) Ferrocene, ferric chloride and polytetrafluoroethylene are mixed uniformly according to the ratio of iron to fluorine molar ratio of 1:1; wherein, the molar ratio of ferrocene and ferric chloride is 1:1 .

[0063] (2) The resulting mixed powder is transferred to an airtight reactor, which is filled with helium, and the volume of the reaction raw materials accounts for 70% of the volume of the reactor;

[0064] (3) Heat-treat the closed reactor in a nitrogen atmosphere, raise the temperature to 400°C for 12 hours at a rate of 1°C / min, and obtain FeF after cooling. 3 / C cathode material.

[0065] The obtained positive electrode material was used as the lithium ion battery positive electrode material for electrochemical performance testing, and the ratio of the electrode sheet was positive electrode mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com